How important is foundation waterproofing? Waterproofing the foundation of a building (house) What to use to insulate the foundation

As the practical experience of users shows, it is not enough to build a strong house. In order for your home to become truly comfortable and serve you faithfully for many years, it must be protected from the damaging effects of groundwater and precipitation. And this requires reliable waterproofing.

So let's try to figure it out:

- For what ?

- What can lead to the failure of waterproofing?

- What is included in the package of measures for waterproofing a house?

- What are the types of modern waterproofing materials?

- In what cases should one or another type of waterproofing be used?

- How to protect waterproofing during backfilling?

- What areas need waterproofing?

- What is roof waterproofing and how is it done?

What is waterproofing for?

The main purpose of waterproofing is to protect buildings and structures from the negative effects of water. The purpose of waterproofing is to increase the life of the house and improve the quality of its operation.

Company director "Kalmatron-SPb"Elena Merzlyakova:

Company director "Kalmatron-SPb"Elena Merzlyakova:

- Waterproofing of a building cannot be done with any one material, even the best. Waterproofing is always a complex of measures.

For example, basement waterproofing might include:

- Waterproofing of floors and walls;

- Waterproofing of junction points;

- Waterproofing of technological seams of concreting;

- Waterproofing of expansion joints, places of input of communications and horizontal cut-off;

- The device of drainage ditches and blind areas.

The choice of technology and materials in each case is strictly individual and depends on the specific operating conditions of the object, its condition, location, and materials from which it is made.

Corporation Expert " TechnoNIKOL"Andrey Zubtsov:

- Water, penetrating into the underground part of the house, reduces its operational properties and worsens the microclimatic conditions in the premises located in the underground part of the structure.

In addition, water penetrating into building structures causes corrosion of reinforcement and destruction of concrete, which worsens the static properties of the structure and, ultimately, leads to its destruction.

In addition, water penetrating into building structures causes corrosion of reinforcement and destruction of concrete, which worsens the static properties of the structure and, ultimately, leads to its destruction.

Company technical specialist Sika Nikolai Mikhailov:

- Waterproofing, made only from the inside, removes the problem of dampness in the basement. But if the outer part of the structure remains in constant contact with water, this will lead to its premature destruction. Therefore, it is important to waterproof the outside as well.

The set of measures for waterproofing includes:

- Waterproofing of communication inputs;

- Wall or deep drainage device.

The need for certain measures is dictated by the type of soil, groundwater level, landscape features and other natural factors.

Foundation waterproofing is the basis of everything

The foundation is the foundation of any structure. The stronger and better, the more reliable and safer the structure or building itself. The main building material for the device is concrete. Many developers believe that since concrete is a strong enough material in itself, waterproofing is useless. But is it really so?

Elena Merzlyakova:

Elena Merzlyakova:

– It must be remembered that concrete is quite hygroscopic and absorbs moisture well, which leads to leaching over time. As a result of leaching, the porosity of the cement stone increases and its strength decreases. The process is accelerated if “soft” water or pressurized water acts on the cement stone.

The main means of combating the leaching of calcium hydroxide is the use of dense concrete and the introduction of active mineral additives into the cement. If problems with water permeability have arisen in an already constructed and operated structure, then the use of penetrating waterproofing will be an effective remedy.

The use of penetrating waterproofing compositions eliminates the possibility of water filtration through the body of the concrete structure.

Andrey Zubtsov:

Andrey Zubtsov:

- Concrete itself is a fairly good waterproofing material. But in order for concrete to show its waterproofing properties, it is necessary to follow a few simple, but, as practice shows, very difficult rules. Namely:

- The design of the foundation must not allow the formation of cracks under load.

- The entire volume of concrete must be poured in one technological cycle without "cold" seams.

Precast concrete from FBS blocks definitely needs additional protection.

- All technological seams must be sealed without fail using swelling cords, sealants, waterstops, etc.

- Working fittings must be installed in strict accordance with the project

- It is necessary to carefully vibrate the already laid concrete.

- It is important to take care of the concrete.

It is necessary to cover freshly laid concrete with wet burlap and spill it with water every 2-3 hours (even at night) for three to five, and in hot weather - seven days.

But is it possible in some cases to do without waterproofing the foundation?

Nikolai Mikhailov:

- You can, if you are not going to use the basement and do not count on the long life of the foundation. For example, a strip foundation for a garage or a barn can be done without waterproofing, nothing will happen to such a foundation in 10-15 years.

Types and types of modern waterproofing materials

Modern waterproofing materials can be divided into three large groups by origin - these are polymeric, bituminous and mineral materials.

According to the method of application, waterproofing materials are made on coated, rolled free-laying membranes, rolled welded and liquid applied materials.

Elena Merzlyakova:

Elena Merzlyakova:

– It is important to know that materials that provide waterproofing are designed to solve specific problems.

- Roll waterproofing.

Traditionally, rolls have a cardboard base impregnated with waterproofing materials (roofing material, glass roofing material).

- Mastics are adhesive plastic compositions based on organic binders and dispersion fillers.

The most famous are cold and hot mastics on oil bitumen.

- Powders.

Mixtures based on cement, synthetic resins and various additives (plasticizers, hardeners). They are sold dry and mixed directly at the work site.

Mixes based on silicones, ester compounds, silicic acids and organic solvents, which, unlike "ordinary" external waterproofing materials, are "absorbed" by concrete surfaces.

- Films.

Basically, they are divided into polyethylene films, polypropylene films and membranes.

- Injection waterproofing.

It is carried out by injecting a binder material into the seams, cracks of building structures or into the soil adjacent to them. They are usually used for repairs.

- Penetrating waterproofing.

The components applied to the concrete surface penetrate deep into the concrete through its pores and capillaries even against high hydrostatic pressure. These formations, densely filling all the pores and microvoids, compact the concrete structure, thus ensuring reliable water tightness.

The service life of the penetrating materials is equal to the life of the concrete itself.

The service life of the penetrating materials is equal to the life of the concrete itself.

materials "penetrating waterproofing" are best suited for the repair and waterproofing of concrete and reinforced concrete products and structures, as well as cement-sand plaster coatings.

But in what cases is it necessary to apply one or another type of waterproofing?

Elena Merzlyakova:

– The choice of material for waterproofing depends on a number of factors, for example:

- Characteristics of the aggressive environment affecting the building structure;

- Operating conditions of the structure;

- Type of construction;

- climatic conditions;

- Results of engineering-geological surveys;

- The probability of mechanical or thermal impact on the structure.

Andrey Zubtsov:

- If the structure is buried in the ground, then in any case it must be waterproofed. Even if your water table is low enough, there can be showers, floods and snowfalls. And groundwater levels can change over time.

Nikolai Mikhailov:

– Mineral waterproofing is suitable for simple-shaped structures that are not prone to cracking. In general, mineral and bituminous coating materials are suitable for waterproofing foundations up to two buried floors. For more serious structures, complex geological conditions and greater reliability, it is advisable to make waterproofing from polymer membranes.

But in addition to protecting the foundation, waterproofing is needed for rooms that are constantly in contact with water.

For example:

For example:

- Waterproofing of balconies and terraces is carried out using mineral waterproofing materials, on which tiles can be laid using mineral or polymer tile adhesives.

There are also polyurethane-based waterproofing materials that can combine the function of waterproofing and elastic bonding of tiles.

- For waterproofing wet rooms, first of all, it is necessary to first find out and eliminate the cause of water penetration. Most often, weak points of structures flow, such as concreting working joints, structural and expansion joints.

Seams are waterproofed by injection of polymeric materials or by waterproofing tapes glued to the surface of the concrete structure. After that, it is necessary to waterproof the floor and walls of the room using cement-based waterproofing.

Methods of laying and applying waterproofing

According to the method of application, waterproofing materials are divided into coating, rolled free-laying membranes, rolled welded, as well as liquid application materials.

Nikolai Mikhailov:

– Coating, spraying and welding materials require mandatory mechanical surface preparation. They can only be applied on substrates that have the necessary strength and, as a rule, at temperatures above +5 degrees.

Sandblasting, high-pressure water treatment or mechanical preparation using power tools are used as preparation of the base.

Andrey Zubtsov:

– Surface preparation before applying waterproofing membranes is one of the most important, and often the most complex and time-consuming technological operation.

Since concrete is the most common building material, surfaces made of concrete and reinforced concrete are most often subject to preparation, less often of brick and natural stone.

The quality of surface preparation depends on the material used as a waterproofing membrane. It is possible to single out the main requirements for the quality of preparation of concrete and reinforced concrete surfaces:

- Absence of loose easily exfoliating elements;

- The absence of cracks (especially parallel to expansion joints), chips and shells, areas of non-vibrated concrete;

- Smooth surface geometry;

- Removal of all contaminants and materials preventing adhesion (dirt, dust, cement laitance, formwork lubricant, etc.).

If the requirements for surface preparation are not met, the quality of the waterproofing membrane and the entire waterproofing system will be poor.

Waterproofing protection

Since waterproofing, as noted above, includes a whole range of measures, it is very important to protect the waterproofing layer when backfilling the foundation.

Elena Merzlyakova:

Elena Merzlyakova:

– The waterproofing layer, as a rule, must be protected from mechanical damage, chemical attack, ultraviolet radiation, etc.

First of all, mechanical protection of the waterproofing is necessary before backfilling the soil of the excavation, as there is a risk of damage to the waterproofing by mechanisms, stones and construction debris.

Various methods are used to protect waterproofing:

- The device of retaining or protective walls made of brick or reinforced concrete;

- Plastering or protective screeds from cement-sand mortar;

- Fastening or gluing various materials: profiled membrane, asbestos-cement sheets, extruded polystyrene foam boards, etc.

Penetrating waterproofing does not require protection, since its principle of operation is based on the penetration of the chemically active part of the composition deep into the concrete and the formation of sparingly soluble crystals in pores and microcracks, thereby forming a homogeneous, monolithic structure with the concrete itself.

Andrey Zubtsov:

– Flexible waterproofing membranes differ from rigid ones by the presence of such an indicator as flexibility, or relative elongation at break. It is expressed as a percentage and means that with various kinds of movements and deformations that may occur in the foundation, the flexible waterproofing membrane will retain its integrity. But flexible membranes additionally need to be protected. Rigid waterproofing membranes do not need additional protection, but they cannot maintain integrity during foundation movements and deformations.

Nikolai Mikhailov:

– It should be remembered that no protection will save the waterproofing from backfilling made with frozen soil and soil containing construction debris and stones.

Roof waterproofing

Roof waterproofing is an indispensable element in the construction of any building. In order to prevent the roof of your house from leaking, it must be waterproofed. But it has its own peculiarities and secrets.

Corporation Expert "TechnoNIKOL" Anastasia Pokachalova:

Corporation Expert "TechnoNIKOL" Anastasia Pokachalova:

– When installing roof waterproofing, it is extremely important to pay attention not only to the quality of the material, but also to the quality of the installation of the waterproofing coating, and to the correct design of the roof.

Construction specialists from Germany received the following figures:

- 45% of problems with a roof are caused by its poor-quality installation;

- 34% of errors are due to bad design;

- 7% of problems are due to damage to the roof during construction;

But only

- 14% are due to deterioration of the material or the use of unsuitable roofing materials.

If the roof waterproofing is installed incorrectly, the developer risks losing all the advantages of the material he has chosen.

The choice of waterproofing material for the roof is influenced by the following factors:

- fire safety requirements.

Because waterproofing materials differ in fire hazard class.

- Roof area and type of foundation.

- Type of use - operated or non-operated roof, and the degree of its load.

- The frequency of operation and maintenance of the roof.

- roofing cost.

- Climatic features that affect the life of the roof.

To choose a waterproofing material that is suitable for your type of roof, you need to take into account the technical features and types of waterproofing.

Among the modern materials for roof waterproofing, the following can be distinguished:

- bituminous materials.

- Polymer materials based on PVC.

The basis is high-quality plasticized polyvinyl chloride, which includes plasticizers (up to 35%) and various additives (up to 8%).

- Polymer materials based on TPO.

- EPDM materials.

The base is synthetic rubber.

- Sprayed roofs.

Let's consider each of the materials separately.

Bituminous materials:

- Well suited for residential buildings where access to the roof is unlimited.

- Basically, they require laying in two layers, and this leads to an increase in the installation time of the roofing carpet.

Anastasia Pokachalova:

- It must be remembered that the combustibility group of this material is G3 / G4, which means that with roofs of a large area, fire belts or gravel backfill are required.

PVC membranes:

- The combustibility group is G1/G2, which means that it is possible to use PVC membranes with an area of up to 70,000 sq.m without additional fire prevention measures.

- Installation can be done quickly, regardless of the season and on roofs with any slope: from 0 to 90 degrees.

Anastasia Pokachalova:

- Among the features of this material, high vapor permeability can be distinguished - PVC membranes are able to remove excess steam pressure from under the roof space into the atmosphere.

This property of polymer membranes allows them to be widely used in the reconstruction of old roofs without dismantling the existing roofing pie.

EPDM membranes:

- They are highly resistant to aggressive chemicals.

The choice of EPDM membranes is justified if your home is located near a plant that produces chemicals.

And in order for the EPDM membrane to provide good waterproofing of the roof, the following features must be taken into account.

Anastasia Pokachalova:

– The service life of the carpet is determined by the quality of the seam, not the membrane itself. The average service life of glued joints does not exceed 10 years. It is possible to ensure reliable connection of sheets by vulcanization with a strip of raw rubber. At the same time, it is necessary to observe the continuity of the process, to ensure that there are no gaps in the application of reagents and contamination on the seam.

The temperature minimum for installation is +5 degrees, since this temperature is the working temperature for sealants, adhesives and adhesive tapes.

But when choosing such a roof waterproofing, you need to know that:

- EPDM membrane requires additional measures for the construction of a "breathing" roof.

- The EPDM membrane gets very hot in summer due to its black color.

Sprayed roofs

Anastasia Pokachalova:

- This is the most expensive way to waterproof the roof. But it allows you to waterproof the roof, containing a large number of penetrations on the surface.

The features of such waterproofing include:

- Increased requirements for the qualification of the master performing the installation work.

- The composition for spraying is prepared directly at the construction site.

And the quality of the sprayed material largely depends on weather conditions and compliance with the manufacturer's instructions for storage, transportation and preparation of the mixture.

- When spraying several layers, it is necessary to wait for the complete drying and polymerization of the previous layer, which increases the construction time.

- It is necessary to pre-prepare the base and clean it from dirt and moisture.

When applied to an unprepared surface, the service life of such a roof is rapidly reduced.

- When installing roofs of a large area, it is necessary to install fire belts or use gravel backfill.

Thus, when installing a waterproofing system, every detail must be taken into account, and the system itself includes a whole range of various installation and construction works and materials. And only taking into account all of the above factors, you can build a truly comfortable and reliable home.

Do you need waterproofing strip foundation? The answer to this question users can find our forum. You can read a detailed and visual story of our forum member about how he poured concrete under the foundation just into the ground. And in our forum there is a discussion of the correct pie of multilayer waterproofing of the foundation. A hot discussion: “Do I need waterproofing for a “cold” roof” is underway. In this video clearly shows all the stages of work on the quick repair of the roof of the garage with the help of bituminous waterproofing self-adhesive tapes. From this video you will learn everything about waterproofing, its types and application. And this video clearly demonstrates what nuances must be taken into account when installing waterproofing on a flat exploited roof.

Waterproofing of foundations is one of the main areas of work of the TekhnoNOVO company. We will promptly draw up an estimate, conclude an agreement, and also professionally advise on the choice of the necessary technology and materials!

Any construction begins with a foundation pit and laying the foundation. To paraphrase the statement of the famous captain Vrungel, we can say: - Whatever you make the foundation, the whole building will be like that. It is the foundation that ensures the strength of the structure and the duration of its uninterrupted operation.

When building the foundation of a house, it must be remembered that the foundation will be in the ground, which means that it will continuously have to withstand the negative effects of groundwater, precipitation, floods and storm flows.

In order for your house to be as strong as the Egyptian pyramid, and not afraid of snow, rain, or other natural disasters, it is necessary that the foundation be completely waterproof. And for this, it is important that the waterproofing of the foundation of the house is done correctly, and taking into account the materials and type of foundation.

Foundation types

The foundation in construction is called the underground foundation of the building, on which all the loads of the ground part of the structure fall. That part of the foundation, which is located directly at the bottom of the pit, is the base of the foundation, and its upper part, on which ground construction is already carried out, is the surface of the foundation.

The choice of the depth of laying the underground part is carried out depending on the level of groundwater rise, the type of soil and the expected freezing depth.

Construction on sandy soil, abundantly saturated with water or on silty soils must be carried out in compliance with all safety rules and with the utmost care. In no case should construction be started using bulk soil and peat as a natural base. In the event that the existing soil is absolutely unsuitable for construction, an artificial foundation is being arranged for the foundation.

The choice of the type of foundation depends on the type of future building and its purpose. In modern construction, such types of foundations are used as:

Strip foundation

This type of foundation is considered the most durable, reliable, durable in construction, and at the same time quite simple in terms of execution technology. It is installed for buildings with heavy masonry made of stone, concrete or heavy brick. The laying of the strip foundation is carried out under the main load-bearing walls, both external and internal.

The strip foundation, in turn, can be made using two technologies, these are:

- Monolithic building, in which formwork, reinforcement are set around the entire perimeter of the pit, and thermal insulation blocks are laid. Then concrete is poured into the finished structure. To exclude heat loss of the building, insulation is laid before pouring, from materials such as:

- Styrofoam,

- Expanded clay,

- Mineral wool boards.

The main advantage of the monolith is its reliability and high strength. The foundation made using this technology can be brought under the building of the most bizarre shape.

- prefabricated foundation having the form of concrete or reinforced concrete blocks. This technology is characterized by ease of implementation and minimal laying time. But they can only be installed under buildings of a simple shape without intricate bends.

Pile or column foundation

This type of foundation is the most economical compared to other types. In addition, the bearing structure of the pile foundation is excellent for soil with a high degree of freezing, which is important for many regions of our country.

But, unfortunately, the columnar foundation can not be used in all types of soils. So on moving soil it can be laid only with the use of reinforced concrete grillage. And for weakly bearing soil or heavy buildings, such a foundation cannot be used. In addition, there are problems filling the space between the base, pillars and the ground.

For light, small buildings, a pile foundation is ideal. A huge plus will be the simplicity of the work performed and significant cost savings.

Solid or slab foundation

The principle of this type of implementation is over the entire area of the future building. At its core, it is a solid slab or foundation made of prefabricated beams with a rigid joint screed.

Great for options like:

- weak ground,

- heavy building structure,

- bulk soils,

- High groundwater level,

- Uneven compaction of the soil.

The advantages of this type are the simplicity of technology, reliability in construction on mobile and sedimentary rocks. The disadvantage is considered to be a large overspending of material, which entails the high cost of only one foundation.

Each of the listed types of base is made of the most common material in construction - concrete. But, since concrete is able to absorb moisture, and in direct contact with water, penetration into the pores of concrete is not excluded, which will further lead to its destruction. Waterproofing the foundations of buildings is an obligatory stage of construction and a guarantee of its future reliability.

Features of waterproofing the foundation of the house

Neglecting the stage of waterproofing the foundation, as not a particularly significant point or in order to save money, can later result in not only additional repair costs, but also cause the destruction of the building. In addition to the fact that the correct waterproofing of the foundation is a reliable barrier to water and dampness, it still does not allow mold and fungus to grow, and most importantly, it keeps the building warm.

In construction, cases are indicated when there is no need for waterproofing, these are:

- Performing the correct blind area,

- Low groundwater level even during high water,

- The predominance of dry weather throughout the year.

Unfortunately, in the climatic conditions of our country, the combination of all three conditions is almost impossible. Therefore, the issue of waterproofing is relevant in all regions.

The type of waterproofing and materials for its implementation are selected in accordance with the type of foundation and the technology for its implementation. It is important to take into account the specifics of the soil and the purpose of the building. And most importantly, do not skimp on the purchase of high-quality waterproofing products suitable for the selected type of insulation.

The quality of waterproofing will depend not only on the level of annual rise in groundwater, but also on the aggressiveness of their composition. The ideal option is to study this indicator even before choosing the type of foundation and type of waterproofing, since often the reason for the destruction or corrosion of the base concrete is precisely the negative impact of an aggressive environment, and not the pressure of the water flow.

Foundation waterproofing axioms

- Without waterproofing the foundation, the walls and roof of the building will quickly darken and become covered with mold and fungus.

- Without a vapor barrier between the foundation and the building, steam from the living quarters will seep into the basement, creating conditions for mold and fungus to grow and destroy the foundation walls.

Types of building foundation waterproofing and implementation technology

In modern construction, despite the wide choice of types of waterproofing for the foundation, they are all performed by two technologies, these are vertical and horizontal insulation methods.

Horizontal insulation carried out at once on several levels, at the junction of the basement and the wall of the main building and along the basement floor. According to this technology, waterproofing work is carried out simultaneously with the construction of the foundation.

The bottom of the pit is covered with a layer of clay, compacted, and the first thin layer of concrete is poured. An insulating material is laid on it, and covered with a final layer.

Vertical technique pursues the application of a protective layer on internal and external surfaces, and is divided into such types as:

- Coating,

- Penetrating

- Pasting (roll)

- injection

The task of vertical isolation is protection from ground and flood waters with normal and aggressive environments. And also from the penetration of moisture into the capillaries of concrete surfaces.

Coating waterproofing

This is the most economical method of waterproofing, performed using bituminous mastic. It is applied to dry, even walls, as a protective layer from surface groundwater, and capillary absorption of moisture by concrete. After complete hardening, bituminous mastic is not only an obstacle to water and moisture, but also protects the waterproofing of the walls from mechanical damage.

In addition, bituminous mastic perfectly withstands the negative impact of an aggressive environment and keeps the foundation under increased loads associated with seasonal soil movement.

The application of this material is carried out either on the base walls themselves, or on a pre-laid fiberglass reinforcing mesh.

It is most often used as a waterproofing strip foundation, due to the flexibility of the material.

Roll (pasting) waterproofing

The most popular material for rolled waterproofing, despite many modern inventions, is roofing material. Roofing material competes with:

- stekloizol,

- glass mast,

- hydrostekloizol,

- technoelast.

These materials are made of special polymer raw materials, due to which they are much superior to their competitor in durability and durability.

Rolled waterproofing using polyester is much superior to bituminous materials. Moreover, they have not only strength, but also elasticity, which allows them to be used to create an insulating layer, both in a strip foundation, and in a tiled, and pile foundation.

Penetrating waterproofing

Special materials, consisting of a mixture of quartz and cement, with the addition of active components, are applied to the internal and external surfaces of the foundation in several layers. Each layer should not exceed three millimeters in thickness.

The solution penetrates into all microscopic cavities of concrete, and with the help of active components combines with calcium salts present in concrete (). The result of such a reaction is a strong connection, breaking all possible defects and voids with a monolithic layer.

The disadvantage of penetrating waterproofing is its high cost. At the same time, waterproofing the foundation with this method means providing the building with durable and reliable protection.

Foundation injection waterproofing

The most innovative method is. The principle of its implementation is the introduction of various binders into the supporting structures through the prepared holes.

A feature of the polymers used for injection is the ability to swell upon contact with water, thereby completely blocking access not only to the water flow, but to wet vapors.

Another integral part in the waterproofing of foundations are injection materials: resins, liquids, solutions. They are practical, easy to use and in case of leakage or cracks they serve as reliable protection to the base.

Foundation waterproofing materials

Foundation waterproofing protection

The need for additional protection of the waterproofing layer arises only when flexible materials are used. Usually they are not resistant to mechanical damage, and can deform under their own weight.

For this, methods such as:

- Retaining shields made of brick or reinforced concrete;

- Applying plaster from a cement-sand mortar;

- Gluing asbestos-cement sheets.

house foundation waterproofing cost

The cost of waterproofing the foundation of the building and the term of the work in each case are determined individually - they depend on the volume and complexity. Our specialists will be happy to come to your site at a convenient time for you to assess the situation. They will choose the most optimal option for waterproofing the foundation and advise certain materials for waterproofing, make an estimate. We are always happy to help you!

One of the important factors in extending the life of the base of the house is the implementation of high-quality waterproofing. The need is due to the fact that in any soil there is moisture, which adversely affects the foundation.

If you ignore this process or carry it out poorly, then soon cracks and other signs of destruction of the basis will form in the walls of the house.

For high-quality protection against moisture, reliable materials for waterproofing the foundation are needed. In this regard, the questions of what material to choose and how to work with it are of particular relevance when considering.

Why waterproofing

Frozen water in the cracks of the foundation can destroy it

Frozen water in the cracks of the foundation can destroy it Many may begin to argue and convince that water is not terrible for concrete, but, on the contrary, in some way, thanks to it, it gains strength. However, let's try to give a few indisputable facts that indicate that waterproofing is one of the most critical processes.

- Concrete in its structure resembles refined sugar. If you dip it a little in tea, you can observe how the liquid begins to rise up on its own. This property is called capillarity. Its essence lies in the fact that through the smallest pores formed in concrete, moisture very easily rises up. This is fraught with the fact that not only the base of the house will contain moisture, but also the walls. Therefore, constant dampness will be present on the basement and on the walls of the room. And this entails an increase in heat loss, the occurrence of fungus and mold.

- During frosts, the water freezes, while expanding. And if it is in the pores of concrete, then pressure naturally arises, which begins to destroy it.

- Nowadays, the foundation consists not only of concrete. For its reinforcement, steel reinforcement is used. Upon contact with moisture, the metal begins to rust and gradually collapse. It is known that during the corrosion process, the metal increases in volume by almost three times, and this creates a certain internal pressure on the concrete.

- In groundwater very often there are aggressive components that adversely affect concrete.

Carrying out high-quality waterproofing helps to exclude or, at least, minimize the process of concrete destruction.

materials

There are various waterproofing technologies that use different types of materials. Based on this, we list the ways to protect the foundation:

- coating;

- sprayed;

- roll;

- penetrating;

- plastering;

- screen method.

Consider a brief description of the materials used for waterproofing foundations, depending on the method chosen.

Coating method

Bituminous mastic can be prepared by yourself

Bituminous mastic can be prepared by yourself When performing insulation in this way, materials that have a bitumen base are used.

They provide protection by applying bitumen in several layers to the material using a brush, roller or construction spatula.

This raw material can be found under the name bituminous mastics.

They are widely sold in the construction industry packaged in buckets.

It will not be difficult to cook them yourself. To do this, we provide cooking instructions:

- acquire a piece of bitumen and crush it by splitting. The smaller the pieces, the faster they will melt. Next, place the pieces in a metal bowl and put on fire to melt;

- after that, used engine oil or diesel fuel is added to the molten bitumen. It is necessary to add these components about a third of the total volume of mastic. Then mix everything thoroughly with a wooden stick.

When using ready-made mastic, it is pre-mixed, while adding a solvent: solvent or white spirit. On the container in which the mastic is sold, instructions for preparing it for work should be placed.

Mastic is produced by various manufacturers. For waterproofing the foundation, you can purchase any. But it is necessary to pay attention to its purpose. Since there is mastic not only to protect the foundation of the house, but also for roofing.

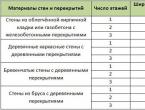

Brief characteristics of mastic according to ENiR standards

Mastic is applied only on a clean surface

Mastic is applied only on a clean surface Do not apply mastic on an uncleaned and dirty surface. It must first be prepared and primed. The priming solution has a special composition and is called a bituminous primer. It can be purchased at hardware stores. In terms of viscosity, it is slightly inferior to mastic.

After priming the surface, apply mastic in several layers. Each subsequent layer should be applied after the previous one has completely dried. As a result, we get a protective surface of mastic with a thickness of 5 cm.

The advantage of this material is its affordable price. But there are also disadvantages. Mastic coating is not very durable and requires a lot of time for arrangement and periodic maintenance.

Spray method

This method has another name - "liquid rubber". The foundation is waterproofed with a bitumen-latex mortar in the form of an emulsion.

This method has another name - "liquid rubber". The foundation is waterproofed with a bitumen-latex mortar in the form of an emulsion.

Application method: spraying with a special device. Sprayed waterproofing is a more modern look that can be completed in a very short time.

Also, the method of application, and the materials themselves, provide a higher quality than the use of mastic. But all this entails an increase in costs due to the high consumption of raw materials.

The technical characteristics of "liquid rubber" are provided in this table, taking into account the ENiR standards

Waterproofing with roll materials

Ruberoid is the most popular material

Ruberoid is the most popular material To provide rolled waterproofing, waterproofing materials are used for the foundation on bituminous or modified polymer compositions applied to any base.

The most popular and well-known example of rolled materials is roofing material. The basis for applying bitumen to roofing material is cardboard. In more modern materials, the basis is fiberglass, fiberglass or polyester.

Here are some examples of modern roll materials:

- roll material - waterproofing. Its second name is glass isol, which is made by impregnation with a special composition of fiberglass. The cost of glass isol, of course, is high, but the service life is much longer;

- Bicrost is a fiberglass fabric on which bituminous compositions are applied on both sides.

Waterproofing is melted with a burner

Waterproofing is melted with a burner There are two ways to carry out protection using rolled waterproofing materials: gluing or fusing.

Before performing work, the surface should also be carefully prepared to ensure a high degree of adhesion. In the beginning, it is necessary to clean it of dirt and dust, eliminate obvious defects and prime with a bituminous primer.

The process of fusing glass isol is carried out using a burner or a building hair dryer. First, the composition applied to the roll is melted, and then it is glued onto the surface to be treated.

The positive characteristics of roll materials include:

- increase in service life when compared with coating materials;

- relatively low price.

Of course, modern materials, such as stekloizol, have prices a rank higher.

The disadvantage is the high labor costs in the performance of work. Moreover, it is quite difficult for an inexperienced person to carry out high-quality waterproofing, especially alone.

There are self-adhesive roll materials that greatly simplify the process of waterproofing protection.

Penetrating waterproofing

To perform penetrating insulation, solutions are used that are able to quickly penetrate into the concrete through its pores. After drying, the pores are clogged, and thus the infiltration of moisture is limited. For more information about waterproofing the foundation, see this video:

Also, this process increases the degree of frost resistance of concrete and provides protection from the effects of various aggressive environments. Examples of solutions for penetrating waterproofing: Penetron, Hydrotex, Aquatron and others.

The price of these solutions is quite high, so they are not widely used in private construction.

Most often, they are used to eliminate defects in the waterproofing of foundation walls and to carry out repair and installation work in already constructed buildings from the inside.

Insulation with plaster

This type of insulation is a subspecies of coating protection of the base from moisture.

This type of insulation is a subspecies of coating protection of the base from moisture.

It is based on the use of plaster mixtures, to which special moisture-resistant components are added.

The mixture prepared for work is applied with a construction spatula or trowel.

Sometimes a brush is used to apply.

In order to ensure higher quality and prevent the formation of cracks, a mesh is additionally used to reinforce plaster surfaces.

The advantages of such materials include a very simple and fast execution technology.

To the disadvantages:

- short service life;

- low degree of waterproof protection.

Experts advise using waterproofing plaster to prepare the base surface for roll waterproofing, for example with glass isol. Particular care should be taken to process the lower part of the walls from the foundation. For more information about plaster insulation, see this video:

Screen type waterproofing

Swellable bentonite mats are used for this type of insulation device. At its core, it is a modern version of a clay castle. Mats are attached to the surface of the base by means of dowels overlapping each other. The width of the lining is 15 - 20 cm.

The foundation is an important component of any structure, the quality and stability of which determines the durability of the building as a whole. Why use insulation? The base is exposed to many negative factors - one of them is moisture, which destroys the structure. Do-it-yourself waterproofing of the foundation, performed competently according to technology, will help to cope with this trouble.

There are two types of moisture that affect the base:

- melt water and precipitation falling into the ground from the outside;

- bottom waters, their level is changeable, depending on the season.

What waterproofing to choose for the foundation? The base is selected based on the type of base and material; the slab and column support are protected from moisture in different ways.

It acts on the base in several ways:

- if aggressive components are present in the bottom or rain moisture, then potholes and flaws caused by washing out of solid particles may appear in the body of the base;

- collapses from freezing of the moisture which has got into a basis material. The only element in nature that expands when exposed to sub-zero temperatures is water. Penetrating into micropores, it exerts a strong load on the base from the inside, as a result - cracks, crevices, gaps;

- washing away the soil with water leads to skew and subsidence of the structure, which can lead to the destruction of the walls.

Now it becomes clear why waterproofing the base is needed. For this reason, it is necessary to isolate the base as soon as the structure is ready.

Types of applied insulation

Three groups of arrangements for protecting the constructed foundation from groundwater can be distinguished:

- horizontal waterproofing of the foundation inside the house;

- creating a blind area.

Foundation waterproofing materials for the arrangement are different. There are such foundations that several types of protection are used in combination to protect them at once:

- Cut-off foundation waterproofing is used for foundations on pillars and strip foundations.

- Horizontal foundation waterproofing - suitable for all types of foundations. With its help limit the impact of moisture in the interlevel space. This insulation is made from different materials, depending on the construction budget.

- A blind area is constructed to protect the base from rain or melt water. It is advisable to make the structure wide enough, otherwise moisture will penetrate to the base, and put an additional load on other types of insulation.

Horizontal and vertical waterproofing

These two types of base protection should be disassembled separately, the materials for waterproofing the foundation are very different from those used in the construction of the blind area.

The insulation of the buried part of the support is carried out by several types of protection:

- by coating;

- pasting;

- plastering;

- penetrating compounds;

- made with the help of installation;

- structural;

You need to understand what waterproofing materials for foundations to use for a certain type of foundations and how horizontal foundation waterproofing is constructed.

Coating method in isolation

Coating waterproofing of the foundation is carried out with bitumen-based mastics. Two-component and one-component compositions are used to coat the part of the base located in the ground and the walls of the building. In addition, many new, modern and high-quality insulating materials have recently appeared:

- resins based on polymers and bitumen-polymer;

- bitumen and rubber mastics.

Thanks to additives in bitumen, the material tolerates low temperatures well, and does not crack like ordinary bitumen when frozen. The disadvantage of modern materials is the high cost, so private developers use the base of the house as insulation.

Okleyechnaya

How to waterproof the foundation with gluing compounds? A demanded and frequently used type of protection is the use of various materials in rolls mounted on a binder layer of bitumen, such as hydrostekloizol. Pasting protection is equipped in two ways - by gluing or fusing.

Fused waterproofing involves the use of a gas burner, with which the top layer will be heated to a viscous state, after which the material is glued to the base plane. If there is no adhesive base on the roll insulation, then mastic is used as a binder from the outside. You need to choose the right material.

Before equipping the insulation, the surface is primed.

Adhesive materials are:

- roofing - is considered an obsolete material for insulation, but is still widely used. Due to its low cost and the ability to quickly recover in case of damage. This is cardboard, the surface of which is treated with bitumen;

- glassine is a good waterproofing material based on thick construction cardboard, treated on both sides with bitumen. It cannot be said that this is a reliable insulation, but the cost of a roll coating allows you to save;

- roofing material is the leader among insulating materials, good insulating characteristics and affordable price make the material in demand among developers. But it is worth noting that the service life is short;

- materials based on polymers, with bituminous impregnation at the base of which fiberglass or polyester is used. There are several common insulation options: Gidrostekloizol, Linocom, Technokol, Bikrost, and so on.

The most reliable options for foundation waterproofing are the materials listed in the last list, but often their use entails additional costs. Hydrostekloizol is especially in demand, its technical characteristics and the latest technologies in production make it possible to insulate the foundation inside an old house for a period of 30 years.

But it is worth noting that these materials serve for a long time, which allows you to save on the frequency of repairs. Another positive point is the ability to apply hydrostekloizol for any building materials:

- metal;

- concrete;

- tree;

- asphalt concrete;

- gidrostekloizol is used for repeated and restoration of waterproofing without dismantling the old coating.

Plaster protection

Do-it-yourself waterproofing of the foundation on piles using plastering or painting is impractical and unreliable. Such insulation serves only five years, after which repair work will have to be carried out.

Insulation with penetrating compounds

An excellent way to treat the base to protect the base from moisture, penetrating foundation waterproofing is able to clog all the pores of the concrete, while increasing the resistance of the material to the effects of a humid environment. Usually this protection is used in combination with other types of insulation - gluing or coating. Mining was previously used as a penetrating waterproofing.

The penetration depth of the insulation reaches 25 cm, but more expensive materials are buried by a meter. The disadvantage of this method is the limitation in use - it is only suitable for concrete bases.

There are the most popular compositions that are used to process the foundation for waterproofing:

- "Penecrete";

- "Penaplag";

- "Hydrohit";

- "Penotron".

This insulation is most effective on new builds as the surface must be clean, free of grease and even.

Recently, many construction companies offer such a service as waterproofing the foundation with polyurea. This is an innovation in the arrangement of the insulation of supports, produced by spraying, and guarantees high-quality protection.

Mounted insulation

This isolation method is used when the bottom water level is high and exerts a lot of pressure on the base. Equip on foundations of tape type with. Various materials are used for mounted protection, for example, sheet steel, which is sheathed on the inside of the base. The metal should be 6 mm thick. This method is used very rarely, due to the high cost.

From the outside, brickwork is erected along the perimeter of the foundation.

It is erected after carrying out insulation work by coating or pasting methods. In this situation, the waterproofing between the foundation and the masonry will be protected from mechanical damage.

Structural waterproofing of the foundation slab is the addition of special insulating additives directly to the concrete. It is used very rarely due to the high cost, so it is better to choose more economical materials.

Injection isolation

This method is used for injecting foundations that are in operation when repairing the waterproofing of the foundation is needed. This technology contributes to the protection of the base from the effects of moisture, without developing soil around the perimeter. Injectors are brought to the base, which are able to deliver insulating material.

The following compositions are used:

- resin;

- rubber;

- foam;

- acrylate gel;

- polymers;

- cement mortars.

This method involves the use of special equipment and a professional approach, so it is impossible to do injection insulation with your own hands. But at the same time, you can easily waterproof the existing foundation of an old house.

The arrangement of the blind area

In the case of using external waterproofing to protect the base, the following materials are used:

- sidewalk tile;

- concrete;

- diffusion membrane for foundation waterproofing;

- asphalt concrete.

The choice of material for arranging the blind area depends on the foundation, the availability of material, financial capabilities, the preferences of the owners and the design of the building. If we are talking about savings, then the best option would be laying asphalt or concrete. Typically, this option is used to protect foundations in apartment buildings, industrial facilities and administrative buildings.

Builders advise for private houses to use a waterproofing membrane for the foundation, as it is the most reliable protection option.

Technological features of waterproofing of different types of bases

Different types of building foundations require separate types of insulation. Before pouring, you need to determine what measures to perform for high-quality waterproofing.

Strip base insulation

For prefabricated and monolithic options, the waterproofing of the strip foundation has distinctive features. The prefabricated view of the base requires the following actions:

- waterproofing of the foundation slab of industrial production and the concrete walls of the basement require the arrangement of a high-quality, reinforced seam joint;

- waterproofing of the foundation walls with rolled material is laid from the first seam located at the lower level of the basement flooring;

- at the joints of the foundation structure and walls, along the edge of the foundation, insulating material is mounted;

- external waterproofing of the foundation of the buried part is carried out in a vertical way;

- blind area installation.

Bituminous waterproofing of the foundation is not used to isolate the joints, as it can lead to displacements of the structural elements of the foundation. In this case, you need to mount a full-fledged, thickened concrete seam.

The edge of the foundation is insulated to fully protect the base material from destruction under the influence of moisture. The foundation is waterproofing pasting, performed with roll materials, pasting type.

Vertical waterproofing of the new strip foundation is carried out along the outer perimeter of the building, this helps to protect not only the structure of the support, but also the interior of the basement.

Coating and pasting waterproofing of the foundation can be used. The inner side is isolated during finishing work, it is permissible to use an injection and penetrating type of protection.

For waterproofing a monolithic tape, the following measures are needed:

- vertical protection;

- insulation of the edge of the base;

- arrangement of the blind area.

The sequence of work is carried out in the same order as when protecting the prefabricated type of base.

Pile and column foundation - waterproofing

These types of bases do not require complex isolation from the influences of a humid environment. The main work will consist only in measures to protect the edge of the foundation, with a priming solution. The main attention should be paid to the grillage, the location of the waterproofing depends on the material of its manufacture.

If the grillage and supports are monolithic, then the protection is laid at the points of contact between the walls and the base. If a basement is equipped, then it is waterproofed from the outside and from the inside from groundwater.

When using a screw base, on the pillars, which immediately fit the first row of a wooden house, the insulation is equipped with waterproofing between the foundation and the wall.

Slab foundation protection

Do you need moisture? The answer is yes. For quality protection, you need to provide the following:

- footing made of depleted concrete, for isolating the slab support from bottom waters;

- waterproofing of the footing, it is treated with mastic;

- external waterproofing.

When arranging the second layer of the slab, it is necessary to carry out high-quality insulation using the most modern materials. It should be understood that as the waterproofing under the foundation slab will be incorrect, it will be impossible to restore the waterproofing of the foundation when it is destroyed.

If the building is small and has a low specific gravity, you can use a simple bifold polyethylene film, which is laid on the footing.

After the plate is ready, it is worth taking care of its external insulation using roll material. Particular attention should be paid to the connections of the base and walls of the house.

Now you understand how to properly waterproof the foundation.

In custody

To the question of whether it is necessary to waterproof the foundation or not, you can safely answer - yes, it is necessary to carry out work on arranging the protection of the support from moisture. Which waterproofing is better to protect the foundation from the inside can only be determined by studying all the rules for the arrangement and the material from which the building support is made.

The foundation is the most important part of the house, on which the reliability and durability of the building depends. Being an underground element, the foundation is more susceptible to the harmful effects of water and moisture than others. In most cases, the foundation of the house is a monolithic or precast concrete, which is characterized by a porous structure.

Do foundations and walls need to be waterproofed? Undoubtedly. Penetrating deep, water destroys metal elements. Experiencing temperature changes and moving from one state of aggregation to another, water changes in volume. This cannot but have a negative impact on concrete, which is destroyed more and more with each cycle - cracks and voids appear. As a result, the functionality of the foundation is lost.

Therefore, it is very important to ensure that the underlying structure is completely protected from moisture penetration. The question is how to waterproof the foundation. There are many factors affecting the quality of a hydro-barrier - from the nature of the foundation and the type of terrain to the type of insulating material and the readiness of the base to accept it. That is why it is worth using specialized services - only professionals clearly understand how to properly waterproof the foundation. Small errors can lead, at a minimum, to the need for frequent repairs of moisture protection.

What waterproofing to choose for the foundation?

The answer depends on the orientation of the base - horizontal or vertical surface, on the budget and the degree of rationality. Materials to protect the foundation from moisture are divided into:

- pasting;

- coating;

- penetrating.

Pasting insulation

One of the types of roll insulation. Previously, it was widely used for processing the horizon, creating a waterproofing layer under the foundation. As a roll material, roofing material usually acts, which is glued onto a surface treated with hot bitumen. It is recommended to use in combination with penetrating waterproofing, which is described in more detail below.

Coating insulation

Represented by a range of materials, divided into:

- bituminous;

- polymeric;

- cement-polymer.

Like roll, coating is much better used in conjunction with penetrating insulation.

Penetrating insulation

First, let's talk about the cons of other types. This will help to understand the absolute advantages of impregnation. Other materials are relatively good for outer surface treatment. The pressure of the water presses the insulation against the base. The liquid acts on the internal hydroprotection by separation, and this greatly reduces the life of the barrier.

Plus, all materials, except for impregnations, are prone to damage. Even small problems are a reason for groundwater to work to wear out the foundation. Finding damaged areas often requires a lot of work.

What is the right way to waterproof the foundation if the liquid creates so many problems, and the materials are so easily damaged? We need an indivisible union of concrete and waterproofing. This is how penetrating insulation works - the mixture migrates deep into the concrete structure, filling absolutely all the pores and layers, crystallizing in them and creating a reliable moisture barrier. In the impregnation market, the undisputed leader is the materials of the Penetron family.

The better to do foundation waterproofing - Penetron materials

Understanding the essence of impregnations and related materials will tell you how to waterproof the foundation according to the rules.

- penetrates to a depth of at least 30-40 cm; over time, the depth reaches up to 90 cm;

- easy to use - applied with a brush;

- increases frost resistance at least twice;

- increases the strength of concrete up to 15%;

- protects reinforcement from corrosion;

- resistant to aggressive environments;

- characterized by self-healing of microcracks;

- vapor permeable;

- a huge range of uses (up to nuclear power plants, thermal power plants, etc.);

- environmentally friendly, allowed in contact with drinking water.

Penetron is the main material of the complex. Certainly present as one of the components. Advantages:

Still wondering what kind of waterproofing to choose for the foundation? Penetron is characterized by the highest maintainability. Problems are fixed quickly and locally.

Penekrit: the composition is used to seal joints / seams / junctions / cracks in combination with Penetron. It is distinguished by the absence of shrinkage, high strength and water resistance, good adhesion to concrete, stone, brick, metal.

Peneplug and Waterplug - Hydraulic seals that quickly eliminate pressure leaks in structures made of concrete, stone and brick. Fast setting time (depends on temperature and material). Characterized by the ability to expand. Used in conjunction with the two previous species.

Penetron Admix - An additive that is used at the stage of concrete preparation. Increases the performance of the concrete foundation in terms of strength, water resistance and frost resistance. Can be used in combination with Penebar or Penekrit (after setting concrete with additive).

Penebar is a waterproofing bundle designed to seal structural and working seams and communication passages. Increasing several times upon contact with water, Penebar creates pressure and becomes an excellent hydro-barrier.

These are not all the materials of the complex, but those described are the main ones. About how to properly waterproof the foundation with their help, further.

Foundation waterproofing technology

Preparatory work

It is not enough to know how to waterproof a foundation. You need quality training. All surface defects should be identified. Loose concrete, places with bare rubble and / or reinforcement must be dismantled and plastered with a repair mixture of Scrape M500. The fittings are pre-cleaned and primed with an anti-corrosion solution. Defects are not always noticeable, they can be hidden by cement laitance. This milk is removed, for example, with the composition of Himfreza.

In a concrete foundation, especially if it is a block structure, there are a lot of seams. These are the most vulnerable places. The joints are pre-deepened by 20-25 millimeters, cleaned and, washing well moistened. Then we recommend sealing these places with Penekrit.

Cracks and crevices are sealed, again, with Penekrit. The moistened surface is treated with Penetron, in two layers. Possible leaks in concrete are eliminated with the help of Waterplug or Peneplag mixtures. Leaking places are embroidered, at least in width, by 25 mm and deepened by 50 mm. It is recommended to deepen the expansion in the form of a dovetail. In the case of abundant hydrofiltration with a large water inflow, it is necessary to use injection resins of the PenePurFom type. But this is already with the help of special devices and equipment.

Very often there are brick inserts in the FBS foundation. What waterproofing to choose for the foundation in this case? In this situation, you should again pay attention to the M500 Skrepa. It is used to plaster a brick over a metal mesh, achieving at the same time a significant increase in strength and a waterproofing effect. Do not forget about Penekrit, which close up the joints, and in this case, along the border of the M500 M500 and the FBesok themselves.

Final treatment with Penetron

This completes the preparation and you can proceed to the final stage. After the used mixtures have set, the surface to be treated must be cleaned and moistened very well. Finally, the Penetron mixture is prepared and the solution is applied in two layers - with a break of 4-6 hours, or as soon as the first layer dries. After completion of work, the foundation, with a frequency of several hours, is moistened for three days. At this stage, we can say that you already understand how to properly waterproof the foundation.

The finished compound must be used within half an hour, so prepare the amount that can be applied during this time, otherwise the composition will turn into stone!