Diamond drill pen drill a concrete wall. Drilling holes in concrete

The need to hang a chandelier, install hanging cabinets, a socket, etc., sooner or later arises in the life of every owner of a living space. Given that concrete columns, ceilings and ceilings are a common thing for modern apartments, it may turn out that the fasteners have to be mounted on a concrete structure. If you are “lucky," then it will be natural to wonder how to drill concrete?

Building materials to date. However, its strength, in this case, is the main problem, since it is not possible to drill reinforced concrete without specialized equipment and relevant knowledge. In this case, the call of specialists to form several small holes will cost you a disproportionate amount.

If you want to save money, it is quite reasonable to think about an independent solution to this problem. Despite the obvious complexity - the right approach and strict adherence to the technological part of the process will help you achieve a high-quality result. This article will provide you with detailed instructions about how to drill concrete with your own hands.

Tools

To drill a reinforced concrete surface, the use of specialized tools is necessary - in this case, dispensing with a homemade tool will not work.

Depending on your preference and hole diameter, you can use a hammer drill or a small-sized electric hammer drill. The first option has less power, but it has less weight and a convenient design. The hammer drill, respectively, has greater potential, weight and dimensions.

Note! Since the use of construction equipment is often of a one-time nature, it is more rational to rent them. Given that their price is quite high, this way you will save a considerable amount of money.

In addition to the existing tool, you need to purchase special drill bits that allow you to work with a concrete surface. Drills with a victory tip are selected for a punch drill.

The puncher has its own set of impact nozzles, which, in most cases, is quite enough. As additional components for the punch, you can also use drills with a tip.

![]()

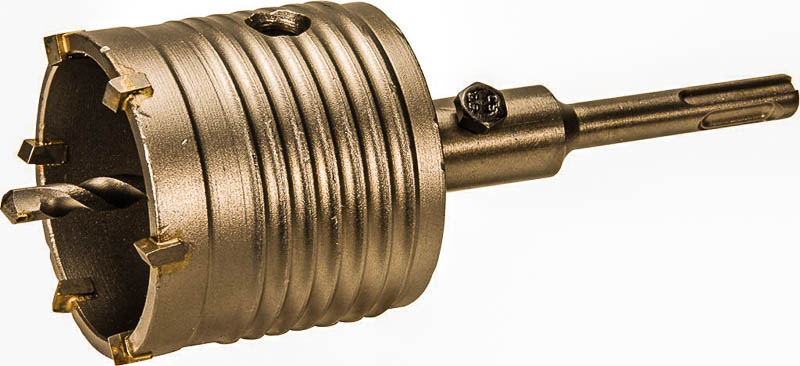

To form holes with a diameter of 35 to 120 mm, crown nozzles are used, which have victory teeth - they are used to drill grooves for sockets, switches, etc. If you are thinking about whether it is possible to drill concrete with a screwdriver, then for this purpose there are also crowns with tungsten-carbide spraying. However, it should be borne in mind that they are only suitable for units with a capacity of at least 1 kW.

Training

- Before drilling concrete, you must prepare the existing tools. First of all, the fixing cartridge is inspected for the presence of sand or other foreign elements - if any, then they must be removed without fail. For this purpose, you can use clean, dry rags;

- The drill must enter the groove freely so that you can feel that it is fully inserted.. This is a prerequisite, the non-observance of which, may lead to a tip inoperability. If we are talking about a punch drill, then you need to clamp the drill as tightly as possible; in punchers, the clamp is automatic;

- Before drilling a concrete ceiling, it is necessary to protect the face with a respirator or plastic visor. When working with walls, the use of personal protective equipment is also desirable, although not so critical;

Drilling

It is not particularly difficult and consists only in the ability to work with the tool. When working with drills, the chipper mode should be combined with drilling.

If you use crown nozzles, then shock mode must be disabled. The only possible problem during this process will be reinforcement from the reinforcement cage, which may be in the way of the drill.

Before drilling reinforcement in concrete, it is necessary to change the tip for working with concrete to a conventional metal drill and drill through the obstacle. It is important not to forget to turn off the chipper mode before drilling reinforcement in concrete.

In addition to the above, there are also a number of useful tips that will help you achieve a high-quality result.

- Unprofessional construction tools are not designed for a long load, which should be considered when working with them. The case must not be allowed to overheat - on average, the continuous operation of the equipment is no more than 15 minutes, after which the mechanism requires cooling. The same 15 minutes of inactivity will be quite enough;

- When drilling, the drill heats up very much and when the critical temperature is reached, the winning tip begins to deform. To cool the drill, simply submerge the tip in water - the more often you perform this operation, the less the consumable will wear out;

- If the drill is stuck, in no case should you try to crank it by increasing the speed - in the best case you will break the drill, and in the worst you will render the tool itself unusable. You need to remove the tip from the socket, charge a similar one and drill a hole next to it - only after that you can try to “rescue” the drill from captivity;

Diamond drilling

If you are thinking about how to drill through a concrete slab through or create a hole of large diameter, then you can’t do it on your own. The most effective is diamond drilling of holes in concrete and cutting of reinforced concrete with diamond wheels, which are carried out using specialized professional equipment.

The cost of installations is quite high, and it is irrational to purchase them for single use. It would be wiser to invite specialists who provide their services at a very reasonable price.

Total

Properly selected equipment and a professional approach will help you cope even with such a difficult task as drilling concrete. You can get more detailed information on this topic by watching the video in this article.

Each master at least once encountered the need to drill concrete. This raises some questions, for example, what equipment and technology to use. If you don’t approach the task correctly, the result may be a failure.

Choosing a Concrete Drilling Tool

If you want to drill holes in concrete using a crown, you must turn off the hammer mode. As a rule, such devices are capable of forming holes whose depth is not more than 15 cm. If there is a need to go deeper into the wall to a more impressive thickness, an extension nozzle can be used. Similar crowns can be used in tandem with a drill. Unlike the previous ones, such additions have a tungsten carbide alloy spraying around the circumference. The advantage here is that if there is a need to make a hole in the concrete, which is tiled, then you do not need to change the nozzle, it will be able to drill well not only the decorative layer, but also the concrete itself. If you want to drill holes in concrete, equipment of the described type can be used with crowns, however, the drill should not have a power above 1000 watts.

Using Boers

If there is a hammer that you want to use with the drill, then the diameter of the latter can vary from 4 to 80 millimeters. Quite often, novice masters ask themselves the question of how to choose the right diameter for the drill.

Together with a punch, it is recommended to purchase a set of metal drills. However, high-quality kits have a very high cost, so the diameter should be the same as the dowel, which is supposed to be inserted into it. When buying such drills, it is recommended to find out which tail they have - SDS + or SDS-max.

Features of concrete drilling

If you decide to drill holes in concrete with a rotary hammer, you must first check to see if there is any contamination in the cartridge. If they were found, you must remove them with a rag, otherwise, during operation, some difficulties may arise.

When inserting a drill into the chuck, it must be ensured that it is installed at a right angle, while the shank is mounted all the way. The biggest problem that you may face when drilling is the collision of the drill with metal fittings. As a rule, this occurs when it is necessary to break through the wall to a greater depth. In this case, the reinforcement must be passed by the punch, only after that you can continue to work. If the holes will be made using an impact drill, then help to cope with the work

If a hole is drilled in concrete with a crown, then every 15 minutes you need to take a break for the same period. This is due to the fact that an unprofessional tool is not designed for a long load. During this time, not only the device, but also the consumables will cool. Before continuing work, it is necessary to moisten the drill with water, this will extend its service life.

Conclusion

When laser drilling of holes in concrete is performed, peeling of wall sections on the back side may occur. In this case, it is necessary to reduce the speed, then the process will occur somewhat more slowly. Despite the fact that the manipulation will take a lot of time, the wall outside will remain untouched.

Concrete is a sufficiently strong material, however, as an evil, it is often necessary to drill it. Either you need to hang something on concrete wallwhether to mount a suspended ceiling, where there are generally holes in concrete floor a lot will need to be done.

With a conventional drill for metal or wood, you will not drill any concrete or even a brick. In order to drill concrete you will need a carbide drill. That is, this drill, on which a special alloy is soldered. Drills with such an alloy are usually called "victorious", although now in such drills it has long been used not only to "win".

The drill bit is as follows:

Fig. 1. Hammer drill for impact drill

Fig. 2. Punch drill bit

One such drill in order to drill concrete is not enough, you need a good tool.

And since a good tool costs good money, you can do, in principle, with a conventional drill. For drilling concrete, it is necessary to give the drill rotational-translational movements, that is, the drill in the chuck should not only rotate around its axis, but also slightly beat towards the hole.

A drill can be either an impact one, which, in principle, will suit us, or an ordinary one, which can only perform rotational movements. If you ordinary drillthen concrete can be drilled as follows. Look for a metal pin that roughly matches the size of your future hole. Next, outline the hole and begin to slowly drill. See that the drill does not overheat, you can occasionally pull it out and moisten it.

After slightly drilling, insert the pin into the small hole that happened and knock on it with a hammer. By the way, instead of a pin, you can use the same drill. Knock on it with a hammer and turn. After that, re-insert the drill and start drilling. Then take it out again and start tapping the pin with a hammer, turning it. Follow this periodicity until you get a hole of the depth you want.

If you have hammer drill, then just switch it to the “punch” position and start drilling, while remembering to periodically pull out the drill and let the drill cool down.

The most successful tool for drilling concrete is, of course, a hammer drill. The puncher is a tool of sufficiently high power. The speed of rotation of the cartridge there is less than that of a drill, but due to strong translational impacts, a hole can be drilled quickly enough in concrete.

Unfortunately, drill bits do not drill or drill metal very weakly. If you try with a carbide drill to drill metal, for example, reinforcement, then you can just ruin the drill and that's it. It is possible that you get into the reinforcement when you drill concrete. In this case, it is better to spend a few minutes setting the drill bit for metal and quietly drill through the fittings. After that, put the “pobeditovy” drill again and continue to drill a concrete wall or ceiling.

It’s better not to buy cheap “winning” drills, they quickly wear out, bend and break, besides using low-quality drills, you can give a big load to a power tool, which will not be good for it later.

Concrete structures occupy one of the leading positions in housing construction. The strength and reliability of concrete is not in doubt, but the material is difficult to process. When repairing and remodeling an apartment, it becomes necessary to install holes in concrete. How to properly drill concrete and not make a mistake in choosing a tool, we will tell in this article.

The better to drill concrete

The composition of ordinary building concrete includes coarse-grained materials - crushed stone or gravel. Moreover, concrete platesused for the construction of buildings reinforced. Therefore, when drilling, the tool must overcome stone and metal barriers.

The quality of the device holes in concrete, as well as the cost of work directly depend on the correct choice of tools and drilling method. Let's consider what tools can defeat a concrete wall.

Concrete drills

It is possible to deal with concrete with an ordinary drill, but it is very difficult, and the result will be unpredictable. There are special drills that have hard alloy soldering, close to diamond in efficiency. The common name for such an alloy is “win” (an alloy of tungsten carbide and cobalt), but now there are other compounds that are not inferior to victory in strength.

Pobedit drill, designed for drill, equipped with a polyhedral or cylindrical shank (part of the drill clamped in the tool holder). Drills for the punch are made with a cylindrical shank, and they are marked with SDS-plus or SDS-max.

Pobedit drill, designed for drill, equipped with a polyhedral or cylindrical shank (part of the drill clamped in the tool holder). Drills for the punch are made with a cylindrical shank, and they are marked with SDS-plus or SDS-max.

For punching holes in heavy reinforced concrete walls are used hammer drills (drills) for drill and punch. They are auger, spiral and flat. Using a screw auger, you can make a deep hole, a spiral drill is used for large diameter holes, a gentle drill is designed for small passages in the wall.

Large holes are best punched with core drills - with diamond dusting or with victorious teeth. The crown for making holes in concrete is a hollow cutting cylinder. When drilling, the cut core goes inside the cylinder and does not prevent the tool from moving further into the plate.

Drills and Hammers

Drills and Hammers

The specificity of drilling concrete is that the drill or drill must not only rotate and crush the material, but also perform impact on the bottom of the punched channel. Such conditions correspond to shock electric drills and perforators.

Drilling shallow holes of small diameter can be done with an impact drill, and for more labor-intensive work it is better to use a hammer drill. The drill punch is faster and easier to enter concrete due to more power than a drill.

The impact of the punch is also stronger, and the amplitude of translational movements is higher and does not depend on the physical efforts of the installer. As a result, drilling work is done quickly and accurately.

Diamond Drilling Rigs

A rotary hammer and hammer drill are used for small volumes of work. If it is necessary to drill many holes, then it is advisable to apply the technology of diamond drilling of concrete. With its help, they break through walls for laying engineering communications, for arranging window and doorways or for other large-scale works.

The main structural element of the diamond drilling installation is a drill bit with teeth coated by spraying from industrial diamonds. The installation can operate from a conventional power supply and carry out drilling of neat holes even in hard-to-reach places.

It is important that, unlike drilling with a drill and a perforator, punching holes with diamond drilling is not accompanied by the formation of a large amount of dust, as a stream of water is supplied to the drill, cooling the crown and removing dust.

It is important that, unlike drilling with a drill and a perforator, punching holes with diamond drilling is not accompanied by the formation of a large amount of dust, as a stream of water is supplied to the drill, cooling the crown and removing dust.

The only drawback of such installations is their high cost, which is why diamond construction services are usually performed by specialized construction organizations.

Technology features

Working with concrete is hard and time consuming. Of course, if you need to hang a shelf on a concrete wall, you can drill holes for it yourself. In case of repair, redevelopment, laying of communications, it is better to invite professional builders. Before starting work, perform the following preparatory operations:

- Determine the location of the electrical wiring.

- Mark in the places of the proposed holes.

- At the indicated points, small indentations are made with an ordinary drill to avoid slipping the tool at the beginning of work, and to set the desired direction for drilling.

In the process, the drill is cooled by water. This will help prevent overheating of the drill, its breakage and destruction of the hole. In the event of a collision with the reinforcement, the core drill is changed to a conventional metal drill, and a punch is used.

Holes up to 10 cm can be drilled. For the construction of channels of larger diameter, it is better to involve specialists performing diamond drilling of concrete. This technology provides high precision drilling, low noise and vibration.

Diamond-coated crowns allow you to punch passages up to 2 m deep and 50 cm in diameter in concrete without much effort, at any angle and in different planes. The drilling speed is from 1 to 6 cm / min.

Subject to all the subtleties of technology, it is possible to qualitatively perform drilling of any holes in the most complex concrete structures. It is more reasonable to entrust large volumes of work to professionals with experience and a modern tool.

Our offers

MosKomplekt company offers its services in the construction and repair of private houses and office buildings. We have at our disposal all the necessary equipment to accurately and quickly punch holes and channels in concrete structures, as well as perform other construction operations.

We work under a formal contract and guarantee full compliance with building codes and rules. Departure to the site to assess the complexity of the planned work and measurements is free.

Our prices

The table shows the approximate prices for the arrangement of holes using the diamond drilling method. The final cost of the work is determined after assessing the complexity and conditions of the work.

Hole diameter mm | Price for 1 cm of passage, rub. | Maximum drilling depth, m |

|

Reinforced concrete |

|||

| 25 | 27 | ||

| 25 | 28 | ||

| 26 | 29 | ||

| 27 | 20 | ||

| 28 | 32 | ||

| 30 | 34 | ||

| 31 | 36 | ||

| 38 | 44 | ||

| 83 | 91 | ||

| 115 | 123 | ||

| 187 | 195 | ||

All modern homes, especially those built in large cities, consist of concrete structures. When repairing, there is a regular need to drill a concrete wall for various purposes: installing suspended ceilings, placing a bookshelf, etc. In some cases, craftsmen encounter difficulties, and in order to prevent a variety of troubles, we will consider in more detail effective methods of drilling concrete material.

Home Technique for Drilling Concrete Holes

Building concrete is a very dense and durable material, the drilling of which must be performed with a special drill. The uniqueness of the tool lies in the presence of a hard coating soldered to the end (working) part. T

these drills are called victorious, although this designation is very arbitrary. All drills were previously made from Pobedit, and today products from other alloys can receive such markings. They are used when there is no high-quality, expensive tool.

The process of drilling concrete is a very difficult process, an important feature of which is not the simple scrolling of the drill, but the mandatory impact on the material. Otherwise, concrete will not succumb.

Watch a video on how to protect yourself from dust when drilling concrete at home

The best option for these purposes is a hammer drill, but you can successfully drill and ordinary. Using such a tool, concrete drilling is necessary as follows:

Read also: Domestic electric compressor: device and principle of operation, characteristics, selection criteria

- a drill of the required diameter (thickness) is prepared;

- marking the drilling site;

- a shallow hole is drilled and a drill is hammered into the channel with the mandatory rotation of the drill at the end of the action;

- then the work alternates: drilling, driving, mandatory scrolling.

Attention! During operation, the drill will be very hot, so it is necessary to periodically moisten (cool) it with water so as not to spoil the tool!

When a drill with impact function is used, then no additional tools are required. It is only necessary in time to switch the operating mode to the desired level of functioning. The simplest and fastest way to drill concrete is to use a hammer drill.

Drilling a concrete wall with diamond crowns

A fairly effective technique used for minor home repairs is the method diamond drilling concrete. This method is effective, uncomplicated in execution and allows you to make neat openings-channels. The problem is the need to purchase special equipment - diamond segments and a drilling machine.

Work with a drill or perforator is accompanied by large dust pollution, which greatly interferes with the work and littering of the room. The use of the drilling rig does not cause such problems, since it is equipped with a local water spray system.

Work with a drill or perforator is accompanied by large dust pollution, which greatly interferes with the work and littering of the room. The use of the drilling rig does not cause such problems, since it is equipped with a local water spray system.

Read also: We choose which boiler is better to buy

It flushes away the dust and cools the crown at the same time. This technique is widely used in construction, in the repair, laying of the necessary communications and drilling of individual channel openings in reinforced concrete walls. Manually such work is almost impossible to produce.

Take into account! A special drilling rig is a very expensive equipment, which is completely unprofitable to purchase only for home use!

Take into account! A special drilling rig is a very expensive equipment, which is completely unprofitable to purchase only for home use!

Having considered the options and figured out how to drill concrete, you need to familiarize yourself with the important recommendations that will surely help to complete the job as efficiently as possible.

1. Reinforcing bars and stones in concrete constitute the most difficult obstacle for drilling. You can cope with the problem by additional use of the damper, capable of destroying stones and cutting rods.

2. The drill during operation needs regular wetting with water to precipitate dust and cool the working nozzle.

3. When drilling is performed above head level, the resulting debris goes directly to the operator. This can be prevented by making a wire funnel covered with polyethylene. This nozzle is placed on the tool and during operation prevents the spread of fragmentation elements.

Read also: Choose a construction mixer. The device, types and characteristics of mixers

As such protection, you can use a small old rubber ball. It must be cut in half and made in one part a hole of the desired size. Then half the ball is put on the end of the drill.

As such protection, you can use a small old rubber ball. It must be cut in half and made in one part a hole of the desired size. Then half the ball is put on the end of the drill.

4. To prevent settled dust from spreading over the area, you can use a vacuum cleaner to regularly remove settling debris. It will be necessary to replace the “native” filter bag with a more durable analogue, which can then be discarded.

5. When working, you need to use a protective mask and plastic glasses to avoid injuring the eyes and respiratory tract.

Hint! If there is no opportunity to protect yourself from the resulting debris, you need the entire working area, and it is better to completely free the room from paths, carpets and similar flooring. It is advisable to cover the laminate or parquet with film or newspapers!

Hint! If there is no opportunity to protect yourself from the resulting debris, you need the entire working area, and it is better to completely free the room from paths, carpets and similar flooring. It is advisable to cover the laminate or parquet with film or newspapers!

Conclusion

Drilling holes in concrete is not an easy task, however, using the right tools and accessories, work can be done relatively quickly and easily. Compliance with competent tactics will allow you to drill an even hole of the required depth.

How to choose metal scissors? The principles of choice, o ...

Wire Connectors: Caps (PPE), Terminals ...

We drill correctly: types of drills and types of drills ... 220V voltage regulators for the home. Types of stability ...