Concrete drilling without impact. Diamond drilling holes in concrete

Diamond drilling concrete is widespread in construction. The technology has become popular due to its high efficiency. Since most of the supporting frame of modern building structures is an monolithic reinforced concrete, other traditional drilling technologies under these conditions are inefficient. Even the most powerful hammer drill will not be able to compare with this method.

Today, diamond drilling of holes in concrete remains the most effective for producing through or blind holes in reinforced concrete walls, and if they are saturated with reinforcement, the only way. In addition to concrete, using this method you can work with such solid materials as granite, marble, steel.

Benefits

Diamond drilling has many advantages over other methods:

- depth can reach 15 m .;

- the ability to work from any angle;

- lack of dust and debris that are completely precipitated by water;

- the possibility of drilling, despite the location of the fittings;

- high speed;

- absolutely precise and round holes with a runout of up to 2mm and practically polished edges;

- low noise during operation;

- lack of vibrations that can lead to microcracks;

- drilling is carried out in a vertical and horizontal surface;

- 220V voltage of the power supply network is sufficient for work;

- you can work in hard-to-reach places where it is difficult to apply traditional methods.

The method also has its disadvantages:

- expensive equipment requires very careful handling and maintenance by an experienced specialist;

- consumables should be changed periodically;

- water, the cooling process, pours onto the floor or along the wall and requires the use of additional drainage equipment.

Diamond Concrete Drilling Technology

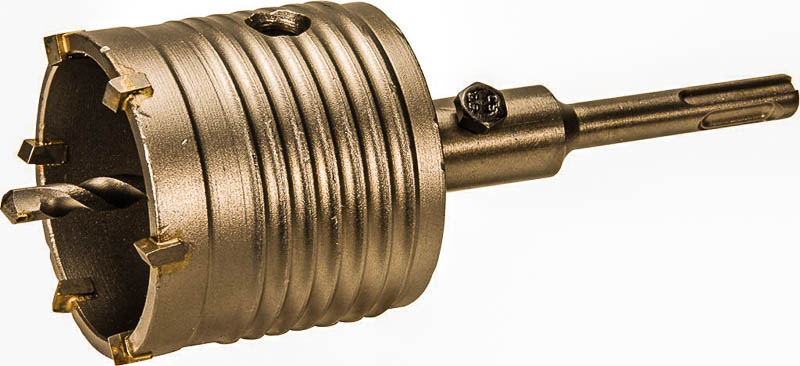

Drilling is carried out by a powerful installation, which consists of a base, a stand, an electric motor and a drill bit. The diamond teeth are soldered to the base of the crown.

consist of crystals of industrial diamonds binding - powder metal.

During drilling, under the influence of high temperatures, the crown is transformed into a monolithic matrix, which can quickly and efficiently drill in the toughest material: reinforced concrete and granite pass equally well. Moreover, you can drill in brick, foam concrete and other traditional building materials. The speed of drilling and its great accuracy, with ideal positioning relative to the marking, the evenness of their geometric dimensions and other characteristics distinguish diamond drilling from traditional, but outdated methods.

Diamond drilling is a shockless method that compares favorably with jackhammers. To conduct it, it is enough to have at hand an ordinary household electrical network with a voltage of 220 volts and a water source. Water cooling the working tool is collected immediately with an industrial vacuum cleaner.

Stages

- The place of work, the place of wiring communications, wiring, pipes, etc., is being studied.

- The optimal crown size is selected, the center and contours of the hole are determined.

- The bed is attached.

- The installation with a crown is mounted on the base.

- The design is checked for play. The fixing elements, crown fastening, bed carriage are examined.

- The water cooling system is connected and connected.

- Work is being done.

When may be required

Drilling with a diamond crown may be required both in the apartment of a multi-storey building and during the construction of a suburban cottage. The minimum noise level and dynamic shock effects allow working in residential buildings during reconstruction and repair, and even in already renovated apartments. The technology can be used for:

- drilling holes in the foundation for vents or sewers;

- installation of gas and heating pipelines;

- power wiring;

- installation of fire fighting systems;

- air conditioning systems;

- installation of chemical anchors;

- holding ventilation ducts in the walls: pipes and sockets;

- installation of fences.

- other cases where precise drilling without dust and noise is required.

The method is used when the task is to make a hole with an accuracy of up to a millimeter. Vertical holes are made, for example, for installing machines or securing supports for creating a canopy, installing garden furniture, etc.

During the repair of residential apartments and offices, it is sometimes required to break through a new opening. In the repair process, sometimes there is a need to change the layout, within which you need to make a door or window opening. A series of holes can be made to form one large or even opening of any shape.

Diamond drilling holes in concrete - prices

The price of diamond drilling depends on the diameter of the hole and its width. Calculation of cost is made in centimeters. The following factors influence the cost of an order:

- drilling at height;

- at non-electrified facilities;

- saturation of reinforced concrete reinforcement;

and some other possible factors.

Diameter in (mm) | The cost of work for 1 m.p. drilling depth (rub.) |

||

Brickwork | Monolith not reinforced (Concrete) | Monolith reinforced concrete (reinforced concrete) |

|

1550,00 | 2300,00 |

||

1600,00 | 2450,00 |

||

1690,00 | 2600,00 |

||

1740,00 | 2790,00 |

||

1850,00 | 2950,00 |

||

2000,00 | 3350,00 |

||

2200,00 | 3540,00 |

||

2940,00 | 4420,00 |

||

3950,00 | 6080,00 |

||

4800,00 | 7500,00 |

||

5950,00 | 9050,00 |

||

7800,00 | 12000,00 |

||

13300,00 |

|||

11050,00 | 17000,00 |

||

The cost of the work is given for vertical drilling of reinforced concrete of medium reinforcement (no more than two reinforcement meshes with a diameter of up to 22 mm., With a mesh pitch of at least 150 mm.), Concrete grade 300, without water drainage.

The minimum departure cost is 4500.00 rubles.

Increasing drilling ratios

K1- If water drainage is required during work | |

K2-Reinforced concrete above average | |

K2.1-Reinforcement of concrete above average to four reinforcement nets at a distance of 30cm | |

K2.1-Reinforcement of concrete above average over four to six mesh reinforcement at a distance of 30cm | |

K3- Work is carried out in a horizontal plane | |

K4-Cramped Conditions | |

K5-Works at a height of over 1.8 m | |

K6-Works in concrete M400 | |

K7-Works concrete brand M500 | |

K8-when working without the possibility of supplying water to the drilling site | |

K9-Winter rise in price for street works | |

K10- Adding with increasing depth by a step \u003d 0.45m from the base 0.9m | |

K11-Work at night or on weekends | |

K12-Works are performed at an angle | |

K13-During operation, the fittings fall along the hole | |

K14-When drilling holes in the ceiling |

The need to hang a chandelier, install hanging cabinets, a socket, etc., sooner or later arises in the life of every owner of a living space. Given that concrete columns, ceilings and ceilings are a common thing for modern apartments, it may turn out that the fasteners have to be mounted on a concrete structure. If you are “lucky," then it will be natural to wonder how to drill concrete?

Building materials to date. However, its strength, in this case, is the main problem, since it is not possible to drill reinforced concrete without specialized equipment and relevant knowledge. In this case, the call of specialists to form several small holes will cost you a disproportionate amount.

If you want to save money, it is quite reasonable to think about an independent solution to this problem. Despite the obvious complexity - the right approach and strict adherence to the technological part of the process will help you achieve a high-quality result. This article will provide you with detailed instructions about how to drill concrete with your own hands.

Tools

To drill a reinforced concrete surface, the use of specialized tools is necessary - in this case, dispensing with a homemade tool will not work.

Depending on your preference and hole diameter, you can use a hammer drill or a small-sized electric hammer drill. The first option has less power, but it has less weight and a convenient design. The hammer drill, respectively, has greater potential, weight and dimensions.

Note! Since the use of construction equipment is often of a one-time nature, it is more rational to rent them. Given that their price is quite high, this way you will save a considerable amount of money.

In addition to the existing tool, you need to purchase special drill bits that allow you to work with a concrete surface. Drills with a victory tip are selected for a punch drill.

The puncher has its own set of impact nozzles, which, in most cases, is quite enough. As additional components for the punch, you can also use drills with a tip.

![]()

To form holes with a diameter of 35 to 120 mm, crown nozzles are used, which have victory teeth - they are used to drill grooves for sockets, switches, etc. If you are thinking about whether it is possible to drill concrete with a screwdriver, then for this purpose there are also crowns with tungsten-carbide spraying. However, it should be borne in mind that they are only suitable for units with a capacity of at least 1 kW.

Training

- Before drilling concrete, you must prepare the existing tools. First of all, the fixing cartridge is inspected for the presence of sand or other foreign elements - if any, then they must be removed without fail. For this purpose, you can use clean, dry rags;

- The drill must enter the groove freely so that you can feel that it is fully inserted.. This is a prerequisite, the non-observance of which, may lead to a tip inoperability. If we are talking about a punch drill, then you need to clamp the drill as tightly as possible; in punchers, the clamp is automatic;

- Before drilling a concrete ceiling, it is necessary to protect the face with a respirator or plastic visor. When working with walls, the use of personal protective equipment is also desirable, although not so critical;

Drilling

It is not particularly difficult and consists only in the ability to work with the tool. When working with drills, the chipper mode should be combined with drilling.

If you use crown nozzles, then shock mode must be disabled. The only possible problem during this process will be reinforcement from the reinforcement cage, which may be in the way of the drill.

Before drilling reinforcement in concrete, it is necessary to change the tip for working with concrete to a conventional metal drill and drill through the obstacle. It is important not to forget to turn off the chipper mode before drilling reinforcement in concrete.

In addition to the above, there are also a number of useful tips that will help you achieve a high-quality result.

- Unprofessional construction tools are not designed for a long load, which should be considered when working with them. The case must not be allowed to overheat - on average, the continuous operation of the equipment is no more than 15 minutes, after which the mechanism requires cooling. The same 15 minutes of inactivity will be quite enough;

- When drilling, the drill heats up very much and when the critical temperature is reached, the winning tip begins to deform. To cool the drill, simply submerge the tip in water - the more often you perform this operation, the less the consumable will wear out;

- If the drill is stuck, in no case should you try to crank it by increasing the speed - in the best case you will break the drill, and in the worst you will render the tool itself unusable. You need to remove the tip from the socket, charge a similar one and drill a hole next to it - only after that you can try to “rescue” the drill from captivity;

Diamond drilling

If you are thinking about how to drill through a concrete slab through or create a hole of large diameter, then you can’t do it on your own. The most effective is diamond drilling of holes in concrete and cutting of reinforced concrete with diamond wheels, which are carried out using specialized professional equipment.

The cost of installations is quite high, and it is irrational to purchase them for single use. It would be wiser to invite specialists who provide their services at a very reasonable price.

Total

Properly selected equipment and a professional approach will help you cope even with such a difficult task as drilling concrete. You can get more detailed information on this topic by watching the video in this article.

Concrete structures occupy one of the leading positions in housing construction. The strength and reliability of concrete is not in doubt, but the material is difficult to process. When repairing and remodeling an apartment, it becomes necessary to install holes in concrete. How to properly drill concrete and not make a mistake in choosing a tool, we will tell in this article.

The better to drill concrete

The composition of ordinary building concrete includes coarse-grained materials - crushed stone or gravel. Moreover, concrete platesused for the construction of buildings reinforced. Therefore, when drilling, the tool must overcome stone and metal barriers.

The quality of the device holes in concrete, as well as the cost of work directly depend on the correct choice of tools and method of drilling. Let's consider what tools can defeat a concrete wall.

Concrete drills

It is possible to deal with concrete with an ordinary drill, but it is very difficult, and the result will be unpredictable. There are special drills that have hard alloy soldering, close to diamond in efficiency. The common name for such an alloy is “win” (an alloy of tungsten carbide and cobalt), but now there are other compounds that are not inferior to victory in strength.

Pobedit drill, designed for drill, equipped with a polyhedral or cylindrical shank (part of the drill clamped in the tool holder). Drills for the punch are made with a cylindrical shank, and they are marked with SDS-plus or SDS-max.

Pobedit drill, designed for drill, equipped with a polyhedral or cylindrical shank (part of the drill clamped in the tool holder). Drills for the punch are made with a cylindrical shank, and they are marked with SDS-plus or SDS-max.

For punching holes in heavy reinforced concrete walls are used hammer drills (drills) for drill and punch. They are auger, spiral and flat. Using a screw auger, you can make a deep hole, a spiral drill is used for large diameter holes, a gentle drill is designed for small passages in the wall.

Large holes are best punched with core drills - with diamond dusting or with victorious teeth. The crown for making holes in concrete is a hollow cutting cylinder. When drilling, the cut core goes inside the cylinder and does not prevent the tool from moving further into the plate.

Drills and Hammers

Drills and Hammers

The specificity of drilling concrete is that the drill or drill must not only rotate and crush the material, but also perform impact on the bottom of the punched channel. Such conditions correspond to shock electric drills and perforators.

Drilling shallow holes of small diameter can be done with an impact drill, and for more labor-intensive work it is better to use a hammer drill. The drill punch is faster and easier to enter concrete due to more power than a drill.

The impact of the punch is also stronger, and the amplitude of translational movements is higher and does not depend on the physical efforts of the installer. As a result, drilling work is done quickly and accurately.

Diamond Drilling Rigs

A rotary hammer and hammer drill are used for small volumes of work. If it is necessary to drill many holes, then it is advisable to apply the technology of diamond drilling of concrete. With its help, they break through walls for laying engineering communications, for arranging window and doorways or for other large-scale works.

The main structural element of the diamond drilling installation is a drill bit with teeth coated by spraying from industrial diamonds. The installation can operate from a conventional power supply and carry out drilling of neat holes even in hard-to-reach places.

It is important that, unlike drilling with a drill and a perforator, punching holes with diamond drilling is not accompanied by the formation of a large amount of dust, as a stream of water is supplied to the drill, cooling the crown and removing dust.

It is important that, unlike drilling with a drill and a perforator, punching holes with diamond drilling is not accompanied by the formation of a large amount of dust, as a stream of water is supplied to the drill, cooling the crown and removing dust.

The only drawback of such installations is their high cost, which is why diamond construction services are usually performed by specialized construction organizations.

Technology features

Working with concrete is hard and time consuming. Of course, if you need to hang a shelf on a concrete wall, you can drill holes for it yourself. In case of repair, redevelopment, laying of communications, it is better to invite professional builders. Before starting work, perform the following preparatory operations:

- Determine the location of the electrical wiring.

- Mark in the places of the proposed holes.

- At the indicated points, small indentations are made with an ordinary drill to avoid slipping the tool at the beginning of work, and to set the desired direction for drilling.

In the process, the drill is cooled by water. This will help prevent overheating of the drill, its breakage and destruction of the hole. In the event of a collision with the reinforcement, the core drill is changed to a conventional metal drill, and a punch is used.

Holes up to 10 cm can be drilled. For the construction of channels of larger diameter, it is better to involve specialists performing diamond drilling of concrete. This technology provides high precision drilling, low noise and vibration.

Diamond-coated crowns allow you to punch passages up to 2 m deep and 50 cm in diameter in concrete without much effort, at any angle and in different planes. The drilling speed is from 1 to 6 cm / min.

Subject to all the subtleties of technology, it is possible to qualitatively perform drilling of any holes in the most complex concrete structures. It is more reasonable to entrust large volumes of work to professionals with experience and a modern tool.

Our offers

MosKomplekt company offers its services in the construction and repair of private houses and office buildings. We have at our disposal all the necessary equipment to accurately and quickly punch holes and channels in concrete structures, as well as perform other construction operations.

We work under a formal contract and guarantee full compliance with building codes and rules. Departure to the site to assess the complexity of the planned work and measurements is free.

Our prices

The table shows the approximate prices for the arrangement of holes using the diamond drilling method. The final cost of the work is determined after assessing the complexity and conditions of the work.

Hole diameter mm | Price for 1 cm of passage, rub. | Maximum drilling depth, m |

|

Reinforced concrete |

|||

| 25 | 27 | ||

| 25 | 28 | ||

| 26 | 29 | ||

| 27 | 20 | ||

| 28 | 32 | ||

| 30 | 34 | ||

| 31 | 36 | ||

| 38 | 44 | ||

| 83 | 91 | ||

| 115 | 123 | ||

| 187 | 195 | ||

When making holes in materials characterized by increased strength, which include concrete, brick, etc., drills for metal work are useless: their cutting part quickly dulls. In such situations, it is better to use a drill for concrete, which is characterized by a number of distinctive properties, when compared with that used for drilling metal.

Types and parameters of concrete drills

The feature that distinguishes drill bits for concrete is that their cutting part is equipped with solders made of a special alloy, the hardness of which is very close to the hardness of diamond. Due to its unique characteristics, such an alloy is called "win". Concrete drill bits are the most durable tool for processing this material.

Among concrete drills, two main categories are distinguished:

- a concrete drill for a drill whose design differs in a cylindrical or multifaceted configuration;

- tool for work complete with a hammer drill having a cylindrical shank on which the designation SDS-plus or SDS-max is placed.

Home masters often have a question about how to choose equipment and tools for making holes in reinforced concrete structures. To solve this problem, a perforator with drill bits for concrete is ideally suited for impact drill. Drills for drills of this type are often called drills and are divided into three main types:

- screw screws with which you can drill holes of considerable depth;

- spiral (holes of large diameter can be made with them);

- gentle, which allow you to get holes with small diameters and depth.

Due to such design features as a thickening on the shank, the drills are installed in the tool holder by a simple click. As a rule, they are chosen by professional builders and installation specialists to get holes with a diameter in the range of 4-30 mm.

In the event that the question arises of how to drill concrete, having received a hole of a larger diameter, choose a crown type tool. It forms holes, the diameter of which reaches 12 cm. Core drill bits for concrete are also divided into several categories:

- diamond drills on concrete in the form of a tube or crown, which are fixed on a solid section rod (diamond spraying is applied to the working part of such a tool, which is why it is called diamond drill);

- drill bits having a similar design with diamond, but differing from them by the material of the teeth on the cutting part (these teeth are made of winnings).

The need for a core drill for concrete arises if it is necessary to prepare seats for electrical outlets and switches, conduct communications and perform other work related to the need to obtain holes and recesses of large sizes.

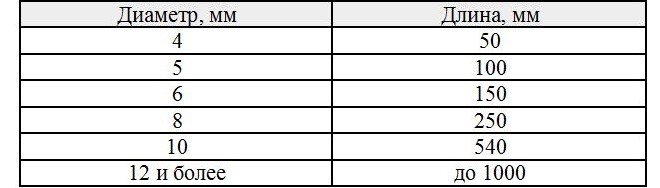

The choice of drill for brick and concrete is also determined by the diameter and depth of the formed holes. A diamond or drill bit can have the following ratios of diameter and length:

In the table below you can see a simple pattern: the larger the diameter, the greater the length of the drill for concrete. This is because a long and thin instrument does not withstand perceived loads.

There are several rules, the adherence to which will allow you to perform drilling work on concrete as efficiently as possible.

- If you do not know how to drill a concrete wall with a drill, stock up on various drills, including those that are designed to perform metal work. Each type of drill is designed to perform certain tasks: on brick - to drill brick wall, for concrete - for forming holes in concrete structures, for ceramics - for drilling surfaces finished with ceramic tiles. However, when deepening into the structure of the processed material, the tool can abut against metal reinforcement, then it is necessary to temporarily replace it with an appropriate drill. Individual craftsmen, making holes in concrete structures, sharpen used drills in such a way that they can cope with metal. However, in order to give the drill drill such universality, it is necessary not only to have the appropriate knowledge, but also to have extensive experience.

- In no case should the overheat of the drill on concrete be allowed. It is necessary to take breaks every fifteen seconds and cool the tool naturally, without using water or any other liquids.

- In the structure of concrete, solid stones are necessarily present, upon encountering which, the drill cannot move on. Such a stone must be crushed with a chipper and only after that continue drilling.

- If necessary, make a hole in the carrier concrete wall or overlapping it is best to use a puncher that will solve such a problem as efficiently as possible.

- To drill a hole in a ceramic coating on a wall or on the floor, you must turn off the shock mode of the drill or perforator, otherwise the ceramic tile will simply collapse. When working with such surfaces, it is possible to use concrete drills.

- Inexpensive concrete drills made of not very hard material should be sharpened periodically. To do this, you can use an angle grinder on which a diamond blade is mounted.

The most popular brands of concrete drilling tools

Drills that are used to perform concrete work on the modern market are represented by both foreign and domestic brands. The prices of such an instrument often depend on the fame of the manufacturer who manufactured it.

How to choose a drill for concrete? It should be understood that higher prices for these products are justified, given its guaranteed high quality and long service life.

In the list of foreign companies that offer consumers high-quality concrete drills, manufacturers such as:

- Makita;

- Bosch;

- Metabo;

- Stayer

It should be borne in mind that the quality products offered by these companies are quite high in price.

Especially noteworthy is a tool from Bosch, which has a four-spiral design, which allows it to easily remove processing waste from the hole being formed.

Bosch CYL-9 Multi series drills are universal and, in addition to concrete, are used for drilling bricks and wood

Among the concrete drills from domestic manufacturers and companies from the CIS countries and China, it is worth highlighting products manufactured under the following trademarks:

- Interskol;

- "Bison";

- "Encore";

- Uragan et al.

Mid-range core drill bits provide sufficient precision drilling but have a limited life

It should be noted that Chinese-made drills can be reliable if they are quite expensive. It must be well understood that a quality tool cannot be too cheap, because only the best materials and innovative technologies are used to manufacture it.

The low cost of individual copies of such drills can be explained by violations technological process their manufacture, which is allowed by individual manufacturers, as well as the use of cheap and low-quality materials. On the modern market, one can also encounter fakes, which are difficult to distinguish from original products. Among experts, there is an opinion that fakes have a darker color, since some stages of their production are carried out incorrectly. However, deciding to choose a drill bit for concrete, pay attention to the cost of such a tool, which should not be too low.

To save on purchase, you can purchase drills in sets, then the price for a single copy will be slightly lower.

Distinctive features of concrete drills

There are several criteria to distinguish a drill for concrete work from tools for drilling other materials.

Form of the working part- Drills for wood work have the sharpest tip, which at the initial stage of processing is inserted into the material.

- The tip of the tool for working on metal differs in a conical shape, there is no pointed part on it.

- A rather blunt concrete drill bit is made of a winning plate.

Each master at least once encountered the need to drill concrete. This raises some questions, for example, what equipment and technology to use. If you don’t approach the task correctly, the result may be a failure.

Choosing a Concrete Drilling Tool

If you want to drill holes in concrete using a crown, you must turn off the hammer mode. As a rule, such devices are capable of forming holes whose depth is not more than 15 cm. If there is a need to go deeper into the wall to a more impressive thickness, an extension nozzle can be used. Similar crowns can be used in tandem with a drill. Unlike the previous ones, such additions have a tungsten carbide alloy spraying around the circumference. The advantage here is that if there is a need to make a hole in the concrete, which is tiled, then you do not need to change the nozzle, it will be able to drill well not only the decorative layer, but also the concrete itself. If you want to drill holes in concrete, equipment of the described type can be used with crowns, however, the drill should not have a power above 1000 watts.

Using Boers

If there is a hammer that you want to use with the drill, then the diameter of the latter can vary from 4 to 80 millimeters. Quite often, novice masters ask themselves the question of how to choose the right diameter for the drill.

Together with a punch, it is recommended to purchase a set of metal drills. However, high-quality kits have a very high cost, so the diameter should be the same as the dowel, which is supposed to be inserted into it. When buying such drills, it is recommended to find out which tail they have - SDS + or SDS-max.

Features of concrete drilling

If you decide to drill holes in concrete with a rotary hammer, you must first check to see if there is any contamination in the cartridge. If they were found, you must remove them with a rag, otherwise, during operation, some difficulties may arise.

When inserting a drill into the chuck, it must be ensured that it is installed at a right angle, while the shank is mounted all the way. The biggest problem that you may face when drilling is the collision of the drill with metal fittings. As a rule, this occurs when it is necessary to break through the wall to a greater depth. In this case, the reinforcement must be passed by the punch, only after that you can continue to work. If the holes will be made using an impact drill, then help to cope with the work

If a hole is drilled in concrete with a crown, then every 15 minutes you need to take a break for the same period. This is due to the fact that an unprofessional tool is not designed for a long load. During this time, not only the device, but also the consumables will cool. Before continuing work, it is necessary to moisten the drill with water, this will extend its service life.

Conclusion

When laser drilling of holes in concrete is performed, peeling of wall sections on the back side may occur. In this case, it is necessary to reduce the speed, then the process will occur somewhat more slowly. Despite the fact that the manipulation will take a lot of time, the wall outside will remain untouched.