Determination of the strength of concrete structures. Strength testing of concrete by destructive and non-destructive methods. I. Testing of concrete, mortar and ceramic products

The properties of concrete and the correctness of the selected components are difficult to determine, knowing only the parameters and proportions of the individual fillers. To test the composition, concrete is tested in various ways.

Defined qualities

The quality control of concrete work has many different parameters, respectively, there is a list of different methods and methods for testing the solution.

Concrete examination cost

The air content measures the total air content in the sample of fresh concrete, but does not indicate what the final air content will be in place, since a certain amount of air is lost during transportation, consolidation, placement and decoration. The weight of the block measures the mass of the known volume of fresh concrete. Pouring cylinders from fresh concrete and measuring the force required to break concrete cylinders at forbidden intervals, as they harden, experience compressive strength.

If the strength tests do not meet these criteria, steps must be taken to increase the average value. However, instead of measuring vertical displacement, the average spread of the resulting concrete patty is measured horizontally. This number is written as a recession stream.

Types of Parameters

Analyze the following parameters of the non-solidified solution:

- consistency (formation time, properties for filling out the form, compaction index);

- porosity;

- density;

- quality and proportion of ingredients.

For quality control of hardened concrete, the following are important:

- reaction to the load during compression, bending, tension (presses, etc. are used for verification);

- abrasion;

- density;

- bulk mass;

- porosity;

- water absorption and water resistance;

- frost resistance;

- creep;

- shrinkage of the solution.

Why do you need quality control. Samples and Samples

To check the quality of concrete, make concrete samples and samples in the form of cubes, cylinders, beams. Tests are needed when designing a solution for specific application conditions, assessing its quality.

Additional information about the mixture can be obtained by measuring the time it takes for the cap to reach 500 mm. The column is filled with concrete and is allowed to sit for a while after placement. Then the column is divided into three or four parts. Each section is removed individually, and concrete from this section is washed with sieve No. 4, and the weighed unit is weighed. A non-segregation mixture will have a consistent cumulative mass distribution in each section. The segregation mixture will have higher aggregate concentrations in the lower sections.

Samples should be created and hardened in conditions as close as possible to the working medium of concrete. They must be of the highest quality, smooth, and compacted. Deviation in the evenness of their surface by 1 mm gives a significant distortion of the result.

The following table shows some of the latest or commonly used methods. Measurement is a cylindrical container made of steel or other suitable material. Q: Why is it important to test concrete? Critical physical parameters must be measured to quantify performance and strength, ensuring our safety and the safety of our environment. Question: Why does a particular cube weigh before compression test? This is a way to get closer to whether concrete is being used correctly or not.

Accurate results can now be calculated using a specific compression test machine that will give the force that the block can hold. If the value does not match the set value, then the concrete mixture is incorrect, and the compression test is useless, since the concrete used cannot be used in building structures.

- The volume of the required form is 300 g of cement, and 30 weight is added to it.

- Or 90 g of water.

- These ingredients are thoroughly mixed.

- The time interval must be between 3 ¾ to 4 ¼ minutes.

Concrete quality control is carried out before the start of construction work, before taking the mortar from the manufacturer, as well as during product testing during production.

Manufacturers are determined with the necessary parameters uncured solution (consistency, delamination, laying and tamping properties), hardened masses (compressive strength, etc.) and compare them with the test results of the samples. The characteristics of the samples must correspond to the designed parameters (a deviation of 3% is allowed).

If penetration is between 5 mm and 7 mm from the base of the mold, the added water is correct. Q: Can jackhammers reliably measure compressive strength? Although jackhammers can be used to assess the strength of concrete, rebound numbers should be compared with the compressive strength of molded samples or cores taken from the structure. Why do we need specific testing? Concrete testing, you need to know if a particular concrete meets the requirements technical specifications or not.

Test procedure and steps

Testing is a party to the quality control system. Inspection is simply a subsystem of the quality plan. The owner can use it to evaluate the future acceptance of work or contractors and material manufacturers for quality control purposes. It includes visual observations, measurements and field and laboratory tests of activities, components and materials according to the specified requirements, along with the recording and evaluation of a large amount of data.

Hardening test

For such methods, already frozen samples are taken with a minimum exposure time of 28 days. If you need to know special qualities, the period may vary.

Strength tests can be divided into two types:

- mechanical, with the destruction of concrete;

- mechanical non-destructive. They give the opportunity to repeat the manipulation on the same sample in order to study the changes in the properties of the material over time.

Many of the methods are laboratory using test presses, etc. Some can be done with your own hands, having the appropriate devices.

What is the significance of verification and testing in construction? Requirements for verification and testing vary depending on the specific area and construction needs and must be adapted to each project. The content of the inspection plan depends on the type and complexity of the project, the informed functions, the desired level of quality, the requirements for the building code and the responsibilities of the inspection organization performing the work.

Inspection activities generally fall into the following categories: owner inspection, quality control inspection, contractor, and third party compliance inspection. What are the field tests for fort concrete? The most common test is the "Competition for decline", designed for workability of concrete. All tests should not be performed for each batch of crying.

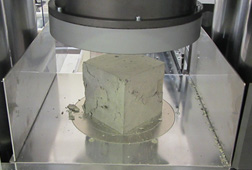

The compressive strength test determines the brand of the mixture. The designed characteristics of the solution depend on its strength and mainly on the withstanding of compressive loads in the structure.

In most cases, several types of samples are used for this:

- cubes;

- cylinders;

- prisms.

Concrete is poured into steel or cast-iron cubic, cylindrical, prismatic forms. For cubes, for example, a size of 15 * 15 * 15 cm is used. The solution should fill the container well, the mixture is thoroughly compacted with a board or a vibrating table, electric, pneumatic hammers are used.

The number of tests will be indicated depending on the intensity. What is the usefulness of a concrete rolling test? The compression test of fresh concrete indicates the following. If the amount of water added to the mixture is accurate and the surface mixture of fine aggregates is constant, then it will indicate changes in graduation or changes in the dosage of the element or units. If the consistency of the mix for the particular workability is most adequate, due to the inadequate construction of the concrete mixes and the dosing, the concrete core will be destroyed or sheared.

Standard samples are checked on a test press for 28 days, additional tests are carried out after 3 and 7 days. After pouring, the mold is left for a day at a humidity of at least 90%, and a temperature of 14–19 ° С. The sample is placed in a press, which produces a pressure of about 140 kgf / m2 on cubes. The result is displayed on the instrument panel. This method gives an indicator with an accuracy of 3.5 kgf / cm2. The load for all samples is applied perpendicular to the molding plane.

In general, the decline test gives an idea of \u200b\u200bthe consistency of the concrete lot with concrete. The decay test method depends on the fall of concrete. For very legitimate recessions, the compaction factor method, the low-frequency mid-sections, the precipitation core and the high-speed flow method.

All these methods are applicable to concrete without impurities. What are the three types of recessions? What are the acceptability limits for adoption? How do you rate the “cement content” in fresh concrete in fourth concrete? The National Council for Concrete and Building Materials has developed a simple field inspection based on the current content in quay concrete. The apparatus contains a wooden box with a 2 L plastic cup in the center, surrounded by non-conductive materials. It is equipped with a lid and gaskets for installing thermometers and mixers.

Quality control during bending and stretching

The concrete holding strength of tensile loads indicates the susceptibility of the mortar to cracking. It is important for reinforced concrete to ensure structural continuity and prevent corrosion of reinforcement.

It is difficult to create a direct tensile force. Therefore, the bending of an unreinforced straight bar is used with a test press. Important here is an indicator of tensile stress in the lower fibers of the test beam - this is the ultimate strength in bending. Bending rather than direct tension gives a more accurate value.

Add 800 ml of water and allow to balance to room temperature, and the initial temperature is recorded after mixing the concrete well. Due to the exothermic reaction, the temperature of the concrete rises to the maximum extent and tends to drop. The temperature of the beak to recedes, gives the pace.

The cement content of 1 kg of fresh concrete can be calculated using the formula. Cement Content in Grams Personal error in this method can be minimized to a greater extent by holding a Reneval mixer with known amounts of cement and a known degree of cult. How do you define “concrete setting time”? How do you sample concrete?

The value of the flexural strength depends on the parameters of the beam and the load conditions. There are two load systems on the press: central (in the middle of the span) and symmetrical at two points, creating a stable bending moment between two points. The latter method is interesting in that it can be used to determine the weak point of the beam - cracks form exactly where the solution is weaker, optionally in one place as in the first case.

Benefits of contacting us

What is the minimum frequency to be adopted? What do you understand by the acceptance criteria for a particular? What are the requirements for compliance with compressibility requirements for different grades of concrete? The compressive strength of a concrete cube gives an idea of \u200b\u200ball the characteristics of concrete. From this single test, one can judge whether concreting is performed correctly or not.

The compressive strength of concrete depends on many factors, such as water-cement ratio, cement strength, quality of concrete material, quality control in concrete production, etc. The compressive strength test is carried out either on a cube or on a cylinder. Various standard codes recommend a specific cylinder or concrete cube as the standard for testing.

Method of plastic deformation, elastic rebound and shock impulse

With the method of plastic deformation, the parameters of the imprint remaining on the solution are measured upon impact with a special test hammer (Kashkirova hammer) or after the fall of a steel ball.

The basis of the elastic rebound is the measurement of the value of the rebound of the test device when it hits concrete - this is the number of recoil, it is shown by the arrow on the scale of the plunger or percussion device. For this, a Schmidt sclerometer and its modifications are used.

Procedure: Compressive Strength Test of Concrete Cubes

This concrete is poured into the mold and repelled properly so as not to have any voids. After 24 hours, these forms are removed and test samples are introduced into water for curing. The top surface of these samples should be even and smooth. This is done by applying cement paste and smooth melting over the entire area of \u200b\u200bthe sample.

The following is the test procedure for compressive strength of concrete cubes

These samples are tested with a compression test machine after 7 days of curing or 28 days of curing. The fracture load divided by the area of \u200b\u200bthe specimen gives the compressive strength of concrete.

Concrete Cube Testing Machine

Preparation of concrete cube samples. The ratio and material for the manufacture of these samples are samples of the same concrete used in the field.

The shock pulse method records the impact energy at the moment the displacer interacts with the concrete surface. For this, various modifications of sclerometers are used. They can be used under normal conditions.

Ultrasound

First of all, he checks, since the passage of an ultrasonic wave depends on this indicator. Knowing the density, the strength of the solution can also be assumed, although these two indicators do not necessarily depend on each other. An ultrasound device is used for this method.

Mixing concrete for cube dough

Mix concrete by hand or in a laboratory mixer. Mix cement and fine aggregate on a waterproof absorbent platform until the mixture is thoroughly mixed and uniform in color. Add a large aggregate and mix it with cement and fine aggregate until the large aggregate is evenly distributed throughout the batch.

Add water and mix it until the concrete is homogeneous and has the desired consistency. Clean the mounds and apply oil. Seal each layer with at least 35 strokes per layer using ramming. Level the top surface and grease it with a spatula.

This is the most accurate method. The disadvantage is the high complexity, the inability to use on densely reinforced segments, partial damage to the sample. It is made by special devices - a kind of vice and presses with screw-in screws, they are equipped with an electronic display.

The test samples are stored in moist air for 24 hours, and after this period, the samples are marked and removed from the molds and left immersed in clear fresh water until they are removed before the test. Remove the sample from the water after the indicated curing time and wipe off excess water from the surface.

Clean the bearing surface of the test machine. Place the sample in the machine so that the load is applied to the opposite sides of the cubic molding. Center alignment of the sample on the base plate of the machine. Gently rotate the movable part so that it touches the top surface of the sample.

The bottom line is to measure the force exerted by the press to shear a part of concrete or to break it locally when tearing out a previously screwed-in anchor device.

Cement control

Silicate compounds in Portland cement are more readily destroyed than silica in the aggregate; they dissolve in dilute hydrochloric acid. So are calcium compounds in cement and aggregates (with the exception of limestone components). Given this, the soluble calcium oxide method is used.

Record the maximum load and pay attention to any unusual functions in the form of a failure. A minimum of three samples must be tested at each selected age. If the strength of any sample varies by more than 15 percent of the average strength, the results of such a sample should be rejected. The average of the three samples gives the compressive strength of concrete. Strength requirements for concrete.

Calculations for concrete cubic tests for compressive strength

Sample area \u003d 225 cm 2. Characteristic compressive strength 7 days \u003d. A similar calculation should be performed for compressive strength of 28 days.

The compressive strength of concrete in different eras

The strength of concrete increases with age. The table shows the strength of concrete at different ages compared with strength 28 days after casting.A concrete sample is crushed under a press, the resulting dust is dried and processed with a small amount of hydrochloric acid, while the silica compounds contained in the cement are released. The remaining filtrate consists of calcium oxide from aggregate and cement. Further, their proportions are calculated by chemical methods.

Uncured mortar control methods

They are used during preparation or after mixing the solution.

An analysis of the measurement of the cone precipitation determines the heterogeneity and consistency of the mixture of nominal composition. This is important for the workability of the solution, although the precipitate itself is not always associated with it.

The cone precipitation parameters may mean, for example, that the amount of moisture in the aggregate has increased, and also that its particle size distribution or insufficient sand has changed.

Seal test

The method is carried out by an apparatus consisting of two containers with funnels. The solution is carefully poured into one without tamping it, the valve opens below, the mixture flows into another, smaller container, from it it enters a cylindrical shape. Mathematically, the density of the mixture in the cylinder is calculated. In this way, the compaction coefficient is recognized.

Concrete is poured into a truncated test cone, which is placed on a special table that can drop a few centimeters with shaking.

Then the form is removed, the table is pushed down with jerks - spreads over it. The average diameter of the spreading solution is measured.

There are three methods for measuring the presence of air in a solution. The first method is weighted. It is very simple: the weight of the mixture is measured before and after shaking and mixing in a container (pycnometer). Very accurate weighing instruments are used here.

The second is the pressure method, it is not used for mixtures with porous aggregates. Special air meters are used here, they show the percentage of air. The decrease in volume of the sample is measured at a known pressure, which is created by a test press or pump and indicated by a pressure gauge. The pressure rises - the volume of air in the solution increases, this lowers the water level above the sample. In hardened material, the air content is measured on polished sections under a microscope with the calculation of chords or a high-pressure air meter.

Quality control "by eye"

Signs of good concrete:

- normal fat content and viscosity;

- uniformity;

- - dirty gray-greenish or pure gray. The bluer (bluer) the mixed mixture, the better. Yellowness is a sign of poor quality, the presence of clay impurities, slag additives. The main sign of quality is the lack of yellowness;

- there should be cement milk on the surface of the concrete, not dirty water. The thicker the milk, the higher the grade of the mixture;

- there should be no filler grains not coated with the solution;

- the larger the gravel, the higher the grade, but the gravel should not be too large;

- a good solid solution resembles moist plastic soil;

- an ordinary hammer should bounce off the concrete, leaving very small dents or leaving no traces at all, but not chipping away the frozen concrete with moderate force.

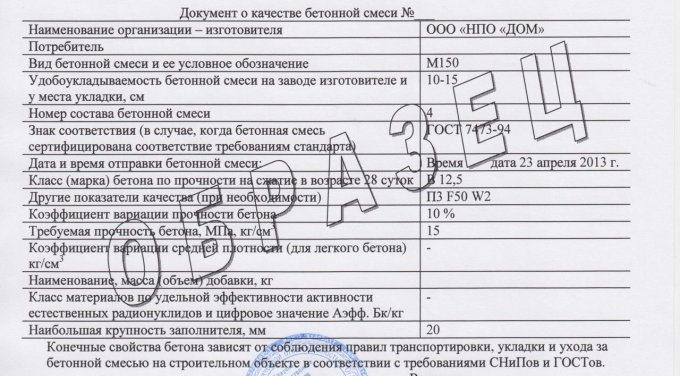

Documents, quality certificate

According to the test results, a quality certificate for tested concrete and a certificate are issued. They are created on the basis of state standards, their completed forms are issued for each batch of goods. These documents are approved by the company. The passport is issued by the concrete manufacturer based on tests by certified chemical and technical laboratories. This is the main document on the quality of concrete mix.

The issuance of a passport may be delayed, since it needs to provide the results of a number of tests in the laboratory. Tests for:

- compressive strength;

- mobility;

- water tightness;

- density;

- tempering humidity;

- frost resistance.

If the composition will be used in special conditions, then conduct other tests. Documents for acceptance tests of the concrete mix, protocols for determining standardized indicators, and test certificates are also needed to obtain a passport. The completed passport form must be sealed with the seal of the company.

Testing the concrete for strength, the presence of unacceptable mineral impurities according to GOST and other parameters is conveniently ordered in the Standard laboratory. Our customers are guaranteed the professional provision of expert services in Moscow with strict observance of the GOST provisions when conducting research. We have many years of experience in laboratory testing of concrete and high-precision modern testing equipment. This allows you to get the most informative, reliable and objective data. Research can be carried out both at a construction site and in a concrete testing laboratory. We test concrete samples in a complex or do tests for individual parameters.

Service Prices

| № p / p |

Measured Product Test Indicator | The scope of work included in the testing of products | Normative document | Cost, rub., Incl. VAT 18% |

| 1 | Compressive strength by the test method of control samples of one series (3 samples 100x100) | - Preparation of equipment - Testing samples - Processing of results - Registration of protocols |

GOST 10180-2012 GOST 10181-2000 GOST 18105-2010 |

500 |

| 2 | Determination of concrete strength in products and structures by elastic rebound method (1 test) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 18105-2010 GOST 22690-2015 |

400 |

| 3 | Construction of the calibration dependence "strength of the samples - elastic rebound (ultrasound)" with the manufacture of samples (1 dependence) | - Preparation for the test - Production of samples - Testing - Processing of results |

GOST 22690-2015 | 10 500 |

| 4 | Support for monolithic work at the facility (control of concrete strength at an intermediate and design age) (1m3) | - Drawing up and approval of the test program - Building a calibration dependence - Preparation for the test - Testing - Processing of results - Registration of protocols |

GOST 22690-2015 GOST 18105-2010 GOST 10180-90 GOST 10180-2012 |

from 50 |

| 5 | Density determination by weighing of tested control cubes of concrete of one series (6 samples) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 12730.1-78 | 500 |

| 6 | Determination of concrete strength in products and structures by the ultrasonic method (1 test) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 17624-2012 | 500 |

| 7 | Ultrasonic cracking of concrete structures (1 test) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

SP 13-102-2003 | 1 000 |

| 8 | Testing of concrete structures by peeling with chipping (1 test) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 22690-2015 | 1 000 |

| 9 | Construction of the calibration relationship "separation with cleavage - elastic rebound" (without manufacturing samples) (1 dependence) | - Preparation for the test - Testing - Processing of results - Building a calibration dependence |

GOST 22690-2015 | 6 000 |

| 10 | Construction of the calibration relationship "separation with cleavage - ultrasound" (without manufacturing samples) (1 dependence) | - Preparation for the test - Testing - Processing of results - Building a calibration dependence |

GOST 22690-2015 | 7 000 |

| 11 | Water absorption by the test method of control samples of one series (3 samples) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 12730.3-78 | 700 |

| 12 | Determination of humidity of concrete (1 test) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 12730.2-78 | 500 |

| Additional services: | ||||

| 13 | Storage of samples in a chamber of normal hardening (1 sample / day) | - Storage of samples in a normal hardening chamber | GOST 10180-2012 | 20 |

| 14 | Determination of the location and diameter of the reinforcement in the structure (1 m2) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 22904-93 | 500 |

| 15 | Determination of the thickness of the protective layer (1 m2) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 22904-93 | 500 |

| 16 | Drilling concrete core, sawing to standard sizes, grinding end surfaces (1 core) | - Preparation of equipment - core drilling - Sawing up to standard sizes - Registration of the act of sampling |

GOST 28570-90 (ST SEV 3978-83) |

2 500 |

| 17 | Strength test of concrete cores (1 test) | - Preparation of equipment - Testing - Processing of results - Registration of protocols |

GOST 28570-90 (ST SEV 3978-83) |

500 |

In the table of the cost of testing concrete, the price is for the study of samples in laboratory conditions. If necessary, the departure of specialists at the customer’s site, this service is paid separately.

Targets and goals

The laboratory conducts tests of concrete for strength in order to form the optimal composition of concrete with high operational parameters. The main characteristics of the mixture are determined in any construction process with the active use of concrete components. The main objective of the study is to check the performance of the frozen solution. This is necessary to identify the degree of strength and level of wear of finished products. Testing control concrete samples provides the necessary operational safety of the structure.

Expert procedures are performed:

- in case of suspicion of the presence of internal defects in the concrete structure;

- before work on raising the floor in the basement;

- when flooding the basement;

- when external damage and cracks in the concrete structure;

- if necessary, assess the state of the concrete structure before purchasing the object;

- before starting work on major redevelopment and reconstruction of the building;

- when checking the quality of the material and construction work for compliance with project documents.

Timely quality testing will prevent possible collapse of the building or parts of the structure. Making a decision to carry out repairs in the future will help reduce the cost of repairing serious damage.

Testing

Both manufacturers and consumers of concrete are interested in determining its strength. To do this, laboratories test concrete cubes or drilled cylinders. Samples are taken from the batch of the mixture at the intermediate and design age (28 days). In cubes, the dimensions of the ribs are 100, 150, 200 or 300 mm. The diameter of the cylinders is 100, 150, 200, 300 mm, and the height is two diameters.

Sample making

For the manufacture of samples, special metal forms are used with cells having an inner rib of 100 mm in size. In the manufacture of samples, standardized sizes are provided. The 2FK-100 type shape is convenient for providing a normalized tolerance in the perpendicularity of adjacent faces. It is also rational in the manufacture of samples due to the manufacturability and speed of assembly and disassembly and low weight.

In the manufacture of:

- A sample of the mixture is taken from the middle of the batch (when using a concrete pump - in 3 doses in 10 minutes with stirring before laying).

- The mixture is laid and compacted no later than 20 minutes after selection and not higher than 100 mm of the layer height. With a cone draft of more than 10 cm, laying is done by bayonet. With a smaller OK, vibration is additionally applied.

- Prepare a series of samples for testing (3-4 pieces in a series) under the same conditions. The permissible deviations of the average density at the time of testing the concrete cubes do not exceed 50 kg / m3.

- Defective samples are taken. Before testing concrete cubes for strength, remove those from the series in which there are foreign inclusions, shells, chipped ribs, cracks, areas of weak compaction and delamination (except for large-porous concrete).

- Testing of concrete samples for compression or strength is carried out in the number of batches of material at the design age equal to 28 days, regulated by paragraph 5.2. GOST 18105.

- Incoming control requires special storage conditions for samples (air humidity 95%, temperature - +20 degrees). Permissible deviations of humidity - 5 percent, temperature - 3 degrees.

Tests are carried out using different, optimal for determining a specific parameter. Among the studies is the use of ultrasonic sounding, elastic rebound, shock impulse, separation with chipping. Sometimes combined testing methods are used.

Based on the results of the tests, an official expert opinion is drawn up. The document contains:

Based on the results of the tests, an official expert opinion is drawn up. The document contains:

- research results;

- evaluation of concrete mix parameters;

- recommendations for the operation of the structure or the use of concrete.

The document confirms the suitability or unsuitability of concrete and the possibility of further operation of the structure. The recommendations are aimed at improving the quality of the concrete mixture, changing its composition, eliminating structural defects or stopping the operation of the facility.

Concrete Testing Laboratory

Laboratory "Standard" accepts orders of private and legal entities for testing concrete cores and cubes. At the request of the client, comprehensive tests for compliance with standards or verification of specific parameters will be performed. Namely: frost resistance, water resistance, coefficient of variation of strength, the presence of unacceptable mineral impurities. Customers are guaranteed cheap and high-quality expert work with the issuance of relevant documentation.

Advantages of contacting us:

- Customer convenience. Service in the laboratory or on site.

- Wide range of services. Let's test any parameters. We check the strength of concrete in any design.

- Data validity. We work on modern high-precision equipment, we guarantee the objectivity of expertise.

- Low prices. We provide inexpensive expert services.

- High quality work. Competent experts, if necessary, use a specially thought-out combination of various research methods. This allows a more accurate determination of the characteristics of the concrete structure.

- Issuance of official opinionhaving legal force.