Instructions for land reclamation and pipeline construction. Departmental norms and instructions for land reclamation during pipeline construction. Operational quality control of work

Disturbed lands are lands that have lost their economic value or are a source of negative impact on the environment due to disturbance of soil cover, hydrological regime and the formation of technogenic relief as a result of productive activities.

Land reclamation is a set of works aimed at restoring the productivity and national economic value of disturbed lands, as well as improving environmental conditions in accordance with the interests of society.

Causes of land disturbance:

Development of mineral deposits.

Pipeline laying, construction work.

Liquidation of industrial and other facilities and structures.

Warehousing and disposal of waste.

Elimination of the consequences of land pollution.

When placing the pipeline, a construction site is formed. Its right of way depends on the diameter of the pipe. A trench is dug at this location. First, the fertile layer is removed, regardless of the diameter of the pipe, along a 3.5 m wide trench and folded at a distance of 5-7 m from the trench. The soil is piled at a distance of 0.5-1.5 m from the trench.

8 Protective afforestation

Forest vegetation is one of the powerful factors in improving the natural environment. It performs water protection, sanitary-hygienic and health-improving functions and is widely used in forest reclamation to prevent wind and water erosion.

The main forms of influence of protective forest plantations on natural conditions:

They protect the territory from the harmful effects of dry winds, reducing the evaporation of soil moisture, increasing its beneficial use by the plants themselves and protecting the crop from destructive dry winds;

They retain snow on the fields and slow down its melting, increasing the absorption of melt water by the soil.

Retain surface water runoff, thereby reducing soil erosion and helping the beneficial agricultural use of water;

Forest plantations located near natural reservoirs reduce evaporation from their water surface, saving this water for various economic purposes;

Situated on sands and soils easily blown by the wind, forest strips protect crops from drifts and contamination by sand or dust and secure shifting sands and soils susceptible to blowing.

Protective forest plantations have different reclamation effects depending on their construction and location conditions throughout the territory. This determines the division of protective forest plantations into main types according to their main reclamation purpose. Belonging to one type or another, protective forest plantings differ, firstly, in their specific location on the territory and, secondly, in the type of construction that ensures the necessary nature of their reclamation effect.

All forest species used to create protective plantings are divided into main, accompanying and shrub species.

The main species make up the main upper canopy in the plantation and perform a protective wind-breaking function. Therefore, they must be tall, since the height of the trees determines their protective effect. Photophilous. Durable. They should form a fairly dense crown that shades the soil. They renew well with shoots. They include: warty birch (or weeping), downy birch, white willow, silver willow, willow, trembling poplar, white poplar (silver), balsam poplar, Berlin poplar, black poplar (sedge), pyramidal poplar, Scots pine, cedar pine.

Accompanying, or complementary, species grow under the canopy of the main species. These are densely crowned shade-tolerant tree species. They shade the soil well, create more favorable microclimatic conditions for the main species, which contributes to their growth in height, clearing the trunk of branches, and fighting weeds. Should renew well with shoots. They include: Siberian hawthorn, smooth elm, pinnate elm, Ginnala maple, Norway maple, Tatarian maple, ash-leaved maple, small-leaved linden, buckthorn, common rowan. Common bird cherry, Maaka bird cherry, Siberian apple tree.

Shrub species form the undergrowth; unlike tree species, they do not have a single trunk, but form a bush. Shrubs shade the soil, protect it from overgrowing by weeds, help increase soil moisture under the forest belt as a result of snow retention, but they should not dry out the soil too much, which has a depressing effect on the main and accompanying species, and are well renewed by shoots. They include: yellow acacia, common barberry, Thunberg barberry, felt cherry, shelyuga willow, Tatarian honeysuckle, common lilac, Hungarian lilac, golden currant, wrinkled rose hip.

The protective value of forest strips depends on their design. The design of forest strips is the structure of the longitudinal profile in the leafy state, which determines its aerodynamic properties. There are 3 main designs:

Dense (windproof) structure - is a dense planting from top to bottom, which does not have continuous gaps. The wind almost does not penetrate through such a strip. The air flow passes through it, forming numerous turbulences. There may be a pronounced calm in and behind the forest belt, but as you move away from it, the wind speed quickly increases. The uneven distribution of wind speed leads to the accumulation of large snowdrifts near the forest belt. Such forest belts are most often three-tiered, consisting of main, accompanying forest species and shrubs, the number of which reaches 50% of the total composition of the belt.

Openwork design - along the entire vertical profile of the forest strip, gaps with an area of 15-35% are evenly spaced. Such forest belts consist of tree species with a small admixture of shrubs or only trees. Such strips partially allow air flow through themselves and act as lattice barriers. The air flow passing through them is fragmented. Part of the air flow falls over the strip, part passes through it. When connecting behind a lane, they reduce their speed, but this decrease is not as significant as behind lanes of dense construction.

Ventilated design - they have continuous large openings up to a height of 1.5-2 m at the bottom, in which only tree trunks are visible; at the top in the crowns such stripes are closed. There are no shrubs in these strips. The upper part of the strip is almost or completely windproof. Such strips divide the air flow into two parts, one of which passes through the strip, the other rolls over it. In the territory protected by such a strip, the snow cover is more evenly distributed, evaporation is reduced, the temperature and humidity regime of the ground layers of air between the strips changes, and deflation processes are weakened.

Characteristics of the qualitative condition of agricultural land are shown in Table 9, which determines the suitability of soils for afforestation.

According to the agroforestry zoning of the territory of Western Siberia, the first group of soil suitability includes soils suitable for afforestation - these are meadow-chernozem medium-deep medium-humus soils, ordinary chernozem low-dense medium-humic soils.

The second group includes chernozem-meadow solonetzic medium-thick medium-humus, meadow solonetzic medium-thick medium-humus, chernozem-meadow solonetzic medium-thick medium-humus, and ordinary thin, low-humus chernozem is classified as non-forestable.

According to Table 10, a scheme for creating a five-row water-regulating forest strip was constructed, the width between them is 3 m, the width of the edges is 1.5 m.

On the project drawing, the suitability of land for afforestation and the types of protective forest plantings were highlighted in certain colors.

(In development of Instruction BCH 2-59-75)

&£ a and

/i-Ъlrsіm/ ^4>s n eli meadow*/

SYURY* i*si * u

Moscow 1976

Appendix 4

Ministry of Construction of Oil and Gas Industry Enterprises

All-Union Research Institute for the Construction of Trunk Pipelines

AGREED:

Gosstroy of the USSR Ministry of Agriculture of the USSR State Forestry of the USSR

INSTRUCTIONS

ON LAND RECLAMATION

DURING THE CONSTRUCTION OF HIGHWAYS

PIPELINES

VSN 2-59-75 Ministry of Neftegazstroy

CSTI VNIISTa

Moscow 1975

MANAGEMENT

on land reclamation during the construction of main pipelines

(In development of Instruction VSN 2-59-75)

Editor I.R. Belyaeva Proofreader A.A. Aorosheva

Technical editor T.V. Bereneva

d-77349 Signed for printing 24.1.76gLormat 60x84/16 Printed sheet. 2.75 Uchtizd.l. 1.8 Conditions oven.d. 2.5

Circulation 1000 zkz. Price 18 kopecks. Order 29

Rotaprint of VNIIST

UDC 622.692 L7

The instruction is intended for organizations conducting work on the construction of main pipelines.

Employees of VNIIST took part in the development of the Instructions: candidates of technical sciences Mentyukov V.P., Karpenko N.P., Anikin E.L., engineer Podorozhny G.A. and employee of Innnneftegaastroy Kaikov I.V.

"vC" Center for Scientific and Technical Information of the All-Union Scientific Research Institute for the Construction of Trunk Pipelines (CSTI VNIIST), 1975

VSN 2-39-75 Ministry of Oil and Gas Construction

Instructions for land reclamation during the construction of main pipelines

Ministry of Construction of Oil and Gas Industry Enterprises

Developed

I, This Instruction was developed in accordance with the “Basic provisions for the restoration of lands disturbed during the development of mineral deposits, geological exploration, construction and other work”, approved by the State Committee for Science and Technology of the USSR, the State Construction Committee of the USSR, the Ministry of Agriculture of the USSR and the State Forestry of the USSR on June 30, 1971 and is distributed for work on reclamation of lands disturbed during the construction of main pipelines.

When drawing up projects for land reclamation work, you should also be guided by the provisions of the following documents:

"Fundamentals of land legislation of the USSR and Union republics";

SN **52-73 "Norms for land allocation for main pipelines";

SNiP Sh-D. Yu-72 "Main pipelines* Rules for production and acceptance of work."

2* Bringing lands provided for temporary use for the construction of main pipelines to a state suitable for their intended use is carried out in accordance with the land reclamation project developed by the design organization. The specified project is part of the technical (technical and working) project for the construction of the pipeline. The cost of work provided for by the specified project is included in the consolidated construction estimate.

Introduction date: j ^February

Introduced by VNIIST!

Land reclamation during the construction of main pipelines consists of removing the fertile layer of soil before the start of construction work, transporting it to a temporary storage site and applying it to the restored land after completion of construction work.

3. In the land reclamation project, in accordance with the conditions for providing land plots for use and taking into account local natural and climatic features, the following must be determined:

boundaries of lands along the pipeline route in which reclamation is necessary;

thickness of the removed fertile soil layer for each area subject to reclamation;

width of the reclamation zone within the right of way;

location of the dump for temporary storage of the removed fertile soil layer;

methods for removing, transporting and applying fertile soil;

the permissible excess of the applied fertile soil layer above the level of undisturbed lands;

volumes and methods of loading and removal of excess mineral soil, as well as its dumping in designated places;

methods for compacting loose mineral soil and fertile soil milking after backfilling the pipeline.

4. Work on removing, transporting and applying the fertile layer of soil is carried out by the construction organization. Work to restore soil fertility (fertilizer application, plowing and other agricultural work), if provided for by the reclamation project, is carried out by land users at the expense of funds provided for in the project estimate.

All land reclamation work must be carried out within the construction zone established by Table 1 “Land Allocation Standards for Main Pipelines” (SN 432-73).

The minimum width of the strip from which the fertile soil layer is removed should be equal to the width of the trench at the top plus 0.5 m in each direction.

5. The land reclamation project is coordinated with all land users: state farms, collective farms, forestry

organizations and bodies of state control over the use of land, and such with organizations carrying out the construction of the main pipeline.

6. When developing a land reclamation project for a main pipeline laid parallel to the existing one, the design organization must determine the actual position

in plan, the depth and technical condition of the existing pipeline and develop design solutions that ensure its safety and safety of work.

7. When constructing a main pipeline parallel to an existing pipeline, the operating organization, before starting work, must mark on the ground the location of the axis of the existing pipeline, identify and mark with special warning signs dangerous places (places of leaks of the transported product, areas of insufficient depth and sections of the pipeline that are in unsatisfactory condition ).

During the period of work near existing pipelines or at the intersection with them, the presence of representatives of the operating organization is required.

8. In the warm season, the removal of the fertile soil layer and its movement to the dump should be done with bulldozers: longitudinal-transverse moves for a layer thickness of up to 20 cm and transverse moves for a layer thickness of more than 20 cm. For a fertile layer thickness of up to 10-15 cm, it is recommended to use motor graders .

9. Removal of the fertile layer of soil is carried out to its maximum thickness in one pass; removal of the fertile layer in several passes is allowed as an exception. In all cases, mixing of the fertile soil layer with mineral soil should not be allowed.

10. Excess mineral soil formed as a result of volume displacement after laying the pipeline in a trench, the sheet should be evenly distributed and leveled on the strip of removed fertile soil (before applying the latter) or transported to the places specified in the project and agreed upon with the authorities providing land plots for use.

Removal of excess mineral soil can be carried out according to two schemes:

a) after backfilling the trench, the mineral soil is distributed evenly with a roller above the trench using a bulldozer or motor grader along the strip to be reclaimed, then after compaction, the soil is cut with scrapers to the required depth (in such a way as to ensure the permissible excess of the level of the applied fertile soil layer above the surface undisturbed lands), and then the mineral soil is transported to places specially indicated in the project;

b) mineral soil, after leveling and compaction, is cut and moved by a bulldozer along the strip and placed in special piles up to 1.5-2 m high (volume up to 150-200 m 3) in order to increase the efficiency of its loading onto transport, from where it is used with single-bucket excavators or single-bucket front loaders are loaded into dump trucks and transported to places specially indicated in the project.

The choice of work plan is carried out in the project depending on the distance of soil removal"

11. If, at the request of the land user, the project provides for the removal of the fertile soil layer outside the construction zone to special temporary dumps (for example, on especially valuable lands), then its removal and transportation at a distance of up to 0.5 km can be carried out by scrapers, and at a distance of more than 0.5 km. 5 km - by dump trucks. In order to ensure effective loading of the fertile soil layer into transport, the soil is also shifted by a bulldozer in the longitudinal direction along the strip (within the boundaries of the removal zone) and placed in piles up to 1.5-2 m high (volume up to I0Q-I50 m3). It is recommended to load the fertile soil layer onto dump trucks using front-end loaders, as well as single-bucket excavators equipped with a straight shovel or grab.

12. Removal of the fertile soil layer, as a rule, is carried out before the onset of winter with stable negative dealer rounds. By agreement between land users and bodies exercising state control over the use of land, it is allowed to remove the fertile soil layer in winter conditions. Such approval is carried out during land allocation*

13. When carrying out work to remove the fertile soil layer, the frozen fertile soil layer should be developed using bulldozers with the preliminary use of rippers.

Digging should not be done to a depth not exceeding the thickness of the removed fertile soil layer.

When loosening soil with tractor rippers, it is recommended to use a longitudinally rotary technological scheme.

14. To remove and move fertile soil, rotary trench excavators can be used in winter. The depth of immersion of the rotor should not exceed the thickness of the fertile soil layer.

15. The pipeline is backfilled with mineral soil at any time of the year immediately after installation. For this purpose, rotary trench fillers and bulldozers can be used.

In the warm season, after backfilling the pipeline with mineral soil, it is compacted with pneumatic rollers or crawler tractors making multiple passes (three to five times) over the backfilled pipeline. Compaction of mineral soil in this way must be carried out before filling the pipeline with the transported product.

16. In winter, artificial compaction of mineral soil is not carried out. The soil is poured into a trench with a roller, and it acquires the required density after thawing for two to three months (natural compaction). The same compaction method can be applied to a river valley when there is product in the pipeline during the reclamation period.

17. The application of a fertile layer of soil should be carried out in the warm season (with normal humidity and sufficient bearing capacity of the soil for the passage of vehicles). For this purpose, bulldozers are used, working in transverse moves, moving and leveling the fertile soil. The final leveling can be done by longitudinal passes of auto graders.

18. If it is necessary to transport the fertile soil layer to the place of its application from dumps located at a distance of up to 0.5 km, scrapers can be used.

If the transportation distance exceeds 0.5 km, then the fertile soil layer is delivered using dump trucks, followed by leveling it with bulldozers working in oblique transverse or longitudinal moves.

Leveling the fertile soil layer can also be done with motor graders equipped with a blade blade in the front part.

19. Bringing land plots into a suitable condition is carried out during the work, and if this is not possible - no later than within a year after certification of the work.

20. Control over the correct execution of work in accordance with the land reclamation project is carried out by state control bodies over the use of land in accordance with

with the Regulations approved by the Council of Ministers of the USSR, dated May 14, 1970, No. 325. The transfer of restored lands to land users must be formalized by an act in the prescribed manner.

1. General provisions................................... 3

2. Technology of technical work

reclamation of disturbed lands............... 7

Appendix I. Extract from the “Fundamentals of Land Legislation of the USSR and Union Republics” ............... 13

Appendix 2. Basic provisions for the restoration of lands disturbed during the development of mineral deposits, geological exploration, construction and other work............... 19

Appendix 3. Land allocation standards for main pipelines SN 452-73 ..................................... 27

MINISTRY OF ENTERPRISE CONSTRUCTION

OIL AND GAS INDUSTRY

ALL-UNION RESEARCH INSTITUTE

FOR CONSTRUCTION OF MAIN PIPELINES

VNIIST

PIPELINES, PRODUCT PIPELINES, AMMONIA PIPELINES

GLAVTRUBOPROVODSTROY

MAIN DIRECTORATE FOR HIGHWAY CONSTRUCTION

PIPELINES IN EASTERN AREAS

Glavvostoktruboprovodstroy

INSTRUCTIONS

ON LAND RECLAMATION

WHEN CONSTRUCTION OF PIPELINES

VSN 179-85

Ministry of Neftegazstroy

Moscow 1985

This Instruction establishes new methods for land reclamation during the construction of trunk pipelines. For the first time, it is planned to use continuous machines for land reclamation, as well as to carry out work to remove the fertile soil layer in the winter without first loosening frozen soils. The instructions are intended for design and construction organizations involved in the construction of main pipelines. The instructions were developed by A.S. Shatsky with the participation of A.I. Zinevich, K.I. Zaitseva, A.I. Galperina, N.T. Vilenskaya, Kh.M. Saifulova, E.G. Amcheslavsky, V.A. Smirnova, L.P. Semenova, G.I. Kartasheva, S.I. Larina (VNIIST), L.M. Kulikova, V.A. Lysova (Glavvostoktruboprovodstroy), E.A. Podgorbunsky, R.M. Ismagilova (Glavtruboprovodstroy), M.P. Grishaeva, A.I. Ashcheulova, V.A. Ovchinnikova (Ministry of Agriculture), A.P. Iofinova (Bashselkhozinstitute). The instruction was agreed upon by the USSR Ministry of Agriculture and the USSR State Forestry Agency. With the entry into force of the “Instructions for land reclamation during the construction of pipelines” VSN 179-85/Minneftegazstroy, “Instructions for land reclamation during the construction of main pipelines” VSN 2-59-75/Minneftegazstroy, “Guidelines for land reclamation during the construction of main pipelines” (R 204-75). Comments and suggestions on these Instructions should be sent to the address: Moscow, 105058, Okruzhnoy proezd, 19, VNIIST, mechanization-construction department.

1. GENERAL PROVISIONS

1.1. This Instruction applies to the technology of excavation work during the construction of the linear part and ground facilities of main pipelines using new technological solutions and new technical means of continuous operation to carry out work to preserve land fertility.1.2. When developing design documentation for the technology and organization of excavation work, one should be guided by this Instruction, as well as the requirements of current standards, regulations and recommendations [1-17]. 1.3. The entire complex of earthworks, including the removal of the fertile soil layer and its return, must be carried out in accordance with the plans for the organization and production of work. 1.4. Land plots provided for temporary use after completion of pipeline construction must be restored to the same types of land as they were before the violation, by performing technical and biological reclamation.1.5. The area of the construction strip exposed to construction machinery and other types of mechanical impact on the soil is subject to biological reclamation. It is carried out by land users. This Instruction covers technical reclamation techniques performed by pipeline builders. 1.6. Upon completion of construction, the land allotment strip in forest areas must be cleared of stumps and other woody debris and graded.1.7. When carrying out excavation work, it is necessary to use methods and methods that exclude erosion processes (erosion, blowing out), landslide phenomena, as well as salinization, pollution, littering or waterlogging of lands. 1.8. Reclamation of the construction strip after backfilling of main pipelines must be carried out during the construction of pipelines, and if this is not possible, after completion of construction within the time limits established by the authorities providing land plots for use in accordance with duly approved projects. 1.9. In the land reclamation project, in accordance with the conditions for providing land plots for use and taking into account local natural and climatic features, the following must be determined: areas along the pipeline route where technical and biological reclamation is necessary; volume of the removed fertile soil layer; location of the dump for temporary storage of the removed fertile soil layer; the permissible excess of the applied fertile soil layer above the level of undisturbed lands; volume and methods of loading and removal of excess mineral soil after backfilling the pipeline; the cost of technical and biological reclamation work. 1.10. Excavation work must be carried out using safe methods in compliance with safety regulations and industrial sanitation [11-14].1.11. Persons who have completed training are allowed to carry out excavation work and land reclamation; instruction and testing of knowledge on safety precautions in accordance with OST 102-78-83. SSBT "Organization of labor safety training for workers. General provisions." 1.12. Management of excavation work and land reclamation work, as well as ensuring conditions and labor protection requirements in specialized departments, is entrusted to the managers and chief engineers of these departments. At construction sites or in areas where work is directly carried out, responsibility for compliance with labor safety requirements rests with the heads of flows, sections, foremen and foremen.2. TECHNOLOGY OF EARTHWORK FOR CONSTRUCTION OF LINEAR PART OF PIPELINES WITH A DIAMETER OF 820 MM AND LESS

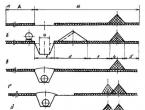

2.1. Before removing the fertile soil layer, poles 2-2.5 m high are installed along the axis of the trench. On straight sections of the route, poles are installed within visibility, on curves - after 5-10 m.2.2. With one pass along the axis of the trench, a rotary excavator ETR 254-05 removes the fertile layer of soil from a strip 3.5 m wide (Fig. 1). Technical characteristics of the ETR 254-05 recultivator are given in the appendix. 1. 2.3. The soil dump is placed on the excavation strip (B) at a distance of 5-7 m from the edge of the reclamation strip to the middle of the dump (Fig. 1a). 2.4. The trench is developed by excavators moving along a strip free of fertile soil (Fig. 1b), the brands of which, depending on the diameters of the pipelines being constructed, are given in the appendix. 1, 2. 2.5. After the construction flow has passed, the pipeline laid in the trench is backfilled, moving all the mineral soil from the dump using a DZ-18, DZ-27 bulldozer (Fig. 1c). Technical characteristics of bulldozers are given in appendix. 3.2.6. Excess mineral soil is distributed along the reclamation strip with a longitudinal passage of a DZ-18, DZ-27 bulldozer or a DZ-40B motor grader and compacted with a bulldozer. After performing this operation, the reclamation strip should look like a recess with clearly marked edges (Fig. 1c). 2.7. The return of the fertile soil layer is carried out by bulldozers DZ-18, DZ-27, moving it from the storage dump, distributing it and performing the final leveling with longitudinal passes (Fig. 1d). For surface leveling, motor graders of any brand can be used, the technical characteristics of which are given in the appendix. 4.2.8. The return of the fertile soil layer can be carried out using an ETR 254-05 excavator. In this case, the passage is made deeper than the base of the soil dump in order to compensate for the loss of soil in the ridges remaining on the sides of the working body. These ridges are graded using longitudinal passes of bulldozers or a motor grader.|

Pipeline diameter, mm |

||||||||

|

Installation strip A, m |

Excavation strips, m |

|||||||

| Up to 426 | ||||||||

| 529-726 | ||||||||

| 820 | ||||||||

| 1020 | ||||||||

| 1220 | ||||||||

| 1420 | ||||||||

Rice. 1. Sequence of excavation operations during the construction of pipelines with a diameter of up to 820 mm with any thickness of the fertile layer, as well as during the construction of pipelines with a diameter of 1020-1420 mm with a thickness of the fertile layer of more than 50 cm:

A - strip of installation work; B - excavation strip; B - trench width

3. TECHNOLOGY OF EARTHWORK DURING CONSTRUCTION OF LINEAR PART OF PIPELINES WITH DIAMETERS 1020-1420 mm

3.1. The preparation of the construction strip is carried out in the same way as during the construction of small-diameter pipelines (see clause 2.1). 3.2. The fertile soil layer is removed with an ETR 254-05 rotary excavator from a strip 3.5 m wide and placed on the excavation strip at a distance of 11-13 m from the edge of the reclamation strip to the middle of the dump. For this purpose, ETR 254-05 excavator transporters, which have hydraulic suspension, are equipped with a device that increases the soil transportation range. In the absence of such devices or when the conveyor is suspended by cable, which does not allow the installation of additional means, the layer of fertile soil is removed with an ETR 254-05 excavator and additionally moved with a bulldozer. 3.3. The sequence of further operations depends on the thickness of the fertile soil layer. 3.4. The sequence of excavation operations with a fertile soil layer thickness of more than 50 cm and the parameters of the construction strip are shown in Fig. 1. 3.5. When the thickness of the fertile soil layer is 20-50 cm, it is necessary to carry out operations in the following sequence: 3.5.1. The dump of the fertile soil layer is removed from a 3.5 m wide strip with an ETR 254-05 excavator and placed on the excavation strip (Fig. 2 a). 3.5.2. Rotary or single-bucket excavators moving along the reclamation strip develop a trench, placing a dump of mineral soil on the excavation strip at a distance of 0.5-1.5 m from its edge (Fig. 2b). The technology for digging and backfilling trenches is given in Section 5 of this Instruction. 3.5.3. After the construction flow has passed, the pipeline laid in the trench is backfilled, moving all the mineral soil from the dump to a strip with the fertile soil layer removed, mainly using powerful bulldozers (Fig. 2 c). 3.5.4. With the second pass of the ETR 254-05 excavator along the excavation strip, the fertile layer of soil is removed from a strip 3.5 m wide, i.e. the reclamation strip is expanded to 7 m. The removed fertile layer is placed on the dump of soil developed during the first pass (Fig. 2d).

|

Pipeline diameter, mm |

Construction strip parameters |

|||||||

|

Installation strip, A, m |

Excavation strips, m |

|||||||

Rice. 2. Sequence of excavation operations during the construction of pipelines with a diameter of 1020-1420 mm with a fertile soil layer thickness of 20-50 cm:

A - strip of installation work; B - excavation strip; B is the width of the trench.

3.5.5. Excess mineral soil located above the trench is distributed over the extended reclamation strip using motor graders DZ-40B, DZ-14 or bulldozers and compacted with bulldozers or pad rollers (Fig. 2e). When performing each of the above operations, it is necessary to maintain clearly defined boundaries of the reclamation strip 7 m wide, which, after completing the operations specified in clause 3.5.5, should be a excavation. 3.5.6. Bulldozers DZ-18, DZ-27 or DZ-55 return the fertile soil layer to the reclamation strip (Fig. 2f). 3.5.7. If there is a shortage of ETR 254-05 rotary excavators, it is allowed to carry out operations to remove the fertile soil layer in an unfrozen state (clause 3.5.1) with longitudinal passes of bulldozers DZ-27, D-155A, D-355A to the width of the blades, but not less than 3.5 m with the subsequent expansion of this strip to 8 m (clause 3.5.4) with longitudinal-transverse passages of bulldozers of the same brands. In winter, the operation of removing the fertile soil layer (see clause 3.5.1) can also be carried out with a rotary excavator with a working body no less than the width of the trench. The subsequent expansion of this strip to 8 m must be carried out in unfrozen soil using bulldozers of the above-mentioned brands. 3.5.8. The operations provided for in paragraphs. 3.5.1-3.5.3 are equally feasible in non-frozen and frozen soils.

4. LAND RECLAMATION IN SPECIAL CONDITIONS

4.1. Optimal technology for excavation work in winter. 4.1.1. The sequence of operations of the optimal reclamation technology is shown in Fig. 3, 4. 4.1.2. The main difference between these technological methods and the general technological reclamation schemes discussed above (Fig. 1) is the placement of a dump of the fertile soil layer on the installation work strip. 4.1.3. Removal of the fertile soil layer is carried out using an ETR 254-05 recultivator without a conveyor extension. 4.1.4. The layout of the dump of the fertile soil layer is carried out by the longitudinal passage of bulldozers DZ-18, DZ-27 to the width of their working bodies.

|

Pipeline diameter, mm |

Construction strip parameters |

|||||

|

Installation strip, A, m |

Excavation strips, m |

|||||

Rice. 3. Sequence of operations for the optimal excavation technology for the construction of pipelines with a diameter of up to 820 mm at any thickness of the fertile soil layer, as well as for the construction of pipelines with a diameter of 1020-1420 mm with a thickness of the fertile soil layer of more than 50 cm:

A - strip of installation work; B - excavation strip; B - trench width

|

Pipeline diameter, mm |

Construction strip parameters |

|||||

|

Installation strip, A, m |

Excavation strips, m |

|||||

Rice. 4. Sequence of operations for optimal excavation technology for the construction of pipelines with a diameter of 1020-1420 mm with a fertile soil layer thickness of 20-50 cm:

A - strip of installation work; B - excavation strip; B - trench width

4.1.5. These technological methods determine the most economical use of land during construction, the quality of reclamation and the minimum labor intensity of both technical and biological land reclamation. 4.2. The technology given in clause 4.1 should be used when constructing pipelines in unfrozen soils in the dry season. 4.3. The fertile soil layer less than 20 cm thick and unfrozen is removed by longitudinal passes of bulldozers. In this case, the width of the reclamation strip is taken to be 1 m larger than when using ETR 254-05 excavators. All excavation operations are carried out depending on the diameter of the pipeline in accordance with the technological diagrams given in sections 2 and 3. The expansion of the reclamation strip is carried out by reducing the excavation strips 3 and 5 (Fig. 1, 2). To remove the fertile soil layer in a frozen state, you should use an ETR 254-05 excavator or conventional bucket wheel excavators. 4.4. In areas where the width of the top of trenches, excavations and embankments exceeds 3.5 m (curves, approaches to transitions, crane units, areas with rocky and frozen soils that require preliminary loosening with mechanical rippers or an explosion, etc.), the fertile soil layer is removed from the entire area to be developed before the start of excavation work (cutting, leveling, digging wide trenches, pits, filling embankments, etc.). 4.4.1. The fertile layer of soil is removed and moved to a storage dump on one or both sides of the excavation zone at a distance that ensures the placement and return of immoral soil to the disturbed area, while preventing its mixing with the fertile layer of soil. 4.4.2. In an unfrozen state, the fertile soil layer is removed using ETR 254-05 bucket wheel excavators, bulldozers or single-bucket excavators. 4.4.3. The fertile soil layer in a frozen state is removed in one or several passes with an ETR 254-05 excavator and moved to a storage dump with a DZ-18, DZ-27 bulldozer; with a total width of the reclamation strip of up to 7 m, it is distributed along the strip of installation work. 4.4.4. After excavation, installation and construction work is completed, the mineral soil is returned to the construction strip or site using bulldozers DZ-18, DZ-27, D-355A, leveled with bulldozers of the same brands or motor graders, and compacted with pad rollers or bulldozers. Then the same bulldozers move the fertile layer of soil from the dump, leveling it over the entire disturbed area. 4.4.5. After moving the fertile soil layer in the case of the formation of excavations and embankments, their slopes are strengthened in accordance with the work plan for this transition, for example, by laying turf or sowing perennial grasses. 4.5. In areas with low bearing capacity of soils, the fertile layer of soil should be removed from a strip at least 3.5 m wide using single-bucket excavators, placing it in a dump on the installation work strip and leveling it (see clause 4.1). This allows you to carry out the operation of removing the fertile soil layer simultaneously with the development of a trench using a single-bucket excavator with reduced specific pressure on the ground (EO-4221) or from sleds. Such an excavator can perform operations to backfill the pipeline and return the fertile soil layer according to one of the options in sections 2, 3 and clause 4.1, without waiting for the soil to dry out on the site. 4.6. If it is necessary to lay drainage ditches or drainage wells to drain a section of the route, the fertile soil layer and mineral soil must be laid sequentially on their opposite sides, and the mineral soil and fertile soil layer must be returned in the reverse order. 4.7. In the case where the work project involves the removal of excess mineral soil, the width of the reclamation strip is determined by the width of the trench and the possibility of passage of excavators developing the trench along this strip. It is advisable to remove the fertile soil layer using ETR 254-05 rotary excavators or excavators with working bodies 1.2-1.8 m wide. It is possible to remove the fertile soil layer using single-bucket excavators simultaneously with the development of the trench and laying the fertile soil layer and mineral soil on opposite sides of the trench in accordance with clause 4.5.

5. DEVELOPMENT AND FILLING OF TRENCHES

5.1. Trenches are developed by excavators moving along the reclamation strip. When developing trenches for pipelines with a diameter of up to 1020 mm in soils with a strength above category III and frozen soils, it is possible to move excavators over a strip of removed fertile soil layer 1.2-1.8 m wide. 5.1.1. Rotary excavators (ETR) are used on straight sections of the route in non-sticky soils without boulders. On agricultural land, at least 70% of the trench must be developed with these excavators. 5.1.2. Single-bucket excavators should be used only in conditions where rotary excavators are not applicable: during transitions, crossings, on curved areas, in soils with inclusions of boulders, on waterlogged soils, and pre-loosened rocky soils. 5.1.3. In conditions where ETR is not applicable, excavation work should, as a rule, be carried out in unfrozen soils. 5.1.4. To develop trenches at an accelerated pace for pipelines with a diameter of up to 1020 mm, it is most advisable to use ETR with a power of 184-220 kW with narrow working bodies 1.25 m wide (I-337, ETR 231) or 1.2-1.5 m (ETR 254- 01) *) . They provide a trench development rate in unfrozen soils of up to 1.5-2.0 km per day in one pass. The same rate in seasonally freezing soils can be ensured by a set of two such ETRs when used in a differentiated way, each of which develops its own specific part of the trench without technological jumpers. The main condition for the effectiveness of such sets is the coordination of the working feeds of the machines included in them. For excavators with the same rotor width, working feeds are coordinated by changing the digging depth depending on the change in soil strength along the depth of the trench and the degree of wear of the excavators [16]. *) Excavators with replaceable working bodies 1.2-1.5 m wide have the ETR index 254-01, developed by SKB "Gazstroymashina" according to the initial requirements of VNIIST and Glavtruboprovodstroy, produced by MEMZ at the request of the headquarters and associations. 5.1.5. A trenching rate of 1-1.5 km/day for pipelines with a diameter of more than 1020 mm can be achieved in non-frozen soils with a set of two ETRs with a power of 220 kW, used in a differentiated manner. For this purpose, the most rational set is ETR 254-01 with a rotor width of 1.2 m and ETR 254 with a working body 1.8 or 2.1 m wide. If there are two identical ETR-254 in the set, coordination of working feeds is carried out according to paragraph. 5.1.4. In soils with seasonal freezing, such kits can achieve a rate of up to 1 km per day. 5.1.6. Differentiated methods of digging trenches with sets consisting of single-bucket excavators and powerful bulldozers lead to an increase in the area of disturbed land. Therefore, it is advisable to use them at crossings and in rocky soils, where the dimensions of the trench are significantly larger than usual, and the width of the reclamation strip is determined by the width of the trench. To increase the rate of trench digging under normal conditions, more powerful single-bucket excavators EO-5122 and ND-1500 should be used using traditional technology. 5.2. Backfilling trenches when performing excavation work on agricultural land involves returning a certain part of the mineral soil dump to the trench, leveling it and compacting it at a certain level, depending on the reclamation method. 5.2.1. The most efficient earth-moving machines for filling trenches in terms of labor intensity and productivity are bulldozers. For backfilling trenches of small diameter pipelines and for backfilling large diameter pipelines, TR-351 rotary trench fillers can be used (see Appendix 1). Rotary excavators should be used to sprinkle pipelines. To use them, a preliminary planning of the soil dump with a longitudinal passage of bulldozers DZ-18, DZ-27 is required. To service rotary trench fillers and excavators, bulldozers DZ-18, DZ-27 are required (final backfilling, leveling of soil ridges). 5.2.2. When filling trenches, mineral soil is moved by transverse passages of bulldozers DZ-18, DZ-27 (diameters up to 1020 mm) or DZ-27, D-355A (diameters 1220-1420 mm). The cross-sectional shape of the displaced soil dump is shown in Fig. 14.6. LAND RECLAMATION DURING THE CONSTRUCTION OF GROUND STRUCTURES OF MAIN PIPELINES AND IN MINERAL SOIL QUARRIES

6.1. When constructing above-ground main pipeline facilities, the fertile soil layer is removed from the construction strip or site and moved to temporary storage dumps in accordance with the work plan. 6.2. After completion of the work, including landscaping of the entire construction site, the excess fertile soil layer should be used to improve unproductive lands. The procedure for using the fertile soil layer for this purpose must be provided for by the project. 6.3. Operations to remove and return the fertile soil layer should be carried out by earth-moving machines used for earthworks in ground construction, mainly bulldozers, bucket and rotary excavators with and without the use of vehicles in accordance with the project. 6.4. To remove the fertile soil layer in a frozen state from construction strips and areas, ETR 254-05 rotary excavators should be used, followed by movement to a storage dump or direct loading into transport. In the absence of ETR 254-05 rotary machines, mechanical rippers on tractors with a power of 118-316 kW should be used to loosen the soil. 6.5. When constructing access roads, the fertile layer of soil is removed from the entire construction zone, mainly with ETR 254-05 rotary excavators, if necessary, moving it to temporary storage dumps with bulldozers or vehicles. The fertile soil layer must be preserved and restored in the construction zone. Excess topsoil should be used to improve nearby unproductive land. 6.6. When constructing off-site networks and communications on agricultural lands, land reclamation work is carried out in the same way as during the construction of the linear part of pipelines or branches from them (see sections 2, 3, 4). 6.7. Operations to return the fertile soil layer can only be carried out when the soil is not frozen. 6.8. The technology for reclamation of lands disturbed during quarrying involves removing the fertile layer of soil from the entire area of disturbed lands and moving it to temporary storage dumps. 6.8.1. After completion of work in the quarry, depending on the terrain, they either plan the excavation with the subsequent return of the fertile soil layer to its entire surface, or fill the excavation with mineral soil displaced by the pipeline under construction, followed by its grading and return of the fertile soil layer to it, or plan slopes workings to slopes that ensure their stability. Subsequently, the slopes are covered with a fertile layer of soil and sown with perennial grasses. Reclamation of exhausted quarries should be provided for by the project. 6.8.2. Work to remove the fertile soil layer can be carried out both in cold and warm seasons, and work to return it only in the warm (frost-free) season.7. QUALITY CONTROL

7.1. The specifics of quality control of reclamation work during the construction of pipelines are as follows: after returning, leveling and compacting the Mineral soil, a recess (trough) with clearly defined edges should remain on the reclamation strip. The depth of the excavation depends on the thickness of the fertile soil layer; When performing excavation operations, mixing fertile soil with mineral soil is not allowed; The thickness of the fertile soil layer on the reclamation strip must be at least 30 cm (in a compacted state). If zonal soils have less thickness, then the fertile soil layer should be applied with the same thickness. 7.2. General provisions for quality control of linear earthworks are given in Appendix 5. An extract from the “Fundamentals of Land Legislation of the USSR Union” is given in Appendix 6.8. SAFETY

8.1. When carrying out excavation work and land reclamation using earthmoving equipment, one should be guided by the following regulatory documents on safety precautions: SNiP III-4-80 “Safety in construction” [11]. “Safety rules for the construction of main steel pipelines” [12]; Passports and operating manuals for machines issued by manufacturers; “Unified safety rules for blasting operations” [14]. 8.2. When constructing oil and gas industry facilities in the security zone of existing communications (pipelines, power lines, etc.), one should be guided by the "Instructions for the safe conduct of work in the security zones of existing communications" (VSN 159-83 / Ministry of Neftegazstroy), as well as the "Rules protection of main pipelines", approved by Resolution of the Council of Ministers of the USSR of April 12, 1979, No. 341 (M., Mingazprom, 1982); "Instructions for construction work in security zones of main pipelines of the Ministry of Gas Industry" (M., Mingazprom, 1982); “Rules for the protection of communication lines” (M., Svyaz, 1969); “Rules for the protection of high-voltage electrical networks” (Moscow, Gosenergonadzor, 1961). 8.2.1. All personnel involved in the construction of facilities in the security zone of existing communications must undergo additional training in safe labor methods, regardless of the timing of previous training. 8.2.2. Excavation work in a strip limited by a distance of 2 m on both sides of an existing pipeline or electrical cable, as well as at intersections with underground utilities, should be carried out only manually in the presence of a representative of the operating organization. 8.2.3. When carrying out work in security zones, dumps of mineral and fertile soil should be located between the existing and the pipelines being laid, leaving a free berm with a width of at least 0.5 m. The location zones of dumps of soil (mineral and fertile) are indicated in the work plan. 8.2.4. To carry out work on backfilling a pipeline with machinery, the person responsible for carrying out the work is obliged to give the operator of the trench backfilling mechanism a work plan, show the boundaries of the mechanism’s operation and the location of existing pipelines on site. 8.2.5. Work on backfilling, returning and leveling the bead over an existing pipeline (including after winter backfilling) should be carried out using a technology specially developed and agreed upon with the operating organization, which prevents vehicles from colliding with the existing pipeline. A permit is issued for this work. 8.2.6. The passage of earth-moving and other machines over existing communications is permitted only at specially equipped crossings in places specified by the operating organization. These crossings are constructed from prefabricated reinforced concrete slabs connected by steel strips welded to mounting loops. In areas where existing communications are buried less than 0.8 m, signs must be installed with inscriptions warning of special dangers. In places that are not equipped with crossings through existing communications, the passage of construction equipment (tractors, excavators, bulldozers, pipe layers, etc.) and vehicles is prohibited. 8.2.7. It is prohibited to move construction vehicles and mechanisms in the dark, as well as during non-technological breaks, without the accompaniment of a person responsible for the safe performance of work in the security zone of existing communications. 8.2.8. The operation of construction and road vehicles in the security zone of power lines is permitted if the drivers of the above-mentioned machines have a work permit and when the voltage is completely removed by the organization operating this power line. 8.2.9. The distance from the lifting or retractable part of a construction machine in any position to the vertical plane formed by the projection onto the ground of the nearest wire energized by an overhead power line is given in the table.|

Voltage, kV |

(DC) |

||||||

| Distance, m |

APPLICATIONS

Annex 1

Mandatory

TECHNICAL CHARACTERISTICS OF ROTORY DIGGING MACHINES

|

Name of parameters |

Trench excavator brand |

Brand of trench filler TR-351 |

||||||

| Dimensions of the trench to be torn off, m: | ||||||||

| depth | ||||||||

| width | ||||||||

| Engine power, kW | ||||||||

| Technical productivity, m 3 /h, in category 1 soils | ||||||||

| Range of soil movement to the dump, m | ||||||||

| Working speed, m/h |

From 38 to 224 |

From 60 to 360 |

20-509 (32 speeds) |

|||||

| Transport speed, km/h | ||||||||

| Overall dimensions, mm: | ||||||||

| length | ||||||||

| width | ||||||||

| height | ||||||||

| Weight, kg | ||||||||

| Specific ground pressure, MPa | ||||||||

Appendix 2

Mandatory

TECHNICAL CHARACTERISTICS OF MAIN SINGLE BUCKET EXCAVATORS

|

Name of parameters |

Excavator brand |

|||

| Diesel brand | ||||

| Engine power, kW | ||||

| Clearance under the turning part, m | ||||

| Track width, m | ||||

| Average ground pressure when moving, MPa | ||||

| Bucket capacity, m 3 | ||||

| Maximum digging depth, m | ||||

| Weight, kg | ||||

Appendix 3

Mandatory

TECHNICAL CHARACTERISTICS OF MAIN BULLDOZERS

|

Name of parameters |

Bulldozer brand |

|||||||||

| Bulldozer type |

Fixed |

Turning |

Fixed |

Turning |

Fixed |

|||||

| power, kWt | ||||||||||

| Basic tractor | ||||||||||

| Blade length, mm | ||||||||||

| Working body drive |

Tractor hydraulic system |

|||||||||

| Overall dimensions with tractor, mm: | ||||||||||

| length | ||||||||||

| width | ||||||||||

| height | ||||||||||

| Weight with tractor, kg | ||||||||||

Appendix 4

Mandatory

TECHNICAL CHARACTERISTICS OF MOTOR GRADERS

|

Name of parameters |

Motor grader brand |

|||

| Engine power, kW | ||||

| Blade dimensions with knife, mm | ||||

| length | ||||

| height (chord) | ||||

| Wheel track, mm: | ||||

| front | ||||

| rear | ||||

| Overall dimensions, mm: | ||||

| length | ||||

| width | ||||

| height | ||||

| Motor grader weight, kg | ||||

Appendix 5

Mandatory

Extract from the “Instructions for the performance of work during the construction of main pipelines. Earthworks" VSN 2-130-81/Minneftegazstroy

3. QUALITY CONTROL AND ACCEPTANCE OF EARTHWORK

3.1. Quality control of excavation work consists of systematic observation and verification of compliance of the work performed with the design documentation, the requirements of the SNiP chapter "Main pipelines. Rules for the production and acceptance of work" in compliance with the tolerances given in table. 3.2. The purpose of control is to prevent the occurrence of defects and defects during the production process, eliminate the possibility of accumulation of defects, and increase the personal responsibility of performers. 3.3. Depending on the nature of the operation (process) being performed, operational quality control is carried out directly by performers, foremen, foremen, foremen or a special controller. 3.4. Devices and instruments (except for the simplest probes and templates) intended for quality control of materials and work must be factory-made and have passports confirming their compliance with the requirements of State standards or technical specifications approved in the prescribed manner. 3.5. Defects identified during inspection, deviations from designs and requirements of building codes and regulations or technological instructions must be corrected before subsequent operations (works) begin. 3.6. Operational quality control of excavation work should include: checking the correctness of the transfer of the actual axis of the trench with the design position; checking the marks and width of the strip for the operation of bucket wheel excavators (in accordance with the requirements of work projects); checking the profile of the trench bottom with measuring its depth and design elevations, checking the width of the trenches along the bottom; checking trench slopes depending on the soil structure specified in the project; checking the thickness of the bedding layer at the bottom of the trench and the thickness of the layer of filling the pipeline with soft soil; the size of the actual radii of curvature of the trenches in the areas of turning of horizontal curves. 3.7. Control of the correct transfer of the trench axis in plan is carried out with a theodolite with reference to the alignment axis. The distance from the alignment axis to the wall of the trench along the bottom in dry sections of the route should be at least half the design width of the trench, this value should not be exceeded by more than 200 mm; in flooded and swampy areas - by more than 400 mm. 3.8. The actual radii of rotation of the trench in plan are determined by a theodolite (the deviation of the actual axis of the trench on a curved section should not exceed ±200 mm). 3.9. The compliance of the trench bottom marks with the design profile is checked using geometric leveling. The marks of the reference benchmarks are taken as the initial ones (if necessary, the network of benchmarks when carrying out marking work is condensed in such a way that the distance from the temporary construction benchmark to the most distant point of the route does not exceed 2-2.5 km). Leveling the bottom of the trench is carried out using technical leveling methods. The actual elevation of the trench bottom is determined at all points where the design elevations are indicated in the working drawings, but at least 100, 50 and 25 m, respectively, for pipelines with a diameter of up to 300, 820 and 1020-1420 mm. The actual elevation of the trench bottom at any point should not exceed the design one and may be less than it by up to 100 mm. 3.10. If the project provides for adding loose soil to the bottom of the trench, then the thickness of the leveling layer of loose soil is controlled with a probe lowered from the trench berm. The thickness of the leveling layer must be no less than the design thickness (tolerance for layer thickness is given in the table). 3.11. If the project provides for filling the pipeline with soft soil, then the thickness of the powder layer of the pipeline laid in the trench is controlled by a measuring ruler. The thickness of the powder layer must be at least 200 mm. It is allowed that the deviation of the layer thickness is within the limits specified in the table. 3.12. The marks of the reclaimed strip are controlled by geometric leveling. The actual elevation of the strip is determined at all points where the design elevation is indicated in the land reclamation project. The actual elevation must be no less than the design elevation and not exceed it by more than 100 mm.

Permits for the production of earthworks

|

Name of tolerances |

Tolerance value (deviation), cm |

Illustration of tolerance (deviation) |

|

|

maximum |

minimum |

||

| Half the width of the trench along the bottom in relation to the alignment axis | |||

| Deviation of marks when planning a strip for the operation of bucket wheel excavators | |||

| Deviation of trench bottom marks from the design: | |||

| when developing soil with earthmoving machines | |||

| when developing soil using the drill-and-blast method | |||

| The thickness of the bed of soft soil at the bottom of the trench | |||

| Thickness of the soft soil layer above the pipe (when subsequently backfilled with rocky or frozen soil) | |||

Appendix 6

Mandatory

EXTRACT FROM "FUNDAMENTALS OF LAND LEGISLATION OF THE UNION OF THE SSR AND THE UNION REPUBLICS"

Article 7. Land in the USSR is provided for the use of collective farms, state farms, other state agricultural, cooperative public enterprises, organizations and institutions; industrial, transport, other non-agricultural state, cooperative, public enterprises, organizations and institutions, citizens of the USSR. In cases provided for by the legislation of the USSR, land may be provided for use by other organizations and individuals. Article 9. Land is provided for indefinite or temporary use. Land use without a predetermined period is recognized as indefinite (permanent). The land occupied by collective farms is assigned to them for indefinite use. Temporary use of land can be short-term (up to three years) and long-term (from three to ten years). In case of production necessity, these terms can be extended for a period not exceeding, respectively, the terms of short-term or long-term temporary use. The legislation of the Union republics for certain types of land use may establish a longer period of long-term use, but not more than 25 years. Article 10. The provision of land plots for use is carried out in the order of allotment. The allocation of land plots is carried out on the basis of a resolution of the Council of Ministers of a union republic or the Council of Ministers of an autonomous republic or a decision of the Executive Committee of the relevant Council of People's Deputies in the manner established by the legislation of the USSR and union republics. Resolutions or decisions on the provision of land plots indicate the purpose for which they are allocated and the basic conditions for using the land. The provision of a land plot in use to another land user is made only after the withdrawal of this plot in the manner prescribed by Article 16 of these Fundamentals. Lands recognized in the prescribed manner as suitable for agricultural needs must first of all be provided to agricultural enterprises, organizations, and institutions. For the construction of industrial enterprises, residential facilities, railways and roads, power lines, main pipelines, as well as for other non-agricultural needs, non-agricultural land or unsuitable for agriculture, or agricultural land of poorer quality, is provided. The provision of land plots from the lands of the state forest fund for these purposes is carried out mainly at the expense of areas not covered with forest or areas occupied by shrubs and low-value plantings. The provision of land plots for development in areas where mineral deposits occur is carried out in agreement with the state mining supervision authorities. Power lines, communications and other communications are carried out mainly along roads, existing highways, etc. It is prohibited to begin using the provided land plot until the relevant land management organizations have established the boundaries of this plot in kind (on the ground) and issued a document certifying the right to use the land. The land use rights of collective farms, state farms and other land users are certified by state acts on the right to use land. The forms of acts are established by the Council of Ministers of the USSR. The procedure for registering temporary use of land is established by the legislation of the union republics. Article 11. Land users have the right and obligation to use land plots for the purposes for which they are provided. Depending on the intended purpose of each land plot provided for use, land users have the right, in the prescribed manner: to erect residential, industrial, cultural and other buildings and structures; sowing agricultural crops, planting forest, fruit, ornamental and other plantings; use hayfields, pastures, and other lands; use common mineral resources available on the land plot for the needs of the farm; peat and water bodies, as well as exploit other beneficial properties of the land. Losses caused to land users are subject to compensation. Violated rights of land users are subject to restoration in the manner prescribed by the legislation of the USSR and union republics. The rights of land users may be limited by law in the interests of the state, as well as in the interests of other land users. The use of land for the extraction of unearned income is prohibited. Land users are obliged to use the land rationally and effectively, treat it with care, and not commit actions on the land plots provided to them that violate the interests of neighboring land users. Enterprises, organizations and institutions developing deposits of minerals and peat, carrying out geological exploration, survey, construction and other work on agricultural lands or forest lands provided to them for use, are obliged, after the need for these lands has passed, at their own expense to bring them into a condition suitable for use in agriculture, forestry or fisheries, and when performing the specified work on other lands - into a state suitable for their intended use. Bringing land plots into a suitable condition is carried out during the work, and if this is not possible, after their completion within the time limits established by the authorities providing land plots for use, in accordance with projects approved in the established manner. Enterprises; organizations and institutions carrying out industrial or other construction, developing mineral deposits, as well as carrying out other work related to soil disturbance, are obliged to remove, store and apply fertile soil to reclaimed lands or unproductive lands. Enterprises, organizations and institutions developing deposits of minerals and peat, as well as carrying out other work that has a negative impact on agricultural, forest and other lands outside the land plots allocated for their use, are obliged to provide and implement measures to prevent or limit as much as possible these negative impacts. Article 16. The seizure of a land plot or part thereof for state or public needs is carried out on the basis of a resolution of the Council of Ministers of a union republic or the Council of Ministers of an autonomous republic, or a decision of the Executive Committee of the Relevant Council of People's Deputies in the manner established by the legislation of the USSR and union republics. The withdrawal of plots and lands used by collective farms, state farms, other agricultural enterprises, organizations and institutions from lands of cultural or scientific significance is allowed only in cases of special need. Confiscation of irrigated and drained lands, arable lands, land plots occupied by perennial fruit plantations and vineyards, cultivated pastures, as well as hayfields and pastures where work has been carried out to radically improve them for non-agricultural needs, lands occupied by water protection, protective and other forests of the first group , for use for purposes not related to forestry, is carried out in exceptional cases and only by resolution of the Council of Ministers of the Union Republic. The seizure of these lands in order to provide them for temporary short-term use for the construction of pipelines, power lines and other linear structures can be carried out, if necessary, on the basis of a resolution of the Council of Ministers of the autonomous republic or a decision of the executive committee of the regional, regional Council of People's Deputies. Enterprises, organizations and institutions interested in the seizure of land for non-agricultural needs are required, before the start of design work, to first agree with land users and bodies exercising state control over the use of land, the location of the facility and the approximate size of the area planned for seizure. Withdrawal of plots from lands used by collective farms can only be carried out with the consent of general meetings of collective farm members or meetings of authorized representatives, and from lands used by state farms, other state, cooperative, public enterprises, organizations, institutions of union or republican subordination - by agreement with land users and relevant ministries and departments of the USSR or union republics.LITERATURE

1. GOST 17.5.1.01-78. Protection of Nature. Classification of disturbed lands for reclamation. 2. GOST 17.5.1.01-78. Protection of Nature. Land reclamation. Terms and Definitions. 3. GOST 17.5.3.04-83. Protection of Nature. Land reclamation. General requirements. 4. Fundamentals of land legislation of the USSR and union republics. Collection of normative acts on nature conservation. M., "Legal Literature", 1978. 5. Resolution of the Council of Ministers of the USSR of June 2, 1976 No. 407. On land reclamation, conservation and rational use of fertile soil layer in the development of mineral deposits and peat, geological exploration, construction and other works Collection of normative acts on nature conservation. M., "Legal Literature", 1978. 6. SNiP II-45-75. "Main pipelines. Design standards". 7. SNiP III-42-80. Main pipelines. Rules for production and acceptance of work. 8. SNiP III-1-76. Organization of construction production. 9. SNiP III-8-76. Earthworks. Rules for production and acceptance of work. 10. SN-452-73. Norms for land allocation for main pipelines. 11. SNiP III-4-80. Safety precautions in construction. 12. Safety rules for the construction of main steel pipelines. M., Nedra, 1972. 13. Instructions for the safe conduct of work in security zones of existing communications (VSN 159-83/Minneftegazstroy) - M., VNIIST, 1983. 14. Unified safety rules for blasting operations. M., Nedra, 1972. 15. Instructions for the performance of work during the construction of main pipelines. Earthworks (VSN 2-130-81/Minneftegazstroy). M., VNIIST, 1981. 16. Guide to methods for developing trenches at an accelerated pace. (R 285-77). M., VNIIST, 1977. 17. Recommendations for removing the fertile layer of soil in the production of mountainous soils; construction and other works. M., Kolos, 1973.Reclamation consists of restoring land disturbed during road construction. The main types of reclamation work are: removal and storage of the fertile layer, land leveling, land drainage, application of the fertile layer, measures to prevent water and wind erosion.

On the transverse profiles of the right of way, a strip of permanent

allocation of land for the road and temporary road strip.

The permanent allotment strip for the road includes areas for embankments, excavations, drainage structures and shoulders 1 m wide on each side of the road. The near-road temporary allotment strip includes the area of lateral reserves, areas under the temporary allotment of plant soil and roads. The width of the temporary allotment strip required for storage and storage of plant soil, passage and maneuvering of an earthmoving machine is assumed to be 10-12 m.

After completion of construction work, the temporarily occupied area must be leveled, and the vegetation layer from the temporary dumps must be evenly distributed over the restored area. If necessary, organic and mineral fertilizers are applied, plowing and harrowing of the soil is carried out with sowing of herbs or planting of seedlings.

4.5.3. Sources of air pollution

The main source of air pollution is cars and other types of transport.

Vehicle emissions, accounting for about half of atmospheric emissions of anthropogenic origin, are formed from engine emissions, wear products of mechanical parts, and road surface tires.

Factors that have an adverse effect on the human body include lead compounds contained in vehicle exhaust gases. Lead is found in atmospheric air almost exclusively in the form of inorganic compounds.

The amount of lead in human blood increases with its content in the air. This leads to a decrease in the activity of enzymes involved in oxygen saturation of the blood and, consequently, to disruption of metabolic processes in the body.

Atmospheric air pollution not only poses a threat to human health, but also causes great environmental damage. Toxic substances in the air poison animals, discolor the paint on the walls of houses and car bodies, and plants die under their influence. Therefore, it is necessary to know the concentration of harmful substances in the atmospheric air.

Maximum permissible concentrations of harmful substances in the atmospheric air of populated areas.

To reduce the concentration of harmful substances in the air, the project provides for double-row planting of trees on both sides of the road.

Green spaces play an important role in air purification. Tree leaves absorb carbon dioxide and release oxygen. In 24 hours, an average-sized tree recovers as much oxygen as

required for three people to breathe.

Green spaces absorb not only carbon dioxide from the air, but also cleanse the atmosphere of carbon monoxide, reducing its concentration to natural - about 0.00001%.

Green spaces not only improve the microclimate, change the thermal regime, humidify and purify the air, enrich it with oxygen, kill pathogens, but also have a beneficial effect on people.

Planting not only reduces gas pollution, but also protects populated areas from noise.

Introduction

Most of the world's population already lives surrounded by technogenic landscapes, which are also actively used for the needs of recreation and mass short-term tourism - the so-called suburban areas. Their characteristic altered biotic systems and complex engineering and technical structures create a constant living environment for people. But most technogenic landscapes in their current state are clearly unfavorable and even dangerous for human health. In addition, all technogenic landscapes, due to low biological productivity and specific biophysical and biochemical properties, form peculiar gaps and barriers along the paths of planetary migration of substances and energy. They distort the normal course of such fundamental processes occurring in the biosphere as the biological cycle of nitrogen, the gas regime of the atmosphere, etc., and reduce their intensity (3).

Their characteristic feature is the violation of the integrity and continuity of the “film of life” in the biosphere, up to the complete destruction of soil and plant covers as a result of human activity comparable in importance to geological processes. Among man-made landscapes, a special place in terms of their negative impact on natural complexes (and on human health) is occupied by the so-called industrial dumps. They are concentrated in the vicinity of most populated areas and all major cities (4).

The main task of research, experimental and production work on reclamation is to eliminate the harmful, polluting impact of these lands on adjacent territories, and restore their biological and socio-economic value.

Thus, land reclamation is understood as a set of works aimed at restoring the biological productivity and economic value of disturbed lands, as well as improving environmental conditions (3).

The purpose of this work is to describe the biological method of reclamation of disturbed lands.

To achieve the goal, the following tasks were set:

1. Reveal the essence of the land reclamation process and the requirements for it;

2. Consider the procedure for carrying out the biological stage of reclamation of lands disturbed during major and emergency repairs of oil pipelines;

3. Describe the technology of biological reclamation of disturbed lands in four combined zones: in the polar-tundra zone; in the forest-tundra northern and middle taiga zones; in the southern taiga forest and forest-steppe zones; in the steppe and dry steppe zones.

4. Compare known methods of reclamation and describe the Canadian method of biological reclamation of oil-contaminated lands.

Chapter 1 Reclamation of disturbed lands and requirements for it

1.1 The essence of the land reclamation process

Land reclamation is a set of works aimed at restoring the productivity and economic value of disturbed and contaminated lands, as well as improving environmental conditions (1).

Disturbed lands of all categories, as well as adjacent land plots that have completely or partially lost productivity as a result of the negative impact of disturbed lands, are subject to reclamation.

Land reclamation is an integral part of technological processes associated with land disturbance and should be carried out taking into account local soil and climatic conditions, the degree of damage and pollution, landscape and geochemical characteristics of disturbed lands, a specific site, and the requirements of the instructions.

Recultivated lands and the adjacent territory after completion of the entire complex of work should represent an optimally organized and ecologically balanced sustainable landscape (1).

In conducting research on the problem of biological reclamation, several stages are clearly distinguished. At the first stage (from 1959 to the end of the 1970s), methods for the biological reclamation of industrially disturbed lands were developed under economic contracts with industrial enterprises. The results of the research were recommendations that were used in the preparation of projects and the practical implementation of biological reclamation. As a rule, taking into account specific environmental conditions made it possible to significantly reduce the cost of design and practical work on the biological reclamation of the studied technogenic formations and even identify a group of areas that do not require biological reclamation. These are old dumps with good restoration of vegetation and soil cover (3).

When carrying out the biological stage of reclamation, the requirements for land reclamation in the areas of their use must be taken into account.

An important area of research on industrially disturbed lands is the study of the dynamics of cenopopulations of cultivated species in phytocenoses created during biological reclamation, and the dominant species of plant communities that arose in the process of self-overgrowing.

The authors' research has shown that the formation of communities occurs according to the type of primary succession in an open, practically lifeless space, often in extreme edaphic (peculiar in chemical and physical properties) and microclimatic conditions. At the first stages of formation, strict ecotopic selection and intensive elimination of plants are carried out, especially in the phase of seedlings and shoots. Species that have advantages in any of the vital parameters have a higher potential for survival and the formation of a viable coenopopulation. Under these conditions, the process of niche differentiation plays a decisive role in the formation of plant communities (4).

1.2 Requirements for land reclamation for various uses

Requirements for land reclamation for agricultural purposes should include:

Formation of areas of disturbed land, convenient for use in terms of relief, size and shape, the surface layer of which should be composed of rocks suitable for biological reclamation;

Layout of disturbed land areas, ensuring the productive use of modern equipment for agricultural work and excluding the development of erosion processes and soil landslides;

Applying a fertile layer of soil to unsuitable rocks when preparing land for arable land;

The use of potentially fertile species with the implementation of special agrotechnical measures in the absence or insufficient fertile soil layer;

Carrying out repairs to reclaimed areas;

Carrying out intensive reclamation with the cultivation of annual, perennial cereals and legumes for the restoration and formation of the root layer and its enrichment with organic substances using special agrochemical, agrotechnical, agroforestry, engineering and anti-erosion measures;

Obtaining a conclusion from the agrochemical and sanitary-epidemiological services that there is no danger of plants carrying out substances toxic to humans and animals (1).

Requirements for land reclamation for forestry should include:

Creation of plantings for operational purposes, and, if necessary, forests for protective, water-regulating and recreational purposes;

Creation of a reclamation layer on the surface of slopes and dump berms from fine-earth non-toxic material favorable for forest growing;

Determination of the thickness and structure of the reclamation layer depending on the properties of rocks, the nature of the water regime and the type of forest plantations;