How to put new asphalt on the old. All about repair, construction and DIY crafts

DIY asphalt laying in the yard. Advantages of asphalting, laying, repair.

Now country houses are becoming more and more popular. People finally realized that fresh air and a spacious house are more profitable than an apartment in the city. Nevertheless, the presence of a country house also implies the willingness of the owner to spend some efforts on the improvement of the yard and the adjacent territory. Perhaps the best solution would be to pave the site. This is part of the plot in front of the house and walkways, driveways. Laying asphalt for many years will solve the problem of landscaping the yard, and make comfortable the movement of people and vehicles in the rain and slush. Next, we will focus on laying asphalt in the yard.

The benefits of asphalt

- Durability

- Reliability

- Moisture resistant

- Ease of maintenance

- Easy to install and repair

- Cheapness

- Aesthetically attractive look.

Asphalt attracts many with its low cost compared to other building materials for landscaping the yard (tiles, paving stones). Installation work is also not difficult, people who are far from the profession of a road worker can cope with it. If the asphalt is still overlaid with a border - there will be no equal to it in terms of aesthetics.

Preparation for laying asphalt in the yard

Fine-grained and sandy asphalt is suitable for laying in the yard. Instruments:

- Shovels

- Rope, ordinary twine

- Manual tamper

- Wooden mop

- Manual skating rink

Manual ramming can be made independently from a sheet of metal 20x20 cm by welding the handle on top. The mop is made of boards, nailed to each other, size 2.5x1 m. The roller should be more than 100 kg. If at the word "skating rink" someone imagined a mighty car, then I hasten to please, there are also small manual skating rinks that will help us in this matter.

Building materials:

- Asphalt crumb or asphalt

- Clay

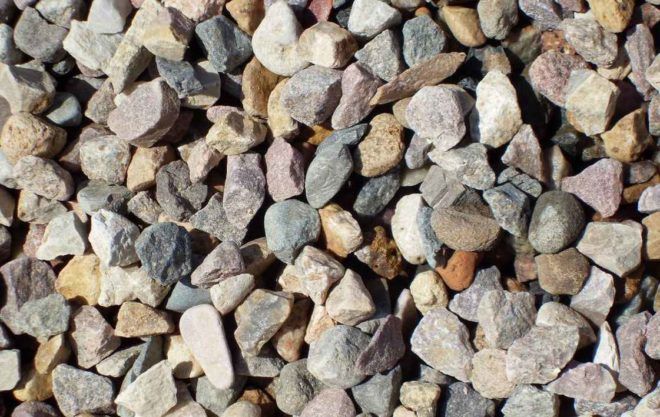

- Gravel

- Sand

- Diesel fuel

- Small borders

The cost of building asphalt paths depends on what kind of load they will withstand. For the construction of access roads for a car, asphalt laying in 2 layers is required, with a crushed stone base from 0.25-0.5 m. For the footpath, such costs are not necessary, just one layer of asphalt and 10 cm of crushed stone under the base are enough. If in the yard the load will be small, the crushed stone will also be enough at the base of 10-15 cm. In order for the asphalt to lie evenly, the base is carefully rammed.

Stages of asphalt laying

To begin with, the upper layer of earth is removed, the base is leveled with shovels. If the area is large, you can attract a small bulldozer.

- Markup. It is advisable to draw all the paths and access roads, to outline the contours.

- The next step will be filling all the sites with clay, sand and gravel. After filling, the resulting mixture should be thoroughly tamped.

- Installation of borders.

- Asphalt laying and rolling.

For the convenience of work, asphalt must first be poured into several piles. Then with a shovel we spread the asphalt, evenly distributing. Under pedestrian paths, a thickness of 5 cm, under a car 10 cm.

To level the asphalt we use a mop engine. On slopes asphalt mix align from bottom to top.

When leveling, it should be borne in mind that the asphalt cools quickly, so it is better to attract a few people for work. When a small area is leveled, one person must quickly roll it off, the remaining ones must quickly align other places. The skating rink should not stop in one place for a long time - it will get bogged down.

When rolling, transverse seams appear so that they should not be rolled across the main asphalt paving. For greater compaction of asphalt on the skating rink, you can get the most busy worker :).

Asphalt Paving Tricks

- It is best to buy ready-made asphalt if there is an asphalt plant nearby. It should be borne in mind that 1 ton of asphalt is 10 square meters. m, 5 cm thick.

- So that the asphalt does not stick to the roller and the squeegee, from time to time they need to be lubricated with diesel fuel (this is where it came in handy).

- The quality of installation depends on vibration, ramming and rolling.

- It is better to lay asphalt in the summer, if the temperature is below 10 ° С (according to the standards below 5 ° С) it cools down quickly and the laying loses its meaning.

- Asphalt needs to be laid in dry weather.

Asphalt Repair

The so-called patching, which you see every year on our roads.

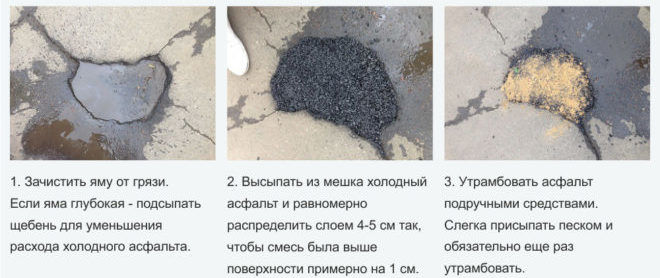

- The edges of the gaps are cut with a bayonet shovel.

- Crushed stone is poured into the hole

- The edges are filled with bitumen.

- Poured into the hole hot asphalt and tamped.

The second way: the hole is completely filled with bitumen and fresh asphalt is laid on top.

As you can see, paving the land near the house is beneficial from all sides. As they say, cheap and cheerful. Asphalt will be inexpensive, laying it is not difficult, you can cope on your own without attracting road workers (also saving the family budget), and in the end you will get a beautiful, well-maintained yard.

Laying rubber asphalt (know-how) video

If you are tired of kneading a swamp in the yard or stumbling in the potholes of old asphalt, and you decide to lay the asphalt in the yard with your own hands, you need to know the following. The main thing is that the asphalt laying was done correctly and then you will not have swamps in the yard for many years.

We need such a tool:

Hand roller with a weight of at least 100 kg. (), a mop-engine (boards, knocked down like a mop 2.5x1 m.), tamper (hand grip on top, and a bottom 20x20 cm square made of metal, for tamping with hands), shovels, lace.

We need such material:

Asphalt (consumption with a layer of 5 cm. 1 t. Per 10 sq. M.), Borders, diesel fuel.

First you need to plan and prepare the foundation, then laying and planning of asphalt, and further rolling. Now we will figure it out in order.

DIY foundation preparation for asphalt:

First of all, the places where the car will drive need to be deepened under the crushed stone base and in the case of large trees half a meter from the asphalt, it is necessary to remove the upper roots, which over time can damage the asphalt surface. In the parking lot, we remove the land 20-30 cm. If the level of the yard allows you to raise it, then you can not remove the land. Now you need to install small borders along the perimeter of the site for asphalting, which will play a decorative role, and will also prevent the creeping of asphalt in the future. We dig holes for a strip of borders, put two extreme borders on the solution and pull the lace so that they are in one line. We mount all the rest on the cord to the solution and also do it around the entire perimeter. The mounting height of the curbs must be calculated under the base and asphalt, or put them above the future asphalt, but at approximately the same level. For parking, pour crushed stone of 10-15 cm of coarse fraction, then fill the entire area of \u200b\u200bthe foundation under asphalt with crushed stone of small fractions of 5-10 cm and pour a layer of sand or screenings of 5-10 cm on top, pour well with water and roll up with a roller, where the skating rink will not get, tamper rammer. The main thing is to evenly distribute each layer. Do not forget to plan the discharge of water into drainage systems or over the territory of asphalt. A good solid foundation guarantees the integrity of asphalt for many years, and water is the best compactor plus compacting with a roller. Of course, you can rent a one and a half ton roller for better compaction, but generally a hand roller is enough for the yard. If the edges are far apart, you can pull the cords to see the plane is even.

DIY asphalt paving:

The asphalt layer must be at least 5 cm. You can order it at an asphalt plant. The temperature for work when laying asphalt with your own hands should not be lower than 10 degrees Celsius and the weather should be without precipitation. There are three types of asphalt: sandy, fine-grained and coarse-grained. For the yard, the best types are fine-grained and sandy. For example, take fine-grained asphalt, consisting of sand, gravel fractions of 5-15 mm., Bitumen and mineral powder. Asphalt is prepared at a temperature of 180 degrees Celsius and taken to the object in a hot state. As soon as the asphalt has been brought in, it is necessary to start laying it immediately and the faster you do it, the denser and more reliable the coating will be. You can pour out asphalt from the car for 2-3 heaps, so that it is more convenient to level it. Now evenly scatter shovels, starting on one side and gradually moving to the other edge of the site. We trim the mop with the engine, what is thrown over with shovels. In the case of pits, you need to prove, remove the mound and do not forget to maintain a layer of at least 5 cm. It is necessary that several people work, one cannot cope, otherwise the asphalt will freeze and you will not do anything with it. So that the asphalt does not stick to the shovels, the engine, the roller, they need to be periodically lubricated with diesel oil. Having planned a certain area, one takes the skating rink and starts rolling, while all the others continue to level the asphalt. The skating rink should move smoothly, without making a reverse movement and the same number of times on all laying lanes. With large transverse slopes, roll up the asphalt from the bottom up. It is forbidden to stop the roller when paving the yard with your own hands on un-cooled asphalt. When rolling with a skating rink, transverse seams inevitably arise and in order to align them it is necessary to roll them perpendicular to the relative direction of asphalt laying. The skating rink should protrude 10-20 cm behind the hot uncoated coating. The weight of the skating rink can be increased by placing a weighty person on the frame of the skating rink, thereby compacting the asphalt.

Do-it-yourself paving asphalt on old concrete or asphalt:

It is necessary to clean the old coating well from dirt, dust and possible falling fragments. Before further work, the coating should be clean and dry, cracks widened and deepened. Now we pour hot bitumen around the perimeter and spread it with the engine, so that we get about a half-meter strip, but the edges should be completely smeared with bitumen. Every half meter, we make the same stripes over the entire area. And then we do everything the same way as with conventional asphalt laying.

Repairs asphalt pavement do it yourself:

To repair the coating from cracks, small pits, you can use bitumen or cold asphalt and you need to do this as quickly as possible. . Cold asphalt can be settled at sub-zero temperatures and the repaired area will meet all the parameters of endurance and strength of hot asphalt. Also, in order for the asphalt to serve you longer, it is necessary to prevent the arrival of equipment that can damage the surface, as well as in severe heat and under the weight of a heavy vehicle, the asphalt heats up and can become deformed.

- Forward\u003e

You do not have sufficient rights to add comments.

You may need to register on the site.

Garden paths should be not only beautiful, but also reliable. There are various materials for their paving, but many of them are expensive. The most economical option, presumably, will be the paving of tracks.

To understand how to lay asphalt with your own hands, you need to familiarize yourself with the features of this process.

By the method of obtaining asphalt is allocated:

- Natural. It is formed as a result of hypergenesis and oxidation of heavy oil fractions.

- Artificial. It is obtained in the factory after mixing mineral powders, crushed stone, sand and bitumen.

Asphalt products are popular, so manufacturers are improving their composition and manufacturing methods. Thanks to this, new varieties of artificial raw materials appear.

Composition and use of hot asphalt

Consists of gravel, mineral powder, viscous bitumen and sand. During production, the components are mixed under the influence of high temperatures, and a homogeneous black mass is obtained.

It needs to be laid a few minutes after manufacture, since when cooling the level of adhesion to the surface deteriorates and a poor-quality coating is obtained.

Features of cold asphalt

It differs from other types in that it uses liquid bitumen, not viscous. In the manufacture of the resinous mass, components are added that slow down the curing of bitumen.

Cast pavement composition

The composition includes the same components as in hot asphalt. However, cast contains twice as much mineral powder and bitumen. Distinctive features of the coating are its small thickness and relief. Operational characteristics are 2-3 times higher than other types.

Colored asphalt

It can be attributed to cold and hot asphalt, since it is produced in the same way. The composition includes color dyes and crushed stone, because of which the resinous mass got its name.

Asphalt crumb

There are two ways to make it: crushing and milling old layers of asphalt. The quality of the crumbs depends on the cutter and the composition of the processed mixture.

How to lay asphalt

Advantages and disadvantages of asphalt

The material is actively used to create country paths, since it has many useful qualities:

- durability;

- tolerance of sudden changes in temperature;

- dense coating;

- resistance to deformation;

- water resistant.

There are also disadvantages that occur during the use of asphalt at the cottage:

- on hot summer days it evaporates, and harmful substances enter the human body;

- the coating is not suitable for decorating the territory, as it does not fit well into garden styles;

- if done incorrectly, then during severe frosts it will begin to collapse quickly.

Styling preparation

Asphalt laying begins with preparation. It is carried out in several stages.

Planning

First, markup is made and the thickness of the crushed stone pillow with asphalt coating is determined.

You need to understand exactly what thickness you need to lay

Updating the coverage of the yard, it is enough to pour 10–20 cm of sand and put a layer of asphalt at 5–7 cm. When paving the driveway of a private house, a more durable coating is made. The thickness of the crushed stone pillow should not be less than 40 cm. Asphalt must be laid in two layers with a total thickness of 15–20 cm.

Earthwork

Before performing land work, the territory is checked for vegetation with large roots, which must be disposed of.

In the place where the asphalt will be laid, the top layer of the earth is removed with a shovel. When carrying out more extensive work, it will not work out manually and you will have to use special equipment. Excess soil is taken out so that during rains it does not lather on the passage. At the end of the process, the prepared land is compacted with a roller.

Foundation preparation

After completion of the land work, crushed stone in several layers is poured onto the compacted plot of land. First you need to pour larger stones, and then put smaller ones. Each layer of crushed stone has its own purpose:

- small stone helps to evenly distribute the layer of asphalt;

- medium contributes to even load distribution;

- large performs the role of drainage.

Large crushed stone is necessary in laying asphalt

During the laying of crushed stone, a slight bias is made towards the soil or water collectors to drain the water.

The crushed stone base is sealed with a roller. He should ride on the surface about five times. When paving a large yard, it is recommended to use a roller with a mass of about 3-4 tons and a built-in vibration function. This will allow to seal the surface qualitatively. Sometimes special equipment cannot reach some places and instead use a vibrating plate.

Asphalting

After creating the crushed stone base, you can start laying. For this, material of different grain sizes is used. At home, preparing a high-quality resinous mixture is difficult, so it is better to purchase it. The advantages of using a factory mixture include:

- saving time on production;

- use of quality material.

To put asphalt in the yard, it is necessary to use fine-grained material. It fits into one layer 5-7 cm thick.

When creating a driveway, the material is laid in several layers. Small asphalt is laid below, and large asphalt above. The coating is compacted with a roller and poured with bitumen for a better connection of the layers.

Old coating

To figure out how to properly lay the asphalt on the old surface, you need to familiarize yourself with some of the nuances.

The process of preparing the terrain varies slightly if the work is carried out on an asphalt surface. In this case, it is not necessary to carry out land work and it is enough to repair the old coating. It is completely cleaned of debris and dirt, after which damage to the surface is poured with bitumen, and a new asphalt layer is laid.

Coating Repair

Over time, asphalt paths collapse. The reasons for this may be different:

- frozen water in cracks;

- surface deformation under the influence of high temperature;

- heavy loads on the asphalt.

You can also use instead of asphalt concrete screed or paving slabs.

Paving asphalt with your own hands is a difficult job, which is difficult to cope without preparation. During asphalting, all technological nuances must be observed, on which the strength and durability of the coating depend.