Reinforced concrete lintel marking. Reinforced concrete lintels for buildings with brick walls

Jumpers

Jumper device

Window, door and other openings in masonry made of bricks and stones of regular shape are covered with lintels of various designs.

According to the work performed in the masonry, the jumpers are divided into bearing and not bearing.

Carrier jumpersIn addition to the mass of masonry sections located above them, they bear the load from the ceilings resting on these masonry sections.

Non-bearing jumpers carry the load only from its own weight and masonry sections located above them.

Jumpers are ordinary, wedge-shaped, arched and beam. They are laid on the formwork.

The most effective jumpers made of precast concrete elements - bars and plates.

To block the openings in the stone walls, mainly block and slab reinforced concrete lintels are used. As well as ordinary, wedge-shaped and arched lintels made of unreinforced masonry.

Reinforced concrete lintels are usually composed of several elements along the wall thickness, the width of which is a multiple of the dimensions masonry.

Prefabricated reinforced concrete lintels.

Reinforced concrete lintels are used to close openings:

· squared jumpers - in bearing wallsperceiving loads from floors,

· plate lintels - in self-supporting walls, perceiving loads only of the wall on which the plates do not rest.

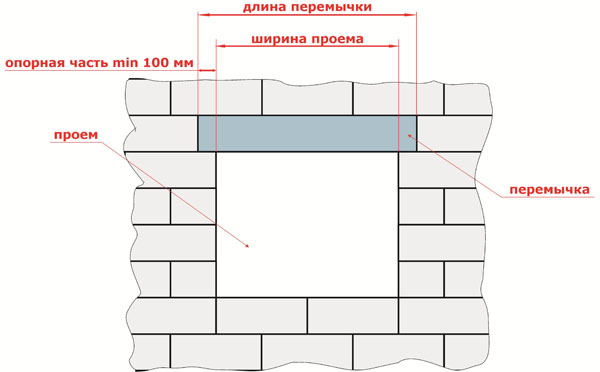

Prefabricated reinforced concrete lintels are installed in the walls and embedded in the walls to a depth of:

· for walls - at least 250 mm;

· for partitions - not less than 200 mm or reinforcement with a diameter of 5-6 mm with a launch of 300 mm.

Prefabricated reinforced concrete lintels are installed in the walls during the laying process.

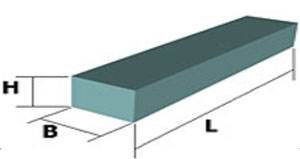

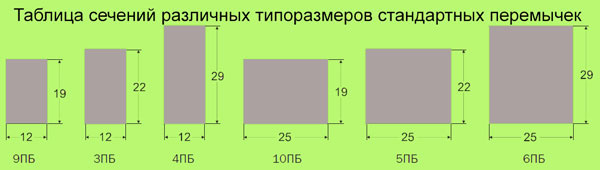

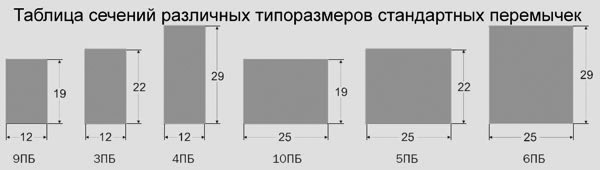

Prefabricated reinforced concrete lintels:

a, 6 - squared (type B), c - plate (type BP), g - beam (type BU)

In accordance with the house construction project, if necessary, the masonry seams under the supports of the lintels are reinforced with nets to increase strength.

Prefabricated reinforced concrete jumpers are sections located above the openings and laid out on the formwork on a solution of increased strength of a grade not lower than M-25:

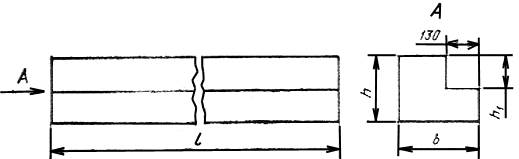

· PB - squared, width up to 250 mm inclusive;

· PP - plate, more than 250 mm wide;

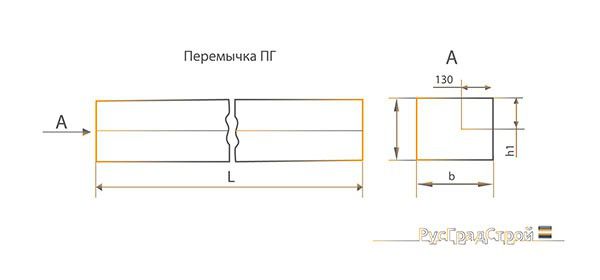

· PG - beam, with a drawing for supporting or adjoining floor slabs

· PF - facade, facing the building’s facade and designed to overlap openings with quarters with a thickness of the protruding part of the masonry in the opening of 250 mm or more.

Jumper type PB Lintels reinforced concrete

GOST 948-84 series 1.038.1-1

№ Brand Dimensions, mm Concrete class

Length Width Height

1 1 PB 10-1 1030 120 65 V 15

2 1 PB 13-1 1290 120 65 V 15

3 2 PB 10-1P 1030 120 140 V 15

4 2 PB 13-1P 1290 120 140 V 15

5 2 PB 16-2P 1550 120 140 V 15

6 2 PB 17-2P 1680 120 140 V 15

7 2 PB 19-3P 1940 120 140 V 15

8 2 PB 22-3P 2200 120 140 V 15

9 2 PB 25-3P 2460 120 140 V 15

10 3 PB 13-37P 1290 120 220 V 15

11 3 PB 16-37P 1550 120 220 V 15

12 3 PB 18-37P 1810 120 220 V 15

13 3 PB 18-8P 1810 120 220 V 15

14 3 PB 21-8P 2070 120 220 V 15

15 3 PB 25-8P 2460 120 220 V 15

16 3 PB 27-8P 2720 120 220 V 15

17 3 PB 30-8P 2980 120 220 V 15

18 5 PB 18-27P 1810 250 220 V 15

19 5 PB 21-27P 2070 250 220 V 15

20 5 PB 25-27P 2460 250 220 V 15

21 5 PB 27-27P 2700 250 220 V 15

22 5 PB 30-27P 2980 250 220 V 15

23 5 PB 25-37P 2460 250 220 V 15

24 5 PB 27-37-P 2700 250 220 V 15

25 5 PB 30-37P 2980 250 220 V 15

Jumpers are made of heavy concrete of the M-200 brand for compression. The jumpers are 120 mm wide reinforced with flat frames, and 250 mm wide with spatial frames.

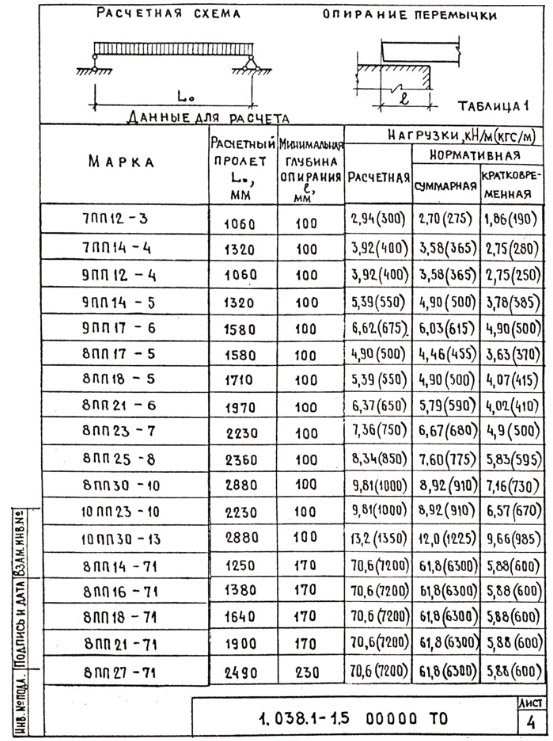

PP type jumper

Heck. 2. 1 -technological bias

Modification Dimensions, mm

Length (L) Width (B) Height (H)

1PP 12-3 1160 380 65

2PP 14-4 1420 380 140

2PP 17-5 1680 380 140

2PP 18-5 1810 380 140

2PP 21-6 2070 380 140

2PP 23-7 2330 380 140

2PP 25-8 2460 380 140

3PP 14-71 1420 380 220

3PP 16-71 1550 380 220

3PP 18-71 1810 380 220

3PP 21-71 2070 380 220

3PP 27-71 2720 380 220

3PP 30-10 2980 380 220

4PP 12-4 1160 510 65

5PP 14-5 1420 510 140

5PP 17-6 1680 510 140

5PP 23-10 2330 510 140

6PP 30-13 2980 510 220

PG jumper

PF jumper

Reinforced concrete PRG runs are manufactured in accordance with the series 1.225-2 issue. 12 and are intended for overlapping openings in the walls of public buildings and office buildings of brick or wall blocks. The runs are designed for a design load of 4000 kgf / m, i.e. used in load-bearing walls.

Runs are made of heavy concrete of the M-250 brand for compression, and for a length of 6 meters - M-350. Reinforcement is possible in 2 options: prestressed and unstressed,

The run brand consists of alphanumeric groups: type of run (PRG - rectangular run) and overall dimensions (length, width, height in dm.). The 2nd group includes the design load without taking into account the dead weight (in t / m) and the class of reinforcement used. For example, PRG 60.2.5-4AtV - a run of rectangular section with a length of 5980 mm, a width of 200 mm, a height of 500 mm under the design load without taking into account its own weight of 4 tn / m, reinforced with AtV steel, i.e. prestressed

Buy lintels reinforced concrete window, girder, plate of all standard sizes in RusGradStroy at the best prices. Favorable delivery conditions that can be calculated online.

Drawings of jumpers reinforced concrete products ПБ, ПП, ПГ beam, plate, squared

The jumpers PB, PP, PG are used in the construction of stone, brick houses to close openings of windows, doors and other technological openings. The task of reinforced concrete lintels is to transfer the load from the wall being erected to the lower masonry, while maintaining the opening of the building. These products are intended for use in buildings in an aggressive environment, with seismicity up to 7 points.

The production of reinforced concrete lintels is carried out strictly according to GOST 948-84. Thus, you get high-quality reinforced concrete products, the technology of which has been developed over the years in the conditions of our country, which eliminates doubts about the choice of lintels as the building materials for your home.

Beam and slab jumpers are available with a slope of the end and side faces, the lower part of which can be less than 20 mm. in length and 8 mm. in width. In this type of reinforced concrete, pre-stressed reinforcement, AtV, is used, however, its type varies from the size of the bridge, can also be manufactured with the release of reinforcement, for buildings in seismically hazardous areas up to 7 points. On PB PP and PG there are sling holes with a diameter of 30 mm. for unloading - loading and installation at your construction site.

The jumpers are transported by motor vehicles in a stacked state with gaskets between the rows of jumpers with a thickness of at least 25 mm., Laid longitudinally to the vehicle axis. The height of the stack should not exceed 2 meters. Unloading - loading should be carried out with a truck crane using special load-gripping devices, with separate unloading - for sling loops.

Subject to the above requirements and conditions, RusGradStroy gives a guarantee for the long life of the reinforced concrete lintels PB, PP, PG.

Decoding of marking. 2PB-27-4p, where 2PB - section 120mm. x 140 mm., 27 - long, 4 - load 400 kg. per meter.

Reinforced concrete products are the most popular in the construction industry. No matter what material the construction is made of and for whatever it is intended, concrete elements are always used in it as concrete support elements. So what exactly are jumpers needed for and what are they?

Technical specifications for these products are reflected in GOST No. 948 of 1984. The document indicates all the requirements for products, their sizes, varieties and the like, but only for products that are manufactured industrially (the so-called prefabricated). If reinforced concrete lintels are mounted at the place of work by pouring concrete mortar in the form (formwork), they are called monolithic. At the same time, the class of concrete, the cross section of the reinforcement are necessarily displayed in the design documentation and cannot go against the requirements of GOST.

Appointment

In the production of lintels, only high-quality steel is used (for reinforcement, with a cross section of 0.4 - 0.6 mm) and “heavy” concrete (class B15 and higher, density not less than 2,200 kg / m 3). And this is understandable, since the main requirements for concrete products are a long service life and the ability to withstand extreme loads. Metal resists bending (tensile) stresses, while concrete protects the material from compression.

Most often, reinforced concrete jumpers are used for window and door openings. In fact, these are horizontally mounted supports that take on all the load (static) from floors, blocks or masonry in this area. Although often such reinforced concrete products are also used in the construction of certain types of fences, designation of areas of responsibility, construction of racks and in a number of other cases. But still, their main purpose is to install in various openings.

Types and labeling

- Reinforced concrete lintels (PB). The maximum width is 250 mm.

- Beam (GHG) - have a ledge (quarter), on which the floors are based.

- Facade jumpers (PF) - used as supports for parts of masonry protruding beyond the perimeter.

- Plate (PP). The minimum width is 250 mm.

Jumpers are marked with groups of numbers and symbols that are separated by a dash (all numerical values \u200b\u200bare in “dm”).

- First one. The number indicates the cross-section (data are given in GOST, table No. 1), the letters indicate the type of product. The number following them is the length.

- The second one. Rebar class and permissible load on the jumper.

- The third. It can indicate the density of concrete, the presence of loops, sling, mortgages and so on. This is specified directly from the seller, according to the documentation.

For example, 5PB 27-37. Section No. 5, squared, length 27 dm, withstands up to 3,700 kN / m 2. Mounting loops missing.

Technical characteristics of the jumpers reinforced concrete

All products are divided into bearing and non-bearing. In the first case, installation is carried out using a hoist (crane), in the second - manually. There are differences in the reference length. For bearing jumpers, this parameter is 17-30 cm, for non-bearing jumpers, from 10 to 15 cm.

The maximum allowable load on the jumpers is from 100 to 3 650 kgf. Bearing can be reinforced (BU) or trim (BG).

Reinforced concrete lintel sizes

The range is so diverse that it makes no sense to list all the typical dimensions. It is pertinent to note only the limiting values \u200b\u200bfor the minimum and maximum of some basic parameters.

For example, you can buy a concrete goods jumper 1PB for approximately 185 rubles (1030x120x65 mm), and a 5PB product with dimensions of 2980x250x220 mm will cost about 4,050 rubles.

More expensive (and massive) reinforced concrete products are practically not used in the private sector.

Transportation rules

- Reinforced concrete lintels are sorted depending on the brand and placed in containers.

- Laying - along the longitudinal axis of the car (trailer).

- The maximum height of stacks during storage is 2 m.

- Between the rows there is a gap (at least 250 mm), which is laid with a dense material (to exclude contact of the products, which is fraught with their damage).

Installation of non-bearing jumpers is allowed on openings of no more than 2 m.

One of the main positions in the assortment of any concrete goods plant is jumpers. These are reinforced concrete products intended for overlapping window, door, arched openings in their upper part, as well as for some other construction works, for example, arranging the facade with exposed masonry.

Jumpers play an important role in the construction of the building. Most developers purchase them from manufacturers. Factories guarantee compliance of their products with GOSTs, use the “right” concrete grades, high-quality reinforcement. An important factor is the affordable price, so manufacturing directly at the facility is rarely carried out. Mostly this occurs when overlapping non-standard openings.

Main types and classification

GOST 948-84, according to which standardization of products of this type is carried out, adopted in 1984. It is designed for buildings with brick walls, but its use is allowed in cases of arrangement of reinforced concrete lintels for blocking openings in the walls of other types of stone.

According to GOST 984-84, 4 main types are distinguished: PB, PP, PG, PF.

They are bars. Their maximum width can reach 25 cm. The standard length is 1030-5960 mm, depending on the brand. For example, the popular 2PB beams are available with a width of 120 and a height of 140 mm, while there are 10 lengths, and in each of them there are 2 varieties that differ in weight and reinforcement.

Tiled, their width is more than 250 mm, such plates consist of several bars, that is, PP is a block reinforced concrete products PB.

Reinforced concrete products of beam type. They have a special recess - a quarter, designed to equip the junction of floor slabs.

Facade. They overlook the facade of the building, the purpose is to cover openings with quarters.

Marking

All reinforced concrete products manufactured at the plant comply with the standard GOST classification. The brand is indicated by the manufacturer. To determine what type is in front of you, you need to decipher the notation, consisting of letters and numbers, separated by hyphens.

Marking is carried out as follows:

1. the first group indicates the size of the section, the type of jumper, its length;

2. the second group contains information on the design load (in kN / m) and the class of prestressed reinforcement;

3. the third group indicates the presence of mounting loops (p), anchor outlets (a), as well as the possibility of installation in special operating modes. To ensure a high level of seismic stability, reinforced concrete products with the marking (C) are used, and in an aggressive environment - with a high density of concrete (P) or (O).

For example, having a beam in front of it with the marking 2PB 10-1-p, we determine its dimensions and parameters:

- section - No. 2 (120x140 mm);

- type - PB;

- length - 10 dm (more precisely, 1030 mm);

- there are mounting loops.

In other embodiments:

1. 8PP 21-71-AtV is a plate jumper with a length of 2070 mm and a cross-section No. 8 (380x190), designed for a load of 71 (more precisely, 70.61) kN / m with tensioned reinforcement of the At-V brand;

2. 5PF17-5 is a facade slab 1680 mm long with a cross-section No. 5 (190 - height, 90 - protruding part, 130 - supporting zone), goes under a load of 5 kN / m.

The dimensions of the slabs are standardized, concrete grades of at least M250 are used. Some manufacturers work on order. Therefore, private developers can buy non-standard reinforced concrete lintels of different sizes that meet the requirements of GOST regarding the quality of concrete products.

Purpose and load calculations

As noted above, the main function of products of this type is to close openings in buildings or to ensure proper joining of floor slabs.

In the construction business, the following groups are distinguished:

1. Bearing concrete. These are reinforced beams, used to take the load transmitted by floor slabs. Withstand weight 3400-3700 kg / m.

2. Non-bearing (beams). Accept the load transmitted by the masonry of the wall located directly above the opening.

3. Pencils. Thin non-bearing; are applied to interroom doorways. Pencil thickness - less than 120 mm.

4. Runs. Large bearing.

5. The crossbar. This runs with a recess (shelf), with significant weight. Crossbars are intended for an emphasis of the designs standing on them.

In low-rise construction, the first three types of reinforced concrete products are mainly used. The size of the jumper and the maximum load on the beam is determined by specialists when creating project documentation.

When erecting small outbuildings, baths, garages and similar structures, the owner will completely cope with the calculations on his own. Jumpers are used for window and door openings corresponding to the 2PB brand. Their length can be from 1.03 to 2.95 m, and the cross-section has standard dimensions of 120x140 mm. The weight of the beams of group 2PB is in the range 43-125. Window ceilings withstand a load of 200-800 kg / m, door - about 3700 kg / m.

Reinforced concrete plants take into account the heavy weight of their products. To facilitate loading, unloading and construction work on beams and plates, mounting loops or locking holes with a diameter of 30 mm are provided. Sometimes developers make reinforced concrete block lintels on their own. In this case, the use of the “right” concrete and reinforcement will be a prerequisite. After all, non-compliance with the technology is fraught with the destruction of the building in a very short time. Beams make 0.3 m more than the width of the opening.

It should be noted that jumpers for buildings with factory-built brick walls have a relatively low price. Therefore, they can always be bought in the right amount. Pouring reinforced concrete window lintels at the facility is unnecessary labor. After all, you will first need to mount the formwork, then pour concrete, let it stand. And only after that they continue laying. Ready-made PB beams will not slightly increase the cost of construction, but they will significantly save time.

Jumper prices

| Name | Price, rubles | Weight kg | Sizes, mm | ||||

| section | length | ||||||

Squared |

|||||||

| 1PB-10-1p | 305 | 20 | 120x65 | 1030 | |||

| 1PB-13-1p | 310 | 25 | 1290 | ||||

| 1PB-16-1p | 336 | 30 | 1550 | ||||

| 2PB-10-1p | 319 | 43 | 120x140 | 1030 | |||

| 2PB-13-1p | 322 | 54 | 1290 | ||||

| 2PB-16-2p | 361 | 65 | 1550 | ||||

| 2PB-17-2p | 386 | 71 | 120x140 | 1680 | |||

| 2PB-19-3p | 476 | 81 | 1940 | ||||

| 2PB-22-3p | 489 | 92 | 2200 | ||||

| 2PB-25-3p | 674 | 103 | 2460 | ||||

| 2PB-26-4p | 741 | 109 | 2590 | ||||

| 2PB-29-4p | 781 | 120 | 2850 | ||||

| 2PB-30-4p | 793 | 125 | 2980 | ||||

| 3PB-13-37p | 639 | 85 | 120x220 | 1290 | |||

| 3PB-16-37p | 778 | 102 | 1550 | ||||

| 3PB-18-37p | 840 | 119 | 1810 | ||||

| 3PB-19-37p | 992 | 138 | 1940 | ||||

| 3PB-21-37 | 1010 | 137 | 2070 | ||||

| 3PB-25-37 | 1100 | 162 | 2460 | ||||

| 3PB-25-8p | 867 | 162 | 2460 | ||||

| 3PB-27-8p | 912 | 180 | 2720 | ||||

| 3PB-30-8p | 984 | 197 | 2980 | ||||

| 3PB-34-4p | 1060 | 222 | 3370 | ||||

| 3PB-36-4p | 1140 | 240 | 3630 | ||||

| 3PB-39-8p | 1490 | 257 | 3890 | ||||

| 4PB-30-4p | 1350 | 259 | 120x290 | 2980 | |||

| 4PB-44-8p | 2000 | 384 | 4410 | ||||

| 4PB-48-8p | 2100 | 418 | 4800 | ||||

| 4PB-60-8p | 2880 | 519 | 5960 | ||||

| 5PB-18-27p | 1460 | 250 | 250x220 | 1810 | |||

| 5PB-21-27p | 2030 | 285 | 2070 | ||||

| 5PB-25-27p | 2120 | 338 | 2460 | ||||

| 5PB-25-37p | 2220 | 338 | 2460 | ||||

| 5PB-27-27p | 2490 | 375 | 2720 | ||||

| 5PB-27-37p | 2870 | 375 | 2720 | ||||

| 5PB-30-27p | 3130 | 410 | 2980 | ||||

| 5PB-30-37p | 3220 | 410 | 2980 | ||||

| 5PB-31-27p | 3280 | 428 | 3110 | ||||

| 5PB-34-20p | 3360 | 463 | 3370 | ||||

| 5PB-36-20p | 3800 | 500 | 3630 | ||||

| 6PB-35-37p | 4480 | 634 | 250x290 | 3500 | |||

| 7PB-60-52 | 14540 | 217.5 | 250x585 | 5950 | |||

| 8PB-10-1p | 330 | 28 | 120x90 | 1030 | |||

| 8PB-13-1p | 363 | 35 | 1290 | ||||

| 8PB-16-1p | 376 | 42 | 1550 | ||||

| 8PB-17-2p | 389 | 45 | 1680 | ||||

| 8PB-19-3p | 396 | 52 | 940 | ||||

| 9PB-13-37p | 613 | 74 | 120x190 | 1290 | |||

| 9PB-16-37p | 737 | 88 | 1550 | ||||

| 9PB-18-37p | 866 | 103 | 1810 | ||||

| 9PB-18-8p | 676 | 103 | 1810 | ||||

| 9PB-21-8p | 759 | 118 | 2070 | ||||

| 9PB-22-3p | 828 | 125 | 2200 | ||||

| 9PB-25-3p | 919 | 140 | 2460 | ||||

| 9PB-25-8p | 1010 | 140 | 2460 | ||||

| 9PB-26-4p | 1070 | 148 | 2590 | ||||

| 9PB-27-8p | 1140 | 155 | 2720 | ||||

| 9PB-29-4p | 1190 | 162 | 2850 | ||||

| 9PB-30-4p | 1240 | 170 | 2980 | ||||

| 10PB-18-27p | 1350 | 215 | 250x190 | 1810 | |||

| 10PB-21-27p | 1830 | 246 | 2070 | ||||

| 10PB-25-27p | 2270 | 292 | 2460 | ||||

| 10PB-25-37ap | 3000 | 292 | 2460 | ||||

| 10PB-25-37p | 2380 | 292 | 2460 | ||||

| 10PB-27-27p | 2750 | 323 | 2720 | ||||

| 10PB-27-37ap | 3950 | 323 | 2720 | ||||

| 10PB-27-37p | 3230 | 323 | 2720 | ||||

Beam |

|||||||

| 1PG-44-8 | 3730 | 484 | 250x290 | 4410 | |||

| 1PG-48-8 | 4070 | 527 | 4800 | ||||

| 2PG-39-31 | 6340 | 792 | 250x440 | 3890 | |||

| 2PG-42-31 | 6360 | 845 | 4150 | ||||

| 2PG-44-31 | 6790 | 897 | 4410 | ||||

| 2PG-48-31 | 8280 | 977 | 4800 | ||||

| 3PG-60-73 | 18750 | 2470 | 380x585 | 5950 | |||

| 4PG-30-40 | 6220 | 753 | 380x290 | 2980 | |||

| 5PG-16-40 | 2510 | 357 | 1550 | ||||

| 5PG-26-40 | 4030 | 596 | 2590 | ||||

| 5PG-35-37 | 5530 | 805 | 3500 | ||||

| 6PG-44-40 | 11770 | 1528 | 380x440 | 4410 | |||

| 6PG-60-31 | 16390 | 2065 | 5960 | ||||

| 7PG-35-52 | 7800 | 1140 | 510x290 | 3500 | |||

| 8PG-60-40 | 20460 | 2930 | 510 × 440 | 5960 | |||

| 1PP-12-3 | 414 | 72 | 380x65 | 1160 | |||

| 2PP-14-4 | 1050 | 189 | 380x140 | 1420 | |||

| 2PP-17-5 | 1340 | 229 | 1680 | ||||

| 2PP-18-5 | 1380 | 241 | 1810 | ||||

| 2PP-21-6 | 1410 | 275 | 2070 | ||||

| 2PP-23-7 | 1580 | 310 | 2330 | ||||

| 2PP-25-8 | 1780 | 327 | 2460 | ||||

| 3PP-14-71 | 2020 | 297 | 380x220 | 1420 | |||

| 3PP-16-71 | 2600 | 325 | 1550 | ||||

| 3PP-18-71 | 2640 | 378 | 1810 | ||||

| 3PP-21-71 | 3510 | 433 | 2070 | ||||

| 3PP-27-71 | 4840 | 568 | 2720 | ||||

| 3PP-30-10 | 3090 | 623 | 2980 | ||||

| 4PP-12-4 | 650 | 95 | 510x65 | 1160 | |||

| 5PP-14-5 | 1410 | 253 | 510x140 | 1420 | |||

| 5PP-17-6 | 2380 | 300 | 1680 | ||||

| 5PP-23-10 | 2908 | 416 | 2330 | ||||

| 6PP-30-13 | 5360 | 835 | 510x220 | 2980 | |||

| 7PP-12-3 | 744 | 99 | 380x90 | 1160 | |||

| 7PP-14-4 | 945 | 121 | 1420 | ||||

| 8PP-14-71 | 1810 | 256 | 380x190 | 1420 | |||

| 8PP-16-71 | 1980 | 280 | 1550 | ||||

| 8PP-17-5 | 1870 | 303 | 1680 | ||||

| 8PP-18-5 | 1940 | 327 | 1810 | ||||

| 8PP-18-71 | 2380 | 327 | 1810 | ||||

| 8PP-21-6 | 2180 | 374 | 2070 | ||||

| 8PP-21-71 | 2660 | 374 | 2070 | ||||

| 8PP-23-7 | 2260 | 421 | 2330 | ||||

| 8PP-25-8p | 2370 | 444 | 2460 | ||||

| 8PP-27-71 | 3630 | 491 | 2720 | ||||

| 8PP-30-10 | 3750 | 538 | 2980 | ||||

| 9PP-12-4 | 790 | 133 | 510x90 | 1160 | |||

| 9PP-14-5 | 980 | 163 | 1420 | ||||

| 9PP-17-6 | 1050 | 193 | 2680 | ||||

| 10PP-23-10 | 3260 | 564 | 510x190 | 2330 | |||

| 10PP-30-13 | 4180 | 720 | 2980 | ||||

- This is a structure used in the construction of buildings as a design for openings - window, door. The jumper performs a supporting function, eases the load on the supporting structures and allows to achieve even greater strength of brick or masonry.

Reinforced concrete lintels are made of heavy stressed concrete, and they are based on a metal frame made of welded reinforcement. The relatively small dimensions of the jumpers allow them to be mounted manually, without the use of equipment.

Data reinforced concrete structures Available in several variations:

Reinforced concrete lintels according to the 1.038.1-1 series

GOST 948-84 reinforced concrete lintels for buildings with brick walls

- PB - these are slabs with a width of 250 mm;

- PP is characteristic for plate (planar) lintels with a width of 250 mm;

- PG - beam lintels, have a quarter for supporting and adjoining adjacent floor slabs;

- PF - these are jumpers for facades, used to close openings that protrude beyond the main masonry.

PB jumpers

|

product name |

Sizes, cm |

Weight kg |

price, rub. |

||

|

Length |

Width |

Height |

|||

| 1PB10-1 | |||||

| 1PB13-1 | |||||

| 1PB16-1 | |||||

| 2PB10-1P | |||||

| 2PB13-1P | |||||

| 2PB16-2P | |||||

| 2PB17-2P | |||||

| 2PB19-3P | |||||

| 2PB-22-3P | |||||

| 2PB-25-3P | |||||

| 2PB26-4P | |||||

| 2PB-27-3P | |||||

| 2PB27-8P | |||||

| 2PB29-4P | |||||

| 2PB30-4P | |||||

| 2PB-36-4P | |||||

| 3PB13-37P | |||||

| 3PB16-37P | |||||

| 3PB18-37P | |||||

| 3PB-18-8P | |||||

| 3PB19-37P | |||||

| 3PB21-8P | |||||

| 3PB25-8P | |||||

| 3PB27-8P | |||||

| 3PB-30-8P | |||||

| 3PB34-4P | |||||

| 3PB-36-4P | |||||

| 3PB-39-8P | |||||

| 4PB-44-8P | |||||

| 4PB-48-8P | |||||

| 5PB-18-27P | |||||

| 5PB-18-37P | |||||

| 5PB-21-27P | |||||

| 5PB-25-27P | |||||

| 5PB-25-37P | |||||

| 5PB-27-27P | |||||

| 5PB-27-37P | |||||

| 5PB-30-27P | |||||

| 5PB-30-37P | |||||

| 5PB-31-27P | |||||

| 5PB-34-20P | |||||

| 5PB-36-20P | |||||

| 8PB10-1 | |||||

| 8PB13-1 | |||||

| 8PB-16-2 | |||||

| 8PB17-2 | |||||

| 8PB-19-3 | |||||

| 9PB-13-37P | |||||

| 9PB-16-37P | |||||

| 9PB-18-8P | |||||

| 9PB-19-37P | |||||

| 9PB-21-8P | |||||

| 9PB-22-8P | |||||

| 9PB-25-8P | |||||

| 9PB-26-4P | |||||

| 9PB-27-8P | |||||

| 9PB-29-4P | |||||

| 9PB-30-4P | |||||

PP jumpers

|

product name |

Sizes, cm |

Weight kg |

price, rub. |

||

|

The company sells and delivers various types of concrete products, including reinforced concrete lintels. Like other reinforced concrete structures proposed by our company, jumpers are made of standard concrete, however, in this case it must be heavy, using metal frames. Reinforced concrete lintels are used for window and doorways of buildings made of various materials. The main types of lintels include reinforced concrete lintels and standard, slab and squared. They differ in width, strength in relation to different loads. So, reinforced jumpers are able to withstand the greatest pressure. Reinforced concrete lintels have a lower price, while they withstand smaller loads due to the smaller width: from 120 to 250 mm. Separately, it is worth saying that there are reinforced concrete load-bearing bridges, they are used in load-bearing walls in order to close openings, non-load-bearing bridges are installed in partitions. All jumpers have a rectangular shape, which is most convenient when placing them. At the same time, it is worth considering the features and dimensions of the future structure. When selecting, you should first clarify all the nuances, we, in turn, guarantee assistance and advice in the selection of the necessary elements, materials. In addition, all information about the assortment is presented in the form of tables in which information on the size, weight and price of the corresponding item is placed. The Entente company offers to purchase reinforced concrete lintels in Moscow, as well as cooperation with all cities Russian Federation. The advantages that we offer include not only delivery to any necessary point in the federation, but a high level of service. All products meet the requirements of GOST, due to which strength and reliability of a high level are ensured. We quickly respond and carry out the order clearly on time, to large and small customers. Favorable prices and flexible systems of discounts and promotions are another reason for a profitable cooperation with our company. | |||||