DIY chicken feeders: photo original ideas. Simple DIY feeders Mechanical chicken feeder

It is a well-known fact that the eggs of chickens that live in the wild, and not in the cramped walls of poultry farms, are much tastier and healthier. Recently, an increasing number of people have been trying to keep these bird representatives.

The greatest difficulties for owners arise when organizing the process of feeding chickens, since it involves significant labor costs and financial expenses. Because of this, the choice of feeders must be approached with all responsibility.

But you can save a significant amount if you independently set up a collection point for bird feed. A do-it-yourself chicken feeder is an opportunity to create a useful device that will be useful in everyday life. You will receive not only material benefits, but also moral satisfaction when the chickens peck grain from these feeders.

Primary requirements

There are a number of requirements that are presented when creating them:

Strength. The creation of feeders should be based on materials that retain their shape and are resistant to mechanical stress.

Ease of use. The device should be easy to clean. It is necessary that the feeder is easy to pour food into, and that it is convenient for poultry to eat from it.

Sustainability. Under no circumstances should the feed collection point change its location after direct contact with poultry.

Rationality. It is necessary to make the device in such a way that it is impossible for droppings or debris to get into it.

There are other requirements for the feeder that apply to them depending on the characteristics of keeping poultry.

Types of devices for feeding chickens

The pressing question: “How to make a chicken feeder?” There are several types of feeders that you can make yourself. Let's present the most interesting of them.

From a plastic bottle

This is perhaps the easiest feeder model to make. To make it you will need two plastic bottles, the volume of which can range from 1.5 to 5 liters. You will also need a flat material of a certain hardness.

First, the bottom part of a 1.5 liter bottle is cut off. This must be done to make it convenient to fill the grain. Holes should be made closer to the neck of the bottle. It is through these holes that the feed will move.

A hole is created in the central part of the cut container, which is the same size as the neck of the bottle. We take a sheet of plywood with a diameter of 50 by 30 and also create holes with a diameter that matches the bottle.

At the last stage, you need to lower a 1.5 liter plastic bottle into a container whose volume is larger. This must be done in such a way that the neck passes through both holes and comes out directly below relative to the piece of plywood. We fix the cover. The plastic chicken feeder is made in the best possible way.

In the photo of the chicken feeder you can visually see the features of this design.

Hopper feeder for chickens

Another chicken feeder idea is to create a hopper feeder. To create this type of bird feeding device, you will need a sheet of plywood from which several elements are cut:

- in front of the bunker (400 x 500 mm);

- back of the bunker (400 x 400 mm);

- 2 pcs. sides. The side walls are made in the form of a cone that connects the main parts of the feeder;

- lid. It should be slightly larger in size than the top of the poultry feeding device.

Simple drawings of chicken feeders demonstrate that an opening is left at the bottom of the installation where food will be delivered to a tray, from which the chickens will subsequently peck grain.

After the chicken coop residents eat a certain part of the feed from the tray, the volume of grain in the bunker will decrease. Adding poultry food to the device is easy.

You just need to open the top of the device and pour in the required amount of feed. You can use a do-it-yourself bunker feeder for chickens for many years.

Photos of chicken feeders

The presence of poultry on the farm has always been considered a good help for the budget. Regardless of the breed of chicken - egg or meat, up to 70% of the cost of rearing is spent on feeding. Therefore, a properly designed chicken feeder is one of the important conditions for keeping poultry.

Variety of feeders

Adequate nutrition of chickens is the key to high productivity of farming. First, it’s worth understanding the variety of types of feeders. Classification is carried out according to several criteria.

According to the material of manufacture:

- Wooden. Used for feeding dry food. Usually the feeder is filled with mixed feed or grain, less often with mineral supplements in the form of shells and chalk.

- Plastic and metal. Ideal for placing wet mash. Such feeders are much easier to clean than wooden structures for chickens.

- Mesh containers are used for feeding green grass.

Do-it-yourself chicken feeders differ in the type of feed supply:

- Trays are represented by flat containers with low sides that prevent feed from scattering. Ideal for feeding chickens.

- The groove structures are complemented by a restrictive removable grille or turntable. Partitions inside the container form compartments for distributing different types of feed. Installing them outside the cages will help facilitate the maintenance of trough feeders.

- Hopper devices are designed for filling with dry mixtures for chickens. Having filled the container with the daily dose in the morning, you don’t have to worry about the feeding process for 24 hours. The closed design of the feeder ensures dryness and cleanliness of the feed, which enters the feeding trays in decreasing portions.

Regarding the position in the poultry house, homemade chicken feeders can be floor-mounted or mounted. Floor-standing ones are characterized by mobility and the ability to easily change their location. Installation of hanging structures usually takes place around the perimeter of the chicken coop using special brackets.

The photo below shows various designs for feeding chickens:

Design requirements

Before you make a chicken feeder, you should familiarize yourself with the criteria that it must meet. The list of conditions contains only three items:

- Rational feed consumption. A design drawing is selected that will not allow chickens to scatter food, climb inside the container and spoil the contents with their excrement.

Note! Turntables, protective sides and various devices for hiding the main volume of food inside the feeder will ensure that this condition is met.

- Easy to maintain. Daily filling of the chicken container with food, periodic washing and cleaning should proceed without hindrance. Therefore, it is important to find a material and design suitable for the given purposes. Lightness and mobility, a simple washing process and the ability to disinfect the feeder will reduce labor costs for caring for chickens.

- Optimal sizes. The tank parameters should provide space for the daily feed requirement, taking into account the livestock. For an adult chicken, 10-15 cm is allotted in trays; for chickens, 5-8 cm is enough. If the tray is made in the shape of a circle, 2.5 cm is enough for the chicken. The ability for all birds to use the feeder at the same time will eliminate the possibility of pushing away weaker individuals.

More examples of containers for feeding poultry are shown in the photo below:

Manufacturing of plastic structures

When making do-it-yourself chicken feeders, plastic buckets or large bottles with handles are often used. The containers are selected from hard plastic so that the walls do not deform under the pressure of the food located inside. Cylindrical containers are optimal for designing a bunker device for feeding chickens. Main process steps:

- 6-8 cm are removed from the bottom edge of the bucket and holes are cut out.

- A plastic tray, the diameter of which exceeds the parameters of the main container by 10-15 cm, is suitable as the bottom of the feeder.

- In the absence of a convenient element, it will be replaced by the bottom of a larger plastic bucket than the one chosen for filling the chickens with food.

- The parts of the feeder are fixed together with self-tapping screws, as shown in the photo:

After filling the container with chicken feed, close it with a lid. The structure can be placed on the floor or hung by a handle so that the bottom is located at a height of 0.2 m from the surface.

By analogy with a bucket, other containers are used to make the structure. Examples are shown in the photo:

There are other designs made from two plastic bottles.

The procedure for decorating the feeder shown in the photo above includes the following steps:

Comment! It is better to place a similar structure inside the chicken coop. When placed in an open area, if it rains, the food may get wet.

Identical designs are suitable for chickens, the manufacture of which involves smaller containers.

Hopper-type feeders can be classified as automatic designs, since the grain is supplied as the chickens absorb the feed.

Let's use pipes

It’s quite easy to make good chicken feeders with your own hands from PVC pipes. There are several design options.

Method 1

To work you need to prepare:

- two pipes 0.4 and 0.6 m long;

- connecting elbow;

- a couple of plugs.

A longer pipe is intended directly for feeding chickens, the second is attached perpendicular to the first and is used to supply dry food. To make it convenient for chickens to peck, holes with a minimum size of 7 cm are marked on the pipe. These can be circles or ovals, the choice is arbitrary and does not contain strict canons. After marking the holes in the feeder, cut them out as shown in the photo:

Further actions:

- one end of the pipe is closed with a plug;

- the second edge is connected to a short pipe using an elbow;

- A convenient feeder for chickens is suspended in the poultry house.

Reliable fastening is ensured by fixing the structure at two or three points. After filling with food, the end of the pipe is also closed with a plug. This type of feeder is also a bunker type and allows you to fill it with grain once a day.

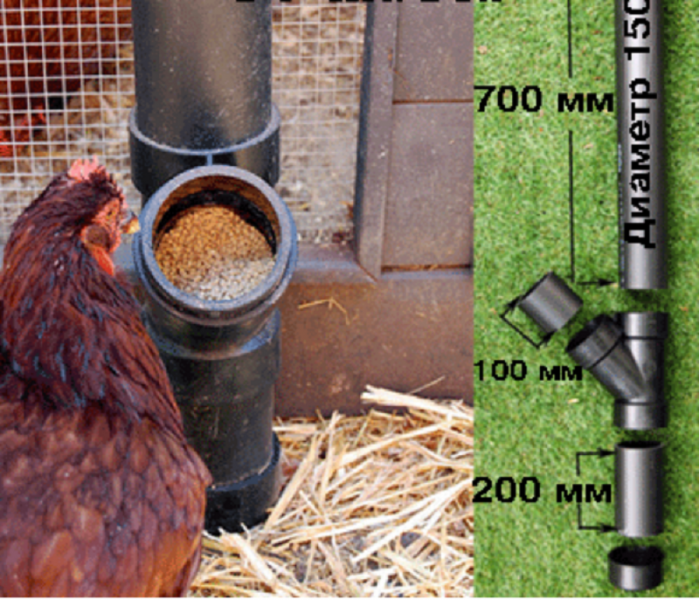

Method 2

For the second design option you will need:

- PVC pipes of sizes 10, 20 and 70 cm;

- tee with a bend angle of 45°;

- a couple of plugs.

Algorithm of actions:

- A pipe 0.2 m long is closed on one side with a plug.

- The tee is placed on the second edge with the knee up.

- The side hole is equipped with a pipe of the smallest size.

- The top of the tee is connected to the longest pipe.

After each filling of the structure with food, the upper part of the feeder is closed with a second plug.

The third method of arranging a feeder for chickens is described in the video material:

Wooden crafts

There are also several design options for wooden chicken feeders.

Method 1

A drawing of an interesting design made of wood or thick plywood is presented below:

According to the drawing, the main elements are marked on the selected material:

- two side parts;

- two rectangles for the front wall;

- back wall;

- bottom of the feeder;

- the top cover where the chickens' feed will be poured.

Further procedure:

- The parts of the feeder are carefully cut out.

- Using a drill, holes for the screws are prepared.

Advice! To prevent chickens from getting hurt on the feeder, all rough surfaces are treated with sandpaper.

- The structure is assembled together using screws. As a result, the front wall is located at an angle of 15 degrees in relation to the back wall.

- The cover is installed on the back of the side walls using hinges.

- To extend its service life, it is better to treat the feeder with an antiseptic composition. The use of varnish and paints is prohibited.

The finished convenient design for chickens is shown in the photo:

Method 2

You can make a feeder tray for chickens, as in the photo below:

A clear drawing will help in making a simple structure from wood or thick plywood:

According to your own or the drawing given above, parts are marked on a wooden surface. The entire structure consists of side and end walls, bottom and beams. For beginning craftsmen, difficulties may arise when cutting out end elements.

Comment! When drawing up your own drawing, select the correct height of the boots so that it is convenient for the chickens to get food. The material for the bottom is chosen to be heavy and thick so that the chickens do not overturn the feeder.

When connecting elements, make sure there are no gaps in which food could spill. The choice of feeder type depends on the number of chickens and the conditions under which they are kept.

Conclusion

Each of the methods is quite simple and accessible to any novice master. Another variation of making a wooden bunker feeder is presented in the following video:

Chickens are the most popular backyard bird. They are prized for their good performance at low cost. And to keep this bird, you need to take care not only of the poultry house, but also of a suitable feeding method. You can read what you need to create a chicken feeder with your own hands in this article.

Vertical feeders made of plastic pipes

There are no strict requirements for chicken feeders, but some tips will help make bird care easier and save money on feed.

The chicken is not very smart; it can easily scatter all the grain. To avoid such a scenario, simple systems are provided to protect the contents: high sides, turntables or other similar devices. It is important to maintain a balance so that, on the one hand, the chickens cannot trample in the feed, and on the other, they have unhindered access to it.

Cage feeder box

Like any thing, chicken feeders require regular maintenance: remove old food, clean the surface from dirt, and sometimes disinfection will be required.

Taking these circumstances into account, it is necessary to make a mobile structure with convenient access to all surfaces. At best, it should be easy to understand.

Dimensions should provide the entire poultry population with a sufficient amount of feed. When installing a tray structure, one adult bird should have at least 10 cm in length (5 cm is enough for chicks). If you have 20 chickens in your yard, then the length of a double-sided tray-type feeder should be at least 1 meter.

If the tray has a circular shape, then a 25 cm perimeter is sufficient. For a population of 20 chickens, the minimum circumference of a circular tray is 50 cm.

It is important that the size of the chicken feeder allows all birds to have simultaneous access to food. Thanks to this, each chicken will receive its portion and the strong ones will not drive away the weak ones.

Popular designs

To make a chicken feeder, you don't need any special skills or tools. The material at hand is suitable for the job. The finished product will meet all requirements and is convenient to use. Consider the most popular designs.

Bunker

A farmer's time is valuable, which is why automatic feeders are common. Such systems can be found in professional stores, but making them yourself is not difficult.

Making a bunker feeder

You should have at hand:

- Large plastic bucket with lid.

- A flat bowl with sections or a bowl. The diameter of the bowl should be larger than the diameter of the bucket.

- Using a utility knife, make holes in the bottom. Using screws, the bowl is secured to the bottom of the hopper. The bunker feeder for chickens is ready.

- Having poured the required amount of food into the bucket, it scatters itself in the required volume throughout the bowl. Chickens will not be able to get into the bunker itself, thanks to the closed lid. Another advantage is mobility.

Ready-made bunker feeder from a bucket

Hopper feeders can be made from plywood. You will need to cut three 0.9 meter high walls and nail them together into a box until the front wall is needed. The bottom should be longer than the side walls; the required amount of feed will be poured onto it. In order for the grain to flow freely, a piece of plywood is secured to the bottom of the box at an angle of 12°. If you plan to dispense granulated feed, then the angle should be at least 20°.

To limit the access of chickens to the feeder itself, high sides are installed: side 12 cm, front 6 cm. Another option is a mesh with large cells. This will prevent the bird from getting into the food and throwing it around.

Plywood bunker feeder

Finally, the front wall is attached. The bunker feeder is placed in the chicken coop or hung on the wall, which saves space. Large volume will allow you to add grain less often.

The only drawback is the material it's made of - it's difficult to clean.

Wooden box feeder

In many private farmsteads, chickens are given food in old troughs, basins or boxes. Such feeders do not protect food from debris and scattering by birds.

To save feed, free space in the yard and the farmer’s time, you can make a two-story box feeder. The lower part holds a week's supply of dry food, and the upper part is intended for daily feeding of mash and other wet food (food waste, crushed potatoes, various additives).

The chicken feeder is made of boards and beams. The main part of the structure will be a box 26 cm wide and 25 cm high. The length of the box depends on the number of chickens. The side edges are made 10 cm higher than the main sides, and grooves are cut into them for the plywood flap.

The second part resembles a lid for a box. Its width corresponds to the dimensions of the lower level. A board 10 cm high is attached in the middle along the entire length of the upper box. Make small sides along the entire perimeter, the height depends on the required depth of the feeder for wet food. To prevent moisture from penetrating to the lower level, old linoleum or plastic film is laid on the bottom. The structure of the second box is installed on the ends of the first.

Such a feeder will not allow the bird to scatter the grain with its paws. A metal mesh is used to protect the mash.

- Before adding dry food, the second level is removed. The grain is poured immediately for one or two weeks.

- The upper part is installed and filled with wet food. Its volume is calculated for a single feeding or daily ration.

- At night, the lower compartment is closed with a flap to protect the food from rodents.

- In summer, the feeder can be left outdoors. In winter, both compartments are filled with dry food.

From plastic pipes

To make a feeder from a plastic pipe, you will need a hacksaw, a sewer pipe (Ø250 mm), plugs and a bend (elbow).

Vertical feeder made of plastic pipes

The minimum pipe length is 1 meter. It is divided into two parts of 0.3 and 0.7 m. They are connected using a bend, and the ends are closed with plugs. In a long pipe, make holes with a diameter of 7 cm on both sides, as shown in the photo.

The entire structure is attached to the wall. The grain is poured into a 30 cm segment and, under the influence of gravity, scatters over its entire length. A lid must be provided to protect the food from rodents.

Such a feeder will provide food for the entire livestock and will help to avoid overconsumption due to the birds’ habit of scattering grain.

Horizontal feeder made of plastic pipes

A simplified version is made with a small number of chickens from a plastic pipe Ø110 mm. Recommended length 0.7 meters. An outlet and a half outlet are attached to the bottom.

The principle of operation is the same - the filled grain is evenly distributed throughout the feeder under the influence of gravity. If necessary, several feeders are made. A visual aid about the construction of feeders and their use in a private backyard is in the video.

From this video you can see the design of plastic pipe feeders and the main advantage through the eyes of a farmer. Another design option for a bunker feeder with step-by-step manufacturing.

It’s not enough to build a good barn for chickens; you also need to equip it: secure perches, make nests, install/hang drinking bowls and feeders. But you need to do this in such a way that it is convenient for you to maintain the poultry house. Chickens don't really care how beautiful their nests are. They will fit perfectly on the floor. It will be inconvenient for you to collect eggs from the floor, and they might even get pecked. Therefore, we arrange the chicken coop in such a way as to make it more convenient for you.

Perches

First of all, you need to equip the inside of the chicken coop with perches. This is a round or oval stick - a tree branch, a shovel handle, a planed block, etc., fixed at some height above the floor.

On average, they take about 20-25 cm of perch length per chicken. They are attached to the wall at a distance of 25-30 cm, one perch from the other - at a distance of 35-40 cm. You can make multi-tiered ones, but there will be fights for the highest place. Please note that all dimensions are approximate only and are necessary for reference purposes. Everything is selected more according to location: different breeds and chicken coops, and their owners too.

To make cleaning easier, a shield made of some smooth material is installed at a distance of 20 cm below the perch. Litter accumulates on it, so choose a smooth surface: it will be easier to sweep away.

The question remains: at what height should the perch, and therefore the shield, be made? It is most convenient to clean it in a cart. It should fit under the shield so that you can dump the droppings directly into the wheelbarrow with a hoe. For the flood, the height of the shield is determined by the height of your car, and above the shield there will already be perch slats. And again, choose the height of the chicken perch so that cleaning is convenient.

Nests

The second required element in arranging a chicken coop is nests. They will lay on the floor, but the eggs will be dirty, and they may even peck. According to the norms, one nest is made for three hens. But in fact, it turns out that no matter how many of them you do, they choose one or two, maximum three, and stand in line. The rest are exactly the same, standing empty next to each other. From time to time their tastes change, they begin to rush to others... From all this it follows that you can safely count 5-6 heads per nest, half will still be empty.

It is better to place the nests so that it is convenient for you to pick up the eggs, i.e. hang on the wall. So that the bird can safely get there, they make ladders - an inclined board with perches/sticks nailed across it. The same ladders are made for perches. If the nests are placed close to the perches and at approximately the same level, they will move back and forth. Quite convenient.

You can make such civil nests

If possible, make sure that the back side of the nests faces the corridor, if there is one. A door is made on the back side. Then to pick up the eggs you don’t need to go into the pen - open the doors and collect them.

Chickens also love to rush in the dark, or at least in dim light. That’s why the entrance is made small, and so that they don’t sit inside for a long time, sleep and shit, the roof is made with a strong slope (in the photo).

You can simply arrange or hang the boxes along the wall, but organize the darkening by placing a partition in front of the nests. In general, it is difficult to predict their behavior. Sometimes the nests are simply ignored and are carried anywhere. Then a stencil or mock-up can help: cut out an egg from white paper and place it in the nest. It might help: they will start rushing there.

Several nests in different designs are shown in the photo below. These are all real chicken coops, you can use them.

Plastic is very practical: it’s easy to wash, it’s inexpensive, you can do a lot of things, and chickens really love these plastic nests. Place more hay in them and they will fly. The space below can be used for perches or an IR lamp can be hung on the bottom to make a solarium.

In the nest you always use your hands with caution: you never know what the chickens laid there... It is much more convenient and safer when the eggs are rolled into a special compartment - the egg receptacle. The main catch in this device is to choose the angle of the floor and the flexible material so that the egg moves it away and stops before it reaches the wall. To soften the “landing”, sawdust is poured onto the bottom.

Since the eggs roll up and the bird does not see them, they may refuse to lay eggs in such nests. In this case, you can make a dummy egg - from thick foam plastic in full size or cut out a stencil from paper - and glue it to the bottom. This almost always works.

Chicken cages

Sometimes the birds are kept in cages. But this is for industrial or semi-industrial maintenance. With this method of cultivation, a large number of birds live in a small area. A drawing of a cage for chickens with dimensions is posted below.

Broiler cage drawing with dimensions

All sizes are according to the standards, and there is no need to invent anything. This is the minimum that laying hens need. And what can come out of such cells is in the photo below.

Watch the video to see how to make broiler cages from wood. Everything is described in great detail: what, for what, what sizes, how to assemble and what is needed for this. Really useful.

Drinkers and feeders

Setting up a chicken coop is unthinkable without drinking bowls and feeders. Moreover, they should be there too. There are periodic and bunker feeders. Periodic - this is when you came, poured out the amount of food and that’s it. Until the next feeding they stand empty.

Climbing in and digging around is a favorite thing

Bunker feeding is when there is a decent supply of feed, which is constantly poured into some container. Both have their drawbacks: periodic ones require you to go to the chicken coop every time and add grain, and the birds crowd around and fight for the best place, which sometimes leads to the feeder being overturned.

If you have a bunker feeder, you need to go much less often, but it is possible to overfeed the bird, which is a disaster for laying hens. Therefore, either the laying hens are given a large walk or only broilers are fed in this way.

There are many designs of periodic feeders, but not all of them allow you to use feed economically. The easiest way is to pour the food into a bowl or container. But, if there is at least some opportunity, the chickens begin to rake up the food, spilling it out and then trampling it down. I have to throw it away. And such feeders allow you not only to dig into the food, but also to climb into the feeder with your feet. Therefore they need to be improved. To do this, install wire dividers on the container. Feed consumption decreases sharply: it is more difficult to rake it out.

You can make, for example, another similar feeder (or drinking bowl), which is conveniently attached or placed against the wall. It is probably easier to weld it from metal, although there are craftsmen who can make something similar from wood.

There are some interesting ideas. For example, an economical auto-feeder is assembled from an old car disk, a basin of suitable diameter and a plastic water bottle with a capacity of 5-10 liters.

Look for a disk of the type shown in the photo: with a large number of small holes along the outer edge. In the middle, cut a hole the size of the neck of the bottle. Cut out the bottom of the bottle cap, leaving only the threaded ring. The feed mixture is poured into the bottle, a disk is put on it, and the cut-off lid is pressed against it. Feed is poured into a basin and a structure is installed on top.

In order not to disassemble the feeder every time when you need to add food to the bottle, you can cut the bottom, making it like a lid. Then the bottle itself can be secured more seriously: fixation with the thread from the cap is not very reliable. But such an improvement does not allow anyone to rummage through the food, and no one can get into the basin.

You can make a feeder from a piece of plastic sewer pipe. Holes with a diameter of about 7 cm are cut out on both sides. They do not have to be round at all - square or rectangular will also work. A corner is installed at the ends at 90° with the socket up and along a small piece of pipe: feed can be poured here.

A simple but spacious bunker feeder is a decent chest with a folding bar attached at the bottom. In the open position, food is poured onto it.

Another option for an economical feeder is made from plastic sewer pipes. But this is already a bunker structure: there is a decent supply. The design is simple, and consumption is reduced.

An even more interesting design of the chicken feeder in the video: with a lid. To open it, you need to jump on it.

Another option is a bunker feeder made of PVC pipes and a plastic water bottle.

Homemade drinking bowls for chickens

It's almost the same story with drinking bowls. Only here is water splashed, which, when mixed with droppings, gives an exceptionally persistent odor, as well as dirt. All this does not contribute to easier and faster cleaning. Therefore, the choice of drinkers is no less important than the feeders.

The simplest option for a small number of birds - up to 15 pieces - is siphon drinkers. They have legs and allow you to save water. If the legs are designed well, even a chicken flying onto the top will not knock them over.

Siphon drinkers - factory-made and homemade from a plastic bottle

Factory drinking bowls, of course, look more attractive, but a homemade version is almost free, and they work no worse. In the photo you see a simple homemade siphon waterer for chickens: a support was nailed in the corner - a piece of board with a hole cut out for the neck. On top there is a fastening system and a load so that it does not get knocked down. A hole is cut into the former bottom of the bottle into which water is poured. The trick here is to choose the distance at which to install the water container: so that there is not too little or too much of it.

Cup drinkers are convenient when grown in cages, as they are conveniently attached to the mesh. But no one bothers you to hang a piece of mesh, say, on a wall or come up with another mount.

They allow you to water the birds without splashing. Water is supplied to the cup, it tilts under the influence of gravity, cutting off the supply. They drank the water, the cup rose, the water flows again. A hose is connected to the side fitting, the second end of which is located in a container of water, which should be above the level of the drinkers. Convenient and economical.

Nipple drinkers for chickens. These are small devices, a few centimeters in size. A cone-shaped stainless steel rod is inserted into the plastic case.

These nipples are screwed into plastic pipes into which water is supplied. A hole of the required diameter is drilled, a thread is cut and the nipple is screwed in. When you press the rod, a few drops of water appear. The chickens peck at the rod, drinking the drops that appear. The main disadvantage of this method is the drops that fall on the floor. To prevent this from happening, a special drip catcher is placed under each drinker. It simply snaps onto the pipe.

Despite their miniature size, these small drinking bowls cost a lot, especially if they are high-quality - read - imported. Ours are, of course, cheaper, but they break faster.

And the rest are different cups and basins into which water is simply poured. Their disadvantage is that birds often turn them over, and the water in them quickly gets dirty.

There are also interesting ideas from homemade ones. For example, such a pipe drinking bowl is shown in the photo. In a piece of plastic pipe, the water level is controlled by a float mechanism from the toilet cistern. Three drinking bowls are attached to the pipes.

The video demonstrates a drinking bowl with auto-filling.

If you want to arrange the chicken coop, you can arrange it in such a way as to minimize the need for its maintenance. In this case, the bird will bring not only income, but also pleasure: it is always pleasant to look at objects made with your own hands, but keeping a bird in a chicken coop without “direct” hands is difficult and expensive.

Beginning farmers who have decided to have poultry, for example: ducks, geese or chickens, are, of course, primarily interested in methods of feeding and maintaining feathered animals. In particular, they are concerned with the question: how to properly arrange the feeding area.

Properly made and installed feeders mean not only well-fed parrots, geese, ducks and other representatives of bird life, but also huge savings in feed. For example, feeders must be selected and installed in such a way that they do not have the opportunity to rake up the food. After all, the fact that chickens, and chickens in particular, love to dig up food poured into them is known to everyone.

This article will talk about how to make homemade bird feeders. There is nothing complicated about this, and the purchase is an unnecessary, thoughtless expense.

Feeders can be divided into separate types according to different parameters; below are examples of the most popular classifications.

Classification by material used in assembly

- Made of wood. Ideal for dry food: grain, grinding, granules, mixed feed and so on.

- Made of metal, they are ideal for wet food, for example, mash. This does not mean at all that dry food or, for example, mineral supplements: chalk, shells, and so on cannot be poured into such containers.

- Plastic. The purpose is the same as metal ones. A huge advantage of such products is that they are easy to construct with your own hands.

- Feeders made of mesh or metal rods. They are necessary for feeding hay or grass.

Classification by type of feed dispensing

- Tray. This design is a flat container with sides, thanks to which the feed does not scatter. Ideal for feeding chickens.

- Grooved. The tray has a top, which contributes to even less feed loss. This design is also suitable for feeding broiler chickens and more.

- Bunkers. The good thing about a bunker feeder, or as it is also called, an auto feeder, is that you can fill it with the daily allowance of the bird’s diet and not have to worry about feeding until the next day. They are also called automatic due to the fact that the feed is not available all at once, it comes as needed.

Classification by location

- Floor-standing. They can be placed in any part of the poultry house or paddock.

- Mounted feeders are placed along the perimeter of the fencing of a cage, poultry house or run; they are fixed to the fence.

You can also give many more types of classifications, for example: by the type of bird that will feed from these feeders, or by the age of the birds. A separate type for chickens, for example, broilers and for adults. But this is already unnecessary.

Requirements and characteristics for the feeding container

In fact, the list of requirements is not that long. The only thing I would like to pay attention to is that for chicks, ducklings, goslings and other chicks the feeding area should be different from that of adult birds. There are also a few other special rules.

- For chickens or adult chickens, it is installed so that they have a minimum opportunity to rake feed. Why are hens and chicks mentioned? It’s very simple, these birds love to rake food more than any other species. The ideal solution would be automatic.

- An important factor is ease of maintenance; it must be made so that it is easy to clean and wash if necessary. It should also be as mobile as possible.

- Optimally selected size. A distance of at least 10 cm is allocated for an adult. For young animals, including broilers, 5 cm is enough.

DIY making

Of course, in the market and in stores you can choose any feeder for broiler chickens, laying hens and any other bird. But it is much more profitable to make a feeder yourself.

There are a huge number of manufacturing options and materials from which they can be made on the global network: plastic bottles, old buckets, plywood and other improvised means. Very little time will be spent on their production.

Plastic feeder

The simplest option is made from an ordinary lemonade bottle.

At a height of 10-13 centimeters, it is necessary to make a cut through which the bird will peck food. Such a structure must be secured to the fence of the pasture. Otherwise, the birds will turn it over and all the food will end up on the ground.

You can also make it from paint buckets and other building materials. To make it you will need: two buckets of different diameters. We make holes at a height of 3-5 cm from the bottom of the bucket, through which food will flow. We cut a larger bucket at a height of 10-12 cm. We fasten the two parts of the future with self-tapping screws or bolts. Now you can pour in the food, it will come automatically as needed.

From sewer pipes

To make it you will need:

- sewer pipe with a diameter of 14-20 centimeters;

- tee of the same diameter;

- two plugs.

We cut two pieces from the pipe measuring 20 and 10 centimeters, respectively. We will also need another piece of pipe of arbitrary length, but more than fifty centimeters. Using a tee, we connect the largest piece with a twenty-centimeter segment, and install plugs at the ends. We connect the remaining ten-centimeter segment to the tee, which will serve as a feed tray. This option has one significant disadvantage. A large number of chickens will not be able to peck from it at the same time.

For a larger number of birds, you can make a slightly different design. To do this you will need:

- plastic pipe;

- two plugs;

- connecting elbow.

We cut a piece of 30-40 cm in size from the pipe. We make round holes in it with a diameter of 2-3 centimeters at a distance of 40-50 millimeters. We connect the two parts of the pipe with an elbow and place plugs on both sides.

Wooden feeders

To collect you will need the following:

- plywood,

- self-tapping screws or self-tapping screws

- two hanging loops,

- sandpaper,

- jigsaw,

- measuring tape or other similar device,

- stylus,

- screwdriver or screwdriver,

- drill with a set of drills,

- clamp

Having prepared everything you need, you can proceed directly to the manufacturing process.

First you need to select the dimensions of the product, you can use those provided below.

- Front panel 270×290 mm.

- Sidewalls 400x290 mm from the bottom and 400x260 from the top. The side panels must be made with a recess. The narrowest point should be 170 mm wide.

- Cover 350×260 mm.

- Rear wall 390×290 mm.

- The apron is 70x290 mm, it is installed from below and serves as protection against birds raking up feed.

- Bottom 170×290 mm.

We mark the parts on the plywood.

- We cut out the parts with a jigsaw.

- Using a drill, we make small indentations in the places where the screws will be screwed in. Or we drill full holes if screws are used instead of self-tapping screws.

- We process the edges of the workpiece using sandpaper.

- Using a clamp and self-tapping screws (screws), we assemble all the parts together.

- We install the lid on hinges for ease of use.

If this design seems too complicated to make, you can also make an ordinary wooden tray with your own hands. It is very simple to manufacture, so it does not even require any additional explanation.

The benefits of making it yourself over buying it are obvious.

- Firstly, you will not waste anything except your personal time.

- Secondly, as a rule, handmade products are much more reliable and durable than purchased ones. After all, there is a huge difference between manual work for one’s own use and assembly line work.

- And thirdly, you will find a use for things that would mostly be thrown in the trash: plastic bottles, old sewer pipes, and so on.

Undoubtedly, it is worth taking care of the payback of keeping poultry. And if you add up all the costs together, it turns out that it is much more profitable to buy meat and eggs in the store. But, of course, it's up to you to decide.