Is it possible to drill a brick wall. How to drill a concrete wall: technology. Choosing a tool for work

Drills on a brick, concrete for a drill

Many people are faced with the problem of repairing an apartment, when you need to hang a wardrobe, a picture, curtain rods. All this is always connected with drilling walls, and if your house is made of brick or concrete, you will need the appropriate drill and, of course, a tool (drill, or punch). How to drill concrete?

The hole can be made using a drill with the function of impact, for this you need a special carbide drill, the tip of which is made of solid steel (VK8), popularly referred to as “win”. The drill has a special sharpening for impact drillThe shank is cylindrical. The sizes of drills for a drill have diameters from 4 to 12 mm. The maximum drill length is 400 mm. Drill is not capable of drilling larger diameter holes, due to its not very strong impact. Therefore, manufacturers do not produce diameters larger than 12mm. Drilling a brick with a drill is quite simple, which cannot be said about drilling concrete (inefficiently). To do this, it is better to use a hammer drill. The impact force is much greater (about three times), drilling takes much less time and saves your strength. If the farm does not have such a tool as a hammer drill, and you need to drill 2-3 holes, you can use a drill. But at the same time, the drills quickly blunt, high consumption. Approximately 2-3 holes with one drill. When drilling a punch, you can make 20-30 holes. This is the expense when drilling with inexpensive drills (the approximate cost is 20 rubles per 6 mm drill and 40 rubles per drill for a perforator). We can conclude: drilling concrete is much cheaper with a puncher.

After the hole is ready, you will need a plastic dowel, insert it into the hole, and screw it into it already. The size of the dowel is selected according to the following scheme: the diameter of the dowel should be approximately two times the diameter of the self-tapping screw. So for example, for a 3.5mm self-tapping screw you will need a 6mm dowel. The dowel itself must be exactly the same size as the size of the drill, and accordingly as the size of the hole. What drill to use in order to hang a kitchen cabinet? For this, 8 mm is quite suitable. To hang the picture, 5-6mm diameter is enough.

If necessary, drill a large hole, over 12 mm, you will need a hammer drill. He is able to drill a hole up to 120 mm. Such are necessary when laying plumbing pipes, for example. Drills (drills) for a perforator have sizes from 4 - 28 mm. The length of the drill can also be different. A drill of diameter 4mm - has a maximum working length of 50mm, 5mm - 100mm, 6mm - 150mm, 8mm - 250mm, 10mm - 540mm. Drills with a diameter of 12 mm and above have a maximum length of 1000 mm. Small drills are not very long, as they simply break when drilling.

The drill shank has an SDS-plus connector (standard for all rotary hammers). There is also a SDS-max connector (as a rule, it is used in the industrial field), this is hardly useful in domestic conditions, it has the ability to drill with very large diameters (over 30 mm), powerful and has impressive dimensions. An important point if you will use a long drill (800-1000mm): it is recommended to start drilling with a short drill (approximately 350mm), then insert a long drill. All this is done to avoid a fracture of the drill at its base.

Drills (drills) for the puncher

There are also crowns for concrete, such have sizes from 35mm to 120mm. Carbide weldings are located around the perimeter. They need to drill without impact. Those. turn on the hammer drill in simple drilling mode, as opposed to drilling with a drill. So that the soldering at the crown does not stupid quickly, you need to take a break, not in one pass to drill a hole. The standard hole depth is about 150mm. If you need to go deeper, elongated shanks are commercially available. You can go deep and 300mm. It should be noted that for crowns of large diameter, a powerful hammer drill (1000 W and above) is desirable. This is easier to cope with, the engine will heat up less, for small diameters, a unit of 700-800W is enough, for example, for an opening for an electrical outlet (usually 68mm).

Concrete and brick crowns

There are also crowns for concrete with tungsten carbide spraying. Their advantage is that you can drill not only concrete, brick, but also ceramic tiles. It is very convenient when you need to drill a hole in the wall under the outlet, and on the walls there is tile. No need to change crowns, immediately go through all one, and concrete and tile. It should be noted that such a crown has a hexagonal shank designed for drilling with a drill. A powerful drill is desirable (at least 800W).

Kornka on brick, concrete, tile

As for the quality of drills, crowns and prices: inexpensive manufacturing companies - “Stayer”, “Fit”, “Encore”. The cost of such drills, crowns is quite low. For example, 6-8mm (the most commonly used) costs about 35-50 rubles. Crown for a socket about 300-350 rubles. Dear branded drills for example, “Bosch” are several times more expensive. But their service life is noticeably longer. For the house, inexpensive options are quite suitable, since they are rarely used.

You can buy a tool for drilling both in construction stores and order on the Internet.

You might be interested in::

5 Comments

Little mistake

“The hole can be made using a drill with the function of impact, for this you need a special carbide drill, the tip of which is made of solid steel (VK8), popularly referred to as“ will win ””

VK8 is not steel, but a tungsten carbide-based carbide, it does not contain iron, and this is not the only carbide used to solder a drill.

The rest of the article is wonderful

Any construction and finishing work is not complete without drilling holes of various diameters and depths for the installation of communication systems, ventilation, electrical wiring, elements of interior decoration or hanging furniture. Almost everyone came across, however, not everyone knows how to drill correctly brick wallwhat tools and technologies to use. There is nothing complicated in the process itself, given the fact that the brick is a sufficiently strong material, so you need to have some theoretical knowledge to work with it.

Brick drilling process

How to choose a drill

If you plan to carry out volumetric repairs with a large number of holes, it is better to buy a punch or rent it from any construction company. A conventional drill may not be able to withstand the load and become unusable.

If you decide to buy your own, when choosing the right equipment, you should proceed from the following indicators:

- the device must have a good electric motor with a power of at least 600 watts;

- it is desirable to have an engine speed regulator, since a brick will require a maximum of 2500 rpm;

- a drill chuck should allow the use of drills with a diameter of 0.5 to 12 mm;

- drilling shock mode required. This function, in addition to the rotational one, also creates a reciprocating movement of the drill, which allows you to destroy hard rocks, and the drilling process is much more efficient;

- a special switch for the direction of rotation of the drill will be useful. For a brick, such a function is not needed, but it will be useful in working with some other materials;

- convenient chucks have the function of self-clamping the drill without using a key. However, it should be borne in mind that this feature significantly affects the cost of the instrument.

If the hammer drilling function is not available, the drilling procedure for one hole will be delayed for a long time. Without shock movement, the edge of the drilling element cannot catch the rock, and you have to put great pressure on the tool during operation. This leads to increased loads on the internal mechanisms of the tool itself. The drill begins to heat up quickly, as a result of which it may collapse and remain in the hole.

Tools for work

Before drilling a wall, prepare the necessary tools in advance and. You will need:

- electric drill or rock drill;

- fixing dowels;

- drill bit from drill alloy with a drill;

- a Phillips or straight screwdriver, depending on the selected dowels;

- gloves and safety glasses.

If you use a drill without a shock drilling mode, a drill with a drill will not suit you. In addition to the tools listed above, you will need to work:

Preparation for drilling

Before drilling a brick, it is necessary to determine in advance the location of future holes and, using a pencil or marker, apply the appropriate marking to the surface. It is important to remember that inside the wall there can be water supply systems, cable communications or steel reinforcement, which is often used in the construction high-rise buildings. It is necessary to carefully examine the wall and make sure that the drill does not damage the communication system and does not stumble on a metal rod.

If you started a major repair, not knowing the location of communications and pipes, it is better to purchase a portable construction metal detector and a contactless device for detecting hidden electrical wiring in a hardware store. These devices are relatively inexpensive, and it is highly discouraged to save on this. If during the drilling process you damage the communications, their repair or replacement will cost you a much larger amount, so excess reinsurance will not hurt here.

In many cases, electrical cables can be hidden at the seams between the bricks and hidden. In such cases, use a regular screwdriver and carefully make a hole in the plaster or putty to the surface of the brick to make sure that there is no wiring. After that, you can start drilling with a drill or punch.

At the very beginning of the work, it is necessary to use a hammer and core to make a recess in place of the future hole. This is done so that the drill does not go sideways at the initial stage. Most importantly, during the whole process, protect yourself from small fragments by wearing safety glasses or a special plastic shield.

Try to keep the drill as straight as possible so that the drill does not experience bending stress, as it may break during operation. If you use a puncher and a drill with a drill bit, the work will go quickly, but if you use victory drills without a drill and a conventional drill, then the process requires observance of special technology.

During drilling, do not push the tool too hard, this will lead to increased loads, and the device will fail. Periodically remove the drill from the hole and cool it in a container of cold water.

Video on how to drill a brick wall:

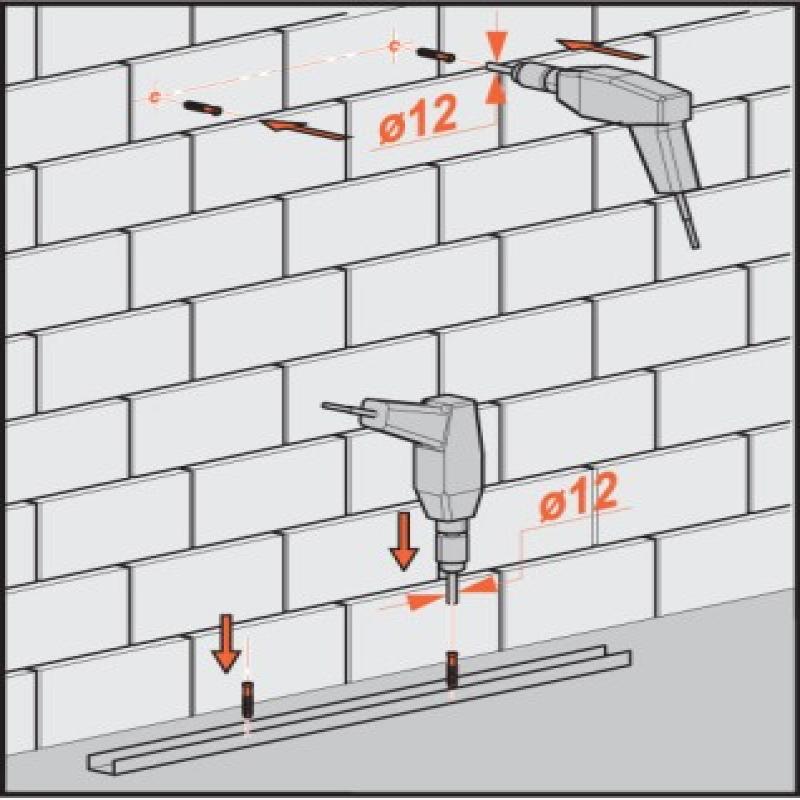

If you need to make a hole with a diameter of 12 mm, you should not immediately install a similar drill in the chuck and try to work. Start with a 4 or 6 mm drill, make a hole to a predetermined depth, then replace it with an 8-10 mm drill and repeat the procedure. After that, put the final drill with a diameter of 12 mm and expand the hole to the desired size. the process will go much faster.

Conclusion

Today it is one of the most popular building materials. It is used mainly for the construction of low-rise buildings and private cottages. This material allows you to build houses of complex geometric shapes without the use of construction equipment, in addition, it has increased strength. The owners of such houses note a high level of heat conservation and increased sound insulation of the material.

Carry out any types of repair work in brick building much easier and faster than in concrete, as the material lends itself well to all types of processing. The main thing is that in the process of working, observe safety rules and use personal protective equipment.

Drilling a brick wall includes the practical implementation of certain skills, as well as preparatory processes regarding the tool used, and we process the surface of the brick wall itself.

The quality of the final result depends on the type of drill used. The latter should have a strength exceeding the strength of the brick used at the time of masonry. Usually, drill bits with diameters of 4, 6, 8 and 12 mm are used, respectively.

Tools & Inventory

The list below is optimal with respect to the drilling process, or more precisely, the implementation of the task without interrupting the process itself.

So, the list consists of such items:

- percussion drill;

- dowels;

- drill (winning / 4 - 12 mm);

- curly screwdriver;

- limited range metal detector;

- cold water poured into any convenient container;

- metal core;

- eye protection element.

Tool preparation

The tool used in drilling a brick wall is a percussion drill. Such a drill must be powerful, and therefore have at least 600 watts and 2500 thousand revolutions per minute. The main feature that you should pay attention to is the possibility of smooth adjustment of revolutions to maximum.

If buying a drill is still an upcoming event, then the emphasis should be on drills with reverse rotation, as well as a self-clamping chuck. The latter eliminates the need for constant use of a key for clamping drills, although one is included.

The presence of a shock function is a prerequisite, since its absence will undoubtedly lead to:

- overheating of the drill, and in particular surfacing from win (sudden wear of the cutting part);

- normal drill pressure without engaging the cutting edge, as it increases exclusively static load.

Preparatory work: positioning relative to the brick wall

Preparatory work in relation to the brick wall itself immediately before drilling is more familiarization in nature than the “strategic” - design one. From the point of view of the safe execution of such work, it is necessary to use the metal detector, which was indicated in the list above.

Its practical use immediately before drilling will eliminate the possibility of damage to the wiring, internal heating systems, as well as various reinforcing components.

Marks of sockets, switches and fixtures - the final stage of preparation. Taking into account the features of laying electrical wires from the above “points” to the junction box, and this is usually a vertical laying, but not excluding the possibility of a diagonal, we determine the location of the drilling.

Despite the assumed accuracy in choosing the drilling location, the recess for the first 10-20 mm must be performed with a screwdriver. The use of this will allow timely identification of communications buried in the plaster, as well as avoiding their critical damage.

Direct drilling of a brick wall

The answer to the question of how to drill a brick wall with a drill can be obtained solely due to independent practical developments. So let's get started!

The drilling process itself, regardless of the finish of the brick wall or its complete absence, begins with a mark. The hole in the wall is marked with a core. Why do we need a mark? After using the core, a slight depression remains, which reliably fixes the cutting part of the drill at the initial stage of work.

The drill, during the entire drilling, must be kept level, as otherwise the cutting element (drill bit) will break.

The human impact factor on the drill and the static load on the drill are interrelated values. The first, namely “pressure” on the drill, should be smooth and soft, despite the need for significant loads in order to achieve the final result.

If significant static loads can be handled by regularly cooling the drill (returning the tungsten and cobalt alloy to its original state), then uniform drilling is the result of a uniform and smooth effect on the tool itself.

Using coolant (water) during drilling can damage the tool. The working cutting drill bit is lowered into the water only 70% of the working length, that is, the one that remained after the latter was fixed in the cartridge.

The drilling process is uniform and does not require special skills, but it requires considerable attention. So, for example, the latter will help to identify and, of course, overcome the burnt brick, if, of course, one got in the way of drilling. You can determine the burnt brick by the color of the dust. Usually, she is black.

The passage of such sections must be carried out at low speeds, which, in turn, must be combined with the activation of the shock function. Observing these two conditions, as well as making efforts in relation to the tool itself, it is necessary to carefully control the heating of the drill bit.

Drilling holes of 12 mm in size requires a slightly different approach, namely the consistent use of all of the above sizes of drill bits. To start drilling a brick wall under a hole of 12 mm, you need to start with a drill size of 4 or 6 mm.

One of these drills achieves the planned depth, then the width of the hole expands with a 10 mm drill. Once the depth in relation to the previous size of the drill has been achieved, a similar action should be repeated with a drill of 12 mm.

Taking into account such a technology to achieve the required hole diameter, namely a diameter of 12 mm, the final result will be achieved much faster, and at the same time, bypassing unnecessary efforts. Regarding how to quickly and efficiently drill any brick wall with a drill in order to obtain a diameter of, for example, 30 mm, it is worth paying attention to diamond drilling.

First of all, drilling holes in a brick wall is associated with the improvement of an apartment or a country house. This service is in demand in cases where you need to make an internal outlet or securely mount the mount under the TV.

The price of drilling holes in a brick wall depends on the diameter and depth of the opening, as well as on factors that complicate the process. These include working in hard-to-reach places and at high altitude, the need to use antifreeze, etc.

Wall Drilling Price List

| Hole diameter (mm) | Cost of 1 cm. Drilling depth (rub) |

|---|---|

| up to 72 mm | 15 |

| 82-102 | 17 |

| 112-122 | 18 |

| 132-142 | 20 |

| 152-162 | 22 |

| 172 | 24 |

| 180 | 27 |

| 200 | 30 |

| 220 | 33 |

| 250 | 38 |

| 270 | 43 |

| 300 | 47 |

| 320 | 53 |

| 350 | 59 |

| 400 | 71 |

| 450 | 85 |

Difficulty factors

Benefits of Diamond Brick Wall Drilling

- Cracks and chips do not form. Destruction of a wall, ceiling or foundation is not possible.

- The cost of drilling holes in a brick depends on the amount of time required. Punching can take several days, and using a tool with diamond crowns can take minutes.

- The boundaries of the aperture are clear and exactly corresponding to the marking. The surface is perfectly flat and does not require additional grinding, which saves the financial cost of repairs.

- No dust and sludge: it is possible to carry out work in rooms with decoration.

- Noise levels up to 80 decibels do not cause discomfort to others.

Scope of application

In Moscow, many are interested in the cost of drilling bricks. The method is used in everyday life, in the construction and reconstruction of buildings. Private individuals apply for a service when it is necessary to equip an apartment: install sockets or change wiring. At construction sites diamond drilling it is used when it is necessary to organize a ventilation system, lay pipes of the water and gas supply, heating and sewage systems, install fences or railings.

We provide a full range of services: we make holes in concrete, reinforced concrete, brick and other materials, install pipes, change plumbing fixtures.

Company certificates and licenses

|

|

|

|

Services of drilling brick walls in Moscow

Make an order in the company "San Master": we have been working since 2004, we have favorable prices for drilling holes in the wall and other services. Check out the prices for company services on the website and leave a request for a call back if you have questions!

Concrete structures, walls and ceilings are not uncommon in our homes and apartments. In high-rise construction, they are generally used with special frequency, since houses with concrete walls come out the most reliable. Reliability of concrete is determined by the good strength of such a material, which is achieved through the use of the correct components of the concrete mixture and the quality of work done on its construction.

And here we are proud of our sturdy walls. But usually there is a need to drill a hole in this very wall. And it may be needed quite often, for example:

- when decorating walls and ceilings;

- during the installation of air conditioners;

- when installing plumbing;

- when embedding furniture;

- when working with electrical wiring, its installation;

- the need for holes for mounting under the picture or other home decoration.

As you can see, there are many reasons to drill a wall. The main thing is not only to do the job well, but also to make your life easier using the right good tool. Which one can you choose to drill concrete?

It would seem that this is so: just take a regular drill and drill yourself. But no, in fact, in the process of performing this task, many difficulties can arise. Firstly, concrete walls are very durable and hard to take, and secondly, their structure is heterogeneous, and you can easily risk getting on gravel or a piece of reinforcement. Get stuck with regular concrete wall You can not drill anything for a long time in the end.

How to drill a hole?

The answer to this question will not be too complicated. The fact is that drilling a wall of concrete, as mentioned above, is an extremely difficult process. To solve this issue, one of two types of tools should be used: either a hammer drill or a drill.

Both will be good in certain conditions. I will explain why. The best thing, of course, is to use a hammer drill: it is designed specifically for concrete walls and it is common practice to use it. After all, a punch easily pierces both stone and concrete surfaces. Another of its advantages is the ability to drill large diameter holes, which a drill cannot do.

But, if you have a wall of foam concrete in front of you, or if you need to drill several small holes - a drill is quite suitable. In this case, the punch can split the surface of the wall, which is not very successful. But, as already mentioned, do not count on large holes, only with a diameter of no more than 12-15 cm. In addition, drilling a concrete wall has its own nuances, which we will consider below.

How to drill a concrete wall with a conventional drill?

Let's talk a bit about drilling ordinary drill. So, let's start with the fact that the usual here is hardly suitable. Those. theoretically, of course, this is possible. But in practice it is extremely difficult. Mandatory in this case, the use of a special drill bit for concrete work with a tip coated with a composition of hard alloys.

The best way would be to use a special impact drill. How is it different from usual? By the fact that in such a drill, drill movements are carried out due to special ratchets with teeth interacting with each other. It is not difficult to use such a drill to carry out high-quality work. To do this, simply transfer the drill from the normal rotational mode to the shock rotation mode.

But no matter what type of drill you use, how much the use of specialized nozzles is relevant. Nozzles (crowns) are sold in two configurations: for hammer or hammerless drilling.

The nozzle classification is as follows:

Toothed crowns for drilling with impact function. A concrete wall can be drilled with such crowns with a cutting edge from separately soldered teeth made of strong alloys. For quick-clamping chucks, drills are available on such SDS tails. Their strength is so high that it is possible to cut metal, only the impact mode contributes to their destruction, creating unacceptable loads. That is why such drills are used to drill a hole between the reinforcement of reinforced concrete slabs or brick walls.

Diamond crown for drilling shockless. These are more modern nozzles that simplify the task several times better than usual. The abrasive edge with cuts on them is created by diamond spraying or by spraying corundum sand. As you know, diamond is distinguished by its unprecedented strength. That is why he easily copes with concrete wall reinforcement. Such a nozzle can make a hole at least 1.5 meters deep and more than half a meter in diameter. This type of nozzles is already used by professionals, but nozzles with a diameter of up to 100 mm can very well be used in domestic conditions.

KS standard crowns. Crowns with diamond crystals embedded on the cutting edge. You can use them for slabs, rocky soils, monolithic concrete structures from high strength brands. It can easily replace hard carbide toothed crowns.

Based on your conditions, you can safely choose the necessary drill for a drill and drill a hole. But there are also a number of recommendations for working with a conventional drill, which is not equipped with a shock function.

To do this, you start drilling a wall, but are interrupted periodically. It is necessary to drive a pointed drill into the concrete surface with your hands and destroy the concrete with metal punches. We take our drill or chisel, other fixtures of the appropriate and required diameter metal and hit them with a hammer / sledgehammer. Rotate the punch periodically. Then take the drill again.

Note that when drilling a hole in a concrete wall with a conventional drill, you risk breaking the tool. Necessarily a low-power drill must be given rest. Drills also have the ability to heat, so you need to cool them with water. At the same time, take a break every 10-15 minutes of work, leaving the same amount of time for a break for the instrument.

How to drill a hole in concrete without hammer drillsee in the video: