Limit of Detection and Limit of Quantification. On the approval of the guidelines for the validation of analytical procedures for drug testing. XVIII. Visual assessment

Limit of quantification

"... Limit of Quantification (LOQ) (in analytical determinations): The lowest concentration of an analyte or analyte in a test sample that can be quantified with an acceptable level of precision and confidence, as demonstrated by collaborative laboratory testing or other suitable method validation ... "

A source:

"FOOD PRODUCTS. ANALYSIS METHODS FOR DETECTING GENETICALLY MODIFIED ORGANISMS AND THE PRODUCTS OBTAINED FROM THEM. GENERAL REQUIREMENTS AND DEFINITIONS. GOST R 53214-2008 (ISO 24276: 2006)"

(approved by the Order of Rostekhregulirovanie from 25.12.2008 N 708-st)

Official terminology... Academic.ru. 2012.

See what "Limit of quantification" is in other dictionaries:

quantification limit - 3.7 limit of quantification [LOQ]: a tenfold increase in the estimate of the standard deviation of the sample mass. Note The LOQ value is used as the threshold above which the mass ... ...

repeatability limit - 3.7 repeatability limit: The absolute difference between the results of the maximum and minimum values \u200b\u200bfrom the specified number of measurements performed under repeatability conditions according to GOST R ISO 5725 1. Source ... Dictionary-reference book of terms of normative and technical documentation

reproducibility limit - 2.9 reproducibility limit: The value below which, with a probability of 95%, lies the absolute value of the difference between two test results obtained under reproducible conditions. A source … Dictionary-reference book of terms of normative and technical documentation

repeatability (convergence) limit - 3.11 repeatability limitvalue which, with a 95% confidence level, is not exceeded by the absolute value of the difference between two measurements (or tests) obtained under repeatable conditions ... Dictionary-reference book of terms of normative and technical documentation

Intra-laboratory precision limit - 3.11 intra-laboratory precision limit: The absolute discrepancy allowed for an assumed probability P between two analysis results obtained under conditions of intra-laboratory precision. A source … Dictionary-reference book of terms of normative and technical documentation

reproducibility limit R - 2.19.2 reproducibility limit R: The absolute value of the difference between two test results under reproducibility conditions (see 2.19.1) with a 95% confidence level. 2.19.1, 2.19.2 (Changed edition, title \u003d Change No. 1, IUS 12 2002). ... ... Dictionary-reference book of terms of normative and technical documentation

MI 2881-2004: Recommendation. GSE. Quantitative chemical analysis techniques. Testing Procedures for Acceptance of Analysis Results - Terminology MI 2881 2004: Recommendation. GSE. Quantitative chemical analysis techniques. Procedures for verifying the acceptability of the analysis results: 3.17 critical difference: The absolute difference allowed for an assumed probability of 95% between ... ... Dictionary-reference book of terms of normative and technical documentation

GOST R 50779.11-2000: Statistical methods. Statistical quality management. Terms and Definitions - Terminology GOST R 50779.11 2000: Statistical methods. Statistical quality management. Terms and definitions original document: 3.4.3 (upper and lower) regulation limits The border on the control map, above which the upper limit, ... ... Dictionary-reference book of terms of normative and technical documentation

GOST R 50779.10-2000: Statistical Methods. Probability and basic statistics. Terms and Definitions - Terminology GOST R 50779.10 2000: Statistical methods. Probability and basic statistics. Terms and definitions original document: 2.3. (general) population The set of all considered units. Note For a random variable ... ... Dictionary-reference book of terms of normative and technical documentation

RMG 61-2003: State system for ensuring the uniformity of measurements. Indicators of accuracy, accuracy, precision of quantitative chemical analysis methods. Assessment methods - Terminology RMG 61 2003: State system for ensuring the uniformity of measurements. Indicators of accuracy, accuracy, precision of quantitative chemical analysis methods. Assessment methods: 3.12 Intra-laboratory precision: Precision ... Dictionary-reference book of terms of normative and technical documentation

MINISTRY OF HEALTH OF THE RUSSIAN FEDERATION

GENERAL PHARMACOPEAN ARTICLE

Validation of analytical methods OFS.1.1.0012.15

Introduced for the first time

Analytical method validation is experimental evidence that a method is suitable for its intended purpose.

This General Pharmacopoeia Monograph regulates the characteristics of analytical methods, determined for the purpose of their validation, and the corresponding criteria for the suitability of validated methods intended for quality control of drugs: pharmaceutical substances and drugs.

Methods for quantitative determination, including methods for determining impurities and methods for determining the content limit, are subject to validation. Authentication techniques are validated if necessary to confirm their specificity.

During validation, the analytical method is assessed according to the characteristics listed below, selected taking into account the typical recommendations given in the table:

- specificity;

- detection limit;

- quantitation limit;

- analytical area (range);

- linearity;

- correctness (trueness);

- precision (precision);

- robustness.

Table 1 - Characteristics of methods determined during validation

|

Name specifications |

The main types of techniques | ||||

| Authenticity test | Impurities | quantitation | |||

| Quantitative techniques | Content limit | The main active ingredient, standardized components | Active ingredient in the dissolution test | ||

| Specificity **) | Yes | Yes | Yes | Yes | Yes |

| Detection limit | No | No | Yes | No | No |

| Limit of quantification | No | Yes | No | No | No |

| Analytical area | No | Yes | No | Yes | Yes |

| Linearity | No | Yes | No | Yes | Yes |

| Right | No | Yes | * | Yes | Yes |

| Precision :

- repeatability (convergence) - intermediate (in-laboratory) precision |

|||||

| Sustainability | No | * | * | * | * |

*) can be determined if necessary;

**) the lack of specificity of one analytical method can be compensated for by using another analytical method.

Revalidation (re-validation) of methods is carried out when changing:

- technologies for obtaining the object of analysis;

- composition of the medicinal product (object of analysis);

- previously approved analysis methodology.

Specificity

Specificity is the ability of an analytical technique to unambiguously evaluate an analyte in the presence of associated components.

The proof of the specificity of the validated method is usually based on the analysis of the data obtained with its use of the analysis of model mixtures of known composition.

The specificity of the method being validated can also be proved by appropriate statistical processing of the results of analyzes of real objects performed using it and, in parallel, using another, obviously specific, method (a method whose specificity has been proven).

1.1 For test procedures for authenticity

A validated method (or a set of methods) must provide reliable information about the presence of a given active substance in a substance or dosage form if it contains the components provided for by the recipe, which is subject to experimental confirmation.

The authenticity of an active substance in a pharmaceutical substance or medicinal product is established in comparison with a standard sample or by physicochemical or chemical properties that are not characteristic of other components.

1.2 For assay and impurity test procedures

The same approaches are used for the validated assay method and for testing for impurities - its specificity for the analyte must be assessed, i.e. it must be experimentally confirmed that the presence of accompanying components does not inadvertently affect the analysis result.

It is allowed to assess the specificity of the method being validated both by analyzing model mixtures of known composition, containing the analyte, and by comparing the results of analyzes of real objects obtained simultaneously with the use of a validated and other, obviously specific method. The results of the respective experiments should be statistically processed.

The lack of specificity of the test can be compensated for by another (s) additional test.

When validating methods, if appropriate, samples of medicinal products may be used that have been exposed to extreme conditions (light, temperature, humidity) for the purpose of accumulating impurities or chemically modified in any suitable way.

For chromatographic techniques, show the resolution between the two most closely eluting substances at the respective concentrations.

DETECTION LIMIT

The detection limit is the smallest amount (concentration) of an analyte in a sample that can be detected (or estimated) using a validated method.

The detection limit in the cases shown in the table is usually expressed as the concentration of the analyte (in% relative or parts per million - ppm).

Depending on the type of technique (visual or instrumental), different methods are used to determine the detection limit.

2.1 For methods with visual assessment of the analysis result

Samples with different known amounts (concentrations) of the analyte are tested and the minimum value is established at which the result of the analysis can be assessed visually. This value is an estimate of the detection limit.

2.2 For methods with instrumental assessment of the analysis result

2.2.1 Signal to noise ratio

This approach is applicable to methods for which baseline noise is observed. Compare the signal values \u200b\u200bobtained for the control experiment and for samples with low concentrations of the analyte. Set the minimum amount (concentration) of the analyte in the sample, at which the ratio of the analytical signal to the noise level is equal to 3.

The value found is an estimate of the detection limit.

2.2.2 By the value of the standard deviation of the signal and the slope of the calibration graph

The detection limit (LO) is found by the equation:

PO \u003d 3.3 S/b,

where S

b - the sensitivity coefficient, which is the ratio of the analytical signal to the determined value (the tangent of the slope of the calibration curve).

S and b

S S a the free term of the equation of this graph. The obtained value of the detection limit, if necessary, can be confirmed by direct experiment at amounts (concentrations) of the analyte close to the found value of the detection limit.

As a rule, if there is data on the suitability of a method for the reliable determination of a substance at concentrations that lie both above and below the standard of its content established by the specification, it is not necessary to determine the actual detection limit for such a method.

QUANTITATIVE LIMIT

Limit of quantification is the smallest amount (concentration) of a substance in a sample that can be quantified using a validated procedure with the required accuracy and intra-laboratory (intermediate) precision.

Limit of quantification is a necessary validation characteristic of methods used to assess small amounts (concentrations) of substances in a sample and, in particular, to assess the content of impurities.

Depending on the type of technique, the following methods are used to find the quantitation limit.

3.1 For methods with visual assessment of the analysis result

Samples with different known amounts (concentrations) of the analyte are tested and the minimum value is established at which the analysis result can be obtained visually with the required accuracy and intra-laboratory (intermediate) precision.

3.2 For methods with instrumental assessment of the analysis result

3.2.1 Signal to noise ratio

The minimum concentration of the analyte in the sample is set, at which the ratio of the analytical signal to the noise level is about 10: 1.

3.2.2 By the value of the standard deviation of the signal and the slope of the calibration graph

The Limit of Quantification (LQR) is calculated by the equation:

PKO \u003d 10 S/b,

where S Is the standard deviation of the analytical signal;

b - sensitivity coefficient, which is the ratio of the analytical signal to the determined value.

In the presence of experimental data in a wide range of the measured value S and b can be estimated by the least squares method.

For a linear calibration plot, the value S taken equal to the standard deviation S a the free term of the equation of this graph. The obtained value of the limit of quantitative determination, if necessary, can be confirmed by direct experiment at amounts (concentrations) of the analyte close to the value of the limit of quantitative determination.

where there is evidence of a method's ability to reliably detect an analyte at concentrations above and below the specification limit, it is generally not required to determine the true limit of quantification for the method.

ANALYTICAL AREA OF THE PROCEDURE

The analytical area of \u200b\u200bthe technique is the interval between the upper and lower values \u200b\u200bof the analytical characteristics of the determined component in the object of analysis (its quantity, concentration, activity, etc.). Within this range, the results obtained using the method being validated should have an acceptable level of trueness and intra-laboratory (intermediate) precision.

The following requirements are imposed on the size of the analytical area of \u200b\u200bthe methods:

- quantification techniques should be applicable in the range of 80 to 120% of the nominal value of the analytical characteristic being determined;

- dosing uniformity assessment techniques should be applicable in the range from 70 to 130% of the nominal dose;

- the assay techniques used in the Dissolution test should generally be applicable within the range of 50 to 120% of the expected concentration of the active ingredient in the dissolution medium;

- test procedures for purity should be applicable in the range from the "Limit of Quantitation" or "Limit of Detection" to 120% of the allowable content of the determined impurity.

The analytical area of \u200b\u200bthe technique can be established from the range of experimental data that satisfies the linear model.

LINEARITY

The linearity of the method is the presence of a linear dependence of the analytical signal on the concentration or amount of the analyte in the analyzed sample within the analytical area of \u200b\u200bthe method.

When validating a method, its linearity in the analytical area is verified experimentally by measuring analytical signals for at least 5 samples with different amounts or concentrations of the analyte. The experimental data are processed by the least squares method using a linear model:

y = b · x + a,

x - the amount or concentration of the analyte;

y - the magnitude of the response;

b - slope;

a - free member (OFS "Statistical processing of the results of a chemical experiment").

Quantities to be calculated and reported b, a and the correlation coefficient r... In most cases, linear relationships are used that meet the condition 0.99, and only when analyzing trace amounts, linear relationships are considered, for which 0.9.

In some cases, the possibility of linear approximation of experimental data is provided only after their mathematical transformation (for example, logarithm).

For some analytical methods, which, in principle, cannot be based on a linear relationship between experimental data, the concentration or amount of a substance is determined using nonlinear calibration curves. In this case, the graph of the dependence of the analytical signal on the amount or concentration of the analyte can be approximated by a suitable nonlinear function using the least squares method, which is feasible with the availability of the corresponding validated software.

RIGHT

The correctness of the technique is characterized by the deviation of the average result of the determinations made with its use from the value taken as true.

A validated technique is considered correct if the values \u200b\u200bassumed to be true lie within the confidence intervals of the corresponding average analytical results obtained experimentally using this technique.

The following approaches are applicable to assess the accuracy of quantification techniques:

a) analysis using a validated method of reference materials or model mixtures with a known content (concentration) of the analyte;

b) comparison of the results obtained using the validated methodology and the exemplary methodology, the correctness of which has been previously established;

c) consideration of the results of studying the linearity of the validated technique: if the free term in the equation given in Section 5 does not statistically significantly differ from zero, then the use of such a technique gives results free of systematic error.

For approaches "a" and "b", it is possible to present the obtained data in the form of an equation of linear dependence (regression) between the experimentally found and true values. For this equation, the hypotheses about the equality of the slope to the unit of the tangent are tested b and the vanishing of the free term a... As a rule, if these hypotheses are recognized as correct at a reliability level of 0.05, then the use of the method being validated gives correct, i.e., free from bias, results.

PRECISION

The precision of a technique is characterized by the dispersion of the results obtained with its use relative to the value of the average result. A measure of this dispersion is the standard deviation of the result of a single determination, obtained for a sufficiently large sample.

Precision is assessed for any quantification method based on the results of at least three determinations for each of the three levels of analyte (lower, middle, and upper) within the analytical domain of the method. Repeatability can also be assessed for any assay method based on a minimum of six determinations for samples with near-nominal analyte content. In many cases, the precision assessment can be carried out according to the results of processing experimental data by the least squares method, as indicated in the General Pharmacopoeia Monograph “Statistical processing of the results of a chemical experiment”.

Precision must be tested on homogeneous samples and can be assessed in three ways:

- as repeatability (convergence);

- as in-laboratory (intermediate) precision;

- as interlaboratory precision (reproducibility).

The results of evaluating the analytical method for each of the precision options are usually characterized by the corresponding value of the standard deviation of the result of a separate determination.

Usually, when developing an original technique, the repeatability (convergence) of the results obtained with its use is determined. If it is necessary to include the developed methodology in the regulatory documentation, its intralaboratory (intermediate) precision is additionally determined. The interlaboratory precision (reproducibility) of a method is assessed when it is supposed to be included in the draft of the general monograph, monograph or regulatory documentation for pharmacopoeial standard samples.

7.1 Repeatability (convergence)

The repeatability of an analytical procedure is evaluated by independent results obtained under the same regulated conditions in the same laboratory (the same performer, the same equipment, the same set of reagents) within a short period of time.

7.2 In-laboratory (intermediate) precision

The intralaboratory (intermediate) precision of the method being validated is assessed under the operating conditions of one laboratory (different days, different performers, different equipment, etc.).

7.3 Interlaboratory precision (reproducibility)

The interlaboratory precision (reproducibility) of the method being validated is assessed by testing in different laboratories.

SUSTAINABILITY

The stability of a validated method is the ability to maintain the characteristics found for it under optimal (nominal) conditions and given in the table, with probable small deviations from these conditions of analysis.

The robustness of the procedure should not be determined in relation to easily controlled test conditions. This drastically reduces the need for special studies of sustainability.

Stability should only be studied in cases where the method being validated is based on the use of particularly sensitive analytical methods, such as various types of chromatography and functional analysis. If necessary, the assessment of the stability of the methodology is carried out at the stage of its development. If a low stability of a technique is likely, verification of its suitability is carried out without fail directly in the process of practical use.

Testing the suitability of the analytical system

Testing the suitability of an analytical system is a test that the basic requirements for it have been met. The system being tested for suitability is a collection of specific instruments, reagents, standards and samples to be analyzed. The requirements for such a system are usually specified in the general monograph for the corresponding analytical method. Thus, the verification of the suitability of the analytical system becomes a procedure included in the procedure being validated.

Presentation of validation results

The analytical method validation protocol should contain:

- its complete description, sufficient for reproduction and reflecting all the conditions necessary for the analysis;

- assessed characteristics;

- all primary results that were included in the statistical processing of data;

- the results of statistical processing of data obtained experimentally during the development or verification of a validated method;

- illustrative materials such as copies of chromatograms obtained by high performance liquid chromatography or gas chromatography; electrophoregrams, electronic and infrared spectra; photographs or drawings of chromatograms obtained by thin layer or paper chromatography; figures of titration curves, calibration graphs;

- conclusion on the suitability of the method being validated for inclusion in a regulatory document.

Validation materials for individual analytical methods should be prepared in the form of a consolidated validation report.

THE COLLEGE

DECISION

In accordance with Article 30 of the Treaty on the Eurasian Economic Union of May 29, 2014 and paragraph 2 of Article 3 of the Agreement on Unified Principles and Rules for the Circulation of Medicines within the Eurasian Economic Union of December 23, 2014, the Board of the Eurasian Economic Commission

decided:

1. To approve the attached Guidelines for the validation of analytical procedures for drug testing.

2. This Decision shall enter into force upon the expiration of 6 months from the date of its official publication.

Chairman of the Board

Eurasian Economic Commission

T. Sargsyan

Guidelines for the validation of analytical procedures for drug testing

APPROVED BY

By the decision of the Board

Eurasian Economic Commission

dated July 17, 2018 N 113

I. General provisions

1. This Guide defines the rules for the validation of analytical methods for testing medicinal products, as well as a list of characteristics to be assessed when validating these methods and included in registration dossiers submitted to the authorized bodies of the Member States of the Eurasian Economic Union (hereinafter, respectively, the Member States, Union).

2. The purpose of the validation of an analytical procedure for testing medicinal products is to document its suitability for the intended purpose.

II. Definitions

3. For the purposes of this Guide, concepts are used that mean the following:

"analytical procedure" - a technique for testing medicinal products, which includes a detailed description of the sequence of actions required to perform an analytical test (including a description of the preparation of test samples, standard samples, reagents, use of equipment, construction of a calibration curve, used calculation formulas, etc.);

"reproducibility" - a property that characterizes the precision in interlaboratory testing;

"range of application (analytical area)" (range) - the interval between the highest and lowest concentration (amount) of an analyte in a sample (including these concentrations), for which the analytical procedure has been shown to have an acceptable level of precision, accuracy and linearity;

"linearity" is a directly proportional dependence of the analytical signal on the concentration (amount) of the analyte in the sample within the range of application (analytical area) of the technique;

"recovery (retrieval)" (recovery) - the ratio between the obtained average and the true (reference) values, taking into account the corresponding confidence intervals;

"repeatability (intra-assay precision)" is the precision of a procedure when repeated tests are performed under the same operating conditions (for example, by the same analyst or group of analysts, on the same equipment, with the same the same reagents, etc.) within a short period of time;

"correctness" (accuracy, trueness) - the proximity between the accepted true (reference) value and the received value, which is expressed by the value of the openness;

"quantitation limit" - the smallest amount of a substance in a sample that can be quantified with appropriate precision and accuracy;

"detection limit" The smallest amount of an analyte in a sample that can be detected, but not necessarily quantified;

"precision" - an expression of the closeness (degree of dispersion) of results (values) between a series of measurements carried out on multiple samples taken from the same homogeneous sample under prescribed conditions;

"intermediate precision" - the influence of variations within the laboratory (different days, different analysts, different equipment, different batches (lots) of reagents, etc.) on the results of tests of identical samples taken from the same series;

"specificity" - the ability of an analytical technique to unambiguously evaluate the substance to be determined independently of other substances (impurities, degradation products, excipients, matrix (medium), etc.) present in the test sample;

"robustness" —the ability of an analytical procedure to be robust to the effects of small specified changes under test conditions, which indicates its robustness in routine (standard) use.

III. Types of analytical procedures to be validated

4. This Guide covers approaches to validation for the 4 most common types of analytical procedures:

a) tests for identification (authenticity);

b) tests to determine the quantitative content of impurities (quantitative tests for impurities content);

c) tests to determine the limiting content of impurities in the sample (limit tests for the control impurities);

d) quantitative tests (for content or activity) (quantitative tests of the active moiety) to determine the active part of the molecule of the active substance in the test sample.

5. All analytical techniques used to control the quality of medicines must be validated. This Guide does not cover the validation of analytical methods for types of tests not included in paragraph 4 of this Guide (for example, dissolution tests or determination of the particle size (dispersion) of a pharmaceutical substance, etc.).

6. Tests for identification (authenticity) consist, as a rule, of comparing properties (eg spectral characteristics, chromatographic behavior, reactivity, etc.) of the test and reference materials.

7. Tests to quantify impurities and tests to determine the limit of impurities in a sample are aimed at correctly describing the purity values \u200b\u200bof the sample. The requirements for the validation of methods for the quantitative determination of impurities are different from the requirements for the validation of methods for determining the limit of impurities in a sample.

8. Quantitative test procedures are aimed at measuring the content of an analyte in a test sample. In this Guide, quantification refers to the quantification of the main components of a pharmaceutical substance. Similar validation parameters apply to the quantification of an active ingredient or other components of a medicinal product. Assay validation parameters may be used in other analytical procedures (for example, dissolution testing).

The purpose of analytical methods should be clearly defined, since this determines the choice of validation characteristics that should be assessed during validation.

9. The following typical validation characteristics of an analytical procedure are evaluated:

a) accuracy (trueness);

b) precision:

repeatability;

intermediate (intra-laboratory) precision;

c) specificity;

d) detection limit;

e) quantitation limit;

f) linearity;

g) range of application (analytical area).

10. The most important validation characteristics for validating different types of analytical procedures are shown in the table.

Table. Validation characteristics for validating different types of analytical procedures

Validation | Analytical method type |

||||

characteristic | tests on | impurity tests | quantitative tests |

||

(authenticity) | quantitative | limit content | dissolution (measurement only), content (activity) |

||

Right | |||||

Precision | |||||

repeatability | |||||

intermediate precision | |||||

Specificity** | |||||

Detection limit | |||||

Limit of quantification | |||||

Linearity | |||||

Range of application | |||||

________________

* If reproducibility is determined, intermediate precision is not required.

** Lack of specificity of one analytical method can be compensated by using one or more additional analytical methods.

*** May be required in some cases (for example, when the detection limit and the normalized limit of the detected impurity content are close).

Note. "-" - the characteristic is not evaluated, "+" - the characteristic is evaluated.

The specified list should be considered as typical for the validation of analytical methods. Exceptions are possible, requiring a separate justification by the manufacturer of the medicinal product. Such a characteristic of an analytical technique as stability (robustness) is not shown in the table, but it should be considered at the appropriate stage in the development of an analytical technique.

Re-validation (revalidation) may be necessary in the following cases (but is not limited to them):

changing the scheme for the synthesis of a pharmaceutical substance;

changes in the composition of the medicinal product;

change of analytical method.

Revalidation is not performed if justification is provided by the manufacturer. The extent of revalidation depends on the nature of the changes introduced.

IV. Methodology for validating analytical procedures

1. General requirements for the methodology for the validation of analytical methods

11. This section summarizes the characteristics to be considered when validating analytical methods, and also presents some approaches and recommendations for establishing the different validation characteristics of each analytical method.

12. In some cases (for example, when proving specificity), a combination of several analytical methods can be used to ensure the quality of a pharmaceutical substance or drug product.

13. All relevant data collected during validation and formulas used to calculate the validation characteristics should be presented and analyzed.

14. Approaches other than those outlined in this Guide may be used. The applicant is responsible for the selection of the validation procedure and protocol. In this case, the main goal of validating an analytical method is to confirm the suitability of the method for its intended purpose. Due to their complexity, approaches to analytical methods for biological and biotechnological products may differ from those described in this Guide.

15. Throughout the validation study, reference materials of known and documented characteristics should be used. The required purity of reference materials depends on the intended use.

16. Various validation characteristics are discussed in separate subsections of this section. The structure of this section reflects the progress of the analytical method development and evaluation process.

17. Experimental work should be planned so that appropriate validation characteristics are studied simultaneously, providing reliable data on the capabilities of the analytical method (eg, specificity, linearity, range of application, trueness and precision).

2. Specificity

18. Specificity studies should be performed during the validation of identification, impurity and quantification tests. Specificity confirmation procedures depend on the intended use of the analytical method.

19. The method for confirming specificity depends on the tasks for which the analytical technique is intended. Not in all cases it is possible to confirm that the analytical method is specific for a given analyte (complete selectivity). In this case, it is recommended to use a combination of 2 or more analytical methods.

Lack of specificity of one analytical method can be compensated for by using one or more additional analytical methods.

20. Specificity for different types of tests means the following:

a) when testing for identification - confirmation that the procedure allows the identification of the analyte;

b) when testing for impurities - confirmation that the technique allows you to correctly recognize impurities in the sample (for example, testing for related compounds, heavy metals, the content of residual solvents, etc.);

c) in quantitative tests - confirmation that the technique allows you to establish the content or activity of the analyte in the sample.

Identification

21. A satisfactory identification test should be able to distinguish between structurally closely related compounds that may be present in the sample. The selectivity of an analytical procedure can be confirmed by obtaining positive results (possibly by comparison with a known standard sample) for samples containing the analyte, and negative results for samples without it.

22. To confirm the absence of false positive results, an identification test can be performed for substances with a similar structure or substances accompanying the analyte.

23. The choice of substances potentially interfering with the test should be justified.

Quantification and Impurity Testing

24. When confirming the specificity for an analytical procedure using a chromatographic separation method, representative chromatograms should be submitted with appropriate identification of the individual components. It is necessary to use similar approaches to other separation-based techniques.

25. Critical separations in chromatography should be studied at the appropriate level. In the case of critical separations, the resolution value of the 2 most closely eluting components should be set.

26. When using a non-specific quantitation method, additional analytical methods should be used and the specificity of the entire set of methods should be confirmed. For example, if quantitative determination is carried out by a titrimetric method during the release of a pharmaceutical substance, it can be supplemented with an appropriate test for impurities.

27. The approach is the same for both quantification and testing for impurities.

The presence of impurity samples

28. In the presence of samples of impurities, the determination of the specificity of the analytical procedure is as follows:

a) for quantitative determination, it is necessary to confirm the selectivity of the determination of the substance in the presence of impurities and (or) other components of the sample. In practice, this is done by adding to the sample (pharmaceutical substance or drug) impurities and (or) excipients in an appropriate amount and if there is evidence of their absence of influence on the result of the quantitative determination of the active substance;

b) when testing for impurities, the specificity can be established by adding impurities to a pharmaceutical substance or medicinal product in certain quantities and if there is evidence of separation of these impurities from each other and (or) from other components of the sample.

No sample impurities

29. If there are no standard samples of impurities or degradation products, the specificity can be confirmed by comparing the test results of samples containing impurities or degradation products with the results of another validated method (for example, pharmacopoeial or other validated analytical (independent) method). Where appropriate, reference materials for impurities should include samples that have been stored under specified stress conditions (light, heat, humidity, acid (basic) hydrolysis and oxidation).

30. In case of quantification, it is necessary to compare the 2 results.

31. In the case of impurity testing, it is necessary to compare the impurity profiles.

32. To prove that the peak of the analyte corresponds to only one component, it is advisable to carry out studies on the purity of the peaks (for example, the use of diode array detection, mass spectrometry).

3. Linearity

33. The linear relationship must be assessed over the entire range of application of the analytical method. It can be confirmed directly on a pharmaceutical substance (by diluting the main standard solution) and (or) on separate weighed portions of artificial (model) mixtures of drug components using the proposed method. The latter aspect can be studied in the course of determining the range of application (analytical area) of the method.

34. Linearity is assessed visually by plotting the analytical signal as a function of the concentration or amount of the analyte. If there is a clear linear relationship, the results obtained should be processed by suitable statistical methods (for example, by calculating a regression line using the least squares method). Mathematical transformation of test results may be required to obtain linearity between quantification and sample concentrations prior to regression analysis. The results of the regression line analysis can be used to mathematically evaluate the degree of linearity.

35. In the absence of linearity, the test data should be mathematically transformed prior to the regression analysis.

36. To confirm linearity, the correlation coefficient or determination coefficient, linear regression intercept, the slope of the regression line and the residual sum of squares of deviations should be determined and presented, and a graph with all experimental data should be attached.

37. If linearity is not observed in any kind of mathematical transformations (for example, when validating immunoanalytical methods), the analytical signal must be described using the corresponding function of the concentration (amount) of the analyte in the sample.

V. Range of application (analytical area)

39. The range of application of the analytical method depends on its purpose and is determined in the study of linearity. Within the range of application, the procedure should provide the required linearity, trueness and precision.

40. The following ranges of application (analytical areas) of analytical methods should be considered as the minimum acceptable:

a) for the quantitative determination of an active substance in a pharmaceutical substance or medicinal product - from a concentration (content) of 80 percent to a concentration (content) of 120 percent of the nominal concentration (content);

b) for uniformity of dosage - from a concentration (content) of 70 percent to a concentration (content) of 130 percent, if a wider range is not justified for the medicinal product depending on the dosage form (for example, metered-dose inhalers);

c) for dissolution testing - ± 20 percent (absolute) of the nominal range of use. For example, if the specifications for a modified release product cover an area from 20 percent in the first hour to 90 percent of the declared content in 24 hours, the validated range of use should be from 0 to 110 percent of the declared content;

d) for the determination of impurities - from the limit of detection of an impurity to the 120% value specified in the specification;

e) For impurities that are extremely potent or have toxic or unanticipated pharmacological effects, the detection limit and quantification limit should be commensurate with the level at which these impurities are to be controlled. In order to validate impurity testing procedures used during development, it may be necessary to set the analytical domain near the assumed (possible) limit;

f) if quantification and purity are studied simultaneously using the same test and only 100% standard is used, the linear dependence should be in the entire range of application of the analytical method, starting from the reporting threshold for the impurity (in accordance with the rules for studying impurities in medicinal products and establishing requirements to them in the specifications approved by the Eurasian Economic Commission) up to 120% content specified in the specification for quantitative determination.

Vi. Right

41. Accuracy should be established for the full range of application of the analytical procedure.

1. Quantitative determination of active pharmaceutical ingredients

Pharmaceutical substance

42. Several methods of assessing correctness can be used:

application of an analytical method to an analyte with a known degree of purity (for example, to a standard material);

comparison of analysis results obtained using a validated analytical method and results obtained using a method known to be correct and / or an independent method.

Accuracy can be concluded after precision, linearity and specificity have been established.

Medicinal product

43. Several methods of assessing correctness can be used:

application of an analytical technique to artificial (model) mixtures of drug components, to which a predetermined amount of the analyte has been added;

in the absence of samples of all components of the medicinal product, it is possible to add a predetermined amount of a pharmaceutical substance to the medicinal product or compare the results obtained using another technique, the correctness of which is known, and (or) an independent technique.

Accuracy can be concluded after determining the precision, linearity and specificity.

2. Quantification of impurities

44. Accuracy is determined on samples (pharmaceutical substance and medicinal product), to which a known amount of impurities has been added.

45. In the absence of samples of the determined impurities and / or degradation products, it is acceptable to compare the results with the results obtained using an independent method. The use of the analytical signal of the active substance is allowed.

46. \u200b\u200bThe specific way of expressing the content of individual impurities or their sum should be specified (for example, in mass percent or in percent in relation to the peak area, but in all cases in relation to the main analyte).

47. Accuracy is assessed for at least 9 determinations of 3 different concentrations covering the entire range of use (ie 3 concentrations and 3 repetitions for each concentration). The definitions should include all stages of the methodology.

48. Accuracy is expressed as a percentage of the percentage of the quantitative determination of a substance added in a known amount to the analyzed sample, or the difference between the obtained mean and true (reference) values, taking into account the corresponding confidence intervals.

Vii. Precision

49. Validation of assay and impurity tests involves the determination of precision.

50. Precision is set at 3 levels: repeatability, intermediate precision and reproducibility. The precision should be established using homogeneous, authentic samples. If it is impossible to obtain a homogeneous sample, it is allowed to determine the precision using artificially prepared (model) samples or a sample solution. The precision of an analytical procedure is usually expressed in terms of the variance, standard deviation, or coefficient of variation of a series of measurements.

VIII. Repeatability

51. Repeatability is determined by performing at least 9 determinations of concentrations within the range of application of the analytical method (3 concentrations and 3 replicates for each concentration), or at least 6 determinations of concentration for samples with 100% analyte content.

IX. Intermediate (intra-laboratory) precision

52. The degree to which intermediate precision is established depends on the conditions in which the analytical procedure is used. The applicant must establish the effect of random factors on the precision of the analytical procedure. Typical variables to be investigated are different days, analysts, equipment, etc. There is no need to study these influences separately. When studying the influence of various factors, it is preferable to use experimental design.

X. Reproducibility

53. Reproducibility describes the precision in an interlaboratory experiment. Reproducibility should be determined in the case of standardization of the analytical method (for example, when it is included in the Pharmacopoeia of the Union or in the Pharmacopoeia of the Member States). The inclusion of reproducibility data in the registration dossier is not required.

XI. Data presentation

54. For each type of precision, the standard deviation, the relative standard deviation (coefficient of variation) and the confidence interval must be indicated.

XII. Detection limit

55. There are various approaches to determining the detection limit depending on whether the technique is instrumental or non-instrumental. Other approaches are also allowed.

XIII. Visual assessment

56. Visual assessment can be used for both non-instrumental and instrumental techniques. The detection limit is established by analyzing samples with known concentrations of the analyte and determining its minimum content at which it is reliably detected.

XIV. Evaluation of the detection limit in terms of signal-to-noise ratio

57. This approach is applicable only to analytical procedures for which baseline noise is observed.

58. Determination of the signal-to-noise ratio is carried out by comparing the signals obtained from samples with known low concentrations with the signals obtained from blank samples and establishing the minimum concentration at which the analyte can be reliably detected. A signal-to-noise ratio of 3: 1 to 2: 1 is considered acceptable for the detection limit.

XV. Evaluation of the detection limit from the standard deviation of the analytical signal and the slope of the calibration curve

59. The Limit of Detection (LOD) can be expressed as follows:

where:

60. The k value is calculated from the calibration curve for the analyte. The estimation of s can be done in several ways:

b) along the calibration curve. Analyze the resulting calibration curve for samples with an analyte content close to the detection limit. The standard deviation can be the residual standard deviation of the regression line or the standard deviation of the point of intersection with the ordinate axis (standard deviation of the linear regression intercept).

XVI. Data presentation

61. It is necessary to indicate the detection limit and the method of its determination. If the determination of the limit of detection is based on visual or signal-to-noise ratio assessment, the presentation of appropriate chromatograms is considered sufficient to justify it.

62. If the value of the limit of detection is obtained by calculation or extrapolation, the assessment should be confirmed by independent testing of a sufficient number of samples with the content of the analyte, corresponding to or close to the limit of detection.

XVII. Limit of quantification

63. Limit of quantitation is a necessary validation characteristic of the methods used to determine the low content of substances in a sample, in particular for the determination of impurities and (or) degradation products.

64. Several approaches to determining the quantification limit are possible, depending on whether the technique is instrumental or non-instrumental. Other approaches are allowed.

Xviii. Visual assessment

65. Visual assessment can be used for both non-instrumental techniques and instrumental.

66. The limit of quantification is usually established by analyzing samples with known concentrations of the analyte and estimating the minimum level at which the analyte can be quantified with acceptable accuracy and precision.

XIX. Signal to Noise Quantification Limit Assessment

67. This approach is applicable only to measurement methods in which baseline noise is observed.

68. Determination of the signal-to-noise ratio is carried out by comparing the measured signals obtained from samples with known low concentrations of the analyte with the signals obtained from the blank samples, and establishing the minimum concentration at which the analyte can be reliably quantified. The typical signal-to-noise ratio is 10: 1.

XX. Estimation of the limit of quantitation from the standard deviation of the signal and the slope of the calibration curve

69. The Limit of Quantification (LQR) can be expressed as follows:

where:

s is the standard deviation of the analytical signal;

k is the tangent of the slope of the calibration curve.

70. The k-value is calculated from the calibration curve for the analyte. The estimation of s can be done in several ways:

a) by the standard deviation of the blank sample. The analytical signal is measured for a sufficient number of blanks and the standard deviation of their values \u200b\u200bis calculated;

b) along the calibration curve. Analyze the resulting calibration curve for samples with an analyte close to the limit of quantitation. The standard deviation can be the residual standard deviation of the regression line or the standard deviation of the point of intersection with the ordinate axis (standard deviation of the linear regression intercept).

XXI. Data presentation

71. It is necessary to indicate the limit of quantitation and the method of its determination.

72. The limit of quantification must subsequently be confirmed by analyzing a sufficient number of samples with an analyte content equal to or close to the limit of quantification.

73. Approaches other than those listed above may be acceptable.

XXII. Stability (robustness)

74. The study of stability (robustness) must be carried out at the development stage, the amount of research depends on the analytical methodology under consideration. It is necessary to show the reliability of the analysis with deliberate variations in the parameters (conditions) of the method.

75. If the results of measurements depend on changes in the conditions of application of the analytical procedure, it is necessary to strictly monitor the observance of such conditions or stipulate precautions during the test.

76. In order to ensure that the validity of the analytical method is maintained when using it, one consequence of the study of robustness should be the establishment of a series of system suitability parameters (for example, a resolution test).

77. Common parameter variations are:

stability of solutions used in analytical techniques;

extraction time.

The variation parameters for liquid chromatography are:

changing the pH of the mobile phase;

change in the composition of the mobile phase;

different columns (different series and suppliers);

temperature;

the speed of the mobile phase (flow rate).

The variation parameters for gas chromatography are:

different columns (different series and suppliers);

temperature;

carrier gas velocity.

XXIII. System suitability assessment

78. System suitability assessment is an integral part of many analytical techniques. These tests are based on the concept that equipment, electronics, analytical operations and samples to be analyzed constitute a complete system and must be evaluated as such. System suitability criteria should be established for a specific method and depend on the type of analytical method being validated. Further information can be found in the Pharmacopoeia of the Union or in the Pharmacopoeias of the Member States.

Electronic text of the document

prepared by Kodeks JSC and verified by:

official site

Eurasian Economic Union

www.eaeunion.org, 20.07.2018

Each instrumental method is characterized by a certain level of noise associated with the specifics of the measurement process. Therefore, there is always a limit of the content below which a substance cannot be reliably detected at all.

Detection limit С min, P - the smallest content at which the presence of a component with a given confidence level can be detected using this method.

The detection limit can also be set by the minimum analytical signal y min, which can be confidently distinguished from the signal of the control experiment - y background.

Statistical methods using Chebyshev's inequality proved that quantitatively the detection limit can be determined using the expression

Where s background is the standard deviation of the analytical background signal; S is the sensitivity coefficient (sometimes referred to simply as "sensitivity"), it characterizes the response of the analytical signal to the component content. The sensitivity coefficient is the value of the first derivative of the calibration function for a given concentration determination. For straight-line calibration curves, this is the slope tangent:

(attention: do not confuse sensitivity factorS with standard deviations!)

There are other ways to calculate the detection limit, but this equation is the most commonly used.

In quantitative chemical analysis, the range of determined contents or concentrations is usually given. It means the range of values \u200b\u200bof the determined contents (concentrations) provided for by this methodology and limited by the lower and upper limits of the determined concentrations.

Analysts are more often interested in the lower limit of the determined concentration from n or content m n component determined by this method. Beyond the lower limit of the determined contents usually take the minimum amount or concentration that can be determined with a relative standard deviation

. .

. .

Example

The mass concentration of iron in the solution was determined by the spectrophotometric method, by measuring the optical densities of solutions colored as a result of the reaction of the interaction of the Fe 3+ ion with sulfosalicylic acid. To construct the calibration dependence, the optical densities of solutions with increasing (specified) concentrations of iron treated with sulfosalicylic acid were measured.

The optical densities of the reference solution (control experiment for reagents, i.e., without the addition of iron, (background) were 0.002; 0.000; 0.008; 0.006; 0.003.

Calculate iron detection limit.

Decision

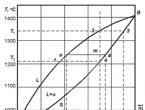

1) As a result of calculations by the least squares method (see example for control task No. 5), the values \u200b\u200bfor building a calibration graph are obtained.

Calculated values \u200b\u200bfor building a calibration graph

2) We calculate the sensitivity coefficient, i.e. the angular coefficient of the calibration dependence (S) according to the table data.

3) Calculate background standard deviation, what is 0,0032 units of optical density.

4) The detection limit will be, mg / cm 3

Control task number 6

Determine the detection limit for iron in water.

Initial data : the values \u200b\u200bof the optical density of the background (reference solution) when constructing the calibration graph for the determination of iron were 0.003; 0.001; 0.007; 0.005; 0.006; 0.003; 0.001; 0.005. The values \u200b\u200bof optical densities corresponding to the concentration of iron in the solution are presented in the table of control task No. 5.

Calculate the detection limit of iron in mg / cm 3 according to the sensitivity coefficients S, calculated on the basis of the data obtained to build a calibration graph by the least squares method when performing control task No. 5;