We put a house from a bar on screw piles. Reliable foundation for a house made of timber (pile-screw) Country house made of timber on stilts

Accurate calculation - this is the main theme that sounds after the decision to build a house. A correctly made calculation will allow you to choose the best version of the future structure from a large number of them offered on the market. Everything can be foreseen in advance: dimensions, number of storeys, materials, and their environmental friendliness, as well as the cost of work.

It is no coincidence that houses made from natural materials are gaining popularity. The use of timber for the construction of cottages is justified, including safety for the health of its inhabitants. Also, special requirements are imposed on the choice of foundation. The construction and price calculation shows that the pile foundation for a house made of timber is sufficient to withstand the loads, and is less burdensome for the financial part of the construction.

This option causes a number of reasons, of which only a minor part is unacceptable. Only the type of soil on the construction site can exclude the use of a pile foundation, the advantages of such a choice will be discussed below.

Options for foundations for a house made of timber

Any capital construction structure needs a foundation, and the stronger it becomes, the easier it will be in terms of repairs to operate the object after construction. However, there is a principle of sufficiency. There is no need, for economic reasons, including, to arrange a massive foundation, with a significant reserve of the safety factor, where you can get by with the same a solid foundation while saving money.

At the design stage, each of the existing foundation options is considered, and the final choice is made taking into account the soil at the construction site, the load from the structure, the customer's wishes in terms of architectural nuances, commissioning dates and, of course, cost.

Tape, the most common option, its popularity is due to the ability withstand and "dissipate", with proper calculation, large loads, even from two-story structures made of heavy timber. The simplicity of the construct of such a choice turns into relative simplicity during construction. In fact, after reading about this option, or after consulting with experts, even a novice in construction can build it, however, with very high labor costs.

Exists two types of strip foundations:

- buried;

- shallow.

The shallow view allows reduce the cost of construction, due to the smaller, in comparison with the more capital type, the volume of earthworks, the consumption of building and related materials. The efficiency and applicability of such a foundation becomes hostage to such a choice.

A prerequisite for its use is favorable geological conditions- low groundwater level, construction is carried out on non-heaving soils. The weight of the building is also limited with this choice. Otherwise, the results of the work will not be used for long.

Recessed view avoids the limitations of the first type of base, respectively, and all types of costs will increase. The volume of excavation, by the way, the most expensive work, will grow significantly, and the cost of purchasing cement, sand, crushed stone, rebar, wood for formwork will also increase. Financial losses are not the only ones. For the qualitative arrangement of this foundation, a large time delay will be required. In some cases, the foundation is required defend up to a year, then to continue construction.

Slab variant doubles the disadvantages (in terms of finance) of the above options, but has one indisputable advantage. He is not afraid of seasonal swelling of mobile, heterogeneous soils. It is extremely difficult to build such a foundation with your own hands, without the involvement of specialists.

Solution

To avoid the disadvantages of the above options allows the choice of pile foundation. This option known in construction for a long time, but mass use began relatively recently.

Pile-screw foundation avoids:

The ability to resist loads is not inferior, if not superior to the more familiar base options, a pile foundation for a house made of timber will be able to ensure the integrity of the structure during operation. Plus adds the ability to build up the foundation of piles at any time. This may be necessary for completion, for example, a terrace. Access under the house for maintenance lightweight and eliminates floor rotting under the influence of external circumstances.

Driving screw piles

So, the result of geological surveys made it possible to realize a double saving at the stage of foundation construction, the designers calculated and chose a pile-screw foundation. It's time to start implementing.

Area set up, getting ready pits for the initial installation of piles with a depth of a meter to one and a half. Further, in accordance with the project, the first pile is installed. It is leveled and after several turns the installation angle is checked again. Screwing is done manually or mechanically. For very light structures, it is enough to insert crowbars into the technological holes, build them up with pipes, and such an impromptu lever will allow you to twist the pile to the desired level.

For capital construction, it is better to use mechanisms. An excavator with a hydraulic drill will perfectly cope with this task, and an experienced driver will check the pile foundation for the reliability of its installation. The first pile is screwed in, it is immediately cut to size. She will become a rapper. Checking the installation of the remaining parts of the pile field is carried out, focusing on this center of the local coordinate system.

The pile foundation for a house made of timber is ready.

The following actions

When the pile foundation field is made, you can proceed to the next step. Tying a pile screw foundation additionally strengthens the structure, is made of a channel, an I-beam, a wooden bar, a coupler. Tying with a bar is the least expensive method, which, nevertheless, is able to give sufficient rigidity to the structure.

Tying the foundation of modern components is often used in the construction of houses and baths from wooden beams. Technologically produced binding of the screw foundation with a bar will ensure the absence of distortions and a long life of the structure.

To do this, you need to follow a few rules. The work is being done under the indispensable condition of leveling all piles in one level. Otherwise, it will have to be leveled by sawing the timber itself in the right places to the desired depth. Also, practice prescribes to carry out the strapping almost “immediately” after the installation of the heads, this will avoid trouble with a violation of the work technology.

For docking, in it cuts are made at the ends. The first is from above, the next from below. Further, the beam is laid at a right angle, the connection surfaces must be strengthened with a moisture-resistant wind-proof material, such as jute.

Designing houses from a bar is faced with the choice of foundation. Due to the light weight of the structure, the construction of lumber houses can be carried out on a lightweight, shallow or pile foundation. The base is easily and simply erected on soils of various bearing capacity and does not require increased installation costs.

Design and implementation of the idea

The basis of any construction work is a project carefully drawn up taking into account all the requirements and regulations. If the documentation is verified, the construction of the house will turn into a structural assembly of elements, to which detailed instructions are attached.

- Minimum financial costs;

- The almost complete absence of land works, due to the uselessness of leveling the landscape and eliminating stumps, boulders, bevels;

- Possibility of arrangement on all soils, except for heavy stony, rocky;

- Facilitated ways of conducting engineering communications and pipelines;

- All-season foundation construction;

- A house made of timber on screw piles can be built even in densely built-up conditions.

The base of the screw pile type is not much inferior in terms of the quality of load resistance to more expensive and familiar foundations. Moreover, it is the pile bearing foundation that will ensure the integrity of the structure during operation during periods of seasonal soil movements, and also allows you to increase the useful area of \u200b\u200bthe house at any time without significant investments.

Foundation arrangement: basic requirements and parameters

After carrying out geological work and confirming the selected pile foundation option, it is necessary to take into account the type of support, it is better to take the values \u200b\u200bgiven in the table below as a standard (lengths are given in cm):

In addition to the bearing capacity of the soil, it is necessary to calculate the weight load (total mass) of the structure, for which the following values are taken into account:

- Number of storeys of the building;

- The material from which the load-bearing and intermediate walls are made;

- The presence of local structures of a massive nature (pools, fireplaces, stoves, etc.);

- Interfloor material.

The weight load is calculated up to the intended furniture, if you plan to install impressive headsets or other household items. After that, you should look at the table given as an example (the calculation is given for a one-story residential building with dimensions of 10 * 10 m without additional weighting factors):

| House type | Pile diameter | Number of piles |

| Frame-panel | 108 | 25 |

| Beam 100*100 | 108 | 25 |

| Beam 100*150 | 108 | 25 |

| Beam 150*150 | 108 | 25 |

| Beam 200*200 | 133 | 25 |

| log cabin | 133 | 25 |

The total area of the foundation is also taken into account. The dependence of the number of piles on the size of the foundation is large, for example, for a 3 * 3 country house, only 4 pile elements with a diameter of 89 mm are required, for a 8 * 8 building there are already 16 piles with a diameter of 89 mm, and for a house of 10 * 10 m 25 screw piles with a diameter of 108 mm .

Note that the size range of pile elements is much wider, so it is easy to choose them for each individual type of building. Regardless of the choice of diameter, it is necessary to monitor the strength and practicality of the piles. Developers most often use welded piles with galvanization or cast with tips. Zinc prevents the development of corrosion and, with a high-quality coating, additional waterproofing procedures can not be carried out.

As for the stage of work, before arranging a house from a bar on screw piles, the following procedure for building a foundation is assumed:

- Prepare a place for installation, mark the site;

- Drill small holes for installing piles, determining the points according to the project documentation (do not forget that the foundation is made both under the bearing walls and under the interior partitions);

- Be sure to make support points under local massive objects, elements.

And now the question is: the distance between the screw piles, what should it be? Developers with experience recommend placing screw supports for a frame house in increments of no more than 3 meters. But if necessary, under a log house with a large mass or if there is a sufficient number of load-bearing internal bases, the gap between the piles can be reduced to 1-1.2 meters (no less). The main thing is that the pile-screw foundation should not be a palisade of supports: such a structure will not have greater strength and stability, but it can violate the integrity of the soil and lose all its positive qualities.

Types of piping pile foundation

After the screw piles are placed, the top of the elements is leveled and an I-beam or channel can be welded along the outer perimeter. In this case, the structure becomes stronger. After that, you can begin the construction of the box, the arrangement of the roof. However, there are still options for tying the above-ground parts of the foundation, selected taking into account the future structure:

- Wooden beam piles require heads, on top of which a subfloor can be made. The strapping must be treated with bituminous mastic to improve the waterproofing qualities.

- The channel or I-beam mentioned above is a strapping to stiffen the entire structure. This type is obligatory for buildings of a massive order, as well as for houses built on flooded soils or on soils with a threat of erosion. Channel size: for piles with a diameter of 108 mm, the width of the material is taken from 140 mm.

- A reinforced concrete grillage resembles a strip foundation reinforced with pile elements. To create it, the piles are screwed in, as shown in the project, then the reinforcing cage is welded, the formwork is made and the concrete solution is poured. Grillage is used only for impressive buildings.

- If the house is very heavy, it is better to pour the slab base on piles. To do this, it is necessary to evenly position the reinforcing cage, fixing it on the screw elements, then pour the concrete mixture into the previously prepared formwork.

A log house on a pile foundation is an ideal option for a developer who wants to save money and get practical housing that will last a long time. Choosing the right and strong screw piles, making an accurate calculation of the distance between the piles, it is possible to erect a building on soils of low bearing capacity and with high water content. At the same time, the relief, building density, groundwater level and other nuances necessary to comply with if a house is being built on any other foundation does not matter.

Everyone wants to build for centuries, so that children and grandchildren can enjoy the family nest. But a house made of timber will not last long if you are careless about the choice of materials for building the foundation. Screw piles provide an ideal combination of price and quality. Read below what you should pay attention to when choosing them.

Decided to build a house out of timber? Great choice! An ideal foundation for your building will be a pile-screw foundation. Firstly, its use significantly expands the possibilities when choosing a place for a log house, since the relief and geodesy of the site are not afraid of steel supports. Secondly, the zero construction cycle will take place in

the shortest times. After all, the installation of screw piles takes a little time, and installation can be carried out at any time of the year (even in winter!), At the same time, without compromising the quality of the foundation. By the way, wood harvested during the cold period has a lot of advantages. Most importantly, in winter it is freed from excess moisture.

“A pile-screw foundation is perfect even for a site with large differences in ground level”

Please note that the landscape affects the calculation of screw piles for a house made of timber in only one case - if the ground level difference is more than 70 cm. You will need to strengthen the foundation, that is, additionally tie it with a channel that will strengthen the pile field.

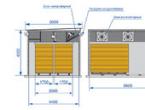

An example of strengthening a pile-screw foundation for a log house built on an uneven site

The choice of screw piles will be affected by the weight of the future building. Note that the wider the support shaft, the more load it can withstand. The standards allow the use of steel supports with a diameter of 89 mm in capital construction. However, it is not worth agreeing to install them under a log house in order to avoid the collapse of the foundation. Having many years of experience in calculations, design experts recommend using supports with a diameter of 108 mm, while a barrel wall thickness of 4 mm is considered quite reliable. Do not forget that during installation, the piles are poured with concrete, which additionally strengthens them from the inside.

If you want to be sure of your foundation not by 100, but by 200 percent, then use screw piles with a diameter of 133 mm to build a house from a bar. It is worth emphasizing that this is not necessary, since the construction is relatively light. As a rule, timber with a diameter of 150 - 200 mm is used for housing construction. In this case, the weight of a linear meter of the wall is approximately 2-3 tons. According to the standards, each screw pile with a shaft diameter of 108 mm can withstand a load of 4-5 tons. So, you will still have a large supply for the installation of furniture, household appliances and friends invited to the housewarming party.

“When choosing piles, do not save on diameter! For a log house, choose 108 mm”

The blade of the product also affects the bearing capacity of the screw pile. Taking into account the peculiarities of the soil of Moscow and the Moscow region, the recommended diameter is 300 mm with a steel thickness of 5 mm. The required number of screw piles under the house from

timber, their length, and, accordingly, the final price of the foundation, can be calculated based on the area of \u200b\u200bthe building. The specialists of our design department will help you with this, if you have a house plan.

The project of a house from a bar on a pile-screw foundation

The project of a house from a bar on a pile-screw foundation Pile-screw foundations are cheaper for a house made of timber than concrete ones. As for their service life, it depends on the quality of steel, production technology, as well as a protective anti-corrosion coating. The better and more modern all of the above, the longer the foundation will last.

“Give preference to piles with high-quality anti-corrosion coating and entrust the installation to professionals”

In conclusion, it is worth saying that it is better to entrust the installation of the foundation to professionals. This will save you time and effort on this time-consuming manual assembly process. Do not forget that professional teams use specialized

equipment. Electromechanical installation ensures high-precision installation of screw piles with minimal deviation. In addition, you will receive a guarantee for the foundation from the manufacturer.

Despite the development of construction technologies, including the creation of new modern building materials, many developers prefer the good old wooden buildings. Houses made of logs and timber are as popular as they were a hundred or two hundred years ago, especially since their modern counterparts have stepped forward significantly compared to traditional peasant huts. Technologies for building foundations for houses from timber are also developing. The best option can be considered a foundation on screw piles.

1. Design features of timber houses

Log houses, in particular log houses, along with stone houses served as the first buildings for human habitation since time immemorial. It can be said that the technology of log buildings has not changed much since then, except that today progressive technologies of building from glued beams are successfully used, the possibilities of high-quality rounding of logs have appeared, house designs have become more complicated, and the houses themselves look very attractive thanks to modern projects of their construction. Compared with other building materials, wood has a number of properties that determine its use for the construction of residential buildings for any purpose:

- Environmental friendliness

- Good thermal insulation

- Compliance to processing

As for the massiveness of houses, this parameter is in the middle between heavy stone or brick houses, houses made of cinder blocks and light frame buildings. As a rule, in terms of weight, houses made of timber are comparable to buildings made of foam concrete and gas blocks. This is due to the porous structure of wood, similar to the structure of foam building materials.

A relatively simple technology for building log houses also plays its role: its walls are built from a series of logs, the so-called crowns, along the perimeter of the building, including internal walls and partitions. The construction of a "box" of logs does not require the use of a significant amount of concrete work and fastening work. Not without reason, the architects of antiquity could build huge towers with the help of an ax alone.

As for the foundation for log houses, they were also built from the hardest wood in the past. Since then, the technology of laying foundations has come a long way. The main requirement for the base of the house is to securely hold it on the ground, so that distortions do not occur during operation - this is especially important for wooden houses, because their design consists of interconnected elements.

As it was said, the weight of houses made of timber is inferior, with equal parameters, to the weight of stone and brick houses. Consequently, the foundation for timber houses may not be as strong, which generally reduces the cost of construction.

2. Advantages of a pile-screw foundation for a house made of timber

Traditionally, several types of foundations are used for log houses:

- slab

- Tape

- Columnar

It should be noted that the creation of monolithic foundations for any structure is fraught with some difficulties:

- High labor intensity

- Cost

- Long commissioning times

- Instability on soft soils, watered and heaving soils

In recent decades, the technology of laying foundations on screw piles has been rapidly developing. It is pile-screw foundations that are devoid of these disadvantages, and their use as foundations for timber buildings has a number of advantages over traditional types of foundations:

- Saving money

- Speed of erection

- Lack of earthworks associated with the loss of soil useful for agriculture

- Possibility of construction on "problem" soils

- All-season work

- Ease of establishing communications in the house compared to other types of foundations

- Ease of erection

- Lack of special preparation of the place for the foundation

- Bookmarking in areas with elevation changes

- Possibility of erection with dense development of the site

3. Features of laying a pile-screw foundation for a house made of timber

What additional requirements may arise for the foundation on screw piles for a house made of timber compared to those for the construction of other types of structures? Obviously, they can be associated with the design features of the timber buildings themselves.

Unlike frame houses, the walls are built from monolithic elements - logs laid horizontally on the ground. Thus, the weight of the roof is transferred to individual logs, and then from the upper logs to the lower ones. Thus, the main weight load is distributed evenly throughout the lower crown. In frame houses, the main loads fall on the racks, that is, they act pointwise along the wall.

Unlike brick and block houses, a wall made of timber is not monolithic and the loads on the lower bars are not so evenly distributed around the entire perimeter of the house.

This is due to the fact that the weight of each log in some part of it may differ from the average - this is due to the uneven density of the wood used, deviations in its thickness, etc.

If for a frame house it is necessary to tie the foundation on supports, and monolithic houses are placed immediately on a monolithic foundation, then in houses made of timber, the lower crown itself can serve as a foundation tie.

Thus, the main feature of the construction of the foundation on screw piles is the possibility of laying the lower crown directly on the piles. However, the lower crowns of different walls are at different levels - two perpendicular rows are laid on two rows of logs. Consequently, only two of the four lower logs of the crowns are laid directly on the pile heads. Accordingly, the other two logs should lie on the strapping.

But the installation of logs on piles should be based on flat areas - this adds requirements to the mandatory equipment of the end of the piles with special heads.

Another requirement for the foundation on screw piles is its sufficient bearing capacity. Although the weight of log houses is inferior to the weight of brick counterparts, it is usually quite large compared to the weight of frame structures. This predetermines the use in this case of screw piles with increased dimensions, as well as with a greater depth of their screwing.

4. Installation of a pile-screw foundation for a house made of timber

In general, the construction of a foundation on screw piles for timber houses is not fundamentally different from laying a foundation for frame houses. First of all, it is necessary to make a calculation of its bearing capacity - this will determine which piles can be used, what will be the step of their installation, and to what depth they will need to be screwed.

The dimensions of the house and the financial capabilities of the owner predetermine the use of heavy equipment or manual labor to lay the foundation.

Standard houses made of timber for permanent residence are usually placed on screw piles with a diameter of 108 cm or more, with a pipe wall of at least 4-5 mm. Accordingly, the blades in the general case have a width of at least 25-30 cm, and the depth of screwing the piles depends on the existing soil properties and is usually 2-2.5 meters. Thus, the use of 3-meter piles with a diameter of 108 mm is considered optimal.

If a lighter structure is being built from logs, for example, a small bathhouse or a gazebo, then, accordingly, the diameter of the piles can be reduced, as well as their deepening.

The course of foundation construction in the standard case consists of several main stages:

- Calculation and planning

- Foundation site preparation

- Pit drilling to facilitate pile driving

- Pile screwing

- Cutting piles by level

- Pile concreting

- Creating a harness

5. Tying a pile-screw foundation under a beam

As we mentioned above, structurally the lower crown can serve as a foundation strapping. In the case of using a beam with a rectangular section, it is enough to screw the lower beams to the pile heads. Some difficulties arise with the use of cylindrical logs - after all, they must fit snugly against the base.

In this case, builders use a number of techniques.

- Firstly, for additional rigidity of the foundation, screw piles are equipped with a grillage made of metal beams or channels welded to the body of the piles.

- Secondly, only two lower parallel logs are placed on the pile heads. Perpendicular logs can be laid on additional lower beams not connected to the frame

6. Conclusion

Installing a foundation on screw piles is the best option for laying the foundation for houses made of timber, even houses for permanent residence that have large dimensions. For such foundations, it is better to use the services of specialists - they will be able to correctly assess the properties of the soil, calculate the parameters of the foundation and carry out high-quality installation of screw piles. If a small building is being erected, especially in the cramped conditions of an already built-up area, then it is quite possible to use the manual method of installing screw piles and make it yourself.