Columnar foundation of asbestos-cement pipes. Do-it-yourself foundation from asbestos-cement pipes The diameter of the asbestos pipe for the foundation

The foundation is the base of the structure. The life of the entire building will depend on the strength of this structure. In fact, this is the main element of any building, because in the event of its drawdown or movement, a number of negative factors may appear:

- swelling of the floors;

- impossibility of closing doors;

- general skew of the structure;

- house destruction.

Your attention is presented to the material on how to make a thoughtfully and reliably columnar foundation from asbestos pipes.

The positive aspects of the use in the construction of asbestos-cement pipes

- Ease of installation. Complete exclusion of special construction equipment.

- Democratic cost of materials.

- Work can be carried out in the shortest possible time.

- Possibility of construction even in flooded areas.

- Long service life.

- Reality of carrying out calculations independently.

Professionals unanimously argue that making a foundation from asbestos pipes with your own hands is not particularly difficult. However, it should be taken into account that during the construction of a pile foundation, the possibility of building a basement is lost. In addition, using this construction technique, it must be taken into account that the floors under the building need thorough insulation and wind protection.

Professionals unanimously argue that making a foundation from asbestos pipes with your own hands is not particularly difficult. However, it should be taken into account that during the construction of a pile foundation, the possibility of building a basement is lost. In addition, using this construction technique, it must be taken into account that the floors under the building need thorough insulation and wind protection.

It should also be noted that the pile foundation can show itself extremely negatively on moving soils. But such a moment can most often be manifested when asbestos pipes were installed contrary to current building codes.

Asbestos-cement foundation is very often used for buildings that have a frame, which are made of timber, wood, arbolite and other alternative light types of materials: baths, verandas, utility blocks, gazebos, change houses, etc. In addition, using a grillage, you can combine the material with a slab or concrete tape. The scope of the foundation of asbestos-cement pipes with their own hands is very extensive, it is erected in areas where flooding occurs, there are strongly heaving soils, and also where the soil can freeze by more than one and a half meters.

Carrying out calculations

To carry out the necessary calculations, you need to know two main parameters:

- Soil freezing temperature.

To determine the freezing of the soil, you can use the reference information. The relevant sources contain data on soil freezing without snow cover. In addition, if the level of snowfall is high enough, the figure given in the guide can be slightly underestimated.

You can add a value from 0.3 to 0.5 meters to the reference data - this indicator will indicate the correct depth of the underground part of the piles. Note that their bases should be visible above the ground, approximately 30 cm, however, with the risk of flooding, this figure can be increased by a few centimeters.  Asbestos-cement pipes for the foundation usually have a diameter that correlates with the weight of the future building. For log buildings, a volume of 20-30 cm is best suited, while for small arbors, the diameter of pipes can be as low as 7 cm.

Asbestos-cement pipes for the foundation usually have a diameter that correlates with the weight of the future building. For log buildings, a volume of 20-30 cm is best suited, while for small arbors, the diameter of pipes can be as low as 7 cm.

The load on the structure under construction will depend on the complexity of the structure of the structure and the material from which it will be made. To carry out calculations, it is necessary to take into account not only the walls, but also the roof, decoration and insulation.

The existing piles are placed along the perimeter of the structure, as well as at its corners and at the intersections of the bearing walls. Their distance should be no more than one meter. Approximate load per pile should average 800 kg. If the resulting weight is higher than the specified value, the number of piles should be increased.

At the end of the actions taken, the required number of pipes and fittings becomes known. The calculation should be made according to the following principle - 2-3 reinforcement bars for each asbestos pipe.

Foundation production step by step instructions

So, there is material, desire and willingness to make the foundation of asbestos-cement pipes with your own hands. Let's consider step by step how to build this structure correctly:

- Design. The construction of frame structures belongs to the group of simple works. So, the mass of a one-story cottage averages 8 tons. This means that for such a foundation it is necessary to use 10 supports, the cross section of which will be equal to 20 cm. Ready-made project documentation can be found on the vastness of the global network, however, as an alternative, it can be ordered from specialists. To date, the statistics of ongoing work on the construction of private houses shows that most customers want an individual construction project.

- Site preparation followed by marking. To prepare the site for the appropriate construction activities, the following steps must be followed:

- clear the area of stones and trees;

- mark the corner marks of the foundation - dig in metal rods or wooden posts with a rope stretched over them;

- retreat two meters from the possible border of the foundation under construction and designate the area from which it will subsequently be necessary to remove fertile soil (more than 30 cm). Such manipulation is necessary so that later weeds do not germinate from under the building;

- remove the turf, level the site and fill it with sand and gravel. Tamp the site.

- Drilling wells for supports. In the case of independent work on the construction of a structure made of asbestos pipes, it is allowed to use an ordinary garden drill. It is common for teams of specialists from construction companies to use special equipment (automatic motor or pit drills). The diameter of the well for the support should exceed its volume by 10-12 cm. In turn, the depth should be 20 cm more than the intended pile height. This approach is necessary for the manufacture of a special foundation "cushion" from building materials of non-metallic rocks.

- Preparatory work on the construction of a columnar foundation from asbestos pipes and the installation of these pipes. The bottom of the prepared well is carefully covered with rubble and sand, methodically compacted and filled with water. The top layer is covered with waterproofing - it can be a film or roofing material. Supports are immersed in the pit and fixed with slats. The base is filled with sand. The length of the pillars should have a margin of length a little more than 10 cm; later, thanks to this technique, you can easily equalize the height of any support. If the soil has high humidity, it is recommended to treat all pipes with a special bituminous or polymer-based solution.

- Concreting and reinforcement. The prepared concrete mixture is poured into asbestos pipes by 30–40 cm. Further, the supports must be raised by 20 cm and fixed. In a similar way, we get a kind of concrete sole, through which the pillars will be more stable.

- Final stage. After the concrete layer has hardened, a reinforcing cage is installed in the pipe, which is connected by wire jumpers or transverse frames made of thin reinforcement. Next, the solution is poured to the required level. To remove the air bubbles that have appeared, you can use a wooden rail or a metal rod. The top layer is covered with a cellophane film to achieve uniform drying of the concrete solution. The drying period must be at least 21 days.

Do-it-yourself pile foundation from pipes

The foundation is the foundation of the building, the durability of the structure depends on its strength. In fact, it is the main supporting structure of the structure, its movements or subsidence lead to distortions of the building structure, the floors begin to swell and the doors stop closing, and, in the worst case, the house can simply collapse . How to build an inexpensive and reliable columnar foundation from reliable asbestos pipes, we propose to consider in this article.

Diagram of a columnar foundation made of pipes

It should be noted that it is in recent years that this type of foundation of the house has become especially popular.

Advantages and disadvantages of a pile foundation

The foundation for a house made of asbestos-cement pipes is financially beneficial and reliable enough for the construction of light buildings and auxiliary structures such as log or frame houses, baths, outbuildings. To build a columnar foundation from asbestos pipes, you will need the pipes themselves, a garden drill, a concrete mixer (it can be rented during construction), several bars of corrugated reinforcement, sand and cement. Due to the complexity of execution, it is quite possible to build it with your own hands.

The following can be said about the advantages of such a foundation:

Asbestos pipes do not require large expenditures, are quickly built, protect against moisture

Asbestos pipes do not require large expenditures, are quickly built, protect against moisture

- compared to monolithic solutions, the foundation of asbestos-cement pipes for a house will cost half as much and require half the effort and time;

- digging a foundation pit for such a foundation is not necessary;

- a pile foundation made of asbestos-cement pipes is built very quickly, after completion of work, you can immediately start building a house, saving up to two weeks compared to a monolithic foundation;

- the height of such a foundation above the ground is usually at least 30 cm, which will prevent water from entering the house during showers and floods, and if floods have ever occurred in the area, the piles can be raised even higher;

- on the foundation of asbestos-cement piles, it is much easier to bring communications to the house - water supply, sewerage, gas supply, and so on.

The application of such grounds is limited by the following factors:

- such structures are applicable only if structures of limited mass are placed on them;

- the duration of the safe operation of pile foundations made of asbestos-cement piles is limited to 80 years;

- in houses on such foundations it is almost impossible to arrange a basement;

- the foundation of a house from asbestos-cement piles is impossible in places with floating soils.

For these purposes, other materials, in particular metal or plastic products, are quite applicable. However, they also have inherent disadvantages. Metal pipes corrode and are more expensive, while plastic pipes have limits on the effect of negative temperatures.

Asbestos-cement pipes have the lowest coefficient of thermal expansion, which ensures the stability of the foundation during operation.

How to make a foundation

When starting construction, you need to take a number of mandatory actions so that the work is not done in vain:

- Find out the quality of soils at the construction site in order to exclude falling on floating soils.

- Specify the depth of soil freezing in a given area, the depth of immersion of piles from asbestos-cement pipes depends on this.

- Calculate the size of the pile, taking into account the maximum redistributed load on the pipe of 800 kg. If the design load is greater, you need to increase the number of intermediate piles.

Calculation of a columnar foundation from pipes

Calculation of a columnar foundation from pipes

Work order

Grill foundations

If it is necessary to strengthen pile foundations, a structural element called a grillage is used. This term refers to a concrete slab or beam that is laid on top of the vertical supports of the foundation.

Types of grillages

Types of grillages

- High- the supporting element is located above the soil surface, it is used in areas with a high location of groundwater.

- Short- it is used at a deep location of soil and in areas with a small depth of soil freezing.

- An elevated grillage is called a supporting element, located at ground level. It is carried out by making formwork, reinforcement and continuous pouring with concrete. The most durable foundation for low-rise and larger construction, as the support turns into a monolithic structure.

Types of grillages according to the materials used:

- Wood- a grillage made of timber, used for the construction of houses made of wood, baths, outbuildings. Easy to do by hand. Needs high-quality protection of wood from rotting and pests.

- Steel- made of steel structures, bars and screw piles. It is used in lightweight construction, it is durable and stable. The disadvantage is susceptibility to corrosion.

- Monolithic- a system of elements from asbestos-cement piles and a cast concrete supporting surface, combining all the components of the structure into a single whole. The most reliable and durable type of pile foundations.

Types of grillages by materials

Types of grillages by materials

If you want to make a foundation for a country house with your own hands, pay attention to the methods described here. You will get a foundation of sufficient strength at low cost. I wish you success!

Asbestos pipe foundation: manufacturing technology

The foundation of asbestos pipes is erected during the construction of light structures. We will tell you how to lay the foundation of asbestos pipes with your own hands

The foundation is the base of the structure. The life of the entire building will depend on the strength of this structure. In fact, this is the main element of any building, because in the event of its drawdown or movement, a number of negative factors may appear:

The foundation is the base of the structure. The life of the entire building will depend on the strength of this structure. In fact, this is the main element of any building, because in the event of its drawdown or movement, a number of negative factors may appear:

- swelling of the floors;

- impossibility of closing doors;

- general skew of the structure;

- house destruction.

Your attention is presented to the material on how to make a thoughtfully and reliably columnar foundation from asbestos pipes.

The positive aspects of the use in the construction of asbestos-cement pipes

- Ease of installation. Complete exclusion of special construction equipment.

- Democratic cost of materials.

- Work can be carried out in the shortest possible time.

- Possibility of construction even in flooded areas.

- Long service life.

- Reality of carrying out calculations independently.

Professionals unanimously argue that making a foundation from asbestos pipes with your own hands is not particularly difficult. However, it should be taken into account that during the construction of a pile foundation, the possibility of building a basement is lost. In addition, using this construction technique, it must be taken into account that the floors under the building need thorough insulation and wind protection.

Professionals unanimously argue that making a foundation from asbestos pipes with your own hands is not particularly difficult. However, it should be taken into account that during the construction of a pile foundation, the possibility of building a basement is lost. In addition, using this construction technique, it must be taken into account that the floors under the building need thorough insulation and wind protection.

It should also be noted that the pile foundation can show itself extremely negatively on moving soils. But such a moment can most often be manifested when asbestos pipes were installed contrary to current building codes.

Asbestos-cement foundation is very often used for buildings that have a frame, which are made of timber, wood, arbolite and other alternative light types of materials: baths, verandas, utility blocks, gazebos, change houses, etc. In addition, using a grillage, you can combine the material with a slab or concrete tape. The scope of the foundation of asbestos-cement pipes with their own hands is very extensive, it is erected in areas where flooding occurs, there are strongly heaving soils, and also where the soil can freeze by more than one and a half meters.

Carrying out calculations

To carry out the necessary calculations, you need to know two main parameters:

- Soil freezing temperature.

To determine the freezing of the soil, you can use the reference information. The relevant sources contain data on soil freezing without snow cover. In addition, if the level of snowfall is high enough, the figure given in the guide can be slightly underestimated.

You can add a value from 0.3 to 0.5 meters to the reference data - this indicator will indicate the correct depth of the underground part of the piles. Note that their bases should be visible above the ground, approximately 30 cm, however, with the risk of flooding, this figure can be increased by a few centimeters.

Asbestos-cement pipes for the foundation usually have a diameter that correlates with the weight of the future building. For log buildings, a volume of 20-30 cm is best suited, while for small arbors, the diameter of pipes can be as low as 7 cm.

Asbestos-cement pipes for the foundation usually have a diameter that correlates with the weight of the future building. For log buildings, a volume of 20-30 cm is best suited, while for small arbors, the diameter of pipes can be as low as 7 cm.

The load on the constructed structure will depend on the complexity of the structure of the structure and the material from which it will be made. To carry out calculations, it is necessary to take into account not only the walls, but also the roof, decoration and insulation.

The existing piles are placed along the perimeter of the structure, as well as at its corners and at the intersections of the bearing walls. Their distance should be no more than one meter. Approximate load per pile should average 800 kg. If the resulting weight is higher than the specified value, the number of piles should be increased.

At the end of the actions taken, the required number of pipes and fittings becomes known. The calculation should be made according to the following principle - 2-3 reinforcement bars for each asbestos pipe.

Foundation production step by step instructions

So, there is material, desire and willingness to make the foundation of asbestos-cement pipes with your own hands. Let's consider step by step how to build this structure correctly:

- Design. The construction of frame structures belongs to the group of simple works. So, the mass of a one-story cottage averages 8 tons. This means that for such a foundation it is necessary to use 10 supports, the cross section of which will be equal to 20 cm. Ready-made project documentation can be found on the vastness of the global network, however, as an alternative, it can be ordered from specialists. To date, the statistics of ongoing work on the construction of private houses shows that most customers want an individual construction project.

- Site preparation followed by marking. To prepare the site for the appropriate construction activities, the following steps must be followed:

- clear the area of stones and trees;

- mark the corner marks of the foundation - dig in metal rods or wooden posts with a rope stretched over them;

- retreat two meters from the possible border of the foundation under construction and designate the area from which it will subsequently be necessary to remove fertile soil (more than 30 cm). Such manipulation is necessary so that later weeds do not germinate from under the building;

- remove the turf, level the site and fill it with sand and gravel. Tamp the site.

- Drilling wells for supports. In the case of independent work on the construction of a structure made of asbestos pipes, it is allowed to use an ordinary garden drill. It is common for teams of specialists from construction companies to use special equipment (automatic motor or pit drills). The diameter of the well for the support should exceed its volume by 10-12 cm. In turn, the depth should be 20 cm more than the intended pile height. This approach is necessary for the manufacture of a special foundation "cushion" from building materials of non-metallic rocks.

- Preparatory work on the construction of a columnar foundation from asbestos pipes and the installation of these pipes. The bottom of the prepared well is carefully covered with rubble and sand, methodically compacted and filled with water. The top layer is covered with waterproofing - it can be a film or roofing material. Supports are immersed in the pit and fixed with slats. The base is filled with sand. The length of the pillars should have a margin of length a little more than 10 cm; later, thanks to this technique, you can easily equalize the height of any support. If the soil has high humidity, it is recommended to treat all pipes with a special bituminous or polymer-based solution.

- Concreting and reinforcement. The prepared concrete mixture is poured into asbestos pipes by 30–40 cm. Further, the supports must be raised by 20 cm and fixed. In a similar way, we get a kind of concrete sole, through which the pillars will be more stable.

- Final stage. After the concrete layer has hardened, a reinforcing cage is installed in the pipe, which is connected by wire jumpers or transverse frames made of thin reinforcement. Next, the solution is poured to the required level. To remove the air bubbles that have appeared, you can use a wooden rail or a metal rod. The top layer is covered with a cellophane film to achieve uniform drying of the concrete solution. The drying period must be at least 21 days.

The foundation of asbestos-cement pipes for a country house

Foundation of asbestos-cement pipes: the advantages of using a columnar foundation, step-by-step instructions for the production of the foundation

Pillar foundation made of asbestos pipes

What is attractive about a columnar foundation made of asbestos pipes? Asbestos-cement pipes are an excellent casing for bored piles. From an economic point of view, a pile from an asbestos-cement pipe, in terms of its bearing capacity and cost, is beneficial in the use of a foundation foundation for light structures (wooden, frame and foam block houses) and auxiliary buildings (garages, sheds, warehouses, barns). The simplicity of the pile foundation makes it possible to build a foundation from asbestos-cement pipes with your own hands. How to do it better will be discussed in this article.

Foundation device diagram

A do-it-yourself columnar foundation of asbestos-cement pipes is erected according to the following scheme:

- pillars in height can be placed protruding above the ground or being level with the ground;

- a grillage is installed on asbestos cement supports;

- a grillage for a wooden panel house is prepared from a wooden beam; under the foundation of the house from foam blocks, reinforced concrete beams are laid on asbestos-cement pipes.

Preparatory activities

Before you make a pile foundation, you need to perform a number of actions:

- Make sure there are no floating soils on the construction site.

- Determine the depth of soil freezing and the level of groundwater;

- Calculate the dimensions of the piles, taking into account the load on each support of not more than 800 kg.

- Align the maximum load on the pile by increasing the number of pillars.

Necessary tools and materials

To build a foundation of asbestos-cement pipes, you will need the following tools and materials:

- cement, sand, crushed stone, water;

- asbestos cement pipes;

- concrete mixer or container for batching;

- garden drill;

- fittings;

- trench tool.

Pile foundation installation technology

A step-by-step guide is necessary to ensure that the installation of a columnar foundation from asbestos-cement pipes is carried out correctly. Having developed instructions on how to build a pile foundation, proceed to the following steps:

- Based on the calculations, they draw up a plan-scheme for the location of the pillars.

- On the site, markings are made of the points where asbestos cement supports will be installed.

- A garden drill drills holes in the ground. The bottom of the pit should be 300 mm below the freezing level of the soil. The diameter of the holes is made larger than the transverse dimension of the asbestos pipes by 50 mm.

- The wide opening makes it possible to adjust the vertical position of the pipe. This is done using different vertical spacers.

- Asbestos pipes are inserted into the wells. A columnar foundation is erected from asbestos pipes with a diameter of 250 mm. This size is the most optimal to ensure the desired bearing capacity of the supports.

- A layer of sand is poured at the bottom of the holes and then it is rammed. The compacted sand cushion should be 150-200 mm thick.

- Vertical reinforcement is lowered into the pipes. Usually it is 3-4 rods. To fix the metal segments, they are interconnected with a wire.

- The cement-crushed stone mixture is laid in layers with a thickness of 200-300 mm. After laying the next layer of concrete, it is compacted with a rammer or vibrator.

- After 3 - 4 weeks, they begin to install the grillage and build the walls of the building.

- The sinuses around the piles are filled with soil and carefully rammed.

In order to more strengthen the foundation of asbestos pipes with their own hands, they make an expansion of the base of the drilled wells.

House on the basis of asbestos pipes

House on the basis of asbestos pipes

Well base expansion

To make the extension of the bases with your own hands, the garden drill is equipped with a home-made device:

- a metal spatula is installed on a vertical stand of a garden drill; the blade handle is attached in such a way that the cutting blade can move up and down;

- having drilled the earth to the desired depth, the blade is gradually raised to the level of the horizon; the removal of the cutting blade will be greater than the radius of the drill by 100 mm;

- as a result, a broadening of the base of the well is formed; this cavity is filled with concrete; it turns out a widened concrete heel, on which asbestos pipes are installed.

The device of a concrete heel does not cause any particular difficulties, but it significantly increases the bearing capacity of the columnar foundation.

Advantages and disadvantages of an asbestos columnar foundation

The attractiveness of the device pile foundation of asbestos pipes can be explained by the following reasons:

- The speed of construction of the pile foundation.

- A columnar foundation made of pipes will cost half as much as a monolithic concrete tape.

- A small amount of earthworks.

- The height of the grillage of such a foundation above ground level is usually about 300 mm. This protects the house from flood waters and moisture penetration from the ground.

- The gap between the soil base and the house allows you to easily bring communications for various purposes (sewerage, water supply, etc.).

The disadvantages of columnar supports are much less than the advantages:

- This type of foundation is not intended for the construction of structures from heavy structures.

- The designers have set a deadline for this type of foundation - 80 years. Although it is worth noting that over such a period the building itself will become obsolete and will become completely unusable.

- Since columnar supports are installed on soft soils, the construction of the building does not allow for the construction of a basement.

From the foregoing, we can conclude that the construction of such a pile foundation is beneficial both from a practical point of view and from the side of saving financial costs.

Do-it-yourself foundation from asbestos-cement pipes

What is attractive about a columnar foundation made of asbestos pipes? Asbestos-cement pipes are an excellent casing for bored piles.

Foundation from asbestos-cement pipes

One of the most popular columnar foundation designs is the foundation of asbestos-cement pipes. This technology is used in the construction of light buildings and frame houses, and its implementation requires a minimum of funds and effort. In addition, the foundation of asbestos-cement pipes is used in regions prone to flooding - the foundation material has the necessary strength and resistance to wetting and destruction.

Foundation from asbestos-cement pipes

Advantages of the foundation of asbestos-cement pipes

- Ease of implementation, eliminating the need to attract special construction equipment;

- Short deadlines for work and endurance;

- A simple calculation of the foundation, which you can do yourself, without contacting the design organization.

- Possibility of construction and long-term operation of buildings in flooded areas;

- Low price for materials.

Scope of columnar foundations

Pillar foundations made of asbestos-cement pipes are used as a basis for the construction of light buildings: summer cottages, small baths and saunas, terraces and verandas, as well as lightweight frame houses. In regions with a cold climate, such a foundation allows significant savings, because the deepening of free-standing pipes is much cheaper in terms of materials and the cost of work than a buried strip or block foundation.

Calculation of the foundation of asbestos pipes

To calculate, you need to know the depth of soil freezing in your area, as well as the planned load on the foundation. The depth of freezing can be determined from reference data. The reference book indicates the depth of freezing of bare soil, without snow cover. If your area has high snow cover, the reference data can be slightly reduced.

Table - the depth of soil freezing in the regions of Russia

It is necessary to add 0.3-0.5 meters to the reference value - this will be the required depth of the underground part of the piles. Pipe piles usually protrude 0.3 meters above the soil level, but if there is a possibility of flooding, they can be made even higher.

The diameter of the pipes depends on the weight of the building. For light gazebos, pipes with a diameter of 10 cm are sufficient; for log buildings, it is better to choose pipes with a diameter of 25-30 cm.

The load on the foundation depends on the design of the building, as well as on the material from which it is made. Below are approximate information about the specific gravity of various materials. When calculating, it is necessary to take into account not only the walls, but also the roof, insulation and decoration.

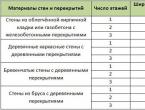

Table - foundation loads

Piles are located at the corners of the building, at the intersection of load-bearing walls, as well as along the perimeter at a distance of no more than 1 meter. The redistributed load on each pile should be no more than 800 kg. If, as a result of the calculation, the load value turned out to be greater, it is necessary to increase the number of piles.

Based on the results obtained, the required number of pipes is determined, as well as the required amount of reinforcement at the rate of 2-3 reinforcing bars in each pipe.

The amount of concrete depends on the diameter of the pipe. On average, to fill 10 meters of a pipe with a diameter of 10 cm, it is necessary, taking into account the base, 0.1 cubic meters of concrete, for a pipe with a diameter of 20 cm - 0.5 cubic meters, and for a pipe with a diameter of 30 cm - 1 cubic meter of concrete.

The technology of making a pile foundation from asbestos-cement pipes

- Preparation must begin with markup. Remove debris and foreign objects from the construction site, level it if possible and remove the sod. Mark with the help of pegs and rope the contours of the future building, corners, intersections of walls. Mark the places of installation of piles with pegs. To check the perpendicularity of the corners and the correct marking, check the equality of the diagonals.

- Wells are being drilled for support poles. This can be done with a drill, and in its absence, you can dig holes with a diameter greater than the diameter of the pipes. The depth of the well is 20 cm more than the estimated size of the underground part of the piles, which is necessary for the installation of a sand cushion.

The process of drilling a well under a pile

- A sand cushion 20 cm thick is arranged at the bottom of each well, compacted and spilled with water. After soaking up the water, the bottom is lined with roofing material. After that, prepared pipes are installed in the well. If the pipes have to be cut to the required size, it is necessary to leave a margin of about 10 cm in height in order to even out the height of the supports after the foundation has been completed.

The process of installing supporting asbestos-cement pipes

- The pipes are leveled, fixed with temporary supports made of wooden blocks. Once again check the equality of the diagonals. In areas with a close occurrence of groundwater, pipes are waterproofed with mastic based on bitumen to the ground level. Dry the mastic.

The process of leveling asbestos-cement pipes using wooden formwork

- Concrete is prepared: 1 part of cement is mixed with 2 parts of sand, diluted with water to the consistency of batter, after which 2 parts of fine gravel are poured into the resulting solution. Mix well and fill the base of the pipe by 40-50 cm.

- The pipe is raised by 15-20 cm and left until the concrete has completely solidified. This technique will help create a solid support base that is resistant to buoyancy forces during soil heaving.

- After the concrete has hardened, the well from the outside of the pipe is additionally waterproofed with roofing material and covered with river sand, spilled and rammed, checking the installation for level. Stretch a string between them or install a bar and align them horizontally.

The foundation of asbestos-cement pipes is ready

- Reinforcement is installed inside the pipe: several bars interconnected by transverse wire jumpers. Concrete is mixed and the rest of the pipe is poured. To remove air from the solution, pierce it several times with a metal bar.

- After the concrete has completely dried, after two to three weeks, the foundation is ready for further construction. In order to extend its service life, it is recommended to waterproof it with bituminous or polymeric materials.

The construction of a pile foundation made of asbestos-cement pipes makes it possible to reduce the cost of building a solid foundation for a building by several times. However, with too much load, such a foundation may not be strong enough. In this case, it is better to choose a different type of foundation, tape or monolithic.

Asbestos-cement pipe foundation - unique and detailed technology

Learn more about the Foundation of asbestos-cement pipes, detailed design technology + step-by-step guide and photos will help you figure it out.

You can build it yourself, but before starting work, you need to consider all the features of this type of foundation, as well as learn in detail about the process technology. This type of foundation acts as a good alternative to a strip, monolithic or slab foundation. Such a foundation, as a rule, is used in the construction of structures that are insignificant in mass. In addition, the work will not be accompanied by too high costs. It should be noted that this type of foundation is almost indispensable when it comes to frame houses or outbuildings. But one cannot ignore the fact that it has certain disadvantages, one of which is expressed in the fact that the building cannot have a basement or basement.

Construction features

The foundation of asbestos-cement pipes does not involve the use of heavy equipment. The foundation, which is based on supports, can be made in one of two ways. The first involves the use of finished piles. But in private housing construction, this method is of little use, due to the need to rent specialized equipment. The second method involves the manufacture of pillars directly in the soil. In this case, it is necessary to pour the solution into the formwork, which is formed in a previously dug hole in the ground. In the role of formwork, various structures are used, among which there may be wooden panels.

The foundation of asbestos-cement pipes is quite easy to equip also for the reason that the pipes that are used as formwork are very light in weight. Using such products, you get a guarantee that the concrete will not be exposed to water. In addition, the supports are not afraid of external damage, because asbestos-cement pipes have a fairly impressive margin of safety. All these qualities make them ideal for arranging fixed formwork. You can choose pipes of the desired diameter for construction.

The foundation of asbestos-cement pipes can be erected on a territory that is characterized by uneven terrain. Moreover, a high percentage of soil moisture is allowed. It is important to take into account the weight of the future structure before starting construction, since with an impressive mass, the number of supports should be increased.

Foundation technology

Initially, all calculations have to be made, the implementation of which is preferable to entrust professionals. When determining the number of pillars, it must be taken into account that the largest step between the supports should not be more than 2.5 m. The next step is to proceed to the preparation of the territory on which construction will be carried out. The soil must be free from debris and foreign objects. We have to get rid of the fertile soil layer. After that, the land, as a rule, is transferred to another part of the site so that it does not act as an obstacle during the work.

Before asbestos-cement pipes, it is necessary to mark the base. At the same time, it is important to check how correctly the corners are set, for which you have to pull a fishing line or a special marking cord. This must be done not only along the sides of the base, but also along the diagonals, while it is important to ensure that a perfect rectangle is obtained. Only after that it is possible to start work on which the supports will be installed.

In order to equip a columnar foundation of asbestos-cement pipes, it is necessary to prepare wells that are drilled through, however, the TISE tool can also be used. If it is planned to carry out work in areas with difficult soil, then it is worth using a drilling rig, which will have to be rented. It must be remembered that this approach will increase the cost of the work. It is necessary to deepen the supports below the soil freezing line.

Pillow arrangement

Before installing asbestos-cement pipes under the foundation, it is necessary to prepare the bottom of the well, for which a sand cushion is poured there. It is necessary to pour so much that after tamping a layer is obtained, the thickness of which is approximately 20 cm. In order to make the pillow easier to tamp, it is necessary to spill it with water. If the work is carried out on excessively weak soils, then a concrete support can be created at the bottom of the well, however, its diameter should be somewhat wider compared to this characteristic of an asbestos-cement pipe. In order to provide insulation, it is recommended to lay a layer of dense polyethylene at the bottom of the well, this will eliminate the possibility of moisture escaping into the soil from the concrete solution.

Pipe installation

When you mount the foundation on asbestos-cement pipes with your own hands, the next step is to proceed with the installation of asbestos-cement pipes. It is necessary to install the element strictly in a vertical position, for this you have to use spacers. It is imperative to analyze the evenness of the installation of pipes, using the building level for this.

Reinforcement

The support must be strengthened; for this, a reinforcing frame made of bars must first be prepared. Horizontal and vertical belts are required. After the fittings can be lowered into the pipe. If it is planned to build a horizontal strapping, then the reinforcing rods must be brought out to connect with the grillage reinforcement.

Pouring concrete

After that, you can start pouring, this must be done in layers, so that it is possible to eliminate air. The space obtained between the pipe and the well must be covered with sand and carefully compacted. The upper part of the pipe must be cut to the level, after which you can proceed with the installation of the head and laying the waterproofing. If it is assumed that there is a grillage, then the next step is to deal with it.

In this article, we will consider a columnar foundation made of asbestos-cement pipes. They are also called a / c pipes or asbestos pipes. This type of fixed formwork is very popular due to its numerous advantages, which we will discuss in this article.

Advantages of a columnar foundation made of asbestos pipes

- Formwork from asbestos-cement pipes together with poured concrete create a solid structure.

- High strength, frost resistance.

- Resistance to aggressive environments.

- Unlike roofing formwork, they have high rigidity. No formwork deformation during concrete pouring.

- They have a smooth outer surface.

Flaws

- More expensive than roofing felt formwork, but this disadvantage pays off with a large list of advantages.

Composition and types of a / c pipes

Composition of a / c pipes: asbestos (15%) + Portland cement (85%) + water.

Varieties: Asbestos pipes are available in 2 types: pressure and non-pressure.

Non-pressure a/c pipes are designed to create networks of non-pressure sewerage, ventilation, etc., where the transported medium is supplied without pressure. They are labeled BNT.

Pressure a / c pipes are more durable and are used in conditions of high pressure (6-9 atm). VT marking.

Average prices for asbestos-cement pipes (St. Petersburg)

Non-pressure asbestos-cement pipes

| Length, mm | External diameter D, mm | Inner diameter d, mm | Weight, kg | Price, rub./pc. | |

|---|---|---|---|---|---|

A / c pipe BNT-100 |

3950 | 118 | 100 | 24 | 360 |

A / c pipe BNT-150 |

3950 | 161 | 141 | 37 | 580 |

A / c pipe BNT-200 |

3950 | 211 | 189 | 64 | 1210 |

A / c pipe BNT-200 |

5000 | 204 | 184 | 74 | 1310 |

A / c pipe BNT-250 |

5000 | 252 | 228 | 94 | 1780 |

A / c pipe BNT-300 |

5000 | 295 | 269 | 121 | 2560 |

A / c pipe BNT-400 |

5000 | 388 | 356 | 199 | 4000 |

A / c pipe BNT-500 |

5000 | 508 | 454 | 359 | 7600 |

Pressure asbestos-cement pipes

| Asbestos-cement non-pressure pipe | Length, mm | External diameter D, mm | Inner diameter d, mm | Weight, kg | Price, rub./pc. |

|---|---|---|---|---|---|

A/c pipe d 100 W-9 |

3950 | 122 | 100 | 45 | 760 |

A/c pipe d 150 W9 |

3950 | 168 | 141 | 67 | 1110 |

A/c pipe d 200 W-6 |

5000 | 224 | 200 | 123 | 1670 |

A / c pipe d 200 W-9 |

5000 | 224 | 196 | 142 | 2010 |

A/c pipe d 300 W-6 |

5000 | 324 | 292 | 199 | 3190 |

A / c pipe d 300 W-9 |

5000 | 324 | 286 | 217 | 3970 |

A/c pipe d 400 W-6 |

5000 | 427 | 385 | 333 | 5310 |

A/c pipe d 400 W-9 |

5000 | 427 | 377 | 390 | 6570 |

A/c pipe d 500 W-9 |

5000 | 528 | 466 | 637 | 7550 |

Based on these tables with prices, two conclusions can be drawn:

- There are pressure pipes, and they are more durable than non-pressure ones. In turn, they cost more. To build a foundation from asbestos pipes, it will be enough to take non-pressure pipes of a popular diameter of 150-250mm. We must not forget that the main role of fixed formwork is not a constructive function, but the formation of reinforced concrete piles.

- As you can see, the price of non-pressure a / c pipes is cheaper than PVC pipes for external sewage. But there is also a plus in the direction of PVC pipes, they have a higher range of lengths (1-6m), they are lighter, have a smoother outer surface, and the price of a pipe with a popular diameter of 200mm is almost the same as that of asbestos free-flow pipes.

Instructions for the construction of a columnar foundation from asbestos-cement pipes

Before proceeding with the marking of the site for the pillars, it is necessary to make calculations for the design of our foundation. It is necessary to determine the number of pillars and their location, determine the depth of drilling depending on the level of soil freezing.

4. We cut the a / c pipe to the length we need (above-ground part + underground part from the top of the soil to the top of the broadening). Then we attach the garbage bag to the bottom of our formwork with adhesive tape. The package will act as a barrier between the concrete and the soil during the formation of the widening. Basically, a barrier in the form of a package is needed if you have high groundwater and water begins to accumulate at the bottom of the well.

5. We form a reinforcing cage. The frame will consist of 4 bars of reinforcement with a diameter of 10-12mm. If you decide to also reinforce the widening at the bottom of the post, then the reinforcement is bent at the bottom in the form of the letter L. Then, when the reinforcing cage is inserted into the widening, you will need to unfold the reinforcement so that the bend looks at the edge of the widening. With this type of reinforcement, we make the frame weakly connected so that it is possible to rotate the reinforcement around its axis. (Below is a picture to make it clear.)

7. We insert the formwork from the a / c pipe into the well.

8. We form the broadening of the column. To do this, pour the first portion of concrete sufficient to fill the widening. Then we raise the post up so that the concrete fills the widening at the bottom of the well through the package. The last operation will be a slight indentation of the formwork down. Do not forget to vibrate or bayonet the concrete. You can bayonet with ordinary fittings.

All pillars should be at the same horizontal level. To do this, we beat off the level using a laser or hydraulic level. We stretch the twine according to the level. On it we will display all the pillars in one line. In order for the post not to sink into the widening, we will make a certain grip in the form of three bars fastened with a self-tapping screw on one side and tied with a rope on the other.

If it is difficult to set the formwork along the twine, then you can make it longer during the harvesting process and then cut all the piles into one level. The main thing is to make a mark on the formwork - to what level you will pour concrete.

9. We install the reinforcement cage in the formwork. The frame should be just below the edge of the formwork. Do not forget that in this example we have a columnar foundation for a timber strapping. If you have a pile-grillage foundation, then the reinforcing cage should be higher than the pillar.

10. To reinforce the heel of the column, unfold the reinforcement. The figure shows two reinforcing cages: without reinforcement of the column widening and with reinforcement.

11. Fill the column with concrete to the edge of the formwork. Do not forget to vibrate or bayonet the concrete to remove voids. Then, until the concrete has set, we fasten the anchor stud to connect the pole with the upper trim of the timber.

To calculate the composition of concrete, we suggest using our service:.

All. On this columnar foundation of asbestos pipes, we are ready. After pouring concrete, the end of the column must be covered with a film for the maturation of concrete. Do not forget also that all pillars must be made in the same level. www.site

Asbestos-cement pipes are in demand not only in the plumbing industry, they are also widely used as formwork in the construction of columnar foundations, the installation technology of which we will discuss in this article.

You will learn what are the advantages and disadvantages of a columnar foundation made of asbestos pipes, how it is calculated and built with your own hands.

Article content

Design features of the columnar foundation

The foundation of asbestos-cement pipes is a columnar base, which consists of two structural elements - support pillars (piles) and a grillage connecting them. Each component of the foundation performs different functions:

- the pillars transfer the load from the building to the deep layer of soil in which their supporting sole is located;

- the grillage acts as a bearing surface for the construction of the walls of the house and the laying of the basement slab, due to the binding of the piles, they receive additional resistance to pushing and overturning loads, since the connected pillars begin to work as a single structure.

The columnar foundation of asbestos pipes is equipped using pipes with a diameter of 300-500 mm. It is impossible to use supports of a smaller diameter for residential buildings; they are only suitable for the construction of technical buildings and heavy fences.

The length of the supporting pile is selected so that its end part (sole) is located 20-30 cm below the freezing level of the soil. Due to this arrangement, the piles receive protection from the pushing loads of heaving soil, which are the main cause of deformation of strip foundations. The depth of soil freezing differs for different regions, the generally accepted norm for the length of the pillars is 2.5-3 meters.

Four types of grillages can be used for tying poles - from a bar, a channel, an I-beam and a monolithic reinforced concrete tape. The best option for the construction of light buildings with your own hands (wooden and frame) is a timber frame, while heavy houses require a reinforced concrete grillage.

The classification of grillages is also carried out according to the location, according to which they distinguish:

- grillage of a raised type - the harness rises above ground level by 30-50 cm;

- grillage lying on the surface of the ground;

- grillage dug into the ground.

In conditions of heaving soil, it is necessary to make a columnar foundation of asbestos pipes tied with a raised grillage - such a harness is not subjected to push-out loads, while a grillage lying on the ground can be torn off the pile due to heaving forces.

Scope, advantages and disadvantages

The foundation from is intended for the construction of light buildings with a height of 1-2 floors. It can be used for the construction of houses from frame and panel panels, timber, log cabins and foam concrete. For heavy brick houses, a columnar foundation is not suitable, since its load-bearing capacity is not enough.

The advantages of a columnar foundation include:

- minimum cost;

- ease of arrangement - the entire cycle of work on the installation of the foundation can be done by hand, without the involvement of special equipment;

- operational terms of construction;

- sufficiently high stability on stable soils;

- the durability of monolithic pillars, if the technology of the support is observed, they will last more than 50 years.

However, there are a lot of disadvantages and a foundation made of asbestos-cement pipes. Firstly, this is a weak bearing capacity and problems with stability (they do not tolerate overturning loads from soil shifts), the inability to build on a slope (which allows a full-fledged pile foundation) and a limited scope.

In general, if you choose a foundation for a bathhouse, a technical building, or a small wooden house, a foundation made of asbestos-cement pipes is the best option that fully justifies its cost.

Features of the calculation of the foundation

Before proceeding with the construction of a columnar foundation with your own hands, it is necessary to perform its calculation, during which the number of supports in the foundation, their dimensions (diameter, length) and layout will be determined.

In order to perform calculations, you need to collect foundation loads (combined loads consist of house weight, snow pressure and operational loads) and obtain information about the characteristics of the soil at the site, which ideally requires surveying the site.

This is an expensive service (up to 30 thousand rubles), and if you are limited in the budget, you can use the tabular data, taking the bearing capacity (resistance force) for the type of soil prevailing in your area in the standards.

The calculation of the foundation of asbestos pipes is performed according to the following algorithm:

- Determine the mass of the building. It is necessary to multiply the area of the structural elements of the house (roof, basement and interfloor ceilings, and walls) by the specific gravity of the materials from which they are made.

- We determine the snow load. The weight of 1 m 2 of snow cover in your region (data are given in SNiP “Climatology of construction”) is multiplied by the roof area of \u200b\u200bthe house.

- We determine the operating loads. We multiply the floor area of \u200b\u200bthe house by the standard load of 100 kg / m 2.

- We calculate the total load. We summarize the data obtained and multiply them by 1.2 - the reliability coefficient.

- We calculate the number of supports in the foundation. We divide the total loads on the foundation by the load-bearing capacity of one support on the ground, determined using the above table.

It remains to draw up a diagram of the location of the supports in the foundation. Piles should be evenly placed along the perimeter of the walls of the house ( step 2-2.5 meters) and must be present at the junctions of the walls and at the corners of the building.

Columnar foundation of asbestos pipes (video)

The technology of erecting a columnar foundation

To install the foundation of asbestos pipes with your own hands, you will need a manual drill of the TISE-F type, with which boreholes for piles will be drilled. If you have mechanized equipment - a gas drill or a motor drill, you can use it, so the drilling stage will be completed much faster.

The supporting pillars are subject to reinforcement, which is carried out by means of 4-6 reinforcement bars connected to the frame with jumpers or a clamp. To reinforce the pillars, corrugated reinforcement with a diameter of 12-16 mm is used, the connecting elements are made of smooth reinforcement with a diameter of 8-10 mm, since it is easier to bend.

Do-it-yourself installation of the foundation from asbestos-cement pipes is carried out in the following sequence:

- The site is cleared of surface vegetation and debris. Boulders are removed from the site, tree roots are uprooted, and materials necessary for the work are brought in.

- The foundation is being marked out - it is necessary to transfer the design contours of the foundation (lines of the external and internal walls of the house) and the placement points of each pile to the site. For marking, cast-off shields or reinforcing pegs are used, between which a building cord is stretched.

- With the help of a hand drill, wells are being developed for supporting pillars. For drilling, a drill is used, the diameter of which corresponds to the cross section of those used, it must fit tightly into the well and, after installation, be clamped with soil layers. To facilitate the work, the handles of the drill can be extended with steel pipes, so you increase the leverage, thereby increasing the efficiency of drilling.

- Upon completion of drilling of all wells, asbestos pipes are installed in the cavity, then the reinforcement of the supports is carried out - a pre-assembled frame of reinforcement is installed inside the pipes. The length of the pipes is selected so that the level of grillage elevation provided for by the project is observed above the ground. Armoframe should not reach the end cut of the pipe by 5 cm, which is necessary for the formation of a protective layer of concrete.

- The concreting of the supports is carried out with a mixture of the M200-M300 brand. Concrete after pouring into asbestos-cement pipes must be bayoneted with a reinforcing bar to remove air cavities from it. When concreting into a pole, it is necessary to wall up a stud (a threaded rod) so that it protrudes from the pile by the thickness of the grillage.

- After the concrete has gained strength (it is required to wait a period of 10-15 days), the pillars are tied with a grillage (it is used beam with a section of 15 * 20 cm). The end parts of the pillars are covered with roofing material waterproofing and a timber fitted to the size is laid on them. Fixing the strapping is carried out using a stud and nut, under which it is necessary to pre-drill holes in the beam.

Do-it-yourself installation of a foundation made of asbestos pipes with your own hands is easy to perform and does not require large financial costs, as a result you get a reliable and durable foundation, ideal for the construction of light one-story buildings.