Do-it-yourself fireplace for a summer residence. How to make a fireplace with your own hands: step by step instructions A simple fireplace for a summer residence with your own hands

The depth of the firebox must reach 30 cm or more, which is necessary for the safe operation of the chamber. Some experienced craftsmen in this case use a little trick: they make a protrusion of the upper beam jumper in the firebox by about 5-6 cm in relation to the vertical axis. In this case, the depth of the combustion chamber will be less than 30 cm.

Walls and heat transfer

In a small fireplace there are two calorific channels located on the side walls. They provide an increase in heat transfer. When wood is burned in the fireplace, cold air from the room enters the 2-3 level channels, heats up there and returns to the room through the holes in the 13-14th row.

Self-construction of a mini-fireplace for a summer residence

The construction of this heating device for a country house is notable for its simplicity. The only difficult process is the overlap of the firebox. When laying a fireplace tooth, some irregularities are allowed, since it is lined with a sheet of metal, respectively, all inaccuracies will be hidden.

A wood-burning mini-fireplace is suitable for use in the autumn-winter season, but it will be problematic for him to cope with a frosty winter. But in a warmer period, this device will heat a room with an area of 16 to 20 m². One of the clear advantages of a mini-fireplace is its low cost: the purchase of all the necessary elements will cost about 5-8 thousand rubles.

A wood-burning mini-fireplace is suitable for use in the autumn-winter season, but it will be problematic for him to cope with a frosty winter. But in a warmer period, this device will heat a room with an area of 16 to 20 m². One of the clear advantages of a mini-fireplace is its low cost: the purchase of all the necessary elements will cost about 5-8 thousand rubles.

One of the most suitable materials for building a fireplace is high-quality red brick. Work begins with the laying of ten rows of the back wall. In the next two levels, it is necessary to make an overlap of 1/4 brick in size. When laying the side walls, it is necessary to provide for a turn at an angle of 25 degrees, while leaving vertical channels. In the third row, you need to make holes that provide passage for cold air. This contributes to the additional heating of the room.

On the back wall of the firebox in the 11-12th row, protrusions are provided for the formation of a smoke tooth. Four metal pins are also mounted here, which will hold the inclined stainless steel screen. The back wall can be made of treated brick.

The dimensions of the fireplace at the base, excluding the pipe, are 1020x510 mm, height - 1120 mm. The cleaning door is installed on the rear wall, which allows you to clean the chimney tooth from ash and soot.

The design of this mini-fireplace for giving is slightly different from the original, which was offered in the original source. In our case, the arch that covers the fuel chamber is made of 9 bricks, not 7, as originally indicated. In the presented project, the gaps between the bricks of the arch are reduced. The central brick has non-standard dimensions and is rather narrow.

Download project

You can download the project of a small fireplace in PDF and DOC formats.

Questions and answers

Question: Is it allowed to connect such a fireplace with a heating stove 51x140 cm in the shape of the letter L?

Answer: We advise you to place the elements side by side or back to back, and make the pipe with two separate channels. Then the stove and the fireplace are guaranteed not to interfere with each other.

IN: Why is this project not about refractory bricks? Or are ordinary bars used for laying the firebox?

ABOUT: This fireplace is a summer cottage, that is, it is not intended for permanent use. Therefore, the entire structure is made of ordinary brick. It means that with a firebox once a week, nothing bad will happen.

IN: Can this fireplace be connected to the Krokha stove?

ABOUT: The cross section of the chimney at the "Crumbs" will have to be increased. The channels will most likely need to be reversed so that the ascender is placed on the side of the fireplace. It needs to be tried.

IN: Can this device be laid out of bricks measuring 230x120x60 mm?

ABOUT: Yes, but the bars will have to be customized.

- On the 17-18th row, the formation of a brick pipe begins. Can it be extended further from metal (round product) and brought out at an angle of 45 degrees to the street? Estimated pipe diameter is 100 mm.

- Does the valve need to be installed before the metal pipe or can it be somehow built into it?

- How is the pipe connected to the brick base?

- It is allowed, but the cross section must be no less than that of a brick pipe. A diameter of 100 mm will not be enough.

- Install the valve where it is convenient.

- It is desirable to have a special adapter from rectangular to round. This element is immured in a brick pipe. A round metal-rolling product is connected to it.

IN: Is it possible to replace the fireplace arch with a straight one with the same protrusion? If so, in what order should the corner be laid?

ABOUT: On the 11th row and on it, make an overlap. Provide gaps so that when heated, the corner does not break the masonry.

- What is the recommended diameter of a round metal pipe?

- What height should she have after 17-18 rows, taking into account the diameter that you recommend?

- It so happened that the size of the fireclay brick turned out to be slightly smaller, the parameters of the grate were 120x120 mm. Is it critical?

- 200 mm.

- 4-5 m.

- No, it's not critical.

IN: Is it allowed to use ordinary metal instead of stainless steel?

ABOUT: Yes, but it is necessary to provide options for replacement when burning.

IN: How to purchase this device?

ABOUT: You can not buy a brick fireplace. However, you can order masonry according to the project from a stove-maker in your city or fold the device yourself.

IN: How much will it cost to build a fireplace?

ABOUT: For pricing, check with the stove-makers in your area. Everyone has their own prices. It depends on the experience of the master and the complexity of the project.

IN: Is it possible to use an asbestos-cement pipe with a diameter of 200 mm? If so, how to make a joint between a square pipe and a round AC? Or can only a metal product be used for a chimney?

ABOUT: For heating or heating-cooking stoves, AC pipes are sometimes used. The flue gas temperature in these devices does not exceed 150 °C. The pipe can hold up to 300°C. The temperature in the fireplace will be much higher. Therefore, it is impossible to put an asbestos-cement product here. For conversions to a round tube, ask those who sell such products.

Currently, fireplaces for summer cottages are almost an indispensable attribute of a country estate. The construction of a traditional “classic” fireplace in the country with your own hands, despite the appearance of boilers and other heating devices on sale, has by no means lost its relevance. Moreover, no one forbids having several life support systems in a rural house that can replace each other or work simultaneously.

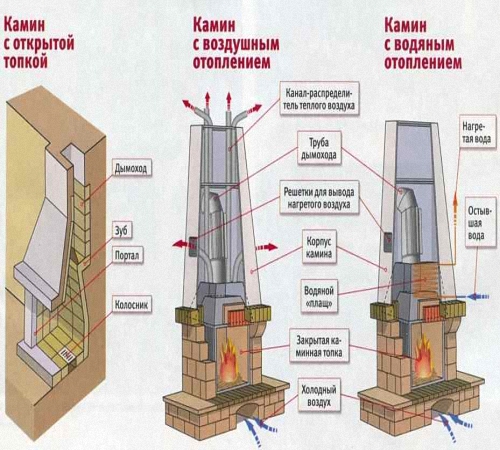

Among the fireplaces for giving, conditionally, three main types can be distinguished:

- traditional wood burning fireplaces;

- electric fireplaces;

- hybrid stoves-fireplaces of long burning.

What you need to know about building a fireplace

To make a fireplace in the country with your own hands, you need to arm yourself with some knowledge. Of course, the best option is when such a structure is provided as part of the construction of the dacha itself. In this case, it is possible to foresee the creation of the necessary solutions at the design stage. In this case, even if for some reason the simultaneous construction of a summer house and a fireplace is impossible, then you can at least plan the necessary conditions for its construction.

There are certain technical requirements that it is desirable to strictly comply with. Among these requirements, first of all, it is necessary to take into account the following:

- enough space for the main body;

- a place in the floors for the chimney.

Also, before you start making a fireplace in the country with your own hands, there will be good to know:

- Unlike a stove, fireplaces are easier to build already in a finished house.

- Although a fireplace is much lighter than a stove, it may require a more solid foundation.

- The design of the fireplace takes up less volume than the stove, and is built faster.

Masonry technology

The construction of a fireplace, although inferior in complexity to the construction of the house itself, but also requires certain skills. Therefore, there are always two alternatives - attracting professionals and making a fireplace with your own hands. But even if an experienced worker is invited for construction, it does not interfere with having such a minimum of knowledge that will allow you to control the masonry process.

The thicker the chimney pipe, the less heat loss.

At the same time, resting a heavy chimney on a light fireplace is very dangerous. In this case, the chimney is made up of metal or ceramic pipes, which are lined with bricks, and the volume between the pipe and the bricks is covered with expanded clay.

The higher the height of the chimney, the better the draft. Usually the height of the fireplace chimney is from five to seven meters.

For security purposes, and to regulate the intensity of combustion and reduce heat loss, a valve is placed on the chimney. Optimal the distance of the valve from the firebox door is from 20 to 50 cm.

Read also: metal fireplace

Frame

The main body or hull can usually be made of brick. Fireplace masonry is done in one of two ways of ordering - with and without a spark arrester.

The main body or hull can usually be made of brick. Fireplace masonry is done in one of two ways of ordering - with and without a spark arrester.

As an example of a chimney masonry, the following diagram can be given:

According to this scheme, after laying out the first three rows, the inside must be covered with sand and gravel. After that, the fourth row must be laid with refractory bricks, and then the L-shaped pins, which are necessary for installing the fireplace grate, are inserted. The order of laying subsequent rows is shown in the attached diagrams.

Thus, this diagram details the entire laying process, as well as the approximate composition of the necessary building materials for the construction of a simple fireplace in 34 rows of bricks with a spark arrester.

Necessary materials

According to this construction scheme, the following materials are needed:

- furnace brick - 370 pcs.;

- refractory bricks - 62 pcs.;

- - 300 kg;

- Refractory mixture - 50 kg;

- sand concrete mix - 150 kg;

- gate valve 240 × 130 mm - 1 pc.;

- fireplace grate - 1 pc.;

- reinforced concrete slab - 4 pcs.

As you can see, a fireplace in the country is a rather time-consuming project that requires the investment of labor and building materials. Nevertheless, guided by the available drawings and manuals (including video instructions), it is quite possible to do such work with your own hands.

Electric fireplaces

Electric fireplaces in their popularity among summer residents, probably, are in no way inferior to their traditional wood-burning counterparts. Construction of electric fireplaces much easier than wood, since you don’t have to think about building a chimney, make a massive foundation and lay thick brickwork.

Electric fireplaces in their popularity among summer residents, probably, are in no way inferior to their traditional wood-burning counterparts. Construction of electric fireplaces much easier than wood, since you don’t have to think about building a chimney, make a massive foundation and lay thick brickwork.

Also a great advantage of the electric fireplace is ease of use. It is not necessary, for example, to constantly stock up on firewood, find a place to store it, prepare firewood for the furnace and monitor the number of remaining logs.

Another great advantage of electric fireplaces is the possibility of adapting them to any interior. There are many ready-made electric fireplaces, from the smallest to super large sizes, with a wide range of prices. Modern electric fireplaces have remote control panels, they can simulate the burning of real firewood, create artificial flashes, crackling and other effects.

In the summer, such modern electric fireplaces can only simulate combustion and consume a minimum of electricity, and in the cold winter they can both shine and heat at the same time.

The presence of a fireplace in your country house will provide you with warmth, coziness and comfort on winter and autumn evenings, as well as add romance to your everyday life. We will talk about how to build a fireplace with your own hands in this article.

How to build a fireplace with your own hands in the country or in a private house

Essential elements

The fireplace consists of several main elements, which include the body, foundation, smoke box, firebox and smoke channel. In order for the fireplace to function properly, the correct ratio of the sizes that its elements have is necessary.

The fireplace foundation is made both from rubble stone or red brick, and from rubble concrete and concrete blocks. If you are building your fireplace in wet ground, it is recommended that the foundation be built from rubble stone. In the same case, if you are laying the foundation in dry soil, it would be advisable to use limestone mortar, which is 1 volume of lime and 1 to 3 volumes of sand (depending on the degree of moisture content of the lime).

Solution

To prepare the solution, lime is mixed with water to the density of sour cream, after which sand is added there. For foundations that are laid in wet soils, the cement mortar should consist of 3 volumes of sand and 1 volume of cement. Dry components are pre-mixed thoroughly, then diluted with water.

foundation pit

The pit, which is supposed to be used for the foundation in length and width, should be approximately 50 mm larger than the foundation for the fireplace. Its bottom is leveled with a level. The first row of the fireplace foundation is laid out dry from stone or brick rubble.

Stones or crushed stone are rammed into the ground, after which they are poured from above with a liquid solution. In the future, the laying is carried out in the correct rows, in compliance with the dressing of the seams. To prevent the process of moisture penetration into the masonry over the foundation, an insulating layer is made from a pair of roofing sheets at least 150 mm above the ground level, after which the fireplace is laid.

fireplace body

Typically, the body of the fireplace is laid out from high-quality red or refractory bricks. When using a red firebox, it will later be better to line it with refractory bricks. The thickness of the brick walls should be no less than half a brick.

In addition, heat-resistant concrete, ceramic blocks or natural stone (excluding silicon and limestone) can be used for the construction of the fireplace body. They line the surface of the body with valuable rocks of stone, or plaster it.

Photo:

You will also need to build a firebox

The depth of the firebox is recommended to be taken equal to about half a meter. At a shallower depth, smoke can enter the room, and at a greater depth, the strength of thermal radiation becomes weaker. The efficiency of the fireplace can be increased by lining the back wall of the firebox with a cast-iron stove or sheet steel. In order to achieve better heat radiation, the upper part of the back wall is laid out with a certain inclination forward, while the side walls expand forward towards the hole. The walls of the firebox are usually laid out from fireclay refractory bricks, while such a fireplace will have an efficiency of up to 17%.

For firebox flooring

Photo:

usually some kind of fire-resistant material is used - for example, concrete, granite, clinker. It is necessary to provide for the presence of a ash pan for collecting ash and coal. The ash pan is located under the firebox. Between them lay a cast-iron grate. The basket is made of steel with a section of 10–15x10–15 mm or a diameter of 10–15 mm. The elements of the basket are located after 15–20 mm. Its legs should have a height of about 80–120 mm. In the process of burning firewood on a basket, fine coal and ash are collected on the hearth and removed after the fireplace has cooled down.

Now let's talk about what is a portal

Portal- an element of the fireplace, on which its functions as a heating device largely depend. The portal can be installed on one, two or three sides, depending on the architectural design of the fireplace and its location. In the event that the fireplace stands separately, it may have a circular portal. The shape and proportions of the portal are set, taking into account the harmonious solution of the fireplace as a whole.

From firebox hot gases enter the smoke box

Photo:

A smoke collector is a pyramid-shaped extension located at the bottom of the chimney, which serves to prevent the rapid lowering of cold air flows down the chimney.

Soot and soot are collected here when cleaning the chimney, which are then removed through a hatch located in the back wall. At the same time, the damper, located slightly lower, provides protection against soot and soot entering the room.

The smoke collector is laid out of red brick (grade 200). In addition, it can be made from iron sheets, which will provide rapid heating of the room. To improve the aesthetic qualities of the fireplace, as well as to cover the hot metal smoke box and ensure its fire safety, a protective casing is made of copper sheet. A burned-out metal smoke box is replaced; at the same time, it is necessary to take into account the possibility of such a replacement when thinking through the design of the fireplace.

gas threshold

Photo:

Cold air descending down to the chimney can, bypassing the smoke box, enter the room, while dragging smoke along with it. To avoid this, a gas threshold is arranged in the back wall of the chimney - a barrier in the form of a protrusion, which contributes to the fact that cold air mixes with hot air and the resulting mixture is discharged upward into the atmosphere. In width, the gas threshold should be equal to the chimney, or be 10–15 mm larger than it. The required width of the gas threshold will ensure its normal functioning and allow it to retain soot that falls off the chimney. The cross section of the chimney must not be narrowed by the threshold.

smoke damper

A smoke damper is placed between the smoke collector and the firebox, which prevents cold air from entering the room when the fireplace is not working. This shutter provides coverage of the entire width of the channel. Its width should be approximately 1/16 of the height of the portal.

Its area is assumed to be 1.25 times greater than the cross section of the chimney. Opposite the gas threshold, a cleaning is constructed, hermetically sealed with a door. Through it, soot is removed, which is collected on the threshold.

Chimney

It is forbidden to build horizontal chimneys, so the chimney must be vertical. If the fireplace is attached to a wall in which there is a smoke channel, then in extreme cases the chimney can be with a slope of no more than 60%. Chimneys are usually made of red brick.

To improve draft and prevent precipitation from entering the chimneys, deflectors are installed on them. Chimneys must be insulated with asbestos gaskets from the wooden elements of the building. The smallest distance between wooden elements and chimneys must be at least 250 mm.

Floor protection

In addition, part of the floor (at least 0.5 m), which is located in front of the fireplace, must be covered with sheet iron or constructed from non-combustible material.

Fireplace Size Chart

To make a small fireplace you will need:

- Brick. When calculating the amount of material, do not forget to take into account 10% waste and scrap;

- Coarse sand. Before use, the sand is sieved and washed to remove small debris;

- Clay. To build a quality fireplace, you will need a blue grade of clay;

- Several buckets of rubble;

- Reinforcement 1 m long and 10 mm in diameter in the amount of 10 pieces.

Tip: Before starting construction, draw a laying plan on paper. Try to strictly adhere to the dimensions of the brick and room in the drawing. Also, do not forget to take into account the masonry scheme of the cottage.

The sequence of actions for the construction of a fireplace

All work begins with calculating the dimensions of the foundation for a small heating system. The foundation of the dacha may not be enough for the normal functioning of the device, so it should be strengthened with non-combustible material - ceramic tiles or other solutions of non-combustible ingredients.

Before starting the construction of a fireplace with your own hands, you need to soak the clay, preferably 3 days before the start of construction. A small amount of water is added to the soaked clay every morning. After adding water, the solution is well mixed with any solid object.

Before starting construction work, do not forget about the need for wetting the material. It is impossible to build a high-quality heating system on non-wetted bricks. The first rows are laid on a solution of clay and cement. Each subsequent row is placed on a cement mortar with a gradual decrease in the concentration of clay in it.

DIY fireplace

Subsequence:

After creating the frame, the heating device must be brought into a divine form - to do the jointing with clay. For jointing, you will need dry sand and wet clay. The solution is mixed by hand until a homogeneous mass is obtained. The grout is applied to the seams with your fingers. Remember, even cottages need accuracy, so do not forget to smooth the seams on the fireplace well and wash out the clay from the brick.

Equipment installation

After the completion of construction work, you need to install the main components of the fireplace with your own hands. Installed in the heating system:

At this stage, the manufacture of a country fireplace can be considered finished. It remains only to add decorative elements for the dacha and build a small shed where firewood will be stored for the firebox.

As for the decorative design of the fireplace, almost any style is suitable for a country house. The main requirement for the design of the fireplace is its simplicity. Heating equipment can be decorated with ceramic silhouettes and other objects made of fire-resistant materials.

Video: Stone fireplace. (Effect-Profi)

The presence of a fireplace in any home makes it cozy and fills with warmth. But, unfortunately, the cost of a purchased fireplace is too high, so it is much cheaper to make it yourself. During the manufacturing process, it is possible to choose the type of device that will be in harmony with the individual characteristics of the room and the overall style of the interior. How to make a fireplace for a summer residence with your own hands, we will consider further.

The classic version of the construction of fireplaces for summer cottages

This version of the fireplace assumes the presence of:

- chimney;

- furnaces;

- smoke chambers.

The initial stage of its construction is the determination of the location of the fireplace in the country. In this case, first of all, the convenience of its use is taken into account. In addition, one should proceed from the possibility of the location of the chimney. Also, the installation site should be convenient for maintenance both outside and inside the building. The chimney for the fireplace and for the stove should be 200-300 mm higher than the ridge. With the central location of the fireplace, the head of the pipe is located near the ridge. This option involves easy installation of the chimney, simple installation and dismantling of the air damper. In addition, in this case, the pipe is cleaned of soot easily and conveniently.

Installation of brick fireplaces for summer cottages near the central wall in the room, if necessary and desired by the owners, is possible. Although in this case, cleaning the pipe and installing the chimney is much more difficult. To solve this problem, temporary means of paving are installed during construction work. For example, a special ladder is mounted, which allows the fireplace to be serviced from the outside.

The next stage of construction is the choice of the appearance of the fireplace portal. It depends on many factors, such as the location of the fireplace, the general style of the interior and the general wishes of the owners.

A variant of the construction of wall, wall, floor fireplaces is possible. Each of them has its own advantages and disadvantages. The most common are wall fireplaces, in addition, they are the most convenient to use and take up little space. The finishing of the portal is the most diverse, ranging from brick or stone masonry to wood, metal or ceramic tiles. It all depends on what materials the walls in the country house are made of and how they are finished. In addition, quite popular fireplaces are corner ones for giving, with their help it is possible to save space. It is convenient to sit in a rocking chair near such a fireplace and watch out the window.

Please note that the materials used in the arrangement of the fireplace must be non-combustible and fireproof. Since at high temperature and in the presence of fire, there is a risk of fire.

When arranging a fireplace in a two- or three-story building, its weight exceeds a ton, so due attention should be paid to the arrangement of the foundation. The best option is the arrangement of a concrete poured foundation. This type of foundation is characterized by high strength and long-term performance.

When arranging this type of foundation, it is required to carry out work on reinforcing concrete using a mesh or reinforcement rods. The easiest option is to use a rebar with a periodic profile. To equip the foundation on solid ground, you will need reinforcement with a diameter of about one centimeter. When working on soft soils, the diameter of the reinforcement increases by 2-4 mm.

Start the procedure for building a fireplace with its design. Accurately measure all the components, details of the fireplace, transfer them to paper. Further, based on the measurements, you should buy the material.

For the construction of the foundation - the foundation will require the presence of:

- about 45 kg of cement, the amount depends on the size of the fireplace;

- sand about 90 kg, based on 45 kg of cement;

- crushed stone of a large fraction - 90 kg;

- reinforcing bars - the size of the structure affects the number;

- edged boards, 3 cm thick;

- hammer;

- grinding machine;

- nails 7 cm.

When constructing the foundation of the pedestal, you will need:

- sand and cement in a ratio of one to three;

- rubble stone, in relation to the size of the fireplace.

To make a fireplace for a wood-fired cottage, you should prepare:

- refractory type brick, its quantity should be calculated based on the design of the fireplace, keep in mind that it will be needed both for the construction of the fireplace and for the chimney;

- 50 bricks will require about one bucket of clay;

- about 10 kg of sifted sand, half a bucket;

- prepare the grate;

- air smoke damper installed in the pipe;

The classic manufacture of a fireplace involves the presence of two such dampers. They are located at the top and bottom of the pipe. The variety and shape of the damper is determined at the design stage and completely depends on the diameter of the pipe.

- take care of the presence of a decorative grill of the firebox;

- about the mantel;

- and a set of tools to help maintain the fireplace.

To lay brickwork you will need:

- a tank in which clay will be kneaded, with a capacity of 12 liters;

- plaster ladle, which will be used for kneading;

- trowels;

- rubber mallet;

- picks;

- plumb;

- building level.

The height of the chimney pipe is affected by the height of the building itself and the ridge on the roof. The size of the pipe should exceed the height of the ridge by several bricks. The inner diameter of the pipe is affected by the inlet located in the furnace. The inlet in the furnace should be five times larger than the diameter of the pipe, then the draft will be good. A brick fireplace assumes the presence of a constant section, that is, a passage size. With the help of specialists, or with certain skills in arranging chimneys, the pipe is made narrower at the top, this procedure helps to increase traction.

Before starting construction, care should be taken to check the availability of all necessary materials and their quality. Sorting the bricks, if there are small cracks in the material, put it aside, it will be used when you need to use half the brick.

Next, start preparing the clay-sand mixture. To check its quality, it is necessary to prepare seven bricks, connect them with mortar and lay them in a column overnight. In the morning, take the structure by the top two bricks, if the rest have not fallen off, then the mortar is of high quality.

Before laying bricks, the clay is soaked in water for 24 hours. If there is no time to soak, soak the clay in warm water for a shorter period of time.

To equip the foundation for the fireplace, you should disassemble the floor, determine the type of soil and the depth of the foundation.

In relation to the size of the fireplace, mark up for arranging the foundation. Please note that its size should be 15 cm larger on each side to ensure the evenness of the structure and the installation of the formwork.

It is forbidden to install a fireplace foundation next to or connected to the foundation of a building. This procedure will significantly degrade the quality characteristics of both foundations and reduce the life of the building.

If the soil is solid, then the foundation is laid at a depth of up to 80 cm, otherwise, a deepening of more than one meter will be required. To make a foundation on a solid grade of soil, you will need to build a formwork. For its design, you will need boards 20 cm high. This is followed by the process of laying reinforcement. The laying step is 50 cm.

The preparation of the concrete mixture is best done in a concrete mixer. Since in it all the ingredients are mixed and a homogeneous consistency will be obtained. This will significantly improve the quality properties of concrete. First, the first layer of reinforcement is poured, it is vibrated using a vibrator for concrete. It will help remove excess air from the solution and improve its strength.

Lay the second layer of reinforcement on the pre-poured concrete and proceed with the subsequent pouring. The surface of the foundation is covered with plastic wrap for 12 hours. Next, the film is removed and the formwork is dismantled. Please note that this procedure must be carried out with extreme caution, since the concrete is still quite soft. Next, install the formwork for pouring the fireplace pedestal, its size fully corresponds to the value of the width and length of the fireplace itself.

After the formwork is installed, the base should be filled with mortar mixed with rubble. Cover the surface with plastic wrap and wait for the foundation to dry.

The best option is to raise the cabinet a few centimeters higher than the finished floor. This process will help improve and simplify the installation of flooring and fireplace trim.

After twelve hours, the formwork is dismantled, the polyethylene is removed. All excess areas on the sides of the foundation are covered with soil and compacted. To improve shrinkage, it is recommended to pour them with water. After another twelve hours have elapsed, begin laying the bricks.

Use a plumb bob to check the corners and attach it to the ceiling with hooks. In the process of laying bricks, one should strictly adhere to the rule that says: the minimum amount of clay ensures the reliability of the masonry. The layer of clay mortar between the bricks is no more than 4 mm.

The main task of the fireplace is to ventilate the room, but not to heat it. Namely, due to the presence of ventilation, the fireplace is not able to fully fulfill the role of a heater. To remedy the situation, the installation of a heat-resistant door is required. With the help of thermal radiation, the room will be heated by the heat that radiates from the fireplace.

To increase the efficiency of the fireplace, you will need to install a boiler in the combustion chamber. This design is characterized by:

- boiler;

- pipeline supplying hot water;

- radiator for heating;

- warm air flow.

The boiler comes into direct contact with the flame blazing in the fireplace. From this device, water enters the radiator, thereby heating it. The cooled water again enters the boiler and heats up in it. Thus, the circulation of water in the system is obtained. It is possible to install a stationary boiler. To mount it, during bricklaying, it is necessary to provide for the presence of threaded pipes. Also, the water system is removable. Although the aesthetics and appearance of the fireplace will suffer a little, the efficiency will increase several times.

Cast iron fireplace for a summer residence: installation features

Before proceeding to the direct installation work on installing a cast-iron fireplace, we suggest studying its advantages and disadvantages.

The presence of a closed firebox in the fireplace ensures complete safety of its operation. Therefore, such a fireplace is most welcome in a house with small children.

The design of the closed furnace has the form of a cast-iron chamber designed for fuel combustion. One of the sides of this chamber has the form of a glass door through which the flame is viewed. The door, which is equipped with lifting parts, is distinguished by ease of use. With their help, the firebox acquires an open look, that is, it is universal. An ash pan is located below the combustion chamber, it is the place where air is supplied to the chamber. The top part of a fire chamber is equipped with a pipe for removal of a smoke. The installation procedure for a cast-iron fireplace consists in the construction of a portal that will give the stove a finished appearance of the fireplace.

Among the advantages of a closed cast-iron firebox, it is worth highlighting:

- the presence of heat accumulators, which significantly increase efficiency;

- the presence of a variety of models that differ in shapes, types and appearance;

- the possibility of replacing damaged parts;

- longer service life than brick fireplaces;

- a high level of fire safety is ensured by the absence of open fire;

- the cost of such a fireplace is much lower than a brick one;

- ease of installation.

Among the large number of advantages of such fireplaces, there are several of their disadvantages:

- visibility of fire is more limited than open fire models;

- care is required, which consists in the periodic cleaning of the glass door;

- the standard firebox is distinguished by the presence of black.

One of the main advantages of such fireplaces is the absence of the need to build a foundation. Therefore, they are easy to install in an already renovated room.

First, decide on the location of the fireplace. It should be convenient for the location of the chimney. For the installation of a fireplace, it is necessary to build a base, which looks like a concrete screed with reinforced elements. Next, waterproofing is laid, and when arranging a fireplace on a wooden field, it is necessary to carry out thermal insulation.

The thickness of the layer for screed equipment is 100-150 cm. To perform reinforcement, use a metal mesh. After waiting for the concrete to harden, start installing the structure that will hold the firebox. For its construction, brick, aerated concrete blocks or other alternative materials are used. It is possible to purchase a ready-made brick base made of natural stone.

In the presence of a not very strong overlap, it is better to give preference to aerated concrete, as it is highly durable, but at the same time very light. With its help, it will be possible to build a structure of any shape and size. Further finishing of the fireplace involves its plastering and cladding with ceramic tiles, natural or artificial stone.

The blocks are interconnected with a special adhesive mixture or a conventional sand-cement mortar. To level the surface, it is required to apply a layer of putty, up to two centimeters thick.

A heat-insulating layer should be laid on the base under the firebox, in the form of asbestos cardboard or steel roofing metal.

Tip: When choosing a place to install a fireplace, take into account the fact that there must be space between the firebox and the fireplace wall for installing a system that provides convection heating. In this case, the length of the chimney must be such as to bring this system to the outer part of the building.

To ensure the correct installation of the firebox, it is necessary to put wooden blocks in place for its installation, with the help of which the firebox will be leveled. After the installation work, the bars are removed. A metal sleeve or pipe is used as a chimney. They must be installed in a specially made hole through which the pipe is brought out into the street. In carrying out this process, all fire safety rules should be taken into account.

Please note: There are several limits on vertical deflection of the chimney. With a total pipe length of less than 500 cm, the maximum deviation should not exceed forty-five degrees, with a length of more than 500 cm, no more than twenty degrees.

To facilitate the finishing of the fireplace, it is necessary to build a frame on which any of the finishing materials will be attached, for this a series of actions should be performed:

- use a thin-walled steel profile or corners, use metal screws to connect them;

- thermal insulation is attached to the inside of the frame, and sheathing is attached to the outer;

- as thermal insulation, it is recommended to use heat-insulating mats, fasten them in such a way that the side with the presence of the foil faces the firebox;

- any material is used for sheathing the frame, in the form of drywall, wood, asbestos-cement slabs;

- the thermal insulation of the cladding must have holes in order for the heat from the fireplace to enter the room.

Options for finishing fireplaces for wood-burning cottages

1. An excellent option for decorating a fireplace that will fit into any style of interior is wood. Please note that wood requires pre-treatment with fire protection. The best option is to use MDF. The firebox in this case is equipped with a protective screen that protects the tree from possible ignition. The fireplace portal should be 10-12 cm larger than the firebox itself, this will help prevent it from heating up.

2. A tile is distinguished by a wealth of colors and shapes. Glazed tiles, terracotta tiles or porcelain tiles can be used to finish the fireplace.

3. Using tiles will give the fireplace a luxurious look. In appearance, they resemble tiles, and differ from it in textured surface and heavy weight. Technology and installation require their fastening with metal wire.

4. Heat-resistant mosaic is a great option for decorating a fireplace portal. With its help, it is possible to create incredible drawings that will complement any type of interior.

5. Marble, drywall, decorative plaster - perfectly decorate the surface of the fireplace. In this matter, fantasy is limitless. The main condition is the use of heat-resistant and fireproof materials.