How to lay cold asphalt. Asphalt care. Do I need to prepare the surface for laying

Your browser does not support audio. Update it.

You can listen to the information on this page.

Unique Cold Asphalt "OLMIKS" (also called dry asphalt or cold asphalt) is a modern road material based on polymer-rubber bitumen, which differs from other brands of asphalt in that it is made on the basis of polymer-rubber bitumen, surfactants and special additives. It does not contain volatile solvents and consists only of polymer additives and natural fibers. Cold asphalt opens up new opportunities for companies and individuals involved in road repair and maintenance.

At the end there is a “smoothing". Concrete is a particularly strong material suitable primarily for roads that are subject to high loads. In standard processes using pavers in the “insert”, large surface areas and runways are generally laid out. First, the truck scatters the concrete in front of the machine. A worm or spray spreader distributes concrete over the entire width of the machine and slides the concrete through a sliding formwork. Between the formwork machines, high-frequency vibrators are used to extinguish air from concrete, which is thus compacted.

Dry asphalt is used for quick patching of highways, city streets and access roads, waterproofing flat roofs, and repair asphalt pavement yard areas and landscaping summer cottages, with its help it is possible to carry out restoration work after laying cables and pipes, as well as cold asphalt is used when installing or replacing a curb stone, at the junction of the curb and roadbed, to level the surface of the adjacent road.

At the same time, pavers can vibrate rods or anchors in fresh concrete. Above the reinforcing elements, welds on the roadway will later be cut. This ensures that cracks, which are inevitably caused by loads and temperature fluctuations, are created in a controlled manner in the concrete casing.

Longitudinal and side trowels align the roadway. The rough texture of the sidewalk is guaranteed by an elongated jute fabric. Uniform hardening of concrete is achieved by applying the slurry to fresh concrete, usually for specific care. The curbstones that absorb the energy of the wall in the lane of the highway, drainage wastewater - there are many molded parts made of concrete. Thanks to the sliding formwork technology, it is easy and economical to lay such monolithic profiles using the displacement method.

The big advantage of cold asphalt is its price, it is cheaper than buying paved asphalt and rental of special equipment, which is very beneficial for individuals. If we compare with European analogues of cold asphalt concrete, then its price is from 250 rubles / kg, and the price of our OLMIX asphalt will be several times cheaper, because we are not tied to the exchange rate and produce asphalt from domestic materials, and specifications Asphalt adapted to the Russian climate and the realities of our roads. It can be used in extreme weather conditions (rain or snow) and various climatic zones, regardless of the season, from -20 C to +35 C.

In offsets, the stacker usually feeds material to the refueling machine. Then it is transported to offset formwork attached to the side of the sidewalk using a rotary belt conveyor or a rotary screw conveyor. While offset pavers move forward, formwork forms monolithic profiles. There are many shapes and sizes, from the most commonly used, such as a jersey profile to special products.

The displacement method is ideal when installing energy-intensive barriers with a maximum height of 2 meters, as well as drainage channels or narrow roads. Offset printing compared to the manual placement of finished products is very fast and efficient. It has long been known that asphalt is the best solution for roads of various intensities. Asphalt plays an important role in our daily activities. When traveling to work or school or when we go shopping, we use asphalt roads for this purpose. Most asphalt pavements are gray or black, sometimes painted with, for example, red or green.

FAQ:

What is the consumption of cold asphalt per 1 m 2?

If you do not know how much cold asphalt you need, then 1 m 2 with a pit depth of 0.05 m needs about 90-100 kg. cold asphalt. We recommend using cold asphalt when repairing potholes and pits up to 10 square meters.

Do I need to prepare the surface for laying?

There are many types of asphalt pavement, each of which has certain properties, among others. Some of them can be porous, while others can flexibly adapt to atmospheric conditions. Asphalt mixtures can also be manufactured using various technologies, such as heat, heat, half heat or cold.

Asphalt is used on roads, railway platforms, airports - runways or taxiways - on bike paths, playgrounds, treadmills, tennis courts, ports, bridges and tunnels. Asphalt is harmless to the environment and to people.

Yes, if laying in the warm season, it is enough to remove dust (remove dust from the pit) and rinse the pit with water, then you can lay it.

What do you need to know?

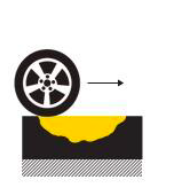

You need to know that it is strictly forbidden to add solvents or plasticizers to the cold asphalt mixture (diesel fuel, gasoline, etc.). It is desirable to carry out repair work at temperatures up to -20 C. When working in winter period at subzero temperatures, cold asphalt is best kept for a day in a warm room for better paving. For compacting asphalt, various compacting hand and mechanical means (hammer, rammer, vibrating plate, soft roller, machine wheel) can be used. After the repair is completed, you can immediately open the traffic. Asphalt Cold "OLMIX" is possibleuse in extreme weather conditions (rain or snow) and various climatic zones, regardless of the season, from -20 C to +30 C. When laying asphalt at subzero temperature it is necessary to maintain it in a warm room.

Here are some important information, why is it better to choose asphalt? First of all, sustainable development! Not without reason, car races take place on paved roads, because they provide the best traction and, consequently, safety or a shorter braking distance. Asphalt is not only pleasing to the eye, but also the safest and safest road surface. Asphalt roads can be built quickly, reducing traffic delays and road costs. Asphalt can be located at night, which saves commuters from costly delays and stands in the morning traffic. Even asphalt surfaces contribute to fuel economy as well as wear and tear on every vehicle, including tires and suspension components. Asphalt pavement is one of the largest renewable resources; Asphalt can be reused to produce high quality mineral asphalt. Asphalt pavements have better visibility in adverse weather conditions. . From Napoleonic times it follows that roads from antiquity to the present day are a measure of the development of societies and states.

Can cold concrete be laid on concrete?

Yes, but if you are working with concrete, we definitely recommend treating the concrete surface with a primer (primer recipe: 1 kg of bitumen and 2 liters of gasoline or kerosene, 1: 2 ratio or purchase a ready-made primer in a hardware store) or with a bitumen emulsion, and only Then lay the cold asphalt.

Currently, the technology used for the construction of asphalt pavements is the most widely used. After Poland joined the European Union, it was necessary to adapt the infrastructure to European requirements, including the construction and reconstruction of the road network. The position of Poland in the center of Europe leads to the fact that the intensity of heavy traffic, especially from east to west, increases every year. The dominant pavement construction technology is the construction of asphalt pavements.

No less important, but, to a lesser extent, cement pavements. Road surfaces can be divided according to their structure, deformability, load capacity and type of materials used on the driveway. Due to surface deformation, we are divided by.

Where can I buy cold asphalt?

You can buy cold asphalt from our regional representatives in 24 regions of Russia from 1 bag (select the city in the black pop-up window and the city will drop out there, and in the upper left corner ) .

What is the packaging of cold asphalt?

Polypropylene bags of 25 kg, on one pallet 40 bags of 25 kg, one pallet - one ton of asphalt.

Vulnerable - sidewalks that are plastically deformed under the influence of loads. Semi-rigid asphalt pavement with concrete, concrete concrete, aggregates or stabilized soils. Rigid - coatings that are elastically deformed by the load. Most hard surfaces are made of hard or hard surfaces. Susceptible sidewalks account for about 90% of the total length of hard roads in Europe and Poland. The types of pavement construction caused by deformability are shown in Fig.

Types of construction pavement main road network in Europe. The design of the asphalt pavement is shown in Fig. Asphalt pavement construction. The structural layers of the sidewalk, that is, the wear-resistant layer, binding and substructure, can be made of mineral asphalt mixes. Mineral-asphalt mixture consists of asphalt binder, fine and coarse aggregate, filler and additives. In bitumen mixtures, asphalt binders make up on average only about 5%, but its effect on the properties of the mixture is decisive.

Why is it better to tamp cold asphalt?

To compact the asphalt, you can use the vibrating plate, small areas can be rammed using a manual rammer, a car wheel, logs.

Can you make delivery to the facility?

Yes, we deliver from 1 ton, if you need several bags, then you can pick them up at pick-up at your nearest retail point.

In Poland, the following types of mineral-asphalt mixtures are used for the construction of pavement layers. For foundation and bonding layers: asphalt concrete and asphalt concrete with a high rigidity module. For wear layer: asphalt concrete, mastic, mastic asphalt, thin asphalt concrete for porous asphalt and asphalt.

Asphalt is the most commonly used mineral-asphalt mixture in which a continuous granular aggregate forms a wedge-shaped structure. Asphalt poured is a mixture of mineral asphalt, in which the volume of filler and binder is greater than the content of free space in the unit.

Technology of laying dry asphalt "OLMIKS"

1 step - To clear a hole from dirt. If the pit is deep, it is advisable to add crushed stone to reduce the consumption of Cold Asphalt.

Step 2 - Pour Cold Asphalt from the bag and evenly distribute with a layer of 4-5 cm. So that the mixture is above the surface about 1 cm.

Asphalt concrete for very thin layers is a mixture of mineral asphalt for wear layers with a thickness of 20 to 30 mm, in which the unit has a discrete particle size. Porous asphalt is a mixture of mineral asphalt with a very high content of combined free space, which allows water and air to flow to provide drainage and reduce communication noise. The figure shows the drainage pattern of traditional and porous asphalt.

Mineral-asphalt mixtures vary depending on. Type of mineral compound used. The content of free space in the mineral-asphalt mixture. Technology execution. Drainage diagram of traditional and porous asphalt. The classification of bituminous binders is presented in the figure. Among the asphalt binders are oil and natural asphalt. Natural asphalt trinidades and gilsonites are used as additives to alter the properties of petroleum asphalt. The melting resin used in the construction of sidewalks and in the insulation industry, due to its low technical and toxic properties, was discontinued in Europe in Poland, as well as in Poland.

Step 3 - Tamp the asphalt with improvised means, sprinkle lightly with sand and be sure to tamp again. After that, you can immediately open the traffic on the repaired area

Asphalt binders are organic binders whose bonding and hardening are reversible physical phenomena that change the adhesion and adhesion of the binder molecules as the temperature changes. The properties of road tar materials depend on the type of crude oil and the technology used. In Poland, asphalt production takes place in three stages during atmospheric distillation, vacuum and oxidation of the vacuum residue.

Currently, asphalt coatings are used for the following types of binders: road bituminous, modified and multi-layer asphalts, asphalt emulsions, liquefied asphalts, foamed asphalts. The table. Classification of bituminous binders. Road bitumenused in the construction of asphalt pavements must meet the requirements of a wide range of technological and operating temperatures.

Attention!If you are working with concrete, then we recommend that you treat the concrete surface with a primer (primer recipe: 1 kg of bitumen and 2 liters of gasoline or kerosene, 1: 2 ratio) or bitumen emulsion, and only then put cold asphalt.

For more convenient use, you can buy cold asphalt in bags or buckets, as well as in the chain of stores YOUR HOUSE and at Lukoil gas stations. We are producers of Unique Cold Asphalt "OLMIKS", therefore our goods are certified and comply with GOST. If you have any questions regarding the laying of asphalt, patching or its acquisition, then call us and we will answer all your questions.

Standard properties are not enough to fully characterize binders in such a wide temperature range. An additional study of rheological properties is required. Based on rheological studies, it is possible to determine in which temperature range the asphalt is in an elastic, viscoelastic and viscous state under the influence of temporary and temperature loads.

The design of modern surfaces, durable and resistant to damage, requires the use of high-quality binders. This binder can be obtained by modification asphalt road with the following additives: polymers, polyphosphoric acid with a polymer, organometallic salts. The “cold” road maintenance technology uses asphalt emulsions, liquefied asphalt and new foam asphalt technology.

Increasingly, one can hear a mention of a relatively new technology for road repair work, which involves the laying of cold asphalt. And this is no coincidence, because cold asphalt allows you to "patch" the road without becoming attached to the season and weather. Now road works they will not interfere with rainfall or frost

For technical and environmental reasons, it is important to use pavers for the construction of pavements to a greater extent. Their use is made from rubber from worn-out car tires. For reasons of economic, environmental, social and economic development, it is necessary to build durable, modern and safe road surfaces.

The materials used for the construction of the sidewalk must be. Simplicity and ease of use. It should be noted that the use of modern materials and technological solutions in the field of binders and asphalt mixtures meets current requirements for sustainable road construction.

Cold asphalt is ready to use. asphalt mix. Repair work can be carried out independently of weather conditions outdoors at temperatures up to 20 degrees below zero.

Cold asphalt gains this property due to its special composition. In the production of this mixture, instead of viscous bitumen, liquid, more elastic bitumen is used, which has the peculiarity of increasing viscosity when the air temperature drops.

Another indispensable element that can not be avoided in the production of cold asphalt is the additive. Its mass usually reaches 25-35% of the total mass of bitumen. The additive makes cold asphalt more durable, and also contributes to the long-term preservation of its beneficial properties.

|