How to choose a foundation for a bath with a drain: we understand installation technologies. Reliable foundation for a do-it-yourself bath Foundation for a bath with do-it-yourself communications

When planning the construction of a bath, you should choose the required foundation and figure out how it is poured. Determining the type of foundation, take into account the depth of soil freezing, soil properties and the mass of the structure. The foundation base erected by pouring concrete mix will ensure the stability of the bath and protect the walls from moisture absorption. We will learn how to pour the foundation under the bath with our own hands, using a concrete solution. We will figure out how the site is being prepared, a pillow is being built, formwork is being assembled and reinforcement is being performed. Let's dwell on the nuances of technology.

We are thinking about building a bath - what kind of base is suitable for building walls

If you are going to start building a bath, you need to choose the design of the foundation, which ensures a uniform distribution of the existing loads on the ground and prevents the walls from becoming saturated with soil moisture. To ensure the durability of the structure, this problem should be seriously approached.

The fundamental part of the building is the construction of the foundation

From a concrete solution reinforced with reinforcing bars, various types of foundations are constructed:

- strip foundation. It is widely used for stone, block and brick buildings, has proven itself on various soils due to its increased load capacity. The base is made in the form of a solid reinforced concrete strip, repeating the outlines of the load-bearing walls and internal partitions. The process of building a monolithic tape provides for the formation of a pit along the perimeter of the bath with a depth of 0.7-0.8 m and a width of 0.3-0.4 m. A crushed stone-sand mixture is poured into the bottom of the trench, formwork is assembled, reinforcement is performed and concrete is poured. A prefabricated version of the tape base is also possible;

- column foundation. It has been tested in the construction of log baths, as well as frame-type buildings and lightweight buildings made of wooden beams. The base of the columnar structure is made in the form of a group of support elements located in the corner parts of the building, as well as in the middle of walls and partitions. For the manufacture of supports, rubble stone, brick, pipes made of steel or asbestos cement, as well as reinforced concrete are used. The columnar design is simple and does not require significant financial costs. Depending on the mass of the bath, the size of the pillars is 15-20 cm, and the interval between them is 2-2.5 m. It is necessary to ensure that the pillars are deepened 0.2 m below the freezing level of the soil;

Various types of foundation foundations are being built to build a bath

Various types of foundation foundations are being built to build a bath - slab foundation. It is made in the form of a solid reinforced concrete platform, the dimensions of which correspond to the dimensions of the bath being built. A monolithic base is rarely used. It is in demand for soils with a close location of water layers and soils with a heterogeneous structure. For the construction of a monolithic base, soil is removed to a depth of 0.3 m. Then the base of the pit is leveled, waterproofing material is laid down and a gravel-sand cushion is formed. The slab is insulated with expanded polystyrene sheet, which, after assembling the formwork structure and performing reinforcement, is poured with concrete. The slab base is a reliable and expensive design;

- screw foundation. It is used to provide stability to buildings erected on weak soils with shallow aquifers and on sloping terrain. As supports, piles made of metal pipes are used, having a pointed working part and helical blades to facilitate screwing into the ground. The depth of screwing of pile supports is determined by the nature of the soil. Depending on the number of supporting elements, installation is carried out manually or using special equipment. After immersion in the ground, the supports are cut to the desired height and poured with concrete mortar.

When choosing the type of foundation structure for building a bath, you should pay attention to a number of factors:

In order for the bath to please with aesthetics and a cozy atmosphere, you should follow the procedure correctly

In order for the bath to please with aesthetics and a cozy atmosphere, you should follow the procedure correctly - soil properties at the construction site;

- moisture concentration in soil layers;

- groundwater level;

- soil freezing depth;

- the total weight of the building;

- the nature of the relief;

- properties of the building materials used;

- bearing capacity of the foundation.

After analyzing the nature of the soil and structural features, it is advisable to decide on the construction of a proven foundation for the future bath in the form of a reinforced concrete tape. This design is the most popular, does not require an increased volume of building materials and is easily built independently.

The choice of design and dimensions of the foundation of the building under construction

Depending on the design features, the tape base is made in various versions:

- monolithic. A solid version is constructed by filling the formwork with a reinforcing cage with a concrete mixture;

- block. The composite structure is built from prefabricated reinforced concrete elements laid in a trench.

The depth of displacement of the sole of the tape base relative to the base mark varies depending on the version.

The tape base is made in various versions depending on the design features of the structure

The tape base is made in various versions depending on the design features of the structure There are the following types of tape bases:

- not buried. It is built on stable soils for the construction of light log and frame buildings. The base of the tape is based on crushed stone and sand bedding and is located close to the zero mark;

- shallow. It is used for heavy buildings made of stone, blocks and bricks, and is displaced deep into the ground by 0.5-0.6 m. The buried tape is constructed when the aquifer is 1 m and deeper;

- buried. The technology for constructing a buried belt provides for the location of its base below the freezing depth of the soil. The level of penetration of the tape-type foundation is determined by climatic conditions and in the northern regions exceeds 2 m.

The most common version of the tape type foundation is a shallow tape of a monolithic structure. By configuration, the strip foundation repeats the outlines of the bath building.

Tape dimensions are:

- depth up to 2.4 m - determined by climatic conditions;

- width 0.25-0.3 m - depending on the material of the walls of the bath;

- elevation above the zero mark of 0.15-0.25 m depends on the slope.

Shallow tape of a monolithic structure is the most common version of the tape type foundation

Shallow tape of a monolithic structure is the most common version of the tape type foundation Before making a final decision on the design features of the strip foundation, geodetic surveys should be performed and their results analyzed.

Requirements for the design of the tape base

The base of the tape type under the bath is erected in strict accordance with the requirements of the current norms and rules for construction.

In addition to the overall dimensions of the foundation tape, the regulatory document provides for a mandatory set of operational characteristics that the strip foundation must comply with:

- resistance to temperature fluctuations;

- increased margin of safety;

- long period of operation;

- design reliability;

- resistance to moisture;

- economy.

To ensure the stability of the bath on the strip foundation and prevent local shrinkage of the walls, it is necessary to take into account what kind of concrete is needed for the foundation:

In strict accordance with the requirements of current regulations, a tape-type base is being erected under the bath

In strict accordance with the requirements of current regulations, a tape-type base is being erected under the bath - concrete mortar marked M150 is suitable for a lightweight tape base of a frame structure;

- concrete mix of the M200 brand will ensure the stability of a one-story bath from blocks with lightweight overlap;

- branded concrete M250 and above will prevent shrinkage of a two-story building made of brick, natural stone or blocks.

At the design stage of the strip base, the requirements of the current standards are taken into account, which are reflected in the project documentation.

How to pour the foundation under the bath with your own hands - detailed recommendations

The formation of the base is carried out as follows:

- Preparatory work is being carried out.

- The contour of the trench under the tape is marked.

- The soil is excavated to a predetermined depth.

- A pillow is made of a mixture of sand and gravel.

- The formwork is assembled from panel elements.

- The interior space is waterproofed.

- The reinforcement frame is assembled and placed in the formwork.

- Concrete solution is being prepared.

- Concreting is in progress.

- Care of the hardening concrete is provided.

Each stage of work has its own characteristics. Let's dwell on them in more detail.

Each stage of work has its own characteristics

Each stage of work has its own characteristics We design the foundation and prepare building materials

Design activities are carried out after determining the location for the construction of a reinforced concrete tape under the bath and performing geodetic exploration. It is important to make sure that there are no engineering communications under the planned foundation that can be damaged during construction activities.

At the design stage, a set of works is carried out:

- The mass of the bath with the floor structure is determined.

- The margin of safety of the foundation is checked by the calculation method.

- The dimensions of the tape structure are calculated.

- Design or sketch documentation is being developed.

- The amount of necessary building materials is calculated.

- Estimated documentation is compiled and the amount of expenses is determined.

At the preparatory stage of work, it is important to purchase and concentrate purchased building materials in the immediate vicinity of the construction site, as well as prepare working tools and equipment.

Building materials for the construction of a bath

Building materials for the construction of a bath For the construction of reinforced concrete tape under the bath, you will need the following building materials:

- cement, screened sand, medium fraction gravel and water for mixture preparation;

- sand-gravel mixture for the formation of damping bedding;

- waterproofing materials to ensure the moisture resistance of the tape;

- boards made of waterproof plywood, wood or metal for formwork assembly;

- steel reinforcement of a variable profile for assembling the reinforcement frame;

- knitting wire used in the assembly of a spatial lattice.

In the case of self-preparation of a concrete solution, a concrete mixer will be required, which accelerates the mixing of concrete in increased volumes and ensures a uniform consistency of the mixture. Do not forget to also prepare a tool for mounting the formwork structure, a deep vibrator for concrete compaction, a grinder for cutting reinforcement and a hook for tying wire.

Selection and marking of the construction site

When determining a place to place a bath on the territory of a country house or cottage, try to choose a flat area to which it is easy to bring water supply lines, sewage lines, and also to supply electrical energy.

Try to choose a flat area to place the bath

Try to choose a flat area to place the bath Before starting marking work, prepare the territory:

- Clear the area of rocky inclusions.

- Remove vegetation.

- Uproot existing roots.

- Remove fertile soil layer.

- Plan the base.

Having completed the preparation, proceed to the markup, for which you will need:

- wood pegs for metal;

- rope;

- level;

- roulette.

Please follow the following procedure:

- Fix the stakes in the ground, guided by the project.

- Make a stretch between the pegs of the rope.

- Check the correctness of the markup.

To do this, measure the diagonals and compare their sizes. The permissible deviation of the diagonals is 2 cm, which confirms the correct marking. When marking up, do not forget to beat off the inner contour of the tape base.

Soil excavation and trench preparation

Carry out earthworks in accordance with the markings:

It is necessary to clean off the top fertile soil layer before digging trenches

It is necessary to clean off the top fertile soil layer before digging trenches - Dig a trench to the specified depth.

- Level the base of the pit.

- Make sure the trench walls are vertical.

- Lay geotextiles on the base of the trench.

- Fill the bottom with dampening compound.

- Moisten the bedding and compact to a thickness of 0.2 m.

Now the pit of the future tape is prepared for the installation of formwork.

Construction and installation of formwork

For the installation of formwork, plywood, steel or wooden panels should be prepared, the height of which exceeds the base mark by 0.2-0.3 m. Attention should be paid to the absence of roughness on the inner surface of the panels to facilitate their dismantling after solidification of the monolith.

Assembly procedure:

- Install shield elements around the perimeter of the future tape.

- Drive in the support posts and install the braces.

- Place bursting bars between wooden shields.

- Connect opposite shields with studs or wire.

- Seal butt and corner areas.

- Attach polyethylene or roofing material inside the formwork for waterproofing.

After completion of work, check the rigidity of the structure.

Formwork device

Formwork device How to make a strip foundation strong?

To increase the strength of the concrete tape, it is reinforced with a frame of steel reinforcement.

Observe the following procedure when performing reinforcement work:

- Cut the rebar blanks to the desired size.

- Secure the rods with knitting wire.

- Lower the lattice frame into the pit.

- Provide with the help of linings the distance from the bars to the bottom of the trench is 40-50 mm.

Do not forget to provide embedded elements for supplying the necessary communications to the bathhouse.

How to pour the foundation for a bath - features of mixing and concreting

It is important to know when deciding to build it yourself correctly. To ensure the quality of work, it is necessary:

Reinforcement with a steel reinforcement frame is performed to increase the strength of the concrete tape

Reinforcement with a steel reinforcement frame is performed to increase the strength of the concrete tape - prepare or purchase a concrete solution;

- to carry out concreting work competently.

Let's dwell on the main points.

How is the concrete mixture prepared for pouring the foundation?

To prepare the concrete solution, the following components will be required:

- portland cement marked M350 and above;

- cleaned sand;

- medium fraction crushed stone or gravel;

- water.

Bulk ingredients should be evenly mixed in a concrete mixer with the gradual addition of water until the desired plasticity. When mixing, follow the standard recipe, which involves mixing fine sand, Portland cement and crushed stone in a ratio of 3:1:5.

Concrete mix for pouring the foundation

Concrete mix for pouring the foundation How to fill the foundation under the bath?

Pouring the foundation for a bath is a responsible operation, during which a number of requirements must be observed:

- do not interrupt the formwork filling process for more than 30-40 minutes;

- first fill the corner areas, distributing the solution along the tape;

- remove air inclusions with a bayonet or using a rammer;

- after compaction, carefully level the surface of the filled tape.

Given the increased volume of concreting, it is advisable to purchase a ready-made concrete solution to ensure continuous pouring.

Final steps after pouring concrete

Properly performed concrete care protects the finished foundation from cracking.

To do this, maintain a constant humidity of the array in the following ways:

- regularly moisten the tape surface;

- cover the concrete with polyethylene after saturation with moisture.

Compliance with these requirements ensures the normal course of the hydration process. A month after pouring, when the monolith gains strength, carry out further work on the construction of the bath.

How to make the foundation correctly - practical recommendations

When building a foundation, professional builders are advised to pay attention to the following points:

- compliance with the requirements of building codes and regulations;

- the use of high-quality building materials;

- compliance with the proportions of the components;

- uniform mixing of ingredients;

- continuous pouring of concrete.

The construction of the strip foundation should be carried out in strict accordance with the technological requirements. Before starting construction, study the provisions of regulatory documents, develop project documentation and take care of purchasing high-quality building materials. The reliability and strength characteristics of the tape base for the bath being built depend on the quality of the foundation work.

A bath is a building that must be present on any personal plot without fail. The foundation for a bath is the first thing construction begins with.

The main types of foundations for installing baths on them are tape, shallowly recessed, pile-screw and columnar. To give the building an original appearance, in some cases, trees can be used as pedestals, but this is more an exception than a rule.

What is the best foundation for a bath to choose depends primarily on the type of soil on which construction is planned. If the area is marshy or has difficult terrain, the ideal option is to equip pile foundation for a bath, while the grillage should be located above ground level.

This design securely holds the frame of the bath. Another advantage of this type of foundation is its openness, due to which the air flows passing under the bath floor dry it well, thereby preventing it from being damaged by moisture. The disadvantage of the design is that in order for the floor in the washing or steam room to be warm, it must be additionally insulated.

For that area where the soil is slightly heaving, sandy, are popular shallow-depth strip and column foundations. A columnar foundation for a bath is used to reduce construction costs, since arranging a strip foundation is an order of magnitude more expensive.

The advantage of the strip foundation is the minimum pressure on the soil, the closed underground space, as a result of which the floor in the bath will be much warmer. In order for the underground space to dry out, they make products. If desired, this space can be covered with loose insulation and made from the side of the floor, which will increase the thermal characteristics of the bath.

Tape foundation for a bath it is worth choosing in the case when the bath is not made of wood, but brick or foam blocks, due to the fact that such a design will have a much greater weight compared to a wooden frame. Since the bath is a small and not complicated building, you can make it on your own. Let's take a closer look at how to build a tape-type foundation for a 4x6 bath on our own.

Do-it-yourself ribbon shallow foundation for a 4x6 bath

The main stage in the construction of a foundation for a bath is the calculation of materials and strength characteristics of the structure. And if it is quite difficult to calculate the strength, such calculations are carried out by professionals, taking into account the density and moisture content of the soil, climatic and other conditions, then it is quite possible to calculate the amount of necessary materials on your own.

Calculation of the amount of materials

To do this, it is necessary to determine in advance the dimensions of the future structure, and then calculate the volume of the foundation using the formula from the school textbook.

When the volume is known, it will not be difficult to calculate the required amount of materials to produce the required amount of concrete mix, since there are many online calculators on the Internet that offer such services and it is very easy to calculate a shallow strip foundation with their help.

The next stage after the calculation is the preparation for the work.

Preparatory stage

At this stage, it is necessary to clear the site for construction and prepare the tool. To make a strip foundation for a bath with your own hands, you will need to have:

- Roulette, to measure the required distance;

- Building level, to control the installation of formwork and leveling the plane of the foundation;

- Chainsaw for sawing boards and making formwork;

- Screwdriver for mounting formwork;

- Shovels, for sampling the soil and preparing the batch;

- Concrete mixer electric or mechanical;

- The necessary materials - sand, cement, crushed stone and rubble stone, must also be prepared in advance.

Bath foundation marking

Marking the location of the foundation is one of the important stages in the process of erecting the foundation for a bath. To carry it out, you will need to prepare a sufficient number of wooden pegs, which will indicate the corners of the building. After the pegs are prepared, you can proceed directly to the marking.

Marking the location of the foundation is one of the important stages in the process of erecting the foundation for a bath. To carry it out, you will need to prepare a sufficient number of wooden pegs, which will indicate the corners of the building. After the pegs are prepared, you can proceed directly to the marking.

First you need to determine the position of the foundation relative to other buildings located on the site. Then the first side of the building is marked and pegs are set to mark its boundaries. Further, a distance equal to the second side is laid off from the pegs. This distance must be temporarily marked by setting the pegs by hand so that they can be easily removed and moved.

Now that we know the distance of both sides, we need to align the diagonals. To do this, the diagonals are alternately measured and the stakes are transferred. After the diagonals are aligned, you need to check the length of each side again.

Important: in no case should you neglect the equality of the diagonals, because, if this requirement is neglected, the foundation will have the shape of a rhombus, therefore, the corners of the building will not be 90 °. In the future, such structural irregularities will be reflected in the laying of the log house and the construction of the roof.

After the external marking is carried out, it is necessary to carry out the internal one. To do this, a distance equal to the width of the future foundation is measured from each side and the lace is pulled.

Soil sampling

To organize a shallow foundation, it is not necessary to choose soil to a great depth. The planting depth is not critical, the main thing is to equip a sand cushion under it to compensate for swelling of the soil, and also arrange a warm one around the foundation.

The width of the blind area should be equal to the depth of freezing of the soil in the place where the construction is being carried out.

sand cushion

To make a pillow, sand is poured onto the bottom of the trench, after which it must be leveled and compacted. The layer of sand should be at least 15 cm. For better compaction, the sand in the trench should be poured with plenty of water and compacted again.

Formwork installation

Before pouring the foundation under the bath, it is necessary to set the formwork. For a shallow foundation, it can be made from edged tess. To do this, it is cut into segments of the required length, equal to the length of each side. Then, with the help of a hammer and nails, shields are knocked together from identical pieces of boards. As jumpers on shields, it is convenient to use short pieces of tesa.

It is necessary to prepare shields both on the outside and on the inside. Once they are ready, you can install the formwork according to the dimensions indicated by the stakes. First, the outer side is exposed and fixed with the help of wooden stakes and spacers, then the inner side. To fix the width, both sides of the formwork are fixed to each other at a certain distance using a transverse rail and self-tapping screws. This needs to be done in several places.

The last stage of formwork preparation is installation of fittings inside it and marking with the help of laces, stretched over the entire length of the formwork, top level pouring concrete. Of course, many people ignore this process due to the fact that the load on the foundation is small. But the technology provides to reduce the load and increase the strength of the structure.

Concrete preparation and strip foundation pouring

As a rule, depending on the required strength of concrete, the proportion of the mixture of sand, crushed stone and cement can vary significantly. To select the strength and, accordingly, the brand of concrete, it is necessary to calculate the weight of the future building. The weight of a wooden bath is small - concrete grade M100 is suitable (concrete marking means the weight that it can withstand per square centimeter in kilograms).

The proportion for the preparation of M100 concrete is as follows: 1 kg of cement, 5 kg of sand and 7 kg of crushed stone. For the convenience of preparing the solution, you can pre-weigh one shovel of each of the components and convert the proportion into the number of shovel. This will allow you to make batches much faster.

To prepare the mixture, it is desirable to use a concrete mixer and prepare the mixture according to the following algorithm.

Despite the fact that the bathhouse is a non-residential household structure, the same requirements are imposed on the construction of its foundation as on any other capital building. It must have good strength, be resistant to loads in different directions. It must reliably isolate the bath from heat leakage and moisture penetration and correspond to all the features of the construction region.

Video - what you need to know when building a foundation with your own hands

Preparatory stage

Since there can be a large amount of moisture in the bath, it is necessary to create a good drainage system around the site of its foundation in order to drain the site. The area around the foundation of the bath may have a slight slope, but not to the north. This will allow the melt water to freely pass by the bathhouse, without lingering in the foundation area. The same slope will avoid flooding in the event of heavy rains.

Level the construction site and remove the top, fertile layer of soil from it. According to the prepared project, we mark the contour of the future foundation. Remember that the width of the foundation tape should be approximately 10 cm larger than the load-bearing wall.

For marking, stock up on a tape measure, a building level, a long cord and wooden or metal pegs.

After building a rectangle and pulling the cord between the pegs, pull the cord along the diagonals of the resulting rectangle. If the stretched diagonals are equal, then you have a rectangle with perfectly right angles.

The foundation for a bath can be built using several technologies. So, the main options for the foundation are a tape monolith or support pillars. Depending on your choice, the site should be marked.

A tape monolithic foundation is recommended to be built in areas with rocky soil, or with a high content of sand. It is also suitable for loams. If the soil in your area has a high moisture content, then it is more advisable to build a columnar foundation. When building a bathhouse in the coastal zone or on slopes, it would be wise to use a foundation on screw piles.

We build a tape monolithic foundation for a bath

This foundation design is a monolithic concrete tape closed around the perimeter. This design can withstand heavy loads and it is possible to build buildings with a lot of weight on it. Concrete tape can even withstand a stone or brick structure.

When drafting a strip foundation, please note that its width should exceed the width of the load-bearing wall by 10 cm.

After marking, we proceed to earthworks. The strip foundation must be buried in the ground. The depth of penetration depends on the characteristics of the soil. A layer of sand and a layer of crushed stone with a thickness of at least 10 cm each are laid and compacted at the bottom of the trench. A plastic film is laid on the resulting pillow.

On the walls of the trench and above it, formwork is constructed from wooden boards to the required height. Opposite sides of the formwork are reinforced with stops or connected with bars or wire.

A metal frame is mounted inside the formwork. It is a three-dimensional cell in which there are at least two horizontal layers connected by bridges. At the intersections, the reinforcement is connected by wire, welding or fixed with clamps.

When laying the concrete solution in the structure, it must be treated to prevent the formation of air cavities. To do this, its mass is pierced with a sharp bar or treated with a deep vibrodrill.

After the concrete has matured, a layer of heat and waterproofing is applied to its horizontal and vertical surfaces.

We build a columnar foundation for a bath

This structure consists of strong pillars that are located under the anchor points of your building. As a rule, such points are corners, junctions of walls and intermediate supports, but no more than 2.5 m from each other.

At the stage of earthworks, holes are dug under the pillars. The width of the pits should be made taking into account the formwork and possible backfilling with a sand cushion. A sand and gravel cushion is placed successively at the bottom, dense polyethylene or roofing material is laid on them.

The wooden formwork structure for supporting pillars can be assembled on the ground, checked for the correctness of its geometry, and then lowered into the pit, aligning it vertically with the help of spacers.

To save labor costs, large-diameter pipe sections can be used as formwork for poles. It can be metal, asbestos-cement or polymer pipes - the material does not play a fundamental role.

A multi-tiered metal frame is placed inside the pipe or wooden formwork, connected by vertical bars.

Concrete mortar is laid in the column formwork in layers, with the obligatory processing of the mortar mass to prevent the formation of air bubbles.

Additional strength can be given to such a foundation by a grillage - a horizontal strapping between the pillars at the upper level.

In addition to the foundation for the walls in the bath, the foundation for the stove is also built without fail. The calculation of the foundation is based on the estimated weight of the furnace. So a metal oven will weigh about 150 kg, but a brick oven will pull at least half a ton.

We build a monolithic foundation for a bath metal stove

- We measure the dimensions of the furnace and in the place of its future location we dig a foundation pit for the foundation in the form of a monolithic slab. Its depth can be about half a meter. At the bottom of the pit, sand, gravel and a layer of rolled waterproofing (roofing material or polyethylene) are successively laid.

- A metal checkered frame is mounted inside the pit, and the walls of the pit are reinforced with wooden formwork.

- Concrete mortar in such a foundation can be poured in layers. When mixing a concrete solution, we take 2.5 buckets of carefully sifted sand and 4 buckets of gravel per bucket of cement. After the pouring is completed, the surface of the foundation for the stove must be checked for horizontality, if necessary corrected by the rule.

We build a foundation for a brick oven

The large weight of the brick oven dictates the need to create a more solid foundation.

The monolithic foundation for a brick kiln should be below the freezing level of the soil and therefore it is better to make it combined - columnar-tape. In this case, the pillars-supports of a wide diameter should go below the freezing line.

Otherwise, the construction technology of such a foundation consists of successive stages of forming a columnar foundation, and then, on top of it, a concrete monolith slab. Nuance - when installing a reinforcing mesh in the formwork of the pillars, the ends of the bars must be brought up, the pillars must be connected to their sweat with the reinforcing belt of the slab.

And yet - the foundations of the bathhouse and the house can not be connected, since they have different loads.

13.06.2014The foundation is the foundation of any building. It has a direct impact on the quality and reliability of the building as a whole. Do you want your bath to be strong and serve you for many years? Make a good foundation!

The base for the building can be of different types: there is a foundation for a bath, columnar, tape. There are other types, but usually during construction it is between these two options.

A strip foundation is the most popular option, which is more reliable than a column foundation, but its construction requires a lot of effort and time.

Tape foundation for a bath: advantages

- ability to withstand high loads. The strip foundation can withstand the weight of even buildings that have several floors;

- simple installation. For the construction of this type of foundation, you do not need to use special equipment and complex technologies;

- construction speed. If you use ready-made concrete, then the construction of the foundation will take a week, and if you do it yourself - less than a month;

- fairly low price. The strip foundation for a bath usually has a compact size, so it does not require a lot of material to create it. During construction, cheap raw materials are used: concrete, reinforcement, boards and crushed stone;

- the ability to subsequently make a cellar or basement;

- versatility. This type of foundation can be used in construction, aerated concrete and even brick.

Tape foundation for a bath: disadvantages

- great weight. Concrete is a heavy material, so if you choose the wrong place for construction, you may encounter the fact that the building will sag on one side;

- the need for a thorough study of the soil and the calculation of depth. The depth of the strip foundation for the bath is directly dependent on the soil. If the base is too shallow, then the building can sag and deform;

- the impossibility of erection on the ground with a weak bearing capacity.

Do-it-yourself strip foundation for a bath: types and their features

This type of foundation is of several types. If we consider its types according to the device, then there are two types: monolithic, prefabricated and monolithic-prefabricated.

A feature of a monolithic foundation is that during its construction a reinforced formwork trench is made into which a concrete solution is poured. The prefabricated base implies the assembly of prefabricated reinforced concrete blocks of factory production.

A monolithic foundation is more difficult to build and also takes time, but its reliability is much higher, so this type of foundation is most often chosen. A prefabricated foundation can only be used when building a bath on soil that has good bearing characteristics.

At present, there is also a prefabricated monolithic technology, which includes two types of foundations: part of the base is made of reinforced concrete, and the other is made of blocks.

Depending on the depth of the foundation, there are also several types: non-buried and buried.

A shallow strip foundation for a bath is the best option for small and light baths, for example, made of wood. It can be laid on sand and clay. Its advantage is its small depth (about 0.5 m), due to which less building materials are required for its construction, which leads to significant savings.

A recessed strip foundation is a high-quality and reliable foundation, ideal for the construction of large and massive baths, as well as those combined with a house, etc. But keep in mind that this type of foundation will require large financial costs, and it is much more difficult to install.

Depending on the material that was chosen for the construction, the foundation is:

- brick;

- rubble;

- sandy;

- soil-cement;

- reinforced concrete.

The foundation made of butobeton is recognized as the most reliable. Large stones weigh about 30 kg and are about 0.3 m long. They are quite inexpensive. Such a foundation is easy to do with your own hands. If the soil is sandy and rocky, a rubble foundation will not work, as it can quickly crack.

The brick foundation is also widespread, but its peculiarity is that the brick is a hygroscopic material, so the foundation cannot be made at great depths or near groundwater. The brick base is suitable for dry sandy soil. For the foundation, only red brick is used, since it is less susceptible to water.

Sand and soil-cement foundations are suitable only for the construction of light non-residential premises on a solid foundation.

Reinforced concrete foundation is a cheap, but at the same time quite strong type of foundation, which is also suitable for baths with complex shapes. To lift this material, you need to use special equipment. You can make a foundation with your own hands using blocks measuring 20x20x40 cm.

More about the features and types of the strip foundation of the bath in the video:

What brand of concrete for a strip foundation for a bath is better?

Of course, the key to the reliability of the foundation is the use of high-quality material. When choosing a brand of concrete, you need to focus on the total weight of the bath, the type of reinforcement and the soil.

If you are planning to build a small and light structure, for example, a frame bath on a strip foundation, then grade 200 concrete is suitable for you. If the building is heavy, but not too bulky, then it is better to choose grades 250 or 300.

For the construction of heavy and massive structures, concrete grade 350 will be required.

Also pay attention to the quality of the soil. If it is strong enough and dense, then concrete grades 200 or 250 will do. For unsteady and heaving soil, use better concrete - from 300 kr

The higher the brand of concrete, the higher the quality and cost. It is not recommended to save on concrete, since a poor-quality foundation will lead to a significant reduction in the life of the entire building and its premature destruction.

How to make a strip foundation for a bath?

So, you have decided to build a bathhouse, made a suitable project and decided on a building site. What's next? We proceed to the installation of the foundation. How to make a strip foundation for a bath will be discussed further.

Stage 1. Territory preparation

It is necessary to clear the area where construction work will take place from debris, stones, trees and shrubs. If grass grows on the territory, it is recommended to remove the top layer.

It is necessary to clean not exactly the site itself, on which the building will be erected, but the territory is slightly larger (at least 1 m on each side).

Stage 2. Marking the foundation plan, preparing the trench

To do this, you will need pegs, a square, a tape measure and twine. It is necessary to drive pegs into all corners of the future building, then pull the twine between them.

It is important that all corners are at a 90 degree angle. To check, first use a square, and then you can check the evenness of the future foundation by measuring the diagonals. It is necessary to strive for the same length of the diagonals (a discrepancy of 2 cm is acceptable).

After preparing all the points, you can proceed to digging the trench.

The dimensions of the strip foundation for the bath may vary depending on the planned construction and type of soil. When choosing the depth of the trench, you need to focus on climatic conditions. The height of the strip foundation for a bath is usually 0.5-0.7 m.

For fine sandy soil and non-rocky clay soil, which is characterized by high hardness, a trench half a meter deep with a freezing depth of up to a meter will be enough, 0.75-1 m - at 1.5-2 m. For sandy soil, the trench should be at least 0.6 m and above freezing depth. For heaving soil, a trench should be prepared to the freezing depth.

The width of the strip foundation of the bath directly depends on the width of the future walls. It should be about 0.5-1 m. But if the soil is weak, then it can be increased to 2-2.5 m. Accordingly, the trench itself should be slightly larger (about 0.2 m) than the width of the foundation.

In addition, the width of the foundation passing under the internal partitions is usually made less than 0.1 m than under the external walls.

If you are going to install a brick oven in a steam room or brick a metal one, then you will need to make a reinforced foundation under it, so you need to install it simultaneously with the construction of the foundation for the building.

The bottom of the prepared trench should be covered with a sand cushion, its thickness should be 0.1-0.2 m. First, we pour a layer of sand into the trench, then pour it with water and tamp it down, and then cover it with rubble, then level it again.

The pillow is needed to prevent distortions and deformation of the building. In addition, a layer of sand protects the foundation from sudden temperature changes during periods of rain and snow.

Stage 3. Formwork for the foundation

The formwork is a frame that will set the shape for the future foundation. For it, you need to use boards with a thickness of at least 30 mm or chipboard 20-22 mm. The height of the formwork must be at least 30 cm, it is necessary that it exceed the height of the future foundation.

When hammering the formwork, make sure that all the nail heads are on the outside. In this case, the disassembly process will be easier and take less time.

It happens that the formwork is left and used as additional thermal insulation. In this case, its height should be equal to the height of the foundation itself.

To install the formwork, you need to install supports along the edges of the trench and attach the walls of the structure to them. It is important that the inner surface of the frame is as even as possible.

So that when pouring concrete, the solution does not get into the cracks, it is recommended to cover the formwork with a film or a layer of roofing material.

Below is a video: Do-it-yourself bath foundation strip. Formwork:

Stage 4. Formwork reinforcement

Despite the fact that concrete itself is a durable and reliable material, it must be taken into account that the load on it will be huge. In addition, concrete is completely non-plastic, so reinforcement should be done. Such reinforcement will help protect it from destruction.

For reinforcement, fittings with a diameter of 1.2-1.6 mm, which have undergone anti-corrosion treatment, are suitable. In the bottom of the trench, you need to drive pieces of reinforcement in two rows. Between them and the walls of the formwork, you need to leave a gap of 5 cm, it is important that the segments are lower than the foundation by about 5 cm.

After that, you should put the rods on the bottom and tie them with wire to vertical supports at a distance of 7-10 cm from the bottom. Broken bricks can also be placed under the bars. The top row of reinforcement should be approximately 7 cm below the foundation level.

If you are making a strip foundation for a bath with a drain, then just at this stage you need to take care of communications. It is recommended to make them underground. To prepare the technological holes, you will need to cut off a part of the plastic pipe and attach it to the fittings in the right place.

Stage 5. Foundation pouring

To fill the strip foundation under the bath, you can prepare the mixture yourself or buy a ready-made one. The advantage of the latter option is to reduce the work and reduce the time to prepare the foundation for the bath.

It is better to pour the solution into the formwork at a time. If it does not work, then the concrete layer should be 0.2 m or more. It is necessary to pour the solution from a height of no more than half a meter, otherwise the concrete may delaminate, which will ultimately reduce the strength of the structure.

After you need to remove all excess air from the concrete to make it more dense. To do this, it is necessary to level it and pierce it with a bayonet shovel. For the same purpose, the formwork from the outside must be tapped with a hammer.

If the weather is hot outside, then you need to water the foundation at least a couple of times a day, if, on the contrary, it rains constantly, then cover the base with a film.

After 3 days, the formwork can be removed. The erection of the walls of the bath can be started only 3 weeks after the construction of the foundation.

Not a single suburban area is complete without a bath. Some owners of land allotments put a bath in the first place, and only then they begin to develop the site and build a house. For construction, you can hire a construction team, but this is expensive, and therefore some decide to build a bathhouse on their own.

The first stage in construction is laying the foundation. This stage is very important and must be carried out with great care. How to build the foundation yourself, what type of structure to choose, we will consider in this article.

Foundation types

Before you start arranging the foundation for a bath, you need to have an idea about the types of foundations, and choose one that suits your structure. The main types of bases:

- strip foundation;

- columnar foundation;

- foundation slab;

- tire foundation;

- prefabricated monolithic foundation, from blocks.

There are some factors that determine the choice of one or another basis. It is important to take into account not only the type of soil on the site, but also the specific gravity of the building itself, and since we are building a small bathhouse, its specific gravity will not be prohibitive.

A columnar foundation is suitable if the walls of the building are timber, log, foam blocks. This foundation is also suitable for a frame bath. If you plan to build walls of brick, aerated concrete, then it is worth installing only a strip foundation, regardless of the type of soil.

How to equip a columnar foundation

The base for a bath made of pillars does not require a large amount of material and financial investments. This is one of the economical options. For this type of bases, the following materials are used:

- logs;

- brick;

- foundation blocks made of reinforced concrete;

- asbestos-cement pipes, which are filled with a concrete mixture;

- concrete.

How to make a columnar foundation - instructions

How to correctly install a strip foundation

This is also a fairly popular base, not only for small baths, but also for other types of buildings. Before you begin to equip the foundation, you need to prepare the soil at the construction site. It all starts with the marking of the site.

For marking, you will need pegs and ropes, the length of which is equal to the line of the walls of the bath. Pegs are driven into the corners, and a rope is pulled between them, at an approximately right angle.

To obtain a right angle, you need to pull a diagonal rope, the length of which should be exactly five meters.

If the site has fairly solid soil, then the depth of the trench to be dug under the foundation can be only 40 cm, but if the soil is heaving and loose, then a trench is dug 70 cm deep. A sand cushion is arranged at the bottom of the trench, which must be well compacted.

Boards are taken for formwork, if possible, it is better to use old lumber, since after pouring it will become unusable. If there is no old material, then you will have to buy the right number of boards.

The formwork is erected in one step, all at once, and then the concrete must be poured in the same way. The height of the formwork is calculated based on the depth of the dug trench, for example, with shallow penetration, 80 centimeters are enough, in other cases a meter. The width of the formwork should be at least 20 centimeters.

Reinforcement

Approximate amount of reinforcement for tying the base: 4 meters per linear meter of the foundation. With the help of a knitting wire, a square is created from the reinforcement and placed in a trench. It remains only to pour concrete.

What you need to know when filling:

- the solution should be poured all at once;

- as soon as the pouring is completed, the concrete is compacted and leveled;

- drying time, almost a month;

- work is not carried out until completely dry.

Video of the arrangement of the strip foundation:

Benefits of a tire foundation

It should be understood that for this type of foundation, you need to select tires that are the same in thickness and diameter, then it will be very simple to work. It is necessary to deliver the required number of tires to the site for arranging the foundation for the bath.

What are the advantages of this material:

- tires are made of special rubber, resistant to various kinds of impacts;

- the property of the material allows you to equip a reliable and durable foundation for building a bath.

- Particular attention should be paid to the insulating qualities of the tires, they tolerate a humid environment and reliably protect the base of the bath.

As for the shortcomings, it is the only one - when heated, the tires emit fumes that are harmful to the environment. But a properly built foundation of tires will not be exposed to the sun, from which the rubber is destroyed.

Tip: when deciding to build a foundation from tires, you should evaluate all the positive aspects and disadvantages of such a structure.

earthworks

- Dig a pit, the size of which will exceed the area of \u200b\u200bthe building by 20 centimeters on each side.

- The depth of the pit is 20 centimeters, regardless of the thickness of the tires.

- The bottom of the pit is covered with sand and well compacted until a flat surface is obtained.

- Then we distribute the tires at the bottom of the pit, setting them as close as possible to each other.

- The next step will be to fill the entire space in the tires and between them, the backfill material must be well compacted, since the strength of the base depends on this.

Concrete works

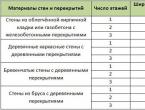

Consider the cost of work and material when arranging a strip, shallow foundation in the table:

Calculation of material consumption and the cost of a columnar foundation in the table:

The tables show the approximate cost of materials and labor, as the final price will depend on the type of soil.

How to repair a foundation

Often, if the technology for arranging the base of the bath is violated, the foundation begins to collapse over time. What to do, completely disassemble the structure, or repair the base?

Repair of the foundation on your own is possible, you just need to know the sequence of work, in each case.

Strip foundation repair

In order to make a quality repair, you need to raise the log cabin of the bath above the base. This is usually done through the use of cargo jacks, ideally there should be at least 8 of them: 4 are placed in the corners, and one in the middle of each wall.

Here you will need help, since it is advisable to lift the corner jacks at the same time.

As soon as the log house is raised to the desired distance, it is necessary to assess the extent of the destruction of the base. If the foundation is cracked and crumbled a little, it can be reinforced with strapping wire and reinforcement around the entire perimeter, formwork can be installed, and poured with concrete. The foundation will turn out to be a little thicker than the previous one, and thanks to reinforcement and pouring it will be strengthened.

If the destruction is significant with a skew of one or more corners, then it will have to be completely removed, up to the sand cushion. Sometimes on heaving soils with a small depth of penetration, the base can break at the time of freezing of the soil. If this is the reason, then it is worth increasing the depth of the trench. Once the trench has been dug to the desired depth, the new foundation is poured. As soon as it dries, the log house is slowly lowered, not forgetting to lay the insulation.

Column foundation - repair

In this type of foundation, skew of the pillars may occur. To fix this problem, you need:

- put a support next to the skewed pole;

- after that, the old post is removed, if necessary, the hole is deepened. Then you need to build a new harness and install it in the hole;

- the first stage is poured, the solution fills the hole to the soil surface;

- the formwork is being built and the pillar is finally poured.

To strengthen the foundation, you can make a concrete tape around the entire perimeter of the log house, which will connect the pillars into a single whole, which will prevent them from further warping.

As you can see, there is nothing difficult in arranging the base for a bath with your own hands. The main thing is to understand some points and know the nuances of pouring foundations of various types.

Do-it-yourself foundation for a bath 4x6, 3x4, 6x6 - step by step instructions

How to make a foundation for a bath with your own hands, what are the options for a room with dimensions of 4x6, 3x4, 6x6? Types of foundations and the most important points for them