Asphalt or paving stones are cheaper. What is better to choose for a summer residence: asphalt or paving slabs

Perhaps the most important drawback of asphalt, experts in this area believe that it is easy to melt in hot weather. Given that the average summer temperature rises all the time, and the melting process begins after 25 ° C, you should seriously think about such a coating in the courtyard of your own house. The main argument is that to call this process melting will still not be entirely true. Asphalt is simply very hot and will be easily deformable. This is not at all like the melting of ice or the same metal, when a solid body in a certain period of time passes into a liquid state, begins to spread over the entire accessible surface. The asphalt pavement does not disappear and does not deteriorate, it simply deforms easily.

To avoid undesirable consequences, the city authorities are able to limit the movement of freight transport in the daytime.

And what about those people who decided to use asphalt pavement in their yard?

Asphalt path in front of the garage

1. There is no need to lay asphalt in the place where there will be a very high load on it (for example, before entering the garage). Or in that place in the courtyard where you are usually accustomed to leave your car for a long time. To completely protect the asphalt from possible overheating and deformation, you can make a living flooring of plants over it. He will be able to protect the coating from exposure to direct sunlight. Asphalt can simply be watered from a hose, lowering its temperature.

2. Do not be afraid of melting asphalt. Melting is not the greatest danger. The thing is that with a significant increase in the temperature of asphalt (even before it starts to deform), the fumes of resins and oil products that make up this coating gradually begin to flow. Breathing such fumes is extremely harmful to the body of adults. What can I say about young children!

3. The cheaper the asphalt, the more will be in its composition truly harmful to your health components. For example, under the asphalt, any soil quickly dies, which makes its further use according to its intended purpose impossible.

If you decide to use asphalt to cover the tracks located between the beds, then immediately keep in mind: they cannot be re-planned. Unlike the same tile, between which there are cracks, the asphalt is laid in a continuous layer, and the soil does not breathe.

The big disadvantage of asphalt pavement is that it is simply impossible to repair. If you put a patch of patches on the damaged area, such repairs will spoil the entire appearance of your yard.

Moreover, it is almost impossible to repair asphalt in other ways. If everything is left as is, then its destruction of the coating will be accelerated several times.

The main advantage of asphalt, which often becomes the key for choosing it in its favor, is ease of installation and its cheapness. Although this concept is quite relative.

The way in which ninety percent of all our citizens lay asphalt in their yard does not fit into the heads of Europeans.

A typical situation. If you tell the Europeans that you agreed with the road crew for a nominal fee, and these guys repaired the road near your home, nobody will believe you. We have such practice all the time. Extra time, as well as materials from such a team will always be found. Much depends only on your ability to negotiate and how much money you will pay them. If you pay a little, the quality of the work performed will be appropriate, and you will have to repair the asphalt very soon. In order not to be in a similar situation (in which the avaricious pays twice), it will be best to pay for the quality laying of asphalt to professional workers. This method will cost you less than the same paving slabs.

Asphalt paving

If you still decide to put the asphalt on your own, then you will come in handy:

- tachanka

- crushed stone

- shovels

- manual skating rink.

It would be best to do such work with a team of three to four people. Asphalt is usually laid on a pillow consisting of crushed stone or fine granite. Then all the prepared asphalt is poured onto the pillow, leveling is carried out with rolling by a mechanical or manual roller.

In the next article, we will reveal the topic, but for now we will focus on the advantages of paving slabs.

If we are on the same square, with the same weather conditions put the pavement and asphalt pavement, then it will begin to collapse much faster than the mentioned paving slabs. The “sidewalk” has a much longer service life.

If we decide to repair the existing asphalt pavement, then we can immediately forget about the decorative component, and the latches hold significantly worse than the whole new asphalt layer.

Red carpet from paving slabs

The tile in this regard is wonderful: it can be easily changed in parts. The decor of the courtyard, the quality of the coating will be preserved. Therefore, we can safely conclude that paving slabs are significantly more expensive to install, but then much cheaper to maintain. After some time, you can save money if you are not greedy at the very beginning.

Another extremely important point is the need to conduct land work on a site with a coating. For example, you need to repair the pipe or conduct additional communications. In the variant with asphalt, the coating will be completely destroyed, and after the completion of work it will have to be restored again. If you nevertheless used paving slabs, then it can be easily disassembled, and then reassembled after all earthwork has been completed.

I must also say a few words about the fact that the tile in its composition much less harmfulthan the same asphalt. In its production, resins and petroleum products are not used. In addition, when the temperature rises, it expands slightly, but perfectly resists deformation and does not emit harmful vapors.

It is due to the fact that in the seams located between the tiles, compacted sand is densely packed, water does not collect on its surface. Seams that are clogged with sand perform 3 important functions. Firstly, they absorb the load on the tiles and do not damage each other. Secondly, through these seams, water goes into the soil and does not accumulate on the surface. Thirdly, air also passes through the seams, the soil under the tile continues to breathe and retains its unique natural properties. You can easily re-plan your own flower beds or beds at your own discretion at any time. Do not forget about it!

The popularity of paving slabs is growing steadily, which is not surprising, because it is difficult to overestimate its advantages over other road surfaces. Perhaps there is no material that would have so many different shapes and colors that turn an ordinary sidewalk into a work of art.

In addition, it is also important that the laying of tiles is quite simple, and its service life is more than 20 years. A large number of owners of private houses and cottages prefer this material, often being guided by the fact that you can lay paving slabs on the asphalt, if the latter is in very poor condition.

Comparison of finishing materials

More recently, asphalt had the primacy in the design of personal plots, but the hobby for them is gradually dying away. Paving stone, which possesses qualities unattainable for its competitor, replaces it decisively. If you study what is better - asphalt or paving slabs, then the results will be as follows:

- The economic component. The cost of paving stones is slightly lower, although not by much, because it can be put manually, which is cheaper than using special equipment.

- Moisture resistance. Paving slabs, unlike asphalt, do not retain water, and gaps help to pass it into the ground.

- Environmental friendliness. With strong heating, the asphalt pavement emits harmful fumes, while paving stones made from environmental materials have no such drawbacks. Moreover, it does not become an obstacle to the circulation of moisture and air exchange in the soil, which positively affects the environment.

- Durability. Asphalt is completely unable to compete with tiles whose service life is more than 20 years, due to its ability to pass water, while remaining intact.

- Repairs. If repair is necessary, the asphalt pavement is acquired with patches that differ in color, and its dismantling does not differ in simplicity. The tile, on the contrary, is quite simple to disassemble and subsequently put in place.

- Appearance. If the asphalt, in addition to strict gray shades, boasts nothing more, then the variety of colors, sizes and shapes of the tiles allows you to lay out absolutely incredible patterns for every taste.

When choosing asphalt or paving slabs, in spite of such obvious advantages of the latter, you should carefully examine it when buying, since cheap options do not have sufficient frost resistance and wear resistance, which means that there will soon be a need for replacement and regular financial expenses.

Stackability

After making the final decision on the transformation of the infield, you should decide whether to lay the tile on old asphalt. Some experts recommend dismantling the previous coating, although it takes a lot of effort and time, since water does not pass through it, but collects, destroying all layers over time, which leads to subsidence of the material. Despite this, there are also many supporters of the fact that paving slabs can be laid on asphalt.

Advice! It is important to determine how much pressure will be placed on the future. If this is a pedestrian section, laying paving stones will not bring any negative consequences, but if cars move on it, then the previous coating will still be better to remove.

DIY styling technology

Before laying the tile, you should take care of all the necessary materials and tools:

- Water.

- Cement.

- River sand.

- Rake (for leveling the embankment).

- The rule.

The most commonly used leveling of the old surface is by laying on it a layer of sand of about 10 cm, which helps to eliminate flaws and provide amortization for future loads. Further, it is evenly distributed over the entire area, leveled with a rule and a rake, while for better compaction it should be watered with water from a watering can. The next layer will be a mixture of cement and sand, which is sold ready-made in construction stores, but it can also be prepared with your own hands, which will help to save additional money. To do this, carefully mix cement with sand at a rate of 1: 3, then lay a layer with a thickness not exceeding 5 cm, and then pour it with water.

Laying paving slabs on asphalt is done in one of two ways. The first involves tamping the tiles laid in their place with a rubber or wooden hammer, constantly monitoring the level and preventing the appearance of dips or ledges. In the second embodiment, all the tiles are laid out first, after which a rubber sheet is installed under the rammer. Next, each tile is fixed in turn, resulting in an ideal single-level surface.

Concrete screed pouring

If there is too rough asphalt, the sand layer will not make it possible to effectively level the surface for further laying of tiles, which necessitates installation concrete screed thickness of 10 cm. To do this, you will need:

- Sand.

- Cement.

- Water.

- Rubble.

- Right andlo.

- Long flat boards.

First of all, a mixture of sand, gravel and cement is prepared, observing a proportion of 3: 2: 1. Before you start directly pouring, you will need to install a formwork of boards around the perimeter of the site, which will prevent the screed from spreading around. After making the screed, the boards are removed after 3 days, and in order to avoid chips, its edges are covered with soil. The next step will be the laying of tiles on concrete.

Remember! It is important to understand that in the manufacture of formwork should take into account the height of the future screed and choose boards slightly exceeding it.

It is also important to drill as many holes in the asphalt with a puncher, which will help to avoid the appearance of voids under the coating. This will allow water to go into the ground without accumulating in the base layers. It will also be appropriate to study the limitation period of asphalt laying and its quality, since it is almost impossible to determine these parameters externally. In the event that it has completely fallen into disrepair, it is advisable to dismantle it, since repairs that will not take long will cost much more.

Laying paving slabs on asphalt requires compliance with all the rules and technologies, which as a result will avoid significant financial costs, as well as the need for urgent repairs. A creative and responsible approach, coupled with accurate execution, will allow you to create an incomparable in appearance coating that will last for more than a dozen years.

DIY tile laying video with comments and detailed instructions. In addition, the video contains both a description of each stage and the preparation of the required materials.

With the beginning of spring, the construction season began, which carries with it a time of active repair, improvement and construction. Specialists of reinforced concrete products of Siberia shared tips on how to maintain aesthetics and reliability of the improvement of their own suburban area.

Paving slabs. Photo: archive of LLC "Reinforced Concrete Products of Siberia".

Often, trying to tidy the house territory, many owners resort to fast and cheap means of covering garden paths and parking lots. Most often, preference is given to asphalt, however, let's see if the asphalt is really cheaper?

The company "Reinforced Concrete Products of Siberia" has been operating in the field of production of improvement elements for more than a year, and during this time they have accumulated a large amount of experience that allows us to combine high quality and affordable price. First you need to figure out what each coating consists of.

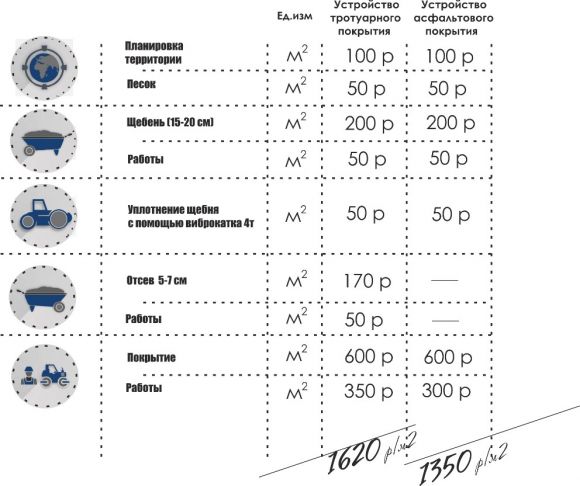

As you can see, in both cases there is a similarity: a layer of sand and gravel is laid on the prepared soil, acting as a drainage system and ensuring surface stability. However, further the asphalt is laid immediately, and the paving slabs are placed on the screenings. As a result, the height of the tiled coating is slightly higher than that of asphalt, that is, a little more materials are required.

Based on average market prices for inert materials, the cost of laying one square meter of paving slabs is higher than asphalt. The difference is only 270 rubles more expensive, but this amount carries additional qualitative characteristics, which asphalt is devoid of.

The indicated cost of the tile (see table No. 1) is the average market price per square meter of vibro-pressed paving slabs for 2016 in Barnaul, taking into account the pallet and delivery.

One layer of asphalt withstands pedestrian loads, the movement of cars and, if not systematic, the movement of small trucks is possible. For larger vehicles, at least two layers of asphalt are needed. In the case of quality work and proper operation, asphalt concrete pavement will last 2-4 years.

However, the evaporation in the hot season of bituminous resins that make up asphalt mix - one of the main disadvantages of asphalt. Plus, moisture and temperature changes violate the integrity of the coating. Most often, “patches” are put on top of us on the roads so that the coating does not deteriorate further, but the effectiveness of this method is extremely small. In this case, it is better to shift the asphalt completely, and this is an additional cost for materials and work. What is the point if in two or three years the procedure has to be repeated again?

As practice shows, paving slabs are a very practical approach to improving both a city street and a residential area. In terms of repair, it is much cheaper. It is extremely difficult to break the integrity of each individual “brick”: vibropressed tiles are inherently fake diamond. Only a violation of the general canvas is possible, but this is mainly observed only in coastal zones when the soil moves. In any case, the tile can be removed and shifted as you like: the material does not suffer from this. In addition, the vibropressed tile is convenient to use: puddles do not remain on the surface after rain, but go into the gaps between the bricks. The canvas looks aesthetically pleasing, well-groomed, and the tile is completely safe for humans and the environment as a whole: the composition of the mixture has no carcinogens.

Another advantage of tiles over asphalt is frost resistance. According to tests in the construction laboratory "Reinforced Concrete Products of Siberia" - vibropressed tiles undergo 200 freezing cycles. The porous structure will allow the tile to breathe, so moisture does not spoil the coating. A good indicator, isn't it?

For every owner who raises the issue of landscaping, sooner or later the question arises: speed or quality? The decision is influenced by many factors, but the result of work depends on this. The famous Russian proverb says: avaricious pays twice.

Are you ready to overpay several times?

The company "Reinforced concrete products of Siberia" in the upcoming construction season has prepared a pleasant bonus for its customers, saving all vibropressed products 2016 prices.

Pursuing the improvement of a country house, their owners are faced with the problem of choosing material for laying paths and driveways. And if we discard less attractive options with gravel filling or concreting, then it remains to determine what is better to choose for a summer residence: asphalt or paving slabs?

Both of these materials are now actively used in road construction and in the improvement of urban residential areas. But the analysis of their advantages should be made solely taking into account the specific conditions of the country house and the operational characteristics of the stacked coating.

Technical features of operation

Of particular importance are the aspects of laying and operating each of the materials in question:

- Asphalt and tile are laid on a specially prepared bedding. And if for the first option you need only a gravel layer, then in the second one you will also need a sand layer. Next, you need to bring and prepare the material itself. Everyone knows that the asphalt mixture is used in a preheated form, after which it is leveled with special rollers. That is, somewhere it needs to be prepared (or brought) and immediately laid. Long-term storage of such road raw materials in the country is not permissible. In addition, ordering equipment for laying asphalt is worth the cost, and the work will need to be carried out in a limited time. With paving slabs, everything is much simpler. You can deliver and store it for a long time in the country, and lay the tracks at any time convenient for you without the use of expensive equipment.

- Obvious advantage asphalt pavement is its smoothness, but it is relevant on highways that transport vehicles at high speed. For a country house, this is not critical, so you can safely use paving slabs. The joints between them are almost invisible, but they play an important role in the drainage of accumulated water.

- As a rule, the cottage is used for recreation and garden work in the hot summer. Strong heat negatively affects the condition of the asphalt. It begins to emit a specific smell and softens, which can lead to its deformation. In winter, temperature changes can cause cracks. For environmentally friendly frost-resistant paving slabs, such problems are not typical.

- Any road surface wear out over time and restoration of damaged areas is required. Asphalt repair is associated with the same problems that existed during its laying (the need for equipment, the purchase of raw materials and limited time). You can tidy up the pavement from the tile at any time using the available hand tools. She and backing material usually remain after laying the tracks and stored in the country.

Paving slabs - beautiful road material

When designing the placement of tracks, I want them to be not only as comfortable as possible, but also provide aesthetic pleasure. For these purposes, paving slabs is the best option.

Firstly, it is much easier to lay out the surface of any configuration from it. It can be both a platform in front of the house and a path to any detached object (bathhouse, garden). Winding paths look very interesting.

Secondly, the tile is much more attractive. It is made in various shapes and colors. This makes it possible to show their creative abilities by laying out a pattern or an original drawing on the sidewalk.

The choice in favor of paving slabs is obvious. Garden paths made from it are much more convenient, more environmentally friendly and more aesthetic. All these advantages are manifested if you use only quality and material with strict adherence to technology. You can buy such tiles of any configuration and order their laying in our company.

LLC Bau-prom is a diversified construction company, the main activities of which are:

- the device of industrial floors;

Polyurea waterproofing;

- thermal insulation polyurethane foam.

Industrial floors

Industrial floors are floors that withstand intense loads. Different types of industrial floors are resistant to abrasion, mechanical damage, to aggressive chemical and biological environments, can work in different temperature conditions, do not dust, satisfy strict sanitary and hygienic requirements. The device technologies for such floors were developed specifically for their use in industrial premises, warehouses, storage facilities, parking lots, repair shops, etc. In addition to their high performance characteristics, many types of industrial floors also have excellent decorative properties. Such floors are widely used in shopping and entertainment, public, administrative buildings. The following types of industrial floors are distinguished: bulk, thin-layer paint, quartz-filled, topping floors.

Beautification

Improvement is a complex of measures that make the human environment comfortable and beautiful. External landscaping means the construction of roads, sidewalks, various areas, sites, as well as landscaping, street lighting and other decorative design. Road construction as part of the improvement includes such works as: paving, laying of paving slabs, foundation, installation of curbs, laying of storm sewers, patching of asphalt concrete pavement.

Concrete works

Concrete work is a set of works on the creation of stationary concrete and reinforced concrete structures. Concrete work includes: arm frame installation, installation of various embedded parts, formwork installation, concrete mix laying, initial processing and maintenance of freshly laid concrete, formwork dismantling, subsequent processing of horizontal and vertical concrete surfaces. One of the most common types of concrete work is the installation of concrete floors.

Sprayable polyurea waterproofing

Polyurea is a synthetic polymer with high elasticity. It is this property that makes it possible to arrange highly effective waterproofing coatings from this material. The sprayed waterproofing with polyurea is performed using special high-pressure apparatuses that spray the polyurea elastomer onto the prepared surface. Polyurea spraying technology is used for waterproofing roofs, basements, foundations, pools, etc. Spraying a polyurea layer is also a way to protect the surface from the negative effects of the environment.

Sprayable thermal insulation with polyurethane foam

Polyurethane foam is a synthetic material that is a hardened polyurethane foam. Rigid polyurethane foam is used in construction as a heater. Today, sprayed thermal insulation with polyurethane foam has become one of the most common methods of insulation. Using special devices, polyurethane foam is sprayed and applied to various surfaces of the most complex geometric shapes, forming high-quality seamless insulation. The method of spraying polyurethane foam is used to insulate roofs, walls, floors of buildings, as well as tanks, vans, heating mains, etc.

Our advantages

The construction company LLC Bau-prom offers its customers:

- free consultations on the choice of coatings;

- client-centered approach;

- performance of work with high-quality materials of foreign and domestic production;

- use in construction processes modern technology and equipment;

- staff of competent executing specialists;

- own fleet of construction equipment;

- compliance with the established deadlines;

- flexibility of pricing policy;

- a guarantee for the work performed from 1 year.

Our works

Khadyzhensky Brewery LLC: installation of bulk floors in a production workshop (Khadyzhensk, Absheron district, 2013)