Incandescent lamps: types, specifications, how to choose the right one. Design, advantages and disadvantages of incandescent lamps Efficiency of 100 W incandescent lamps

A body heated by an electric current can, it turns out, not only radiate heat, but also glow. The first light sources functioned precisely on this principle. Consider how an incandescent lamp works - the most massive lighting fixture in the world. And, although it will eventually have to be completely replaced by compact luminescent (energy-saving) and LED light sources, humanity will not be able to do without this technology for a long time.

Incandescent lamp design

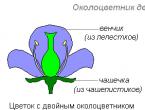

The main element of the light bulb is a spiral of refractory material - tungsten. To increase its length and, accordingly, resistance, it is twisted into a thin spiral. This is not visible to the naked eye.

The spiral is fixed on supporting elements, the outermost of which serve to connect its ends to the electrical circuit. They are made of molybdenum, the melting point of which is higher than the temperature of the heated coil. One of the molybdenum electrodes is connected to the threaded part of the base, and the other to its central terminal.

Molybdenum holders hold the tungsten coil

Air is evacuated from a flask made of glass. Sometimes an inert gas, such as argon or its mixture with nitrogen, is pumped inside instead of air. This is necessary to reduce the thermal conductivity of the internal volume, as a result of which the glass is less susceptible to heat. Additionally, this measure prevents oxidation of the filament. During the manufacture of the lamp, air is pumped out through a part of the bulb, which is then hidden by the base.

The principle of operation of an incandescent lamp is based on heating its filament with an electric current to a temperature at which it begins to emit light into the surrounding space.

Incandescent lamps can be manufactured for power from 15 to 750 watts. Depending on the power, different types of threaded sockets are used: E10, E14, E27 or E40. For decorative, signal and backlight lamps, BA7S, BA9S, BA15S socles are used. Such products, when installed, are stuck inside the cartridge and rotated 90 degrees.

In addition to the usual, pear-shaped form, decorative lamps are also produced, in which the bulb is made in the form of a candle, a drop, a cylinder, a ball.

A lamp with a bulb that does not have a coating glows with a yellowish light, most reminiscent of sunlight in composition. But when applied to the inner surface of the glass with special coatings, it can become matte, red, yellow, blue or green.

Of interest is the device of a mirror incandescent lamp. A reflective layer is applied to part of its bulb. As a result, due to reflection from it, the luminous flux is redistributed in one direction.

Advantages of incandescent lamps

The most important plus in favor of the use of incandescent bulbs is the simplicity of their manufacture and, accordingly, the price. It is impossible to think of a simpler lighting device.

Lamps are manufactured for a wide range of power and overall dimensions. All other modern light sources contain devices that convert the supply voltage to the value necessary for their operation. Although they manage to shove them into the standard overall dimensions of the light bulb, the design becomes more complicated, the number of parts in the device increases. And this does not always improve the cost and reliability indicators. The circuit for switching on an incandescent lamp does not require any additional elements.

LED lamps have replaced conventional ones from portable devices: portable light sources powered by batteries and accumulators. With the same light output, they consume less current, and the overall dimensions of the LED are even smaller than the bulbs previously used in flashlights. Yes, and as part of Christmas tree garlands, they work more successfully.

It is worth noting one more advantage inherent in incandescent bulbs - their luminescence spectrum is closest to the sun than that of all other artificial light sources. And this is a big plus for vision, because it is adapted specifically to the sun, and not to monochrome LEDs.

Due to the thermal inertia of the heated filament, the light from it practically does not pulsate. What cannot be said about radiation from other devices, especially luminescent ones, using a conventional choke as a ballast, and not a semiconductor circuit. Yes, and electronics, especially cheap ones, do not always suppress ripples from the network properly. This also affects the eyesight.

But not only health can be damaged by the pulsating nature of the operation of semiconductor devices used in modern light bulbs. Their massive use leads to a sharp change in the shape of the current consumed from the network, which ultimately affects the shape of the voltage. It changes so much in relation to the original (sinusoidal) that this affects the quality of the work of other electrical appliances in the network.

Disadvantages of incandescent lamps

A significant drawback of incandescent bulbs, which reduces their service life, is its dependence on the magnitude of the supply voltage. As the voltage increases, the filament wears out faster. They produce lamps for different values \u200b\u200bof this parameter (up to 240 V), but at the nominal value they shine worse.

Lowering the voltage leads to a sharp change in the intensity of the glow. And even worse, its fluctuations affect the lighting device; with sharp jumps, the lamp may burn out.

But the worst thing is that the filament is designed to work for a long time in a heated state. When heated, its resistivity increases. Therefore, at the moment of switching on, when the thread is cold, its resistance is much less than that at which the glow occurs. This leads to an inevitable current surge at the moment of ignition, leading to the evaporation of tungsten. The greater the number of inclusions, the less the lamp will live.

Soft start devices or devices that allow you to adjust the brightness of the glow over a wide range help to correct the situation.

The main disadvantage of incandescent bulbs is their low efficiency. The vast majority of electricity (up to 96%) is spent on useless heating of the surrounding air and radiation in the infrared spectrum. Nothing can be done about this - this is the principle of the incandescent lamp.

And one more thing: the glass of the flask is easy to break. But unlike compact fluorescent lamps containing a small amount of mercury vapor inside, a broken incandescent lamp does not threaten the owner with anything other than a possible cut.

Halogen lamps

The reason for the burnout of an incandescent lamp is the gradual evaporation of the tungsten from which the filament is made. It becomes thinner, and then another surge of current when turned on melts it at its thinnest point.

This drawback is designed to eliminate halogen lamps filled with bromine or iodine vapor. During combustion, the evaporating tungsten combines with halogen. The resulting substance is not capable of depositing on the walls of the flask or other relatively cold internal surfaces.

incandescent lamp is an electrical light source that emits light flow as a result of the heating of a conductor made of refractory metal (tungsten). Tungsten has the highest melting point of all pure metals (3693 K). The filament is in a glass flask filled with an inert gas (argon, krypton, nitrogen). inert gas protects the filaments from oxidation. For incandescent lamps of low power (25 W), vacuum flasks are made that are not filled with an inert gas. The glass bulb prevents the negative effects of atmospheric air on the tungsten filament.

To calculate the illumination of a room, you can use the calculator for calculating the illumination of a room.

Varieties of incandescent lamps.

Incandescent lamps are divided into:

- vacuum;

- Argon (nitrogen-argon);

- Krypton (+10% brightness from argon);

- Xenon (2 times brighter than argon);

- Halogen (composition I or Br, 2.5 times brighter than argon, high service life);

- Halogen with two flasks (improved halogen cycle due to better heating of the inner flask);

- Xenon-halogen (composition Xe + I or Br, up to 3 times brighter than argon);

- Xenon halogen with IR reflector;

- Incandescent with a coating that converts infrared radiation to the visible range. (new)

Advantages and disadvantages of incandescent lamps.

Advantages:

- low cost;

- instant ignition when turned on;

- small overall dimensions;

- wide power range.

Flaws:

- high brightness (negatively affects vision);

- short service life - up to 1000 hours;

- low efficiency. (only a tenth of the electrical energy consumed by the lamp is converted into visible light flux) the rest of the energy is converted into heat.

Characteristics of incandescent lamps.

Light flow is a physical quantity that characterizes the amount of "light" power in the corresponding radiation flux.

Light output- this is the ratio of the light flux emitted by the source to the power consumed by it, measured in lumens per watt (lm / W). It is an indicator of the efficiency and economy of light sources.

Lumen- This is a unit of measurement of the luminous flux, a luminous quantity.

Luminous flux and luminous efficiency of incandescent lamps.

|

Type, power, W |

Light flow (lumen) |

Light output (lm/watt) |

|

Lamp incandescent 5 W |

||

|

Lamp incandescent 10 W |

||

|

Lamp incandescent 15 W |

||

|

Lamp incandescent 25 W |

220 |

|

|

Lamp incandescent 40 W |

420 |

|

|

Lamp incandescent 60 W |

710 |

|

|

Lamp incandescent 75 W |

935 |

|

|

Lamp incandescent 100 W |

1350 |

|

|

Lamp incandescent 150 W |

1800 |

|

|

Lamp incandescent 200 W |

2500 |

|

|

Sun |

3,63.10 28 |

|

|

Ideal source Sveta |

683,002 |

Comparative table of the ratio of luminous flux to power consumption of various types of lamps.

|

Lamp incandescent, power, Tue |

L.L lamp, Tue |

Light-emitting diode. lamp, power Tue |

Light flow, Lm |

|

20 W |

5-7W |

2-3 W |

About 250 lm |

|

40 W |

10-13 W |

4-5W |

About 400 lm |

|

60 W |

15-16 W |

8-10 W |

About 700 lm |

|

75 W |

18-20 W |

10-12 W |

About 900 lm |

|

100 W |

25-30W |

12-15W |

About 1200 lm |

|

150 W |

40-50W |

18-20 W |

About 1800 lm |

|

200 W |

60-80W |

25-30W |

About 2500 lm |

Characteristics of different types of lamps in terms of light transmission.

- LN- incandescent lamps;

- GLN- halogen lamps;

- CFL- compact fluorescent lamps;

- MGL- metal halide lamps;

- LL- fluorescent lamps;

- LEDs- LED bulbs.

Characteristics of various types of incandescent lamps.

Lamp voltage - U, Volt;

Lamp power - W, W;

Luminous flux - Lm, Lumen.

General purpose incandescent lamps (standard).

|

Lamp type |

U, V |

W, W |

Lm |

Term services Ch. |

Length mm |

Diam. Mm |

Type plinth |

|

B 220-230-25-1 |

225 |

200 |

1000 |

105 |

E27 |

||

|

B 220-230-40-1 |

225 |

430 |

1000 |

105 |

E27 |

||

|

B 220-230-60-1 |

225 |

730 |

1000 |

105 |

E27 |

||

|

B 220-230-75-1 |

225 |

960 |

1000 |

105 |

E27 |

||

|

B 220-230-100 |

225 |

100 |

1380 |

1000 |

105 |

E27 |

|

|

B 220-235-40-2 |

230 |

335 |

1000 |

E27 |

|||

|

B 225-235-60-2 |

230 |

655 |

1000 |

E27 |

|||

|

B 225-235-100-2 |

230 |

100 |

1203 |

1000 |

E27 |

||

|

B 235-245-150-1 |

240 |

150 |

2180 |

1000 |

130 |

E27 |

|

|

RN 220-230-15-4 |

225 |

600 |

E14 |

||||

|

RN 220-230-200-1 |

225 |

200 |

2950 |

1000 |

145 |

E27 |

|

|

RN 220-230-300 |

225 |

300 |

3350 |

1000 |

140 |

E27 |

|

|

RN 230-240-300 |

235 |

300 |

4800 |

1000 |

200 |

200 |

E40 |

|

RN 215-225-500 |

220 |

500 |

8400 |

1000 |

240 |

132 |

E40 |

General purpose incandescent lamps (minions).

|

Lamp type |

U,V |

W,W |

Lm |

Term Services Ch. |

Length mm |

Diam. mm |

Type plinth |

|

DS 220-230-40 |

225 |

400 |

1000 |

103 |

E14 |

||

|

DS 220-230-60 |

225 |

680 |

1000 |

103 |

E14 |

||

|

DSO 235-245-40 |

240 |

395 |

1000 |

103 |

E14 |

||

|

DSO 235-245-60 |

240 |

670 |

1000 |

103 |

E14 |

General purpose incandescent lamps (mirror).

|

Lamp type |

U,V |

W,W |

Lm |

Term services Ch. |

Length mm |

Diam. mm |

Type plinth |

|

3K 220-230-40(R63) |

225 |

450 |

1000 |

102,5 |

63,5 |

E27 |

|

|

3D 220-230-60(R80) |

225 |

200 |

1000 |

116 |

E27 |

||

|

3D 220-230-75(R80) |

225 |

280 |

1000 |

116 |

E27 |

||

|

3D 220-230-100(R80) |

225 |

100 |

410 |

1000 |

116 |

E27 |

General purpose incandescent lamps (opaque).

|

Lamp type |

U,V |

W,W |

Lm |

Term Services Ch. |

Length mm |

Diam. mm |

Type plinth |

|||||||

|

BO 230-240-40 |

235 |

420 |

1000 |

105 |

E27 |

|||||||||

|

BO 230-240-60 |

235 |

710 |

1000 |

105 |

E27 |

U,V |

W,W |

Lm |

Term Services |

Length Mm |

Diam. mm |

Type plinth |

||

|

MO 36-25 |

300 |

1000 |

108 |

E27 |

||||||||||

|

MO 12-40 |

620 |

1000 |

108 |

E27 |

||||||||||

|

MO 36-40 |

580 |

1000 |

108 |

E27 |

||||||||||

|

MO 36-60 |

950 |

1000 |

108 |

E27 |

||||||||||

|

MO 36-100 |

100 |

1590 |

1000 |

108 |

Term services Ch. |

Length mm |

Diam. mm |

Type plinth |

||||||

|

KG 220-500-1 |

220 |

500 |

14000 |

3200 |

2000 |

132 |

R7s |

|||||||

|

KG 220-1000-5 |

220 |

1000 |

22000 |

3200 |

2000 |

189 |

R7s |

|||||||

|

KG 220-1500 |

220 |

1500 |

33000 |

3200 |

2000 |

254 |

R7s |

|||||||

|

KG 220-2000-4 |

220 |

2000 |

44000 |

3200 |

2000 |

335 |

R7s |

Schemes for switching on incandescent lamps.

Wiring diagram for switching on a single-lamp luminaire with a socket.

Schematic diagram of the inclusion of one lamp with a switch and a socket.

It often happens that a device used in everyday life, which is of great importance for all mankind, does not remind us of its creator. But in our homes it lit up thanks to the efforts of specific people. Their merit for humanity is invaluable - our homes are filled with light and warmth. The story below will introduce you to this great invention and the names of those with whom it is associated.

As for the latter, two names can be noted - Alexander Lodygin and Thomas Edison. Although the merit of the Russian scientist was very great, the palm belongs to the American inventor. Therefore, we will briefly talk about Lodygin and dwell in detail on the achievements of Edison. It is with their names that the history of incandescent lamps is associated. It is said that Edison's light bulbs took a huge amount of time. He had to conduct about 2 thousand experiments before the design familiar to all of us was born.

Invention made by Alexander Lodygin

The history of incandescent lamps is very similar to the history of other inventions made in Russia. Alexander Lodygin, a Russian scientist, was able to make a carbon rod glow in a glass vessel from which the air was pumped out. The history of the creation of an incandescent lamp begins in 1872, when he managed to do it. Alexander received a patent for an electric charcoal incandescent lamp in 1874. A little later, he suggested replacing the carbon rod with tungsten. The tungsten part is still used in incandescent lamps.

Thanks to Thomas Edison

However, it was an American inventor who was able to create a durable, reliable and inexpensive model in 1878. In addition, he managed to establish its production. In his first lamps, the filament was charred shavings made from Japanese bamboo. Tungsten filaments, familiar to us, appeared much later. They began to be used at the initiative of Lodygin, the Russian engineer mentioned above. If it were not for him, who knows how the history of incandescent lamps would have developed in subsequent years.

American Edison mentality

Significantly different from Russian. With US citizen Thomas Edison, everything went into business. Interestingly, while thinking about how to make telegraph tape more durable, this scientist invented paper waxing. This paper was then used as a candy wrapper. Seven centuries of Western history preceded the invention of Edison, and not so much the development of technical thought, but the active attitude to life gradually formed in people. Many talented scientists stubbornly went to this invention. The history of the origin of the incandescent lamp is associated, in particular, with the name of Faraday. He created fundamental works in physics, without relying on which Edison's invention would hardly have been feasible.

Other inventions made by Edison

Thomas Edison was born in 1847 in Port Heron, a small American town. In Thomas's self-realization, the fact that the young inventor had the ability to instantly find investors for his ideas, even the most daring ones, played a role. And they were ready to risk considerable sums. For example, while still a teenager, Edison decided to print a newspaper on the train while it was moving and then sell it to passengers. And the news for the newspaper should have been collected right at the bus stops. Immediately there were people who loaned money to buy a small printing press, as well as those who let Edison into the baggage car with this machine.

Inventions before Thomas Edison were either made by scientists and were a by-product of their discoveries, or by practitioners who perfected what they had to work with. It was Edison who made invention a separate profession. He had a lot of ideas, and almost every one of them became a sprout for subsequent ones that required further development. Thomas throughout his long life did not care about his personal comfort. It is known that when he visited Europe, already at the zenith of fame, he was disappointed with the laziness and dapperness of European inventors.

It was difficult to find an area in which Thomas would not make a breakthrough. It is estimated that this scientist made about 40 major discoveries every year. In total, Edison received 1,092 patents.

The spirit of American capitalism pushed Thomas Edison up. He managed to get rich at the age of 22, when he came up with a quotation ticker for the Boston Stock Exchange. However, the most important invention of Edison was the creation of an incandescent lamp. Thomas managed to electrify the whole of America with its help, and then the whole world.

Construction of the power plant and the first consumers of electricity

The history of the lamp begins with the construction of a small power plant. The scientist built it in his Menlo Park. She was supposed to serve the needs of his laboratory. However, the energy received turned out to be more than was necessary. Then Edison began to sell the surplus to farmer neighbors. It is unlikely that these people understood that they became the first paid consumers of electricity in the world. Edison never aspired to become an entrepreneur, but when he needed something for his work, he opened a small factory in Menlo Park, which later grew to a large size and went its own way.

History of changes in the incandescent lamp device

An electric incandescent lamp is a light source where the conversion into electrical light energy occurs due to the incandescence of a refractory conductor by an electric current. Light energy was first obtained in this way by passing current through a carbon rod. This rod was placed in a vessel from which the air had previously been evacuated. Thomas Edison in 1879 created a more or less durable design using carbon filament. However, there is a rather long history of the emergence of the incandescent lamp in its modern form. As a heating body in 1898-1908. tried to use different metals (tantalum, tungsten, osmium). Tungsten filament, zigzag, began to be used since 1909. Incandescent lamps began to fill in 1912-13. (krypton and argon), as well as nitrogen. At the same time, tungsten filament began to be made in the form of a spiral.

The history of the development of the incandescent lamp is further marked by its improvement by improving the light output. This was done by raising the temperature of the filament body. At the same time, the lamp life was maintained. Filling it with inert high-molecular gases with the addition of halogen led to a decrease in the contamination of the flask with particles of tungsten sprayed inside it. In addition, it reduced the rate of its evaporation. The use of a filament in the form of a double-spiral and a tri-spiral led to a reduction in heat loss through the gas.

Such is the history of the invention of the incandescent lamp. Surely you will be interested to know about what its various varieties are.

Modern varieties of incandescent lamps

Many varieties of electric lamps consist of certain parts of the same type. They differ in shape and size. An incandescent body (that is, a spiral made of tungsten) is fixed on a metal or glass stem inside the bulb with holders made of molybdenum wire. The ends of the spiral are attached to the ends of the inputs. In order to create a vacuum-tight connection with a blade made of glass, the middle part of the bushings is made of molybdenum or platinum. The bulb of a lamp during vacuum processing is filled with inert gas. Then the stem is brewed and a spout is formed. The lamp for mounting in the cartridge and protecting the spout is supplied with a base. It is attached with a base mastic to the flask.

The appearance of the lamps

Today, there are many incandescents, which can be divided by application (for car headlights, general purpose, etc.), by the lighting properties of their bulb or by constructive form (decorative, mirror, with a diffusing coating, etc.), as well as by shape, which the filament body has (with a double spiral, with a flat spiral, etc.). As for the dimensions, there are large-sized, normal, small-sized, miniature and subminiature. For example, the latter include lamps having a length of less than 10 mm, the diameter of which does not exceed 6 mm. As for large-sized ones, they include those whose length is more than 175 mm and the diameter is at least 80 mm.

Lamp power and service life

Modern incandescent lamps can operate at voltages ranging from fractions of a unit to several hundred volts. Their power can be tens of kilowatts. If you increase the voltage by 1%, the luminous flux will increase by 4%. However, the service life will be reduced by 15%. If you turn on the lamp for a short period of time at a voltage that exceeds the rated voltage by 15%, it will be disabled. That is why so often voltage drops cause light bulbs to burn out. From five hours to a thousand or more, their service life varies. For example, aircraft headlights are designed for a short time, and transport lamps can work for a very long time. In the latter case, they should be installed in places that allow easy replacement. Today, the luminous efficacy of lamps depends on voltage, design, duration of burning and power. It is about 10-35 lm/W.

Incandescent lamps today

Incandescent lamps in terms of their luminous efficiency, of course, lose to gas-powered light sources (fluorescent lamps). However, they are easier to use. Incandescent lamps do not require complex fittings or starting devices. There are practically no restrictions on power and voltage for them. About 10 billion lamps are produced in the world today every year. And the number of their varieties exceeds 2 thousand.

LED bulbs

The history of the origin of the lamp has already been written, while the history of the development of this invention has not yet been completed. There are new varieties that are becoming more and more popular. We are talking primarily about LED lamps (one of them is shown in the photo above). They are also known as energy efficient. These lamps have a light output that is more than 10 times that of incandescent lamps. However, they have a drawback - the power source must be low-voltage.

Despite a whole list of shortcomings identified when compared with other sources of artificial light, incandescent lamps remain in demand both in the domestic sphere and in industrial sectors.

Cheap and easy to use devices do not want to give up their positions, although a huge number of more economical and "long-lasting" substitutes have appeared on the market - for example, LED lamps.

What is the main secret of their success and why are they still popular? We will consider these issues in our article, referring to the technical characteristics of conventional light bulbs, their main types. We will also consider the advantages and disadvantages and give recommendations for choosing a traditional light bulb.

Until recently, incandescent lamps (LN) were used everywhere and now they are still being bought - they can work both “at full strength”, brightly illuminating the room, and reduce the brightness with the help of. Due to the prevalence of traditional light bulbs among the population, many are familiar with their design features.

Moreover, they often had to “get acquainted” due to the failure of the light source: the tungsten filament burned out, the glass burst or the bulb flew out of the base.

Some manufacturers have used more reliable and proven materials and treated the production of incandescent bulbs so responsibly that their products have been working for several decades. But this is more an exception than a rule - today no guarantees for a long service life are given.

Schematic representation of a lamp showing the main details. The design of the artificial light source has not changed much since the invention, only the materials and composition of the gas filling the flask have been improved.

The main active element is the so-called filament body, fixed on the holders and attached to the electrodes. At the moment of connecting the electricity, a voltage passes through it, causing both heating and glow. In order for the radiation to become visible, the heating temperature must reach 570 °C.

Tungsten is recognized as the most resistant metal to high temperatures. It begins to melt when heated to 3422 ° C. To maximize the radiation area, but reduce the volume of the filament body inside the glass bulb, it is twisted into a spiral.

The usual comfortable light of a yellow hue, which creates coziness in the house and is visually “warm”, occurs when the thread is heated to 2830-2850 ° C

To protect tungsten from the oxidation process characteristic of metals, air is pumped out of the flask and replaced with a vacuum or gas (krypton, argon, etc.). Vacuum filling technology is outdated; for household lamps, a mixture of nitrogen and argon or krypton is most often used.

As a result of testing, the minimum duration of lamp burning was revealed - 1 thousand hours. But, given the random reasons that disable devices ahead of time, it is assumed that the standards apply to only 50% of the products from each batch. The operating time of the second half may be longer or shorter - depending on the conditions of use.

Types and features of the use of LN

Qualitative characteristics and marking of tungsten bulbs are regulated GOST R 52712-2007. According to the type of filling of the flask, LN devices are divided into vacuum and gas-filled varieties.

The former serve less due to the inevitable evaporation of the tungsten filament. In addition, tungsten vapors are deposited on the glass envelope of the vacuum source, which significantly reduces the transparency and the ability of the glass to transmit light. They are produced with a monospiral, in the nomenclature designation they are assigned the letter IN.

In gas-filled devices, the disadvantages of vacuum bulbs are minimized. The gas reduces the evaporation process and prevents the tungsten from settling on the walls of the flask. Gas-filled monospiral species are designated by the letter G, and light bulbs with a double-wound helix, i.e. bispiral, marked with a letter B. If the bispiral variety has the nomenclature BC, which means that krypton was used in its filling.

In GLN halogen bulbs, bromine or iodine is added to the glass bulb filler, due to which the evaporating tungsten atoms, after evaporation, return back to the filament. Halogens are produced in two formats: in the form of quartz tubes with a long spiral or in a capsule version with a compact working element.

In state standards, the division into groups occurs according to the scope, but other characteristics are also affected. Let's assume that at the same level, "LN electric miniature" are considered ( LN mn) and "LN infrared mirror" ( ZK– devices with concentrated light distribution, ZD- with an average) - as you can see, different criteria are chosen to designate the categories.

There are groups that can be attributed to the most popular:

- general purpose;

- for vehicles;

- searchlights;

- miniature, etc.

Consider the scope and features of various categories, which in some cases may overlap.

Especially for fans of traditional light bulbs, filament devices based on LEDs are produced, similar in shape, but favorably differing in their characteristics.

If you choose a device of lower power, then the luminous flux will be weaker, if you choose a larger one, then you risk the integrity of the shades - they can be deformed due to the high heating temperature.

In addition to the technical characteristics, it is worth paying attention to the quality of the workmanship of the lamp. Preference should be given to products with a wide base contact, a soldered conductor, and a stably fixed filament.

Conclusions and useful video on the topic

Even more informative and interesting information about the production, use and disadvantages of incandescent lamps - in videos shot by experts and amateurs.

Interesting Incandescent Facts:

Considering that we use lighting all the time, and there are usually more than a dozen light bulbs in the house, habits should be reconsidered. Many users have long switched to more reliable, economical, safe LED lamps.

Have you noticed errors or inaccuracies in the material presented? Or do you want to supplement this article with useful recommendations? Write to us about it, please, in the comment block.

If you prefer to use traditional light bulbs instead of more economical energy-saving ones and want to share your opinion on them, write your point of view on the advisability of using conventional light bulbs under this article.

An incandescent lamp is a source of artificial light that generates a lot of heat during operation. Inside it is a metal spiral, most often made of refractory tungsten. This element is placed in a flask, which is filled with an inert gas, less often a vacuum one. Such filling does not allow the metal to oxidize. Such lamps are popular due to their low price.

Path of Creation

The history of these lamps is long and thorny, more than one creator took part in its creation. The creation process can be divided into the following stages:

- Lodygin's invention. A Russian scientist figured out how to light a carbon rod in a glass vessel without air. The problem was that the thread began to burn out quickly. A little later, it was he who proposed replacing the carbon rod with a tungsten one.

- Contribution of Thomas Edison. He managed to create an inexpensive and relatively durable model of such a lamp. He set up stream production, it was possible to make a lamp in the right volumes. Almost all his life he improved the lamp, using different materials to achieve the best effect.

Over time, the lamps began to be filled with inert gases, which significantly increased the service life.

She hasn't changed much since her inception.Scope of use

Not so long ago, incandescent lamps were present in various areas of life, in everyday life and at enterprises. This is due to their simple installation, operation and maintenance. Used in the following areas:

- General purpose for indoor and outdoor lighting in private houses, apartments, offices.

- Local application - for illumination of workplaces.

- There are also special car incandescent lamps.

- They are installed in trains, on ships, and in airplanes.

- Miniature LNs are used in flashlights, instrument scales.

- Subminiature in separate medical devices, control panels.

- There are also switching, lighthouse, film projection.

Expert opinion

Alexey Bartosh

Ask an expertImportant! In many areas today, economical lamps are used, but still consumer interest in the use of LN is not decreasing.

Incandescent lamps have the following characteristics:

- Power spread. Depends on the scope of use, so lamps from 25 to 150 watts are used for domestic purposes, for others - up to 1000 watts.

- The thread is heated up to 2000–2800 degrees.

- Voltage - 220-330 V.

- Light output - 9-19 Lm / 1W.

- The dimensions of the plinth are E 14, E 27 and E 40, which corresponds to 14, 27 and 40 mm. Base type - threaded and pin. The latter can be one- or two-pin.

- The resource of functioning is 1000 hours under optimal conditions.

- They emit a lot of heat during the combustion process, they are sensitive to frequent shutdowns.

- For the price, they are the most affordable of the lamps offered in stores.

- Average weight - 15 g.

Characteristics of lamps of different power

Characteristics of lamps of different power Operating principle

The essence of the operation of all LNs is to use the principle of heating a substance when a current passes through it. In this case, the temperature of the filament rises after the electrical circuit is closed. As a result, the effect of electromagnetic thermal radiation is triggered. To make it visible to a person, the heating temperature must exceed 570 ⁰C - this is the beginning of the red glow.

Inside the lamp, the incandescent filament is heated to 2000–2800 ⁰С. When heated to such a temperature in air, tungsten turns into an oxide - a white coating forms on it, so neutral gases are pumped into the flask. At the dawn of the development of this lighting technology, a vacuum was created in the light bulb, now this is practiced only for products of minimum power. When the lamp base is screwed into the socket and the circuit is closed, the process of glowing the filament starts, and it gives light.

The design of incandescent lamps

The design of incandescent lamps The device of all LNs is similar, they contain:

- The working part is a tungsten wire filament coiled into a spiral. The specific resistance of this metal is 3 times greater than that of copper. Tungsten is used because it is refractory and the cross section of the filament can be reduced as much as possible. This increases the electrical resistance. The spiral receives power from the electrodes.

- The spiral is held by molybdenum elements. It is also refractory, has a low coefficient of thermal expansion.

- Glass flask. Inside it is an inert gas, which prevents the filament from burning out. That is why such lamps are not vacuum, it is the gas that creates pressure inside the bulb.

- The electrodes are connected to the contact elements of the base using copper conductors.

- Plinth. Such an element is in all the light bulbs under consideration, with the exception of special automotive ones. The thread on the plinth and its size may be different.

plinth

The most familiar light bulbs for us are with a threaded base, their sizes are standardized. For models that are used in domestic conditions, E 14, E 27 and E 40 are in demand. They are less commonly used for such light sources without thread, but they are common in the automotive business.

Interesting! In America and Canada, others are used due to a different voltage in the network. For them, the usual thread sizes in mm are: 12, 17, 26 and 39. When reflecting the size of the base on the light bulb, the letter E stands in front of the numbers just like ours.

Incandescent lamp sockets

Incandescent lamp sockets Marking

It is not difficult to understand the marking of incandescent lamps, the main designations that can be found:

- Design specifics and properties. “B” indicates argon bicoil LN, “C” indicates the content inside the vacuum, “G” indicates that gas is pumped into the lamp, “BK” indicates krypton bicoil, “ML” indicates the milky color of the flask, “MT” indicates matte, "O" - opal.

- The second part of the marking will tell about the purpose of the light bulb. "Zh" - railway, "KM" - switching, "SM" - for aircraft, "A" - for cars, "PZH" - high power lamp for use in searchlights.

- The shape is designated as follows: "A" - lampshade, "D" - decorative, "B" - twisted.

- The first digits are the nominal voltage.

Efficiency and durability

Significant disadvantages of such lamps are a short service life and low efficiency. Efficiency is the ratio of power and radiation noticeable to a person. As we remember, the thread is heated up to 2700 K, in this case its efficiency is about 5%. All the rest of the energy, which, by the way, is completely converted into radiation, falls on the infrared spectrum, which is invisible to humans. We perceive it as warmth.

It is theoretically possible to increase the efficiency up to 20%, for this it is necessary to increase the temperature of the filament to 3400 K, the resulting light in this case will be 2 times brighter, however, the service life is reduced by 95%.

If the power is reduced, then the period of operation of incandescent lamps can increase by 5 or more times. Reducing the voltage at the same time reduces the efficiency, but it will turn out to use a light bulb 1000 times longer. This effect is used to create reliable emergency lighting. Of course, this is only possible if there are no critical lighting requirements.

The process of burning out an incandescent lamp

The process of burning out an incandescent lamp Types of lamps and their functional purpose

There are many incandescent lamps, they are classified according to their functional purpose and design features.

General, local purpose

Until 1970 they were called normal lighting. This group is the largest among ordinary LN. Previously, they were successfully used for both general and decorative lighting at home, in offices, and other institutions. At the moment, in many countries, including Russia, their release is limited.

As for local lamps, they are the same in design as the general ones, but they are designed for a reduced operating voltage. They can be used in hand-held portable lamps, for lighting machine tools, workbenches, etc.

General purpose lamp

General purpose lamp Decorative

Their main feature is a curly flask, its dimensions can be very different, as well as the location inside the filament. Such models are very much in demand today, but they do not play the role of lighting as much as decor, especially in vintage or retro design projects. The appearance of such a lamp is very original.

Variants of execution of decorative lamps

Variants of execution of decorative lamps Illuminations

Their flask is painted in different colors, depending on the intended use. Convenient for equipping illumination installations. The paint is mainly applied to the inside of the flask, for this purpose inorganic pigments are used. Much less often, such lamps are painted outside. Their power is small, varies between 10-25 watts. They give the desired effect only the first time, then their color changes, loses brightness.

Illuminated lamp can be of different power

Illuminated lamp can be of different power Signal

They were used in various lighting devices. At the moment, LED lamps are replacing them from this area.

Signal lamp version

Signal lamp version Mirrored

The bulb of such a lamp has a specific shape, inside it is covered with a thin layer of aluminum. Due to this, a mirror effect is created, there is also a transparent part. The main task of such lamps is the distribution of the luminous flux in order to concentrate within a certain zone. It is convenient to use them in shop windows, in trading floors. It is these lamps that are used to heat newborn chicks and other animals.

Mirror incandescent lamp

Mirror incandescent lamp Transport

This group is very extensive, used in various vehicles, for headlights or other lighting. Demanded for:

- Cars.

- Motorcycles.

- Tractors.

- Airplanes and helicopters.

- River and sea vessels.

Such lamps have a number of features, among them:

- High strength.

- Vibration resistant.

- Special socles, due to which it is possible to quickly change a failed lamp.

- They are designed to be powered by the electrical network of the vehicle.

Automotive incandescent lamps

Automotive incandescent lamps double strand

This is a subtype of a special incandescent lamp that is used in:

- Cars. So, headlight bulbs can have 2 filaments. One of them goes to the low beam, the second - to the far beam. The situation is similar for the rear lights, only here there are separate threads for the dimensions and for the brake lights.

- Airplanes. In some models in the landing and taxiing light.

- Railway traffic lights. Here, double-filament lamps are an element of safety and insurance, if one burns out, then the second will be able to continue to give a signal.

Expert opinion

Alexey Bartosh

Specialist in the repair, maintenance of electrical equipment and industrial electronics.

Ask an expertImportant! There are other options for lamps, for example, those with a special radiation spectrum, heating, projection and others. But today they are being actively replaced by other types of light bulbs.

Double filament automotive incandescent lamp

Double filament automotive incandescent lamp Advantages and disadvantages

The most popular lamps in the world have both advantages and many disadvantages, especially with the development of new lighting technologies. It’s worth starting with the advantages, more specifically:

- Affordable price. This is the most budget option at the moment. True, this applies only to the cost, but not to electricity bills.

- Compact dimensions.

- Virtually do not suffer from voltage drops in the network.

- No warm-up time required.

- When operating on AC, the flicker is invisible.

- Electronic dimmers can be used to control and save energy consumption.

- The spectrum is perfectly perceived by the human eye, its type is continuous.

- High color rendering index.

- Can be used at any temperature, regardless of variety.

- Large voltage spread, from fractions to hundreds of Volts.

- They do not require special disposal, as they do not contain toxic components inside. That is, they do not harm people and other living beings.

- No additional ballasts are needed, which is a big plus compared to modern light sources.

- During operation, they do not hum and do not create radio interference.

- Polarity insensitive - it will still work.

- They create a minimum level of UV radiation when compared with other modern light bulbs.

Main pros and cons

Main pros and cons