Foundation for a 1-storey building made of aerated concrete. How and what foundation to choose for a house made of aerated concrete. Tape shallow foundation

Individual construction involves some flight of fancy in the design and construction of a house, but the opinion that an aerated concrete house can be built without a foundation is deeply mistaken. And it is based on the fact that such a building is quite light, and a foundation is not required for it. This is far from the case - aerated concrete still has weight, and for a standard typical house project measuring 6 x 10 meters, this value will be approximately 60-80 tons. Add furniture, finishing materials, communications, the weight of residents and strangers, add the necessary margin of safety - and you will get such numbers that you will no longer want to build a house without a solid concrete foundation.

The main selection criteria are the functionality and profile purpose of structures, assemblies and materials. The requirements listed below apply to any type of foundation:

- Any base is designed to ensure the stability of the geometric shapes of the building, that is, the rigidity of the structure;

- The uniform distribution of loads from the weight of the completed house to the soil is another purpose of this design. Any increase in load in a random area can cause the building to skew, cracking, and material destruction;

- Compensation of heaving forces in order to prevent housing deformation;

- Minimization of lateral forces from the ground on the plinth, base and load-bearing walls of the building.

For any foundation, the depth of soil freezing in the region and the level of groundwater penetration are of decisive importance - these parameters affect the actual depth of the foundation. If there are no groundwater and underground sources on the site, then when calculating the depth of the foundation pit for a house made of gas blocks, the depth of soil freezing is not taken into account, and for all soils, except clay, concrete can be poured above this level.

Clay soil is heaving soil, and therefore, in such areas, the foundation for a house from a gas block is necessarily laid below the geological freezing point of the soil. In such soils, atmospheric moisture seeps into the clay layer and condenses in large volumes. At a negative temperature in the soil, water turns into ice and expands, and only upwards, creating pressure on the foundation. Clay prevents lateral and lower expansion, so the soil swells up.

If the house is built from gas blocks, then such swelling will lead to deformations, cracks, destruction of the concrete structure and walls of the house. Studies show that up to 8,000 kg of soil pressure per 1 m² of foundation. Therefore, for objects built from aerated concrete, it is necessary to equip the reinforcement of the foundation and walls. At critical points (windows, doors, arched openings), the armored belt should be reinforced.

Depth of foundation and types of foundations

Compliance with two rules will make the calculation more accurate:

- The distance (H) from the bottom of the base to the ground surface must be ≥1.5 (H) before the start of the soil freezing level;

- The sole of the foundation should start above the groundwater level ≥2 m, but ≤ 0.3-0.4 m from the depth of soil freezing.

The SNiP for low-rise construction does not indicate the laying of MLM (shallow-depth tape monolithic) foundations. But, since the average freezing depth in the Russian Federation lies in the range of 0.8-2.5 meters, in the south of Russia the MLM foundation is laid to a depth of 0.3-0.4 meters, in the north - 0.7-0.8 m .

slab foundation

It is considered the most reliable design, provides an ideal distribution of all loads from the house and from the soil.

- When equipping a slab base, the manifestation of pressure from heaving of the soil is leveled.

- The probability of deformation and destruction of the concrete slab from the weight of the building is minimal.

- It is necessary to equip the drainage system, which prolongs the life of the foundation and the house.

The slab foundation, which is erroneously called floating and monolithic, is built from reinforced concrete slabs with joints and ceilings filled with concrete mortar.

The advantage of using slabs is the speed of construction, despite the laboriousness of earthworks. The arrangement of the pit includes several stages: the creation of a sand and gravel cushion, tamping and the creation of a concrete cushion between the sand and gravel layer with a waterproofing layer.

The disadvantage is the need to use special equipment for digging a pit and laying reinforced concrete slabs.

Monolithic base

When arranging a monolithic base, it is advisable to prepare concrete immediately on the site or order the required volume at the factory so that the monolith can be poured in one go. With such an organization of the workflow, steps, formwork and other designed house structures can be immediately formed.

Reinforcement is not required for buildings 6 x 10 or smaller. It is recommended to pour the mortar in layers ≤ 15 cm thick - the top layer is poured after the bottom one has set. When pouring in layers, vibrotamping or bayoneting of the mortar is carried out in order to squeeze out all the air from the concrete.

Tape base

The concrete tape is poured after digging a trench that runs along the perimeter of the object and under the internal walls that act as load-bearing. Reinforced concrete monolith provides immobility and stability of the building at much lower estimated costs for building materials and work.

The main requirement for the LF is to level the impact of heaving soils, which is achieved by creating a sand-gravel cushion. Depending on the depth of laying, there are two types of strip foundations:

- Deeply buried - below the initial freezing point of the soil without insulation;

- The same design and the same construction methods, but with insulation against the manifestations of heaving of the soil at low temperatures.

Deeply buried tape (GZLF) is a great opportunity to make a warm basement or basement.

MZLF base

Shallow strip foundation is optimized for non-rocky and immovable soils. The absence of the main destabilizing factors (heaving and soil movements) allows the foundation to be buried to a depth of ≤ 0.3-0.5 m. On the MZLF foundation, it is possible to build a two-three-story house of aerated concrete blocks, even with an attic.

A sand-gravel pillow is required, as it plays the role of the impact of heaving soil. The depth of groundwater passage is also taken into account - if they are too close, it is recommended to lay a pile or column foundation. If the house is placed on a heaving site, then it is necessary to limit one-story project. Also, when laying MZLF, it should gain strength within 6-8 months with constant surface moistening for the first 2-5 days.

brick foundation

The foundation with the main building material in the form of bricks is laid on the same soil as for the MZLF. The requirements for the house are the same - a one- or two-story building, no more. The advantage of such a brick base is that it can be given a complex geometric shape without the use of formwork or additional concreting. The disadvantage is the need for arranging waterproofing. To build such a foundation, you need to use a solid brick M-200 and higher with a frost resistance coefficient of F 35-F 10.

columnar structure

The base for the house of pillars is designed for their fastening at the main load points and along the perimeter of the building. This is the most economical solution, but it is not possible to use such a foundation for all projects and soils, but only for areas with a large slope, when observing seasonal soil slippage or loose soil. Also, for a house with a columnar foundation, it is impossible to build a basement or underground garage.

In practice, two options are implemented - a prefabricated columnar and monolithic foundation on pillars. When pouring the pillars, it is necessary to immediately provide a drainage system for the base itself, the basement and the formwork to protect it from ground moisture.

pile foundation

Piles are driven in cases where groundwater passes close to the surface of the site. Piles are similar to pillars in functionality, but they are smaller in diameter, longer, and are made not only from concrete with a cavity inside - there are metal, wooden, reinforced concrete piles. Piles are also divided into products of screw and bored type.

A screw pile is used for construction on weak, subsiding and heaving soils, as well as if the site has a large slope.

- The most common material for the manufacture of screw structures is steel. The lower end of the pile has blades in the form of spirals, which facilitate deepening and enable the pile to be fixed into the bearing soil layer. Screwing depth – ≥300 mm. The blades of the pile act as an anchor, minimizing the displacement of the foundation;

- Bored piles are used on sandy and sandy loamy soil, on clay and loamy soils, as well as on peat soils, as they can withstand up to 10 tons per pile.

Screwed screw or bored piles are fastened to each other with a monolithic concrete grillage. With the low cost of such a foundation, it is in demand only on complex types of soils.

Requirements for any type of foundation

Dimensions, foundation depth, basement height and other parameters are calculated for each house separately. The project includes the planning of all construction processes, including the construction of any type of foundation, on which the service life and reliability of aerated concrete structures depend. The type of foundation is chosen taking into account the sum of all loads from the house and its contents, including furniture. The less the house weighs, the cheaper it will be to build a foundation for it.

- When designing the base, it is allowed to reduce it in width by 25%, but the depth of the base and the quality of the reinforcing frames should ensure leveling of the influence of soil movements on the house;

- The maximum static load on the concrete base consists of the weight of walls, roofs and ceilings, the maximum load in a local period of time is furniture, household appliances, etc.;

- Terrain relief. With a large slope or frequent height differences, it may be difficult to erect a GZLF or a monolithic slab. For such areas, it is recommended to use piles or poles;

- Geological and geodetic characteristics of the area - the level of occurrence of underground sources and groundwater, bearing parameters and properties of soil heaving;

- Arrangement of waterproofing layers in the vertical and horizontal plane, insulation of the foundation. If hard material is used for insulation, then the load distribution area from the house to the base can be expanded.

- Cost effective design without sacrificing quality and durability. Saving on the quality of concrete, reinforcement or insulation is fraught with the fact that both the foundation and the house will often have to be repaired, and maybe even replace some structural elements, especially load-bearing ones. For the construction of the foundation, concrete grade M200 is recommended in the classic ratio with sand and gravel - 1: 3: 3. Instead of reinforcing bars, chain-link and other flexible materials cannot be used to strengthen the foundation, and the bars themselves can be fastened together only with soft knitting wire. It is not recommended to exclude any unnecessary, as it seems to you, elements or layers of insulation, hydro or sound insulation from the construction of the house.

An erroneous calculation when choosing the type of foundation or incorrect use of calculated data can cause cracks to appear on the walls and in the base.

Any foundation - MZLF or GZLF, slab or monolithic - should be reinforced with reinforcement. Armoframe is necessary, since concrete has a low resistance to tensile loads.

Concrete internal reinforcement takes on most of the breaking moments, which increases the strength of the entire foundation. The foundation for a house made of aerated concrete blocks is reinforced with special rods Ø 12-16 mm in the longitudinal direction, and reinforcement bars Ø 6-10 mm in diameter.

Reinforcing bars are assembled into the frame by connecting with a knitting wire, welding can be used in the corners. Wire is preferred because it creates play between the bars, allowing the carcass to remain flexible and elastic for optimum resistance to dynamic loads.

Armoframe is immersed in concrete by 5-7 cm from all sides of the foundation. This distance is set by lining or fastening special plastic or wooden stands for reinforcement. You can also use broken brick, metal corner, trimming boards or timber.

Foundation for a gas block house updated: January 5, 2017 by: Artyom

As you know, there are such large categories of foundations: strip, slab, column and pile. But what is the best foundation for aerated concrete? We find out.

Criteria for choosing a foundation for a structure made of gas blocks

The choice of foundation is determined by such factors:

- Geological position of the construction site: saturation of the soil with water, groundwater level, strength of the base.

- Mass of the proposed building.

- your financial potential.

The most suitable soils: medium-large. They have excellent strength, there is resistance to heaving during frosts.

Good strength in loams and hard clays. But they are less resistant to heaving. Here, during construction, measures must be taken in time to prevent frost heaving.

Construction activities should go on those foundations that are deepened below the level of soil freezing. Average value here: 1-2 m.

What foundation is needed for an aerated concrete house? If normal, then he should at least half a meter higher than the groundwater level. And depending on the position of moisture, you can use a structure that is at least 1.5 m deep. Another option is a structure at a shallow depth (70-100 cm). Also, when determining the depth of the foundation, it is important to take into account the need for a basement.

Structural features of the building and pressure on the foundation

Here is the following table. It reflects the types of soils and suitable foundations for them.

| Soil types | Gas block house. Single storey. | Gas block house. Double decker. |

| Soils with large fragments. Sands of medium and large parameters. | Stubchaty or shallow-depth tape. | Columnar or tape with a T-like section. |

| Clays, loams and sandy loams (most often they are saturated with water) |

Pile with screw supports. | Tape or slab. The tape is below ground freezing or is powerfully insulated. Monolithic tape is allowed. |

| Zones with a high position of groundwater (marshy zone) | Monolithic tape or FBS tape. The distance between the sole of the base and the position of the water is 50 cm. If the moisture rises very high, a slab base or screw piles are used. |

slab |

Thus, what kind of foundation is suitable for building from gas blocks? This is a tape and slab option.

Strip foundation. Shallow penetration (MLF)

Its advantages:

- Reducing the volume of earthworks.

- High dynamics of construction.

- Additional measures not necessary if the groundwater position is at least 1 meter from the ground surface.

- Laying on conditionally non-rocky and non-rocky soils.

According to the manufacturing method, it can be monolithic or prefabricated. For a house made of aerated concrete, the first is better. It is stronger and more reliable.

According to the type of section, MLFs are rectangular and T-like. The former have weak bearing qualities. Therefore, the latter is often preferred. And MLF in this situation form a tape, a pillow with a horizontal arrangement and a vertical component.

Foundation level

Before installing an MLF, it is important to study how deeply the soil freezes in your area. It is also useful to be based on the data and the table below:

It is equally important to base your work on the position of groundwater. If they are closer than two meters to the intended sole, it is better to make a deep foundation and arrange drainage technology.

Protection methods

They are essential to extend the life of the MLF. They are:

- The tape is insulated over the entire height of the laying. Material - extruded polystyrene foam.

- A warm blind area is being made. The material is concrete. The same insulation is laid under it. Thickness: 10-15 cm.

- Vertical waterproofing is done. She lays down under the heater. Material - bituminous roll, or mastic.

- Water is drained from the foundation. Stormwater and drainage are being installed.

- A sand layer of 30-50 cm is made. The type of sand is coarse or medium.

Stages of MLF creation

They are in many ways similar to the stages of creating a buried tape. They are:

- The zone is marked. A trench of the required parameters is made.

- A sandy layer is arranged (see item 4 above). Carefully rammed.

- Styrofoam formwork is installed.

- The structure is reinforced.

- The concrete composition is poured. The work is done in one session. Required concrete: B15-B25.

- The concrete is compacted with a vibrator.

- The concrete hardens. Care follows.

- if necessary, the formwork is removed.

- The foundation is being waterproofed.

- The foundation is insulated.

- Backfilling follows.

- A blind area is created.

Disadvantages of the tape base

- Impressive spending.

- Lots of building materials needed.

- The need for hydroprotection of each block.

Slab foundation (PF)

For aerated concrete construction, PF is a more reliable and durable option, especially if it is monolithic. It is suitable for the erection of one- and two-story buildings. True, its cost is extremely high - almost a third of the price of the entire building. This is in the case of attracting specialists. If you create a slab yourself, you can save money and create a quality foundation (if you follow the right rules).

Advantages of PF:

- Suitability for buildings of different heights (1-2 floors).

- Suitability for houses with a basement.

- There is no need to lay the log on the floor.

- It turns out a powerful base, resistant to seismic factors.

- Minimal risk of water washout.

- Device in areas with difficult soil.

Typically, slabs are created flat or ribbed. The second option is the most difficult for independent work. But its functionality is better, and it handles building loads better. This is the best option for a two-story aerated concrete house.

For him, you first need to create special edges, and then the slab itself. Sand is used to fill the voids between the ribs.

And when your working area has very difficult soil, and you want to build a medium or small house, then you better arrange a flat PF.

Stages of creating a PF:

- The soil is being prepared. The work area is being levelled. Pouring soil. It is thoroughly rammed with a vibrating tool.

- Suitable base parameters (thickness, length and width) are calculated. The soil is removed to a depth of about 30 cm. It turns out a "capacity" for future pouring.

- The bottom of the "tank" is covered with geotextiles. Drainage is being done.

- "Capacity" is covered with a mixture of sand and gravel. The surface is watered and thoroughly rammed. It fits - thick polyethylene. And then - extruded polystyrene foam.

- Formwork is being assembled. Material - expanded polystyrene. Wall thickness - up to 25 cm.

- . The fewer reinforcing joints, the stronger the knitting will be.

- The end ends of the monolithic slab are reinforced.

- The slab itself is reinforced. Additional reinforcement is placed on columns, walls and supporting elements.

- The slab is to be poured. Required concrete: M350 - M450. The water resistance parameter is at least W6. The supply of concrete comes from the mixer. First, the far side of the PF is concreted, then the near edges. Helpers are needed to get the job done. Someone pours the mixture, someone compacts it with a vibrator.

- The concrete sets. A day later, thoroughly watered. If the work is going on in the heat, the concrete is covered with thick polyethylene.

- Concrete needs 10 days to fully harden (if the air outside is +20 C) or 20 days (outdoor temperature condition is +10 C)

About the monolithic foundation on the video

Material from ProfiBlock:

Pile Foundation (SF)

If the area for an aerated concrete building is a swampy area, a coastal area, a slope, a peat bog, then the best option (and the only one) is the Pile Foundation (SF).

Advantages of SF:

- Earthwork is needed only for a hanging grillage.

- Powerful performance - maximum 14 days.

- No special equipment needed.

- A pick-up is needed only for high grillages.

- Full geological analyzes are not required. A test pile penetration will determine the depth. Next, choose piles of suitable length.

Pile grillages are the best solution for a one-story attic building.

Minuses of the SF: it is necessary to thoroughly connect all the working elements, the slightest miscalculation can lead to the collapse of the SF.

Column foundation (StF)

It should be used when the groundwater position is 2 m from the columnar foot. Suitable areas: those where there is rocky, sandy or gravelly soil. For an aerated concrete structure, such a foundation is not very suitable due to its serious disadvantages.

Cons of STF:

- Weak spatial rigidity.

- Tendency to fall due to lateral movements of the soil.

- The need for a large volume of operations to reduce swelling impulses.

- Complete disrepair for a two-story house.

Material calculations

They follow the example of creating a monolithic LF. Basics of calculations: parameters of blocks and the house itself.

Project example

- The planned living area of the house is 65 sq.m.

- Roof parameters - 124 sq.m.

- House parameters: 9 x 8 x 6.3 m.

- There is a load-bearing partition, it divides the house into two parts

- There are internal partitions. Divide these parts into rooms.

- Clay soil. Freezing - 90 cm.

- The occurrence of water - 2 m.

Based on these data, the foundation is set with the following parameters:

- approximately 45 m long,

- 75 cm high,

- 30 cm - the minimum width according to calculations.

The calculation of materials for the sole comes down to determining the area of \u200b\u200bthe foundation: 0.3 m x 45 m = 13.5 sq.m.

Bookmark depth: 3/4 of the ground freezing mark, but at least 70 cm.

Concrete consumption

The required concrete is M150. The parameter used here is 13.5 cubic meters. This is the result of multiplying 0.3 * (0.25 + 0.75) x 45 \u003d 13.5 m 3.

The specific gravity of reinforced concrete is 2500 kg/cu.m. Gross weight of LF and base:

2500 kg / m 3 x 13.5 m 3 \u003d 33,750 kg.

Blocks for external walls have parameters of 60 x 30 x 20 cm, 500 kg / m3 (density). Each block weighs 20 kg.

It takes 660 blocks to create walls 30 cm wide. Calculation: 36 m (perimeter of the building) and 6.3 m (its height). The length of the block is 60 cm, the height is 20 cm. For the entire perimeter filling, 1890 blocks are needed. Calculation: (36 m: 0.6 m) x (6.3 m: 0.2 m) = 60 * 31.5 = 1890.

Taking into account different openings, this value is reduced by almost three times.

Weight of all blocks: 20 x 660 = 13200 kg.

Blocks for internal walls have parameters 60 x 20 x 12 cm. Density 300 kg / m3. Each block weighs 4.35 kg. They need 560 pieces. Weight of all partitions: 4.35 x 560 = 2436 kg. For convenience, this value is rounded up to 2400 kg.

Metal to create external doors provided that the standard dimensions of the door are 2 x 0.8 x 1.6. Weight - 250 kg.

Lumber for work is selected from their coniferous wood. Their total volume is 23 cubic meters. After all, the specific gravity of such a breed is 500 kg / cubic meter. Calculation: 500 x 23 = 11500 kg.

Concrete slabs for the basement. Type - with voids. Their thickness is 0.22 m. The specific gravity is 1.36 t/m3. Area calculation: 9 x 8 = 72 sq.m.

Volume: 72 x 0.22 \u003d 15.84 cubic meters

Total weight: 15.84 x 1.36 = 21542 kg.

Facing brick. Calculation of the finishing area: (9 + 9 + 8 + 8) x 0.25 \u003d 8.5 m 2.

For 1 m 51 bricks are obtained. Each brick weighs 2 kg. The formula works: 8.5 m 2 x 51 pcs / m 2 x 2 kg = 867 kg.

Calculation of the composition (if 0.02 cubic meters of composition is spent per 1 sq.m. of masonry): 8.5 x 0.02 m 3 \u003d 0.17 m 3.

Mass of the composition: 0.17 m 3 * 1.1 t / m 3 \u003d 187 kg.

The entire weight of the finish: 187 + 867 = 1054 kg.

The entire mass of the building with loads

All calculations are summarized here. And without aerated concrete floor it turns out:

33.75 + 13.2 + 2.4 + 0.25 + 11.5 + 21.542 + 1.054 + 0.61 + + 0.25 + 0.504 + 0.096 + 0.65 + 0.25 = 86.056 tons.

In terms of coverage:

86,056 + 12,116 = 98.172 tons.

Snow load, taking into account a flat roof: 124 m 2 * 160 kg / m 3 \u003d 19,840 kg.

Here 160 is the average value of the snow load.

Calculation of the payload resulting from furniture and residents: 6439 × 180 = 11682 kg, rounded - 11700 kg.

The total value of the load from the entire structure: 88.4 + 18.6 + 11.7 = 118.7 tons.

Calculation of the specific pressure (UD) under the foundation sole: P = 118.7 / 13.47 = 8.81 t / sq.m (the entire mass of the house is divided by the area for this sole).

You need to look at the reference materials. According to them, UD for clay soil = 10 t/sq.m. The parameter is greater than the obtained value (8.81). This means that all calculations are correct. And the LF for the aerated concrete house is designed correctly.

Calculations on a slab foundation

Under the same conditions as in the work on a monolithic LF, it is necessary to calculate the area of the plate and its thickness. The calculation method is similar to the operations for calculating the LF. In this case, the height of the house is 6.3 m, then stiffeners are needed.

The parameters of the reinforcing elements are also important.

So a reinforcing bar is suitable with a cross section of at least 2 cm. Its level is the second. The interval between the bars is 9 cm. The reinforcement extends 5 cm from the cut of the slab. Calculation: 2 x 2 + 9 + 5 x 2 \u003d 23 cm. This is the thickness of the slab for the house in this case.

Calculation of the base for strength

Concrete brand - M350. Calculation:

118.7 tons: 36 (perimeter) x 0.3 (wall thickness) = 10.9. Rounded 11 mPa

The parameter of this brand of concrete is 25 MPa

Bearing capacity calculation: the mass of the slab is divided by its entire area. The result obtained is compared with the tabular data of a certain soil in your area. If the indicator is lower, then the calculations are correct.

Which foundation is cheaper after all? The most profitable design is the one with the least consumption of concrete. And if according to the calculations (which is unlikely) there will be a slab, then there are no questions - we are preparing the basis for the slab structure.

Overview of all types of foundations on video

Webinar from Gleb Green.

When deciding which foundation is better to choose for a house made of aerated concrete, several factors must be taken into account. First of all, the properties of the material of the walls affect the design features. Foundations for houses built from aerated concrete must take into account some of the distinctive characteristics of this material.

Features of aerated concrete blocks

Here we will consider those characteristics that have a direct impact on the foundation for a house made of aerated concrete. Before choosing a type, you need to consider the following features.

Gas blocks are piece material. Even with the right choice of masonry mortar and the observance of the technology for performing work, they are weakly interconnected. This factor translates into the fact that the walls of the building are extremely sensitive to various deformations of the base.

If the foundation under the aerated concrete house sags or, conversely, rises from the ground, cracks may appear on the walls of the building. Cracks in most cases will be oblique. The opening width and length depend on the scale of displacement of the supporting part of the building. To prevent damage, it is necessary to provide reliable supports that will resist various kinds of displacements. The design should link the wall from separate blocks into a single system.

The task of the foundation is to prevent such phenomena.

The foundation for aerated concrete is needed less powerful than for a brick house. This is due to the lower density of the material, and, accordingly, the mass. For comparison, the density of gas blocks is from 350 to 700 kg / m3, while a brick wall will have a density of 1800 kg / m3. Blocks with a minimum density cannot be used as structural elements; the material of load-bearing walls has a mass of 500 to 700 kg per cubic meter.

Despite the advantages of blocks compared to bricks, it is worth remembering that the material is inferior to wood. Also, the building will be heavier than a frame house. When choosing foundations for houses made of lightweight aerated concrete, this feature must be taken into account.

What types of foundations are used

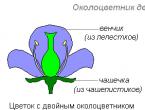

All foundations, depending on the working conditions, can be divided into four large groups:

- columnar;

- pile;

- tape;

- slab.

Variants of applied bases

Variants of applied bases The first and second in private construction (taking into account the most popular sections) have a relatively low bearing capacity. Such elements work only on compressive loads. It is especially advantageous to make them from concrete, since this material has good compressive strength. Also recently they have become widespread.

The strip foundation perceives mainly compressive loads. Small bending effects may also occur when working on soft soils. If the monolithic foundation is made in compliance with the technology, they do not cause problems.

The use of a slab foundation is different in that this design works on bending and punching. Concrete does not resist such influences well. To prevent damage for pouring, a mixture of sufficiently high grades is chosen, and reinforcement is prescribed with special care. Before installing the plate, it is recommended to calculate it for strength and rigidity. Only a professional designer or designer can perform such work.

How to choose the type of foundation

Before choosing which type of support is best for an aerated concrete house, the following points must be considered:

- geological conditions of the construction site, foundation strength, soil water saturation, groundwater level;

- the mass of the building (when comparing buildings made of the same material, this characteristic is strongly influenced by the number of storeys);

- economic opportunities.

Influence of soil characteristics

Moisture in the soil and type of soil affect the foundation level. Soils on the site can be one of the following types:

- coarse-grained;

- coarse sand;

- medium sand;

- clay;

- loam;

- sandy loam;

- fine or silty sand;

- bulk soil.

The last two positions have very low strength characteristics. Building on such foundations is not recommended (only pile foundations can be an exception). The best option would be to replace the material with medium or coarse sand.

The best soils for construction will be coarse and sandy (medium and large). Such bases have high strength and are not prone to frost heaving (one of the main enemies of foundations for houses made of aerated concrete).

High-plastic clays and loams also have good strength characteristics. But all clay soils (clay, loam, sandy loam) can lead to uneven raising of the building in winter. This phenomenon occurs due to frost heaving. At the same time, the outer walls of the building rise more than the inner ones. Cracks appear on the walls of gas blocks. When building on such grounds, it is required to take timely measures to prevent frost heaving.

When building on heaving soils, it is necessary to choose those types of foundation that are buried below the freezing of the soil. The value is determined by regulatory documents. On average, this value is in the range of 1-2 m.

The foundation for a house made of aerated concrete (its sole) must be at least 50 cm above the groundwater level. Depending on the location of the moisture, a recessed structure can be used (it goes into the ground by 1.5 m or more) or (in this case, the laying is taken to be approximately 70-100 cm). Also, when choosing the depth of foundations, it is necessary to take into account the need.

Structural features of the building and the load on the foundation

To choose which foundation is best suited for a block house, it is recommended that you read the table below. The dimensions and thickness of the supporting part are assigned by calculation.

| Soils at the construction site | For a one-story block house | For a two-story block house |

| Coarse clastic soils, medium and coarse sands | To save money, in this case, columnar bases or tape bases with a small laying depth are used. | Pillars are used for such buildings. The strip foundation for a house made of aerated concrete in this case should have a T-shaped section (increased thickness from below). It is better not to use a rectangular section type due to the low bearing capacity |

| Clays, loams and sandy loams (most often they are saturated with water) | You can use a pile foundation of screw supports. They work great even in wet soils. A reliable monolithic grillage is made along the pile heads, which will connect the individual supports into one system. Also, a slab base will be an excellent option (due to the low load, the thickness of the foundation is relatively small, about 200 mm) | The foundation for a house made of aerated concrete in this case is assigned to a tape or slab type. In this case, the tape must be laid below freezing or have reliable insulation. To protect the building from moisture, a drainage system, waterproofing and blind area around the perimeter are designed. The tape can be made from a monolith or FBS blocks. The monolithic option is preferable because the FBS are weakly coupled. According to their edge, you still have to make a reinforced concrete belt. The thickness of the foundation is assigned depending on the thickness of the walls. If a basement is not planned, a shallow slab is used. This approach will reduce construction costs |

| Areas with a high groundwater level (wetlands) | As a supporting part, you can use a tape made of a monolith or FBS. In this case, it is required to observe the distance between the base of the foundation and the water level -50 cm. With a very high rise in moisture, a slab or screw piles are used as the foundation | Screw piles have a fairly low bearing capacity. When building a two-story house in a swamp, it is recommended to use a slab as a foundation |

The answer to the question of which foundation is better to apply depends on many factors. None of them can be missed.

In terms of the ratio of functionality / construction costs, this type of foundation is preferable to more well-known analogues - tape or pile. However, in low-rise construction, the slab foundation is mounted much less frequently. The main reason is the lack of awareness of private developers about all the pluses, features and specifics of the arrangement of the monolith. The article will fill the gap in knowledge and will allow you to choose the best option for a reliable support for any structure, combined with reasonable savings.

There are several names (floating, solid) and modifications of such a foundation. It all depends on the option and installation scheme. In construction, monolithic, prefabricated, "Swedish", ribbed, box-shaped slabs, with or without reinforcement and a number of others are known. Considering all engineering solutions does not make sense. For an individual developer, a monolithic reinforced concrete slab is more interesting, which is the best suited for small private structures. Therefore, attention will be focused on it, especially since the technology of its construction is one of the simplest.

Peculiarities

Advantages:

1. Increased bearing capacity. A monolithic slab creates a slight pressure on the ground due to the uniform distribution of the entire load, regardless of the thickness of the fill. A great option for a house made of timber, cellular concrete, even brick.

2. Spatial rigidity. This eliminates the possibility of subsidence in certain areas (an example is a tape) and the appearance of cracks in concrete, on walls or parted joints.

3. Versatility in application. The slab foundation is suitable for any soil, including those called problematic.

4. Simplified construction technology. The construction of a monolithic slab does not require bulk earthworks, which significantly saves time.

On a note! This does not apply to the option when the project (scheme) provides for a basement (basement, technological) room. In this case, the cost of a monolithic foundation can reach ⅓ - ½ of the entire construction estimate.

5. The possibility of high-quality insulation. Options - laying polystyrene foam under the base, introducing special / additives into the solution.

6. Reduced consumption of concrete. Although this is true only for cases of arranging an unburied monolithic slab.

Flaws:

Many of them are relative, but it is worth noting them.

1. Complexity of calculations. This applies to the thickness of the future plate. If we are talking about a building with a basement, then it is better to choose a different base option. First, the cost of construction will rise sharply. Secondly, the calculations for a monolithic slab will become much more complicated.

2. High costs. Much here depends on the specific scheme, but it is undeniable that with such construction, savings on other materials are achieved. If the slab foundation is shallow, of small thickness, it can be impressive.

3. Labor intensity. The question is how well the construction work is organized. For example, the use of an "automixer" greatly simplifies the technology of pouring concrete mortar and saves time. The same applies to the accuracy of calculations of the thickness of a monolithic foundation.

4. Certain difficulties with individual projects. First of all, when implementing a scheme with a basement and during the construction process on relief soil.

Slab thickness calculation

It is appropriate to give only general instructions and recommendations, since a lot depends on the characteristics of the construction - the characteristics of the soil, the number of storeys of the house, the materials from which it is built, and a number of other nuances.

Initial data for calculating the thickness of the foundation:

- Soil type.

- The configuration of underground aquifers.

- soil freezing level.

- The presence of a drainage system on the site and its scheme (if installed).

What is defined:

1. Thickness of concrete reinforcement elements (bar, mesh).

2. The size of the reinforcement cells and the interval between its layers in the monolith.

3. The distance of the bar from the upper and lower cut of the foundation.

Advice. If you save on anything, then just not on the calculations. In the instructions on the thematic sites devoted to this issue, only a general recommendation is given on the optimal thickness of concrete - in the range from 200 to 400 mm. But this does not take into account the specifics of erecting a monolithic foundation for a specific structure in a specific area.

The difference in this parameter of the base for buildings of the same type can be significant. For example, the thickness of a slab for a wooden house varies quite widely and depends precisely on the characteristics of the soil, although this is a relatively light structure of 1-2 floors.

*Dimensions are in "mm".

- The cross section of the bar is 12.

- 2 levels of reinforcement, the interval between which is 70.

- The distance of the reinforcement from the sections of the concrete monolith is 50.

Calculation: 12 x 2 + 70 + 50 x 2 = 194.

Rounded - 20 cm. For example, this is the minimum thickness of a slab for a house made of aerated concrete. But subject to the construction of a monolithic foundation of shallow depth on good, dense soil. That is why it is advisable to entrust all calculations to a professional.

Construction order

1. Territory marking.

It is carried out after its complete cleaning in accordance with the construction scheme and in the most acceptable way - the "golden triangle", diagonally, etc.

2. Earthworks.

The depth of the pit is determined by the total thickness of the slab foundation and the "cushion". For the latter, this parameter is selected within 350 mm. If additional insulation of the base with Penoplex is expected, then the volume of soil removed will increase accordingly.

Regarding the structure of the "pillow" opinions are very different. There are recommendations to fill up the ASG, someone advises using sand interspersed with gravel. It should be noted that the less the backfill absorbs moisture from the soil, the longer the foundation will last. Based on this, it is preferable to pour coarse-grained sand under the monolith, compact its layer, and already on top - crushed stone, which is also compacted.

On a note! Before arranging the "cushion", the maximum compaction of the soil in the pit is mandatory. The reliability of a monolithic structure directly depends on this. In addition, it is desirable to line the bottom with geotextiles.

3. Installation of formwork.

If the foundation is shallow, then you can limit yourself to only narrow boards made of boards, which are laid out around the perimeter of the pit and knocked into a single structure. As an option - expanded polystyrene plates as a formwork of a fixed type.

4. Waterproofing.

In this case, it is advisable to use a monolithic canvas. Such seamless protection against moisture is much more effective than roll materials, the strips of which still have to be fastened together.

5. Thermal insulation layer.

Not necessarily, but when laying under the Penoplex monolith, the floors of the 1st floor will be much warmer.

6. Reinforcement.

The first mesh is not installed on waterproofing (insulation), but on special devices called "concrete protection". Their height determines the thickness of its layer from the reinforcement to the lower cut of the slab. On sale there are various options for such coasters, so picking up (or making your own) is not difficult.

7. Filling the solution.

There is nothing difficult in this operation, if something is foreseen in advance.

- When choosing concrete, you need to focus not only on its brand (not lower than 300), but also on the size of the filler fractions. The larger they are, the later it will be more difficult to compact the solution. And given the small thickness of the plate, this will have to be done manually.

- Work cannot be left the next day. The monolith is poured immediately, completely. Therefore, you will need at least 1 assistant, even if the foundation is small in size.

Aerated concrete is a popular material for individual construction. It is strong enough, reliable, easy to install and allows you to plan architectural delights. Aerated concrete cottage is considered a stone structure, and it needs a solid foundation. The question of which foundation will be better for building a house from blocks is very relevant. To understand this matter will help the recommendations of experts and reviews of practitioners.

What to consider when choosing

Throughout its existence, mankind has been looking for the most durable and convenient building materials. Aerated concrete block is an artificial porous stone, which is made from quartz sand, water and gas generators. A low-rise building made of this material is heavier than a wooden one, but lighter than a brick one. When choosing a base for a cottage, several factors should be considered:

- The approximate weight of the building, ceilings, roofs and future furnishings.

- Geological features of the site: soil heaving, groundwater level, soil freezing depth, depending on the climatic zone, plus the bearing capacity of the soil.

- Construction site relief.

Experts advise several types of proven bases that can withstand the weight of a block building:

- slab foundation;

- monolithic tape of different levels of penetration;

- column base.

We'll take a closer look at each of these options below.

Common mistakes when building a foundation

Usually a person learns from his mistakes, but in the case of the foundation, a tiny error can leave the owner without a new home. The most common mistakes are:

- Incorrectly calculated depth and width in the case of erecting the base in the form of a continuous tape. In the reviews, the owners of future homes complain that different builders recommend them different sizes of tape. In fact, real professionals consider the dimensions according to a well-known method, taking into account the resistance of the soil.

- Depth. It is logical to assume that if an aerated concrete building is lighter than a brick one, then the foundation for it is not built so deep. Error! Deepening depends on the level of groundwater.

- Independent construction without sufficient experience. The authors of the mass of articles and videos with the headings: “Do-it-yourself foundation” talk about the ease of work and offer to do everything yourself. Of course, you can try your hand at a sauna or barn. But any unaccounted for trifle during the construction of a two-story cottage can turn into unpleasant consequences.

Monolithic reinforced concrete slab

Solid slab construction is considered the most reliable solution for block building. It has a number of undeniable advantages that visitors to construction forums agree with:

- when the soil moves, the plate oscillates with it, protecting the house from deformation;

- such a foundation is stable on the most difficult soils and in any climatic zones.

On the reverse side of the medal are the following characteristics:

- long, laborious filling;

- the highest price of all existing types of base structures.

Advice. Under the block structure, the thickness of the foundation must be at least 40 cm, and 10 cm are in the ground, and 30 cm are the above-ground part. It is recommended to use 2 layers of waterproofing and 2 layers of reinforcing mesh with a thickness of reinforcing bars of 12 mm.

The construction technology involves the participation of 2-3 people and the use of special equipment:

- first they dig a pit, then pour a thin concrete slab;

- on it - waterproofing and wooden formwork with reinforcement;

- concrete is poured into the formwork with a solid slab in layers of 150 mm. At the same time, long temporary breaks between the next filling should not be allowed;

- each layer is leveled, then rammed with a bayonet shovel to remove air;

- formwork is removed after the entire mass of concrete has set.

Such a design should be defended from 3 to 6 months.

Strip foundation under the entire area of the house

Monolithic tape is considered the most economical design. The choice of its depth depends on the features of the structure. If you are planning a two-story mansion with a basement or basement, then the tape needs to be deepened by 1-1.5 m. For a one-story house of a small area, a shallow-depth structure is quite enough.

Attention! Work on the installation of the tape structure can only be carried out in the warm season. If it is necessary to pour the foundation in winter, use concrete heated by heat guns and thoroughly insulate the formwork.

Stages of construction of a shallow foundation:

- along the perimeter of the building and under all the ceilings specified in the project, a trench is dug 70-80 cm deep;

- a sand cushion is poured with a depth of 40-50 cm;

- a wooden formwork is knocked together, and reinforcement is attached to it with a distance between the bars of not more than 30 cm;

- the structure is filled with concrete.

The tape base for a building made of aerated concrete is excellent for erection even on fine and medium soils.

Column foundation for a building without a basement

The base of the columnar foundation, that is, the pillars, are installed at a level exceeding the depth of soil freezing. It is not recommended for use on weakly bearing, loose and heaving soils and on relief, uneven areas.

Attention! With any foundation design, it is very important to apply waterproofing, because aerated concrete perfectly absorbs moisture.

The number of necessary supports for the building is calculated, depending on the intersections of the partitions of the house. 4 posts go under corners, then one under each intersection and one (if necessary) at the points with the expected highest load. The maximum distance between the posts is made no more than 2.5 m.

The pillars themselves are made of brick, stone, concrete or reinforced concrete. Some practitioners advise building them with an extension downwards, which will provide maximum stability.

The pillars are installed vertically to a depth exceeding the freezing depth. It can be a meter or 1.5 m. The space between the supports is covered with sand, then the pillars are connected with a reinforced concrete belt.

Of the three types of foundation given, this design is considered the cheapest.

When performing any type of foundation in accordance with all the rules and building codes, an aerated concrete cottage will be stable, reliable and durable.

Foundation for a house made of aerated concrete