PPR requirements composition. What is POS and PPR in construction

Project for the production of works (PPR) - this is a set of documents that determine the procedure for performing work and their resource support. PPR can be developed for: the erection of individual structural elements, parts of a building and structure; for the construction of buildings and structures in general; for the performance of certain technically complex construction, installation and special construction works and for the work of the preparatory period.

Responsible for the development of PPR are: for PPR for the construction of new, expansion and reconstruction of enterprises, buildings and structures - the general contracting construction organization; for PPR for certain types of general construction, installation and special construction works - specialized construction organizations performing these works.

Organizations responsible for the development of WEP can perform this work either on their own or involve design, design organizations and design and technology trusts (Orgtekhstroy, Orgstroy, etc.).

The initial data for the development of WEP are:

a task for the development of a WEP with a justification for the need to develop it for a building or structure as a whole, its part or type of work and indicating the terms of development;

construction organization project;

necessary working documentation and conditions for the supply of building materials, structures and equipment, the use of the system. telny machines and vehicles, providing workers for builders in the main professions, production and technological equipment and transportation of building materials.

The composition of the WEP for the construction of all or part of a building or structure includes:

A calendar plan for the production of work on the object, in which the sequence and timing of the work should be established with the maximum possible combination of them.

Object construction general plan (stroygenplan), which should show: the boundaries of the construction site and the types of its fences; operating and temporary underground, ground and air networks and communications; permanent and temporary roads, as well as traffic patterns of means of transport and mechanisms; installation sites, travel routes and areas of operation of construction and lifting machines; placement of permanent, under construction and temporary buildings and structures; locations of signs of the geodetic center base; dangerous zones; ways and means of lifting workers to working tiers (floors): passages to buildings and structures; placement of sources and means of energy supply and lighting of the construction site, as well as ground loops; locations of sites and premises for storing building materials and structures, as well as devices for removing construction debris; sites for pre-assembly of structures; location of premises for sanitary and household services for builders, drinking facilities and recreation areas; high-risk work areas.

Schedules for the receipt of building materials, structures and equipment at the facility with data on their receipt for each contract team with the application of picking lists.

Schedules of the movement of workers and the main construction machines around the facility.

Technological maps (schemes) for the performance of certain types of work with the inclusion of operational quality control schemes (SOCC), a description of the methods of production of work, an indication of labor costs and the need for materials, machines, equipment, devices and protective equipment for workers.

Solutions for the production of geodetic works, including layouts of signs for performing geodetic constructions and measurements and indications of the required accuracy and technical means of geodetic control of the construction and installation works.

Safety solutions developed on the basis of SNiP 12-03-2001.

Solutions for laying temporary networks of water, heat, power supply and lighting (including emergency) of a construction site and workplaces with the development, if necessary, of working drawings for supplying networks from power sources.

Lists of technological equipment and mounting equipment, as well as schemes for slinging loads.

Explanatory note.

The required sections include:

justification of decisions on the production of work, including those performed in winter;

the need for energy resources and solutions to meet it;

measures aimed at ensuring the safety and exclusion of theft of materials, products, structures and equipment at the construction site, in buildings and structures;

measures to protect existing buildings and structures from damage;

environmental protection measures.

a list of inventory buildings and structures and devices with a calculation of the need and justification for the condition of linking them to the sections of the construction site;

technical and economic indicators, including the volume, duration and cost of construction and installation works, the level of mechanization and labor costs both in general and per 1 m3 of volume, 1 m2 of building area per unit of physical volume of work, etc.

In accordance with the requirements of SNiP 3.01.01-85*, the mandatory sections of the PPR for the construction of all or part of a building or structure are: the schedule for the production of work on the facility; object building plan; technological maps; decisions on the production of geodetic works, on safety measures, on the laying of temporary engineering networks and an explanatory note.

The composition of the WEP for the performance of certain types of work includes:

The calendar plan for the production of this type of work.

Construction master plan (stroygenplan).

Technological map of the production of this type of work with the inclusion of an operational quality control scheme (SOCC), a description of the methods of production of work, data on the need for basic materials, structures and products, as well as the machines, equipment and fixtures used.

A brief explanatory note, including the necessary justifications and technical and economic indicators.

In addition, the project for the production of geodetic works should include: instructions on the accuracy and methods of performing work when creating an alignment network for a building, structure and detailed breakdowns; location diagrams of points of the scoring network, installation marks, beacons and ways of fixing them; designs of geodetic signs; list of executive geodetic documentation.

The composition of the WEP for the preparatory period of construction includes:

Calendar plan for the production of work on the object (type of work).

Construction master plan (stroygenplan), which indicates: the location of temporary, including inventory buildings, structures and devices, off-site and on-site networks with their connection to connection and consumption points and permanent facilities erected in the preparatory period for construction needs.

Technological maps.

Graphs of the movement of workers and basic construction machines.

The schedule for the arrival at the construction site of the necessary building materials, structures and equipment during the preparatory period.

Schemes of placement of signs for performing geodetic constructions, measurements, as well as instructions on the required accuracy and technical means of geodetic control.

Explanatory note, the content of which is similar to the content of the explanatory note, which is part of the PPR, developed for the construction of the entire building (structure) or part of it.

Project for the production of works (PPR) - a document developed in a construction organization;

The WEP must be transferred to the construction site no later than 2 months before the start of work.

WEP is developed, at least, for an object or its stage.

Raw material:

assignment for development with deadlines;

working documentation, including POS;

condition of supply of material resources, equipment;

use of construction machines, vehicles and provision of workers;

materials of technical inspection of buildings and structures, objects under reconstruction, or existing near standing ones;

requirements for construction and installation work in the conditions of existing production (during reconstruction).

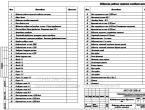

The composition of the PPR:

1) Schedule for the facility by type of work.

2) Stroygenplan

3) Schedules of the movement of work teams, the main construction machines and mechanisms around the facility.

4) Graphs for setting mat. Resources, equipment per site and distribution to teams.

5) Technological maps for certain types of work with operational quality control systems.

6) Geodetic works.

7) Technological equipment, mounting equipment, labor protection and equipment

security.

8) Explanatory note - the rationale for all decisions taken, as well as measures to protect existing buildings and structures and environmental measures.

9) CHP: volume of construction, duration of construction, specific

labor costs, level of mechanization, cost of work, profit. PAR is developed for the preparatory period and PAR for certain types of work.

Construction is an important direction in the development of the country and private business. This area is controlled by the administration and executive authorities, regulated by the current legislation and regulations. They contain a set of norms, rules and mandatory requirements for organizing the activities of contractors and teams.

Consider the definition of one of the mandatory items that must be available to the developer in advance. What is a PPT (territory zoning) and a project for the production of works (PPR) in construction is a package of technological and administrative documentation, including a master plan, decisions on labor protection, industrial safety. On their basis, work is carried out in a standard environment and conditions when there is a possibility or the influence of hazardous factors at the site where construction, reorganization, technical transformation of buildings is underway, as well as the commissioning of hazardous facilities.

It is developed for the construction of a full-fledged building or local parts:

- roof, balcony, additional greenhouse;

- underground premises;

- flight of stairs;

- floors.

It is also possible to develop for individual technically complex construction, installation and repair work during the preparatory period.

The general contractor or a responsible company with a license for the type of activity provided is responsible for its implementation. The head of this organization approves the project and, no later than 2 months before the expected start of work, transfers it to the construction site. If the activity is carried out at an existing enterprise, the document must be agreed with the client.

Package development

Compilation is carried out in accordance with the requirements of labor protection and industrial safety.

To do this, prepare:

- POS (POS - point of sales - place of sale);

- materials of technical inspection of structures to be reconstructed, with the results of the analysis and conclusions, as well as the established requirements for work in the operating conditions of the premises;

- the base of mechanization existing in the organization;

- confirmation of special conditions, potentially unsafe production factors;

- basic working papers.

What is included in the development of PPR in construction

To guarantee the safety of the future building, it is necessary to accurately determine the plan of structures, calculate the load, cost of funds, attract special equipment and labor. Therefore, when drawing up a project, they rely on:

- Inventory of technical inventory, equipment for installation.

- General layout of construction. Here the boundaries of the object, the location of mobile and erected structures, paths, underground and surface engineering networks, communications are indicated.

- Schedules for the receipt of raw materials and equipment at the site, the movement of workers on it.

- Calendar schedule. It sets the deadlines for the implementation of the tasks set, their consistent implementation and priority.

- Technological maps. Decisions made by the commission for conducting geodetic activities and safety.

- Schemes of the correct slinging of goods.

- Explanatory note. It is the rationale for the accepted proposals on production issues, costs for the needs of energy resources. It also stipulates the conditions for assigning mobile structures and mechanized units to the site, lists measures to ensure the complete integrity and safety of property and protect objects from damage, measures and actions taken to protect the environment.

Compilation of the PPR in construction is regulated by legal acts adopted by the executive authorities.

Project documentation software

Most contractors are moving to an automated accounting system. The software greatly simplifies the task and reduces the time spent. Such a process almost eliminates the human factor, which is the most common precedent for accidents.

Utilities that are used for the computerized creation of a work plan in construction:

- Microsoft project.

- Bundle SmetaWIZARD + PlanWIZARD.

- Excel.

- Rillsoft Project.

- Hector: Designer - Builder.

- and others.

A requirement for a number of software is the availability of AutoCAD, NanoCAD, Compass. Products sold by ZWSOFT are also suitable for this. This software is an analogue of ACAD, but its cost is much lower, so both large companies and small organizations, educational institutions can afford it.

Why is PPR needed in construction?

The purpose of the creation is the development of construction methods for its most efficient implementation, as well as a possible reduction in the cost of materials, human resources and the use of special equipment. The requirements for documents are established by SNiP 3.01.01-85, which contains explanations for the correct preparation of a package of papers for the possibility of erecting a building.

Other regulations, bills and ordinances:

- PPB 01-93 "On fire safety in the Russian Federation".

- SNiP 12-04-2002 "On labor protection in construction".

- SNiP 12-03-2001 "Part 1. General requirements".

- PB 03-428-02 "Code of rules for the construction of facilities underground."

How to develop a PPR in construction on a computer

This is a laborious and long process. It requires special training and sufficient qualifications. Due to the lack of experienced workers and the reduction in terms for the preparation of pre-project documentation and PD, which sometimes affects the quality of the task, organizations are increasingly turning to modern information technologies.

To make a layout using the program, decide what components it should include. General wishes of the majority of contractors responsible for compiling the package of papers:

- up-to-date GESN, ENiR with the ability to set your own prices;

- transferring data from estimates of other programs;

- calculation of the critical path;

- deletion and inclusion of roads, buildings, equipment;

- automatic drawing of the master plan, additional schemes (electrification, water supply, communications) with minimal human participation;

- calculation of the cost of energy, special equipment, materials and other resources;

- accounting for cycles of completed volumes with the designation of the repetition of the same work in the schedule;

- issuance of an explanatory note;

- entering the contractor's equipment into the database.

Use a tool that makes work easier and cheaper by providing ready-made tried and tested solutions, automating the design of graphic and text documents.

Taking into account the wishes of specialists, computer software developers offer more and more products that are in demand.

Before compiling a construction design plan using a PC, consider the 3 basic principles that form the foundation of most design tools:

- Organization of an information base, including the methodological and regulatory parts necessary for the correct formation of incoming and outgoing data.

- Possibility of structuring and systematization of production goals and objectives.

- Automation of specific PPR tasks with the help of software modules with graphical components. They can be implemented as an add-on to the ZWCAD or NanoCAD package of the latest versions. Calculated ones can work in C++ and FoxPRO.

Using the example of cranes, consider what these plugins are required to:

- to form technological schemes;

- choose a crane according to certain parameters and the height of the load;

- fix the need for inventory facilities;

- design pits automatically and calculate the drawdown;

- determine an effective version of transport and earth-moving equipment;

- calculate and select lighting fixtures;

- analyze loads and electricity consumption;

- draw a crane, tying it to objects located on the site.

An important point for the designer is the prompt provision of an information base, which includes:

- methods that determine the need for materials, special equipment, technical equipment, various equipment and inventory;

- requirements for warehousing, preservation, transportation of raw materials and special structures, installation of building scaffolds with examples of their possible location;

- instructions on health and safety, fire and environmental safety;

- terms of production control of the work performed and their quality;

- other information on PPR issues.

As a result, the data obtained using the program must represent organizational and technical documentation drawn up in accordance with applicable standards and legislation - in the form of calculation, text and graphic solutions. This is an adaptation of GeoniCS for the ZWCAD 2017 PRO version. It is intended for design and survey work - the production of drawings in which the necessary stamps, explications are filled in and it can be divided into sheets of a certain format.

1. water supply;

2. storm and ordinary sewerage;

3. heat saving;

4. gas pipeline.

It performs many tasks - it forms the main plan and the summary of engineering networks, makes detailing of wells, creating a table, puts geological wells on the diagram.

Choose a convenient program to facilitate your own work.

Here you can find examples of work projects

PPRk (Project for the production of works by cranes)

The installation and safe operation of three tower cranes during the construction of a series of monolithic residential buildings is considered. Due to cramped conditions, cranes operate with a limited service area.

Jaso J110N and Jaso J140N stationary tower cranes lift the structures of a 19-story building from 0.000 to el. +63.000. Cranes are mounted on foundation supports with a plate mark of -2.200, with an anchor fastening of the tower.

The maximum load lifted by cranes at an outreach of 2.5-15m is 5 tons, at an outreach of 15-40m - 2.5 tons.

Tower cranes are used at all stages of the construction of the underground and aboveground parts of the building, namely:

- for unloading from vehicles and storing materials and products as they arrive at the construction site

- for supplying packs of reinforcement, reinforcement meshes and formwork, as well as for supplying concrete in tubs during the construction of monolithic structures

- for supplying small-piece materials and mortar to the assembly horizon

- for the supply and removal from the building of construction equipment, equipment, consumables, etc.

Scope of the project: Explanatory note A4 - 35 sheets, drawings A1 - 5 sheets

This is an example of a PPR for excavation of a pit under the protection of a sheet piling. The excavation is carried out in 3 stages.

- Stage 1. Work at the level of 135.50÷134.60 is carried out by a Hitachi ZX 200 excavator with a bucket capacity of 0.8 m3 (maximum digging radius - 9.75 m, maximum digging depth - 6.49 m) equipped with a "backhoe" bucket with soil loading into dump trucks. With a lag of 4 meters from the operation of the Hitachi ZX 200 excavator, a strapping belt is being installed (1 I-beam N45 B2). Installation is carried out by a truck crane according to a separately developed PPR.

- Stage 2. Works at elevation 132.50 are carried out by a Hitachi ZX 200 excavator. At this level, excavation is carried out to a design depth of 127.84÷127.84 m, by excavation and moving the soil to a dump truck. With a lag of 4 meters from the operation of the ZX 200 excavator, a spacer structure is made, consisting of a strapping belt (2 I-beams N45 B2), spacers from pipes 426x10mm in axes 1 ÷ 10 and struts, as well as pipes 630x12mm in axes 11 ÷ 16. Installation is carried out by a truck crane according to a separately developed PPR.

- Stage 3. The excavation of slopes is carried out by excavating and moving the soil with a Bobcat S330 excavator to the operating area of the Hitachi ZX 225 grab. The grab brings the developed soil to the surface and loads it into a dump truck. From the pit, the Bobcat S330 excavator is issued upon completion of work by a truck crane according to a separately developed PPR.

At the last stage, the berm soil is excavated under the installed sheet piling jibs of the excavation using a mini excavator.

Scope of the project: Explanatory note A4 - 28 sheets, drawings A1 - 5 sheets

The project for the production of works on the construction of a water supply system by the method of auger driving

Laying a water pipe in a case constructed by the closed method of auger driving. The excavation of a working rectangular pit and a round receiving shaft is also being considered.

Works on laying pipes by auger driving are carried out in several stages:

- 1st stage. Punching of the pilot string, consisting of rods and a pilot head, for the length of the interval from the starting to the receiving pit. The exact direction of the route is provided by the pilot head position control system, information about the position of which is displayed on the screen of the monitor suspended in the launch shaft.

- 2nd stage. Punching of casing steel pipes and an expander mounted in the starting pit on the last rod of the pilot string within the length of the entire interval between pits. Punching of working pipes from the starting pit with simultaneous extraction of extruded casing steel pipes in the receiving pit. Crushing of casing pipes with a drill head in the head part of the pipe string, which serves to excavate soil in the face, is being carried out, soil is transported from the face to the tub in the starting pit by a screw conveyor.

- 3rd stage. Punching of working pipes with a diameter less than or equal to the diameter of the casing pipes, with simultaneous forcing of the casing pipes and screw conveyor links into the receiving pit and their disassembly. If the diameter of the working pipes is less than the diameter of the casing, the construction gap (space) formed between the working pipeline and the inner surface of the mine should be filled with cement slurry.

Scope of the project: Explanatory note A4 - 25 sheets, drawings A1 - 4 sheets

PPR for the installation of sheet piling and bored piles

An example of a PPR for the installation of a sheet piling of a pit in the security zone of a power transmission line (power lines). Execution of bored piles: drilling a well with augers, installation of the pile reinforcement frame with a drilling rig, filling the pile with a concrete mixture using the bottom-up method.

Drilling of bored piles Ø620 mm is carried out by a drilling rig based on Hitachi

The drilling of each well should begin after an instrumental check of the marks of the planned surface of the earth and the position of the axes of the contour on the site.

Pile concreting is carried out by supplying the concrete mixture into the well through hollow augers.

As concrete is fed into the well, the auger sections are lifted and dismantled, and the level of concrete in the well must be at least 1 m higher than the bottom of the auger. The distance between the bottom of the well and the lower end of the auger at the start of concreting should not exceed 30 cm.

Scope of the project: Explanatory note A4 - 20 sheets, drawings A1 - 6 sheets

Project for the production of works for the installation of scaffolding

An example of a WEP for the installation of scaffolding on the facade of a building under construction

Clamp rack-mounted scaffolding is a spatial frame-tiered system assembled from tubular elements: racks, crossbars, longitudinal and diagonal ties, which are interconnected using nodal connections - clamps.

The scaffolding is fixed to the wall with the help of anchors laid in holes punched in the walls with a diameter of 14 mm.

Scaffolding must be attached to the wall of the building under construction. Fastening is carried out through at least one tier for fastening racks, through two spans for the upper tier and one fastening for every 50 sq.m of the projection of the scaffolding surface onto the facade of the building.

Scope of the project: Explanatory note A4 - 38 sheets, drawings A1 - 4 sheets

Why are you required to have a PPR? List of normative documents.

It is mainly regulated by the “Manual for the development of projects for the organization of construction and projects for the production of works for housing and civil construction” (to SNiP 3.01.01-85 * “Organization of construction production”), while the design must comply with GOST 21.101-97 “SPDS. Basic requirements for design and working documentation.

12.2. Text and graphic materials, according to GOST 21.101-97, are completed, as a rule, in the following order:

Cover;

Title page;

Project composition:

Explanatory note;

Basic drawings provided by building codes and regulations.

12.3. Since the requirements of GOST 21.101-97 are mainly advisory in nature, for the convenience of developing and familiarizing with the WEP, it is desirable to divide the project into the following main parts:

Common data;

Explanatory note;

The grafical part;

Applications.

12.3.1. General data should consist of materials related directly to the entire project as a whole, as well as defining its structure and content:

Title page;

The composition of the project;

List of reference documents and materials used.

12.3.2. An explanatory note should be drawn up depending on the complexity of the construction site, as well as on the types, composition and specifics of the work for which the WEP is being developed:

Scope (with the definition of the types of work performed and the specifics of the construction object);

- organizational and technological sequence of work performance (for work production projects consisting of several different types of technologically related work, as well as work performed at facilities of increased complexity, large volumes of construction and high-tech facilities);

Instructions for the production of work (technological measures and regulations) for each type of work performed at the construction site, including in winter;

List of used mechanisms and equipment;

Technological kits for the production of works;

Instructions for storing materials;

Fire safety measures;

Measures for environmental protection;

Requirements for safety and labor protection for each type of work performed at the construction site.

12.3.3. The graphic part must be drawn up taking into account the requirements of the "Manual for the development of projects for the organization of construction and projects for the production of works for housing and civil construction" (to SNiP 3.01.01-85 * "Organization of construction production") and include the following graphic materials:

- calendar plan for the production of works by type of work, depending on the developed WEP for the main construction period, the preparatory period or for certain types of work (provided by the customer of the WEP);

Construction master plan by type of work, depending on the developed WEP for the main construction period, the preparatory period or for certain types of work (developed on the instructions of the WEP customer);

Plans for the production of work on individual sections, stages of queues, depending on the complexity of the object, as well as on the type of work, clarifying the technological sequence of construction;

Sections (facades) required for each stage of construction or type of work;

Technological schemes for performing individual operations and works included in the PPR.

12.3.4. Applications include lists of persons familiar with the WEP, approval sheets, licenses and certificates of a construction organization, certificates of attestation of WEP developers, etc. materials not developed by the author of the project, but directly related to the PPR, at the discretion of the customer or developer of the PPR.

12.4. Text and graphic materials must be made on sheets of a standard format, in accordance with GOST 2.301-68 “ESKD. Formats ”(A0, A1, A2, A3, A4) with a frame and a stamp of the form established for each sheet, according to Appendix D, GOST 21.101-97.

12.5. When compiling an explanatory note, one should be guided by the requirements of GOST 2.105-95. “General requirements for text documents”, in particular, according to paragraph 4, to adhere to the same for all sections in the explanatory note, the numbering sequence of chapters, sections, paragraphs, subparagraphs. Similarly, the tables, diagrams, figures, etc. included in the explanatory note should be numbered.

12.6. Drawings of the graphic part (plans and sections) must be carried out on the scale established by GOST 2.302-68 “ESKD. Scales”, while the Stroygenplan is carried out, as a rule, on a scale of 1:200 and 1:500. Technological schemes are allowed to be carried out on an arbitrary scale, provided that the main proportions are observed and the actual dimensions, marks, etc. are indicated, in accordance with GOST 2.701-84 “Schemes. Types and types. General performance requirements”.

12.7. The procedure for the development and completion of projects for the production of work using hoisting mechanisms, as well as individual sections as part of the PPR for types of work technologically related to the use of hoisting mechanisms, is regulated by the requirements of RD-11-06-2007 "Methodological recommendations on the procedure for developing projects for the production of work by hoisting machines and technological maps of loading and unloading operations.

PPR- this is a fundamental aspect of any construction, which requires special attention and professionalism. PSK GORPROEKT LLC offers its services for the creation of PPR, focusing on relatively low prices.

Our company is actively engaged in the development of documentation regulating the construction process. Highly qualified specialists with extensive experience in the construction industry will help to understand any difficult situations in the creation of a PPR. We are active in close cooperation, offering into account our interactive resource that will save you from wasting money.

The key to the successful work of the company lies in an individual approach to any order, we completely exclude the development of standard projects. Taking into account the wishes of customers, we develop a cost-effective project that can compete in the construction industry.

Development of WEP- this is not all the services that our company provides, in addition to compiling documentation, we control the process of coordinating the project with the relevant authorities.

Certificates for the development of PPR

Thanks to the competent and professional preparation of the WEP, the construction process is much faster and better. This is explained by the fact that the WEP includes a plan for the construction of the facility, the preparation of a cost-effective estimate in combination with the budget, as well as the organization of construction and installation works.

In order for the result to be excellent and you to be happy with the constructed facility, it is best to entrust the development of WEP to specialized companies that guarantee you high-quality construction and significant savings in your financial capital.

Factors affecting the cost of developing WEP

![]()

Factors affecting the timing of the development of WEP

![]() This range of services is provided by PSK GORPROEKT LLC, which operates on the principle of interaction between the customer and the general contractor, which contributes to the rapid completion of construction work. We actively cooperate with administrative and technical inspections, significantly reducing the time to obtain the necessary permits. Our specialists in the shortest possible time will open an order regulating the construction and installation work.

This range of services is provided by PSK GORPROEKT LLC, which operates on the principle of interaction between the customer and the general contractor, which contributes to the rapid completion of construction work. We actively cooperate with administrative and technical inspections, significantly reducing the time to obtain the necessary permits. Our specialists in the shortest possible time will open an order regulating the construction and installation work.

By giving preference to the PPR of our company, you:

– you have the opportunity to choose the most optimal solution for construction and installation works;

– get a high quality construction object in the shortest possible time;

- spend the minimum amount of money;

– Ensure 100% safety for workers at the facility.

It's no secret that the preparation of the PPR is of tremendous importance. It is the design and technological documentation that contributes to the thorough study of each aspect during the construction of the facility. In addition, the development of PPR allows you to organize construction and installation work, determine their order and draw up a budget.

Considering all the above nuances, it is worth noting that it is necessary to order a work production project in specialized organizations that have been operating in this area for a long time. In this case, you transfer the solution of all related tasks to the hands of professionals, which provides all the necessary guarantees.

PSK GORPROEKT LLC is engaged in similar activities and provides a full range of services. In particular, when developing a WEP for the main period (preparatory period and other types of work), we coordinate each item with the customer and the general contractor. This helps to solve all issues related to the organization of construction. In addition, having prepared a PPR, the price of which is very low, we will transfer it (if necessary) to the Association of Administrative and Technical Inspections. This will help open an order giving the right to carry out construction and installation work. To top it all, the development of WEP in construction involves the preparation of as-built documentation.

Achieving high quality is determined by the great experience of our employees, who prioritize the development of WEP, taking into account the individual preferences of the client.

Let's consider what aspects and regulatory documents are contained in the development of WEP performed by our company:

Explanatory note

- (project plan, its description, technical standards, cost estimates for building materials);

The grafical part

- stroygenplan - includes the layout of the placement of the object and the construction of the main constituent elements;

- technological schemes for the performance of specific types of work - focused on the cost-effective use of time for the construction of the facility;

- calendar schedule for the production of works - consists in the phased implementation of construction and installation works;

- labor force schedule.

Each aspect of the PPR should be developed in strict accordance with organizational and technical solutions, while we should not forget about finding the most profitable solutions for supplying the facility with the necessary amount of building material that meets a high level of quality.

When developing a WEP in the field of organizing facade works, our employees take into account the effective rental of mechanized equipment, which operates strictly according to the schedule, aimed at maximizing time and resource savings.

PPR includes ensuring the safety of workers at the facility, which consists in conducting operational quality control. You can order our services through an interactive portal that provides detailed information about the development of WEP. You will be pleasantly surprised by the relatively low cost of creating a PPR, despite the functional direction of the customer.

Our offer

Development of PPR in Moscow and regions of Russia.

If you are determined to start building some object, and do not know where to start, then feel free to contact our company, which develops competent and cost-effective PPR.

The range of services of PSK GORPROEKT LLC also includes consulting on any issues of interest to you related to the construction of facilities. A non-standard approach to order fulfillment, based on modern technologies and standards, allows us to provide individual and complex services.

If you want to end up with a beautiful, high-quality construction project, then you should definitely contact our engineers, who work according to the strategy of reverent order fulfillment, in strict accordance with the requirements and wishes of the client.