Alternative heating - biogas installation. Do-it-yourself biogas installation for gasification of the house Gas heating system for a private house using manure

Farms need fuel for heating systems, generating electricity and other daily needs. Since energy prices are steadily rising year after year, every home or small business owner has at least once thought about how to produce biogas at home.

Biogas plants are increasingly being used on farms, allowing them to save money on heatingA biogas plant for a private home allows you to organize the production of biogas right in your yard, which solves the fuel problem. Since a significant percentage of village residents have skills in working with welding and plumbing tools, the question of self-manufacturing a gas production plant seems logical. This way you can save not only on work, but also on materials if you use improvised means.

What is biogas and how is it formed: obtaining and production

Biogas is a substance formed during the fermentation of organic waste, which contains methane in sufficient quantities to be used as fuel. When burned, biogas releases heat, which is enough to heat a house or refuel a car. the source of energy is manure, which is easily accessible and cheap or even free if we are talking about a livestock enterprise or a large private farm.

Biogas is an environmentally friendly biofuel that you can produce with your own hands; biological gas is related to natural gas. The gas is produced by processing waste by anaerobic bacteria. Fermentation takes place in an airless container called a bioreactor. The rate of biogas production depends on the amount of waste loaded into the biogenerator. Under the influence of bacteria, a mixture of methane and carbon dioxide with some admixtures of other gaseous substances is released from the raw material. The resulting gas is removed from the bioreactor, purified and used for its own needs. The processed raw materials upon completion of the process become fertilizer, which is used to improve soil fertility. Producing biogas is beneficial for livestock enterprises that have access to free manure and other organic waste.

Benefits of burning fuel from manure (farm fertilizer) for heating: electricity from methane

The advantages of biogas as a fuel include:

- Efficient and environmentally friendly waste recycling

- Availability of raw materials for gas production in rural areas

- Possibility to organize a closed cycle of waste-free production of gas and fertilizers from manure

- Non-exhaustible, self-replenishing source of raw materials

How to build a bioreactor (installation) with your own hands

Biogas plants that produce gas from manure can be easily assembled with your own hands on your own site. Before assembling a bioreactor for processing manure, it is worth drawing drawings and carefully studying all the nuances, because a container containing a large amount of explosive gas can be a source of great danger if it is used incorrectly or if there are errors in the design of the installation.

Biogas production schemeThe capacity of the bioreactor is calculated based on the amount of raw material that is used to produce methane. In order for operating conditions to be optimal, the reactor capacity is filled with waste to at least two-thirds. For these purposes, a deep pit is used. To ensure high tightness, the walls of the pit are reinforced with concrete or reinforced with plastic, and sometimes concrete rings are installed in the pit. The surface of the walls is treated with moisture-proofing solutions. Tightness is a necessary condition for efficient operation of the installation. The better the container is insulated, the higher the quality and quantity. In addition, waste breakdown products are poisonous and, if leaked, can be harmful to health.

A stirrer is installed in the waste container. It is responsible for mixing waste during fermentation, preventing uneven distribution of raw materials and the formation of a crust. Following the mixer, a drainage structure is installed in the manure, which facilitates the removal of gas into the storage tank and prevents leakage. It is necessary to remove the gas for safety reasons, as well as to improve the quality of the fertilizers remaining in the reactor after processing. A hole is made in the bottom of the reactor for. The hole is equipped with a tight lid so that the equipment remains sealed.

How to ensure active fermentation of biomass at home using a generator and other equipment: waste processing, composition and extraction

In order for the processing process in a bioreactor to proceed faster, heating is necessary. The ambient temperature is sufficient for manure processing to occur without outside help. But under unfavorable weather conditions, in the winter, a mini-biogas plant needs an additional heat source, otherwise gas production becomes impossible. For bacteria to convert waste into gas, the temperature in the reactor must be above 38 degrees Celsius. It is not difficult to obtain biogas with your own hands; the main thing is to know certain manufacturing rules.

The container is heated using a coil, which is located under the reactor, or by installing electric heaters to directly heat the reservoir. , which process waste into gas, are already in the raw material. To activate microorganisms and start the process of biogas production, the temperature in the container must be sufficient for fermentation. To make it easier to control compliance with temperature conditions, automatic heating is connected to the reactor. It heats the container when fuel is loaded into it to the desired temperature and turns off the heating when the desired mark on the thermometer is reached. A temperature control device for, which is easy to find in a gas equipment store, can handle the role of an automatic heater.

Temperature control module. It can be purchased at any hardware storeCorrect gas removal from the bioreactor: drawings, use of technology

To easily remove the formed gas from the tank, biogas plants are equipped with a number of devices:

- Vertically arranged plastic pipes with a large number of holes to facilitate the separation of gas from the raw material. The top of the pipe should protrude above the waste mass, allowing gas to escape freely.

- A film laid over the container and creating a kind of greenhouse effect. It maintains the desired temperature inside the container and also prevents gas from mixing with air.

Sometimes the container is covered with a dome made of concrete or other material. To prevent such a dome from flying away under the pressure of the resulting gas, it is carefully attached to the structure and tied with cables.

- A gas exhaust pipe is placed at the top of the reactor. The pipe is equipped with a tight locking mechanism so as not to violate the tightness of the structure. The newly released biogas, entering the outlet pipe, is saturated with water vapor and contains many impurities. occurs by condensation: when cooled to ambient temperature, water settles in the form of condensation on the walls of the pipe. To avoid corrosion, the discharge pipe is installed in such a way as to facilitate the removal of condensate through the separator.

- To remove hydrogen sulfide impurities from biogas, a filter made of specially treated activated carbon is installed on its way to the storage facility, in which the mixture is oxidized into sulfur and deposited in the sorbent.

WATCH THE VIDEO

A self-assembled biogas plant, processing manure into biogas at home, significantly reduces heating and electricity costs. Such an installation will reduce the cost of providing a private home with heat, reduce the cost of farm products, thereby increasing the profitability of the farm. – the ability to turn waste into a source of energy and an alternative to natural gas. Biogas is environmentally friendly and modern.

On the farmstead of any farm you can use not only the energy of wind, sun, but also biogas.

Biogas- gaseous fuel, a product of anaerobic microbiological decomposition of organic substances. Biogas technologies are the most radical, environmentally friendly, waste-free method of processing, recycling and disinfection of a variety of organic waste of plant and animal origin.

Conditions for obtaining and energy value of biogas.

Those who want to build a small-sized biogas plant on their farmstead need to know in detail what raw materials and what technology can be used to produce biogas.

Biogas is obtained in the process of anaerobic (without air access) fermentation (decomposition) of organic substances (biomass) of various origins: bird droppings, tops, leaves, straw, plant stems and other organic waste from individual households. Thus, biogas can be produced from all household waste that has the ability to ferment and decompose in a liquid or wet state without access to oxygen. Anaerobic plants (fermenters) make it possible to process any organic mass during the process in two phases: decomposition of the organic mass (hydration) and its gasification.

The use of organic matter that has undergone microbiological decomposition in biogas plants increases soil fertility and the yield of various crops by 10-50%.

Biogas, which is released during the complex fermentation of organic waste, consists of a mixture of gases: methane (“swamp” gas) - 55-75%, carbon dioxide - 23-33%, hydrogen sulfide - 7%. Methane fermentation is a bacterial process. The main condition for its flow and biogas production is the presence of heat in the biomass without air access, which can be created in simple biogas plants. Installations are easy to build on individual farms in the form of special fermenters for fermenting biomass.

In homestead farming, the main organic raw material for loading into the fermenter is manure.

At the first stage of loading cattle manure into the fermenter container, the duration of the fermentation process should be 20 days, pig manure - 30 days. More gas is obtained when loading various organic components compared to loading only one component. For example, when processing cattle manure and poultry manure, biogas can contain up to 70% methane, which significantly increases the efficiency of biogas as a fuel. After the fermentation process has stabilized, raw materials should be loaded into the fermenter daily, but not more than 10% of the amount of mass processed in it. The recommended humidity of raw materials in summer is 92-95%, in winter - 88-90%.

In the fermenter, along with gas production, organic waste is disinfected from pathogenic microflora and the unpleasant odors released are deodorized. The resulting brown sludge is periodically discharged from the fermenter and used as fertilizer.

To heat the processed mass, the heat that is released during its decomposition in the biofermenter is used. When the temperature in the fermenter decreases, the intensity of gas evolution decreases, since microbiological processes in the organic mass slow down. Therefore, reliable thermal insulation of a biogas plant (biofermenter) is one of the most important conditions for its normal operation.

To ensure the required fermentation regime, it is recommended to mix the manure placed in the fermenter with hot water (preferably 35-40 °C). Heat losses must also be minimized during periodic reloading and cleaning of the fermenter. For better heating of the fermenter, you can use “ greenhouse effect" To do this, a wooden or light metal frame is installed above the dome and covered with plastic film. The best results are achieved at a temperature of the raw material that is being fermented, 30-32 ° C and a humidity of 90-95%. In the south of Ukraine, biogas plants can operate efficiently without additional heating of the organic mass in the fermenter. In the regions of the middle and northern zone, part of the gas produced must be spent during the cold periods of the year on additional heating of the fermented mass, which complicates the design of biogas plants. It is possible that after the first filling of the fermenter and the start of gas extraction, the latter does not burn. This is explained by the fact that the initially produced gas contains more than 60% carbon dioxide. In this case, it must be released into the atmosphere and after 1-3 days the biogas plant will operate in a stable manner.

When fermenting excrement from one animal, you can get per day: cattle (live weight 500-600 kg) - 1.5 cubic meters of biogas, pigs (live weight 80-100 kg) - 0.2 cubic meters, chicken or rabbit - 0.015 cubic meters.

In one day of fermentation, 36% of biogas is formed from cattle manure, and 57% from pork manure. In terms of energy, 1 cubic meter of biogas is equivalent to 1.5 kg of coal, 0.6 kg of kerosene, 2 kW/h of electricity, 3.5 kg of firewood, 12 kg of manure briquettes.

Biogas technologies have been widely developed in China; they are being actively implemented in a number of countries in Europe, America, Asia, and Africa. In Western Europe, for example in Romania and Italy, more than 10 years ago they began to widely use small-sized biogas plants with a volume of processed raw materials of 6-12 cubic meters.

Owners of homesteads and farms in Ukraine also began to show interest in such installations. On the territory of any estate it is possible to equip one of the simplest biogas plants, which, for example, are used in individual farms in Romania. According to those shown in Fig. 1-a, pit 1 and dome 3 are equipped according to the dimensions. The pit is lined with reinforced concrete slabs 10 cm thick, which are plastered with cement mortar and coated with resin for tightness. A bell 3 m high is welded from roofing iron, in the upper part of which biogas will accumulate. To protect against corrosion, the bell is periodically painted with two layers of oil paint. It is even better to first coat the inside of the bell with red lead.

In the upper part of the bell, a pipe 4 is installed for removing biogas and a pressure gauge 5 for measuring its pressure. The gas outlet pipe 6 can be made of a rubber hose, plastic or metal pipe.

Around the fermentation pit, a concrete groove-water seal 2 is installed, filled with water, into which the lower side of the bell is immersed to a depth of 0.5 m.

Gas can be supplied to the stove through metal, plastic or rubber tubes. To prevent pipes from breaking due to freezing of condensing water in winter, a simple device is used (Fig. 1-b): U-shaped tube 2 is connected to pipeline 1 at the lowest point. The height of its free part must be greater than the biogas pressure (in mm water column). Condensate 3 is drained through the free end of the tube, and there will be no gas leakage.

In the second installation option (Fig. 1-c), pit 1 with a diameter of 4 mm and a depth of 2 m is lined inside with roofing iron, the sheets of which are tightly welded. The inner surface of the welded tank is coated with resin for anti-corrosion protection. On the outside of the upper edge of the concrete tank, a circular groove 5 up to 1 m deep is installed, which is filled with water. The vertical part of the dome 2, covering the tank, is freely installed into it. Thus, the groove with water poured into it serves as a water seal. Biogas is collected in the upper part of the dome, from where it is supplied through the outlet pipe 3 and then through pipeline 4 (or hose) to the place of use.

About 12 cubic meters of organic mass (preferably fresh manure) is loaded into round tank 1, which is filled with the liquid fraction of manure (urine) without adding water. A week after filling, the fermenter starts working. In this installation, the fermenter capacity is 12 cubic meters, which makes it possible to build it for 2-3 families whose houses are located nearby. Such an installation can be built on a farmstead if the family rears bulls on contract or keeps several cows.

The design and technological diagrams of the simplest small-sized installations are shown in Fig. 1-d, d, f, g. Arrows indicate technological movements of the initial organic mass, gas, and sludge. Structurally, the dome can be rigid or made of polyethylene film. The rigid dome can be made with a long cylindrical part for deep immersion into the processed mass, “floating” (Fig. 1-d) or inserted into a hydraulic valve (Fig. 1-e). A film dome can be inserted into a water seal (Fig. 1-e) or made in the form of a one-piece glued large bag (Fig. 1-g). In the latter version, a weight 9 is placed on the film bag so that the bag does not swell too much, and also to create sufficient pressure under the film.

The gas, which is collected under the dome or film, is supplied through a gas pipeline to the place of use. To avoid a gas explosion, a valve adjusted to a certain pressure can be installed on the outlet pipe. However, the danger of a gas explosion is unlikely, since with a significant increase in gas pressure under the dome, the latter will be raised in the hydraulic seal to a critical height and will tip over, releasing the gas.

Biogas production may be reduced due to the fact that a crust forms on the surface of the organic raw material in the fermenter during fermentation. To ensure that it does not interfere with the escape of gas, it is broken by mixing the mass in the fermenter. You can mix not by hand, but by attaching a metal fork to the dome from below. The dome rises in the hydraulic seal to a certain height when gas accumulates and lowers as it is used.

Due to the systematic movement of the dome from top to bottom, the forks connected to the dome will destroy the crust.

High humidity and the presence of hydrogen sulfide (up to 0.5%) contribute to increased corrosion of metal parts biogas plants. Therefore, the condition of all metal elements of the fermenter is regularly monitored and places of damage are carefully protected, preferably with lead lead in one or two layers, and then painted in two layers with any oil paint.

Rice. 1. Schemes of the simplest biogas plants:

A). with a pyramidal dome: 1 - pit for manure; 2 - groove-water seal; 3 - bell for collecting gas; 4, 5 - gas outlet pipe; 6 - pressure gauge;

b). device for condensate removal: 1 - pipeline for gas removal; 2 - U-shaped pipe for condensate; 3 - condensate;

V). with a conical dome: 1 - pit for manure; 2 - dome (bell); 3 - expanded part of the pipe; 4 - gas outlet pipe; 5 - groove-water seal;

d, e, f, g - diagrams of variants of the simplest installations: 1 - supply of organic waste; 2 - container for organic waste; 3 - gas collection area under the dome; 4 - gas outlet pipe; 5 - sludge removal; 6 - pressure gauge; 7 - dome made of polyethylene film; 8 - water seal; 9 - load; 10 - one-piece polyethylene bag.

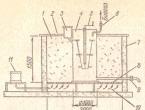

Biogas plant with heating of the fermentable mass by the heat released during the decomposition of manure in an aerobic fermenter, is shown in Fig. 2, includes a methane tank - a cylindrical metal container with a filler neck 3, a drain valve 9, a mechanical stirrer 5 and a biogas selection pipe 6.

Fermenter 1 can be made rectangular from wooden materials. To unload treated manure, the side walls are removable. The floor of the fermenter is lattice; air is blown through the technological channel 10 from a blower 11. The top of the fermenter is covered with wooden panels 2. To reduce heat loss, the walls and bottom are made with a heat-insulating layer 7.

The installation works like this. Pre-prepared liquid manure with a moisture content of 88-92% is poured into the methane tank 4 through Head 3, the liquid level is determined by the lower part of the filler neck. Aerobic fermenter 1 is filled through the upper opening part with bedding manure or a mixture of manure with loose dry organic filler (straw, sawdust) with a moisture content of 65-69%. When air is supplied through the technological channel in the fermenter, the organic mass begins to decompose and heat is released. It is enough to heat the contents of the methane tank. As a result, biogas is released. It accumulates in the upper part of the digester tank. Through pipe 6 it is used for domestic needs. During the fermentation process, the manure in the digester is mixed with a mixer 5.

Such an installation will pay for itself within a year only due to waste disposal in personal households.

Rice. 2. Diagram of a heated biogas plant:

1 - fermenter; 2 - wooden shield; 3 - filler neck; 4 - methane tank; 5 - stirrer; 6 - pipe for biogas sampling; 7 - thermal insulation layer; 8 - grate; 9 - drain valve for processed mass; 10 - channel for air supply; 11 - blower.

Individual biogas plant(IBGU-1) for a peasant family with 2 to 6 cows or 20-60 pigs, or 100-300 poultry (Fig. 3). The installation can process from 100 to 300 kg of manure every day and produces 100-300 kg of environmentally friendly organic fertilizers and 3-12 cubic meters of biogas.

To cook food for a family of 3-4 people, it is necessary to burn 3-4 cubic meters of biogas per day, to heat a house with an area of 50-60 sq.m - 10-11 cubic meters. The installation can operate in any climate zone. The Tula Stroytekhnika plant and the Orlovsky repair and mechanical plant (Orel) began their serial production.

Rice. 3. Scheme of an individual biogas plant IBGU-1:

1 - filler neck; 2 - stirrer; 3 - gas sampling pipe; 4 - thermal insulation layer; 5 - pipe with a tap for unloading processed mass; 6 - thermometer.

The technology is not new. It began to develop back in the 18th century, when Jan Helmont, a chemist, discovered that manure emits gases that are flammable.

His research was continued by Alessandro Volta and Humphrey Davy, who found methane in the gas mixture. At the end of the 19th century in England, biogas from manure was used in street lamps. In the mid-20th century, bacteria were discovered that produce methane and its precursors.

The fact is that three groups of microorganisms alternately work in manure, feeding on the waste products of previous bacteria. The first to start working are acetogenic bacteria, which dissolve carbohydrates, proteins and fats in the slurry.

After processing the nutrient supply by anaerobic microorganisms, methane, water and carbon dioxide are formed. Due to the presence of water, biogas at this stage is not able to burn - it needs purification, so it is passed through treatment facilities.

What is biomethane

The gas obtained as a result of the decomposition of manure biomass is an analogue of natural gas. It is almost 2 times lighter than air, so it always rises. This explains the artificial production technology: free space is left at the top so that the substance can be released and accumulate, from where it is then pumped out for use for one’s own needs.

Methane greatly influences the greenhouse effect - much more than carbon dioxide - 21 times. Therefore, manure processing technology is not only an economical, but also an environmentally friendly way to dispose of animal waste.

Biomethane is used for the following needs:

- cooking;

- in internal combustion engines of automobiles;

- for heating a private house.

Biogas produces a large amount of heat. 1 cubic meter is equivalent to burning 1.5 kg of coal.

How is biomethane produced?

It can be obtained not only from manure, but also algae, plant matter, fat and other animal waste, and residues from the processing of raw materials from fish shops. Depending on the quality of the source material and its energy capacity, the final yield of the gas mixture depends.

The minimum amount of gas obtained is 50 cubic meters per ton of cattle manure. Maximum - 1,300 cubic meters after processing animal fat. The methane content is up to 90%.

One type of biological gas is landfill gas. It is formed during the decomposition of garbage in suburban landfills. The West already has equipment that processes waste from the population and turns it into fuel. As a type of business, it has unlimited resources.

Its raw material base includes:

- food industry;

- livestock farming;

- poultry farming;

- fisheries and processing plants;

- dairies;

- production of alcoholic and low-alcohol drinks.

Any industry is forced to dispose of its waste - it is expensive and unprofitable. At home, with the help of a small homemade installation, you can solve several problems at once: free heating of the house, fertilizing the land with high-quality nutrients left over from manure processing, freeing up space and eliminating odors.

Biofuel production technology

All bacteria that take part in the formation of biogas are anaerobic, that is, they do not need oxygen to function. To do this, completely sealed fermentation containers are constructed, the outlet pipes of which also do not allow air from the outside to pass through.

After pouring the raw liquid into the tank and raising the temperature to the required value, the bacteria begin to work. Methane begins to be released, which rises from the surface of the slurry. It is sent to special pillows or tanks, after which it is filtered and ends up in gas cylinders.

The liquid waste from bacteria accumulates at the bottom, from where it is periodically pumped out and also sent for storage. After this, a new portion of manure is pumped into the tank.

Temperature regime of bacteria functioning

To process manure into biogas, it is necessary to create suitable conditions for bacteria to work. some of them are activated at temperatures above 30 degrees - mesophilic. At the same time, the process is slower and the first product can be obtained after 2 weeks.

Thermophilic bacteria work at temperatures from 50 to 70 degrees. The time required to obtain biogas from manure is reduced to 3 days. In this case, the waste is a fermented sludge that is used in the fields as fertilizer for agricultural crops. There are no pathogenic microorganisms, helminths and weeds in the sludge, as they die when exposed to high temperatures.

There is a special type of thermophilic bacteria that can survive in an environment heated to 90 degrees. They are added to raw materials to speed up the fermentation process.

A decrease in temperature leads to a decrease in the activity of thermophilic or mesophilic bacteria. In private households, mesophylls are more often used, since they do not require special heating of the liquid and gas production is cheaper. Subsequently, when the first batch of gas is received, it can be used to heat the reactor with thermophilic microorganisms.

Important! Methanogens do not tolerate sudden changes in temperature, so in winter they must be kept warm at all times.

How to prepare raw materials for pouring into the reactor

To produce biogas from manure, there is no need to specially introduce microorganisms into the liquid, because they are already found in animal excrement. You just need to maintain the temperature and add a new manure solution in time. It must be prepared correctly.

The humidity of the solution should be 90% (the consistency of liquid sour cream), Therefore, dry types of excrement are first filled with water - rabbit droppings, horse droppings, sheep droppings, goat droppings. Pig manure in its pure form does not need to be diluted, as it contains a lot of urine.

The next step is to break down the manure solids. The finer the fraction, the better the bacteria will process the mixture and the more gas will be released. For this purpose, the installations use a stirrer that is constantly running. It reduces the risk of a hard crust forming on the surface of the liquid.

Those types of manure that have the highest acidity are suitable for biogas production. They are also called cold - pork and cow. A decrease in acidity stops the activity of microorganisms, so it is necessary to monitor at the beginning how long it takes for them to completely process the volume of the tank. Then add the next dose.

Gas purification technology

When processing manure into biogas, the following is obtained:

- 70% methane;

- 30% carbon dioxide;

- 1% impurities of hydrogen sulfide and other volatile compounds.

In order for biogas to become suitable for use on the farm, it must be cleaned of impurities. To remove hydrogen sulfide, special filters are used. The fact is that volatile hydrogen sulfide compounds, dissolving in water, form acid. It contributes to the appearance of rust on the walls of pipes or tanks if they are made of metal.

- The resulting gas is compressed under a pressure of 9–11 atmospheres.

- It is fed into a reservoir of water, where impurities are dissolved in the liquid.

On an industrial scale, lime or activated carbon, as well as special filters, are used for cleaning.

How to reduce moisture content

There are several ways to get rid of water impurities in gas yourself. One of them is the principle of a moonshine still. The cold pipe directs the gas upward. The liquid condenses and flows down. To do this, the pipe is laid underground, where the temperature naturally decreases. As it rises, the temperature also rises, and the dried gas enters the storage facility.

The second option is a water seal. After exiting, the gas enters a container with water and is cleaned of impurities there. This method is called one-stage, when biogas is immediately cleaned from all volatile substances and moisture using water.

Water seal principle

Water seal principle

What installations are used to produce biogas?

If the installation is planned to be located near a farm, then the best option would be a collapsible structure that can be easily transported to another location. The main element of the installation is a bioreactor into which raw materials are poured and the fermentation process occurs. Large enterprises use tanks volume 50 cubic meters.

In private farms, underground reservoirs are built as a bioreactor. They are laid out of brick in a prepared pit and coated with cement. Concrete increases the safety of the structure and prevents air from entering. The volume depends on how much raw material is obtained from domestic animals per day.

Surface systems are also popular at home. If desired, the installation can be disassembled and moved to another location, unlike a stationary underground reactor. Plastic, metal or polyvinyl chloride barrels are used as tanks.

By type of control there are:

- automatic stations in which the filling and pumping out of waste raw materials is carried out without human intervention;

- mechanical, where the entire process is controlled manually.

Using a pump, you can facilitate the emptying of the tank into which the waste after fermentation falls. Some craftsmen use pumps to pump gas from cushions (for example, car inner tubes) into a treatment facility.

Scheme of a homemade installation for producing biogas from manure

Before constructing a biogas plant on your site, you need to become familiar with the potential hazards that could cause the reactor to explode. The main condition is the absence of oxygen.

Methane is an explosive gas and can ignite, but to do so it must be heated above 500 degrees. If biogas mixes with air, overpressure will arise, which will rupture the reactor. Concrete may crack and will not be suitable for further use.

Video: Biogas from bird droppings

To prevent the pressure from tearing off the lid, use a counterweight, a protective gasket between the lid and the tank. The container is not completely filled - there should be at least 10% volume for gas release. Better - 20%.

So, to make a bioreactor with all the accessories on your site, you need to:

- It is good to choose a place so that it is located away from housing (you never know).

- Calculate the estimated amount of manure that animals produce daily. How to count - read below.

- Decide where to lay the loading and unloading pipes, as well as a pipe for condensing moisture in the resulting gas.

- Decide on the location of the waste tank (fertilizer by default).

- Dig a pit based on calculations of the amount of raw materials.

- Select a container that will serve as a reservoir for manure and install it in the pit. If a concrete reactor is planned, then the bottom of the pit is filled with concrete, the walls are lined with bricks and plastered with concrete mortar. After this, you need to give it time to dry.

- The connections between the reactor and the pipes are also sealed at the stage of laying the tank.

- Equip a hatch for inspection of the reactor. A sealed gasket is placed between it.

If the climate is cold, then before concreting or installing a plastic tank, consider ways to heat it. These can be heating devices or tape used in “warm floor” technology.

At the end of the work, check the reactor for leaks.

Gas quantity calculation

From one ton of manure you can get approximately 100 cubic meters of gas. Question: How much litter do pets produce per day?

- chicken – 165 g per day;

- cow – 35 kg;

- goat – 1 kg;

- horse – 15 kg;

- sheep – 1 kg;

- pig – 5 kg.

Multiply these figures by the number of heads and you get the daily dose of excrement to be processed.

More gas comes from cows and pigs. If you add energetically powerful plants such as corn, beet tops, and millet to the mixture, the amount of biogas will increase. Marsh plants and algae have great potential.

The highest is for waste from meat processing plants. If there are such farms nearby, then we can cooperate and install one reactor for everyone. The payback period for a bioreactor is 1–2 years.

Biomass waste after gas production

After processing manure in a reactor, the by-product is biosludge. During anaerobic processing of waste, bacteria dissolve about 30% of organic matter. The rest is released unchanged.

The liquid substance is also a by-product of methane fermentation and is also used in agriculture for root feeding.

Carbon dioxide is a waste fraction that biogas producers strive to remove. But if you dissolve it in water, then this liquid can also be beneficial.

Full utilization of biogas plant products

In order to completely utilize the products obtained after processing manure, it is necessary to maintain a greenhouse. Firstly, organic fertilizer can be used for year-round cultivation of vegetables, the yield of which will be stable.

Secondly, carbon dioxide is used as fertilizing - root or foliar, and its output is about 30%. Plants absorb carbon dioxide from the air and at the same time grow better and gain green mass. If you consult with specialists in this field, they will help you install equipment that converts carbon dioxide from liquid form into a volatile substance.

Video: Biogas in 2 days

The fact is that to maintain a livestock farm, the energy resources obtained can be a lot, especially in the summer, when heating the barn or pigsty is not needed.

Therefore, it is recommended to engage in another profitable activity - an environmentally friendly greenhouse. Remaining products can be stored in refrigerated rooms - using the same energy. Refrigeration or any other equipment can run on electricity generated by a gas battery.

Use as fertilizer

In addition to producing gas, the bioreactor is useful because the waste is used as a valuable fertilizer, which retains almost all nitrogen and phosphates. When manure is added to the soil, 30–40% of nitrogen is irretrievably lost.

To reduce the loss of nitrogen substances, fresh excrement is added to the soil, but then the released methane damages the root system of plants. After processing the manure, the methane is used for its own needs, and all nutrients are preserved.

After fermentation, potassium and phosphorus pass into a chelated form, which is absorbed by plants by 90%. If you look at it in general, then 1 ton of fermented manure can replace 70 - 80 tons of ordinary animal excrement.

Anaerobic processing preserves all the nitrogen present in manure, converting it into ammonium form, which increases the yield of any crop by 20%.

This substance is not dangerous for the root system and can be applied 2 weeks before planting crops in open ground, so that the organic matter has time to be processed by soil aerobic microorganisms.

Before use, the biofertilizer is diluted with water. in a ratio of 1:60. Both dry and liquid fractions are suitable for this, which after fermentation also goes into the waste raw material tank.

Per hectare you need from 700 to 1,000 kg/l of undiluted fertilizer. Considering that from one cubic meter of reactor area up to 40 kg of fertilizers are obtained per day, in a month you can provide not only your own plot, but also your neighbor’s, by selling organic matter.

What nutrients can be obtained after manure processing?

The main value of fermented manure as a fertilizer is the presence of humic acids, which, like a shell, retain potassium and phosphorus ions. Oxidizing in air during long-term storage, microelements lose their beneficial qualities, but during anaerobic processing, on the contrary, they gain.

Humates have a positive effect on the physical and chemical composition of the soil. As a result of adding organic matter, even the heaviest soils become more permeable to moisture. In addition, organic matter provides food for soil bacteria. They further process the residues that have not been eaten by anaerobes and release humic acids. As a result of this process, plants receive nutrients that are completely absorbed.

In addition to the main ones - nitrogen, potassium and phosphorus - the biofertilizer contains microelements. But their quantity depends on the source material - plant or animal origin.

Sludge storage methods

It is best to store fermented manure dry. This makes it more convenient to pack and transport. The dry substance loses less useful properties and can be stored closed. Although such fertilizer does not deteriorate at all over the course of a year, it must then be sealed in a bag or container.

Liquid forms must be stored in closed containers with a tight-fitting lid to prevent nitrogen from escaping.

The main problem of biofertilizer producers is marketing in winter, when plants are dormant. On the world market, the cost of fertilizers of this quality fluctuates around $130 per ton. If you set up a line for packaging concentrates, you can pay for your reactor within two years.

Did you like the article? Share with your friends:

Hello, dear readers! I am the creator of the Fertilizers.NET project. I am glad to see each of you on its pages. I hope the information from the article was useful. Always open to communication - comments, suggestions, what else you want to see on the site, and even criticism, you can write to me on VKontakte, Instagram or Facebook (round icons below). Peace and happiness to everyone! 🙂

You may also be interested in reading:

A DIY biogas plant can be done without much effort. Its use will allow significant savings on energy resources, which today are becoming more and more expensive every time. If you independently decide to build equipment that allows you to obtain biogas from waste, you will be able to consume cheap energy, which will be used for heating your home and other needs.

Beneficial use

If during the operation of the installation excess biogas or fertilizers are generated, then it is possible to sell them at the market price, thereby turning what is literally lying under your feet into profit. If you are a large farmer, then you have the opportunity to purchase a ready-made biogas production station. Such factory-produced installations are very expensive, but have a long lifespan.

A do-it-yourself biogas plant can be made from scrap materials, it will not cost very much, and such equipment will work on the same principle. In this case, you can use available tools, as well as parts available in the master’s arsenal.

Principle of biogas formation

If you set out to make a plant that will run on biological gas, then you need to present the technology for the generation of biogas. So, in a special container, which is called a bioreactor, the process of processing biological mass is carried out, and anaerobic bacteria take part in this.

A do-it-yourself biogas plant for home using quail droppings works on the principle of creating conditions that are characterized by the absence of air and fermentation. All this lasts for some time, the duration of which depends on the amount of raw materials used in the process.

Ultimately, a mixture of gases is formed, which contains 60% methane and 35% carbon dioxide. The remaining gaseous components are contained in the mass in an amount of 5%. Among the latter, hydrogen sulfide can be isolated in small quantities. The gas thus formed is continuously removed from the reactor, and after undergoing a purification process, it is used for its intended purpose.

Service Features

Waste that has undergone processing becomes high-quality fertilizers, which from time to time must be removed from the bioreactor. They can be laid on the fields. A DIY biogas plant can be done without much effort if you have access to livestock and agricultural facilities. This indicates that the production of biogas will become economically profitable only if there is a source of supply of manure and other organic waste from livestock production.

Features of self-construction of a bioreactor

In order to understand how to make a biogas plant yourself, you need to understand what parts it consists of. You can take as a basis the simplest diagram of equipment that you can build on your own. The design does not provide heating and a mixing device, but there is one of the main parts - a reactor, which is also known as a digester. This component is required for manure processing. In addition, there is a bunker through which raw materials are loaded. It is necessary to equip the structure with an entrance hatch, as well as a water seal. But in order to be able to unload waste raw materials, a pipe will be needed. A similar element will be required in order to realize the possibility of removing biogas.

This is what the diagram of a biogas plant looks like. It is not difficult to make such a design with your own hands. In order to receive free biological fuel, you should choose a place on the site where you can build a reinforced container, which will be based on concrete. This vessel will act as a bioreactor. At its base, it is necessary to provide a hole through which processed raw materials will be removed. This hole must be made in such a way that it can be closed well. This is due to the fact that the system can only operate in sealed conditions.

The dimensions of the concrete compartment can be determined taking into account the amount of organic waste used at a time. You need to find out how much raw material will appear on a farm or private farm every day. But you should not save, since it will be possible to ensure full operation of the bioreactor only if the tank is filled to 2/3 of the available volume. If you make a biogas plant with your own hands from a barrel, it will work according to the following principle: as soon as organic waste enters a well-closed bioreactor container, which is located deep in the soil, it begins to ferment, which leads to the release of biogas.

Features of container manufacturing

A DIY biogas plant can be made taking into account the daily use of a small amount of waste. In this case, it is permissible to replace the reinforced concrete tank with a steel container, which can even be a barrel. If you decide to resort to just such a solution, then you need to choose a metal vessel, guided by certain rules.

First of all, you need to pay attention to the welds, which must be strong enough and airtight. When using a small container, you should not expect to obtain a significant amount of biogas. The yield will depend on the mass of organic waste that is simultaneously processed in the reactor. Thus, in order to generate 100 m 3 of biogas, it is necessary to process a ton of waste.

Reactor heating equipment

A do-it-yourself biogas plant for the home can be made in such a way that its operation can be more efficient. This is ensured by heating. Such manipulations will speed up the process of fermentation of biological mass. If the equipment is installed in the southern regions, then such a need does not arise. The ambient temperature provides natural activation of fermentation. However, if the installation operates in regions with a cold climate, then in winter heating acts as a necessary condition for the operation of biogas production equipment. It must be remembered that the fermentation process begins at a temperature that exceeds 38 o C.

Methods for equipping a biogas plant with heating

A do-it-yourself biogas plant for your home can be equipped with heating using several methods. The first involves the need to connect the installation to a heating system using a coil type. It must be mounted under the reactor. The second method involves installing an electric heating element at the base of the tank. The third method is characterized by providing direct heating of the tank by using electric heating systems and gas equipment. Activation of biological gas production at home can be supplemented with the function of mixing the mass in the compartment. To do this, you should design a device that resembles a household mixer. It will be driven by a shaft brought out through a hole in the lid; as an alternative solution, it can be placed in the walls of the tank.

Equipment of the installation with an output system

A mini biogas plant, designed with your own hands, cannot operate without a gas exhaust system. To do this, the installation must have a special hole, which must be mounted in the upper part of the lid, the latter must cover the tank well. To eliminate the possibility of gas mixing with air, it is necessary to ensure its removal through a water seal.

Removal, processing and disposal of waste from hazard classes 1 to 5

We work with all regions of Russia. Valid license. A complete set of closing documents. Individual approach to the client and flexible pricing policy.

Using this form, you can submit a request for services, request a commercial offer, or receive a free consultation from our specialists.

It is not easy for farms to dispose of manure. It is produced in excess, and a lot of money has to be spent on removal and disposal. In small private farms, manure is actively used as a free and effective fertilizer. It turns out that there is another way to usefully use this raw material, which makes it possible to obtain natural gas.

Many farms are already producing biogas from manure, using environmentally friendly technology that allows them to obtain a valuable product. Biomethane from manure is of high quality, which is why it is used in many countries.

What is biogas

Biogas from manure is an environmentally friendly fuel. According to its characteristics, it is close to natural gas, which is extracted from the bowels of the earth industrially.

Biogas can be an alternative to conventional fuel, because it is made from the waste of animals and birds, which can be found in abundance in any agriculture. With proper processing of raw materials, you can obtain colorless biogas without a characteristic odor, which contains at least 70% methane.

Biogas has good characteristics. One cubic meter of such fuel from manure produces the same amount of heat as one and a half kg of coal.

Process Benefits

Manure was processed to produce biogas back in Soviet times. Today, many countries are engaged in this type of industry, as it is profitable, easy and does not pose a threat to the environment.

Such alternative biogas does not require labor-intensive extraction of raw materials for production, the process of its creation is relatively cheap, and no toxic substances are released into the environment.

Of course, manure can be used simply as fertilizer if there are only a few cows on the farm. It is much more difficult for large farmers with hundreds of heads of livestock, because every year they have to get rid of several tons of manure.

In order for manure to become a high-quality fertilizer, it must be stored at a controlled temperature. But this requires extra expenses, so most farmers simply collect it in a certain place and then transport it to arable land.

If stored improperly, manure loses almost half of the nitrogen compounds in it and most of the phosphorus, so its performance becomes much worse. Methane gas is continuously released into the atmosphere from manure, which worsens the environmental situation.

The latest technologies for producing biomethane make it possible to process raw materials in such a way that the resulting biogas does not have a toxic effect on the environment. Biogas releases an incredible amount of energy when burned, and heated manure, after its use, becomes a very valuable anaerobic fertilizer.

Biogas technology

Biogas can be produced using bacteria, which do not require oxygen to function. Therefore, to produce biogas, it is necessary to build sealed containers in which the fermentation of raw materials will occur. The exhaust pipes are designed in containers in such a way that air from the external environment is not able to leak inside.

First, the reservoir is filled with liquid raw materials and the temperature is raised to the required level so that the world organisms begin to work. Methane rises up from liquid manure and accumulates in special tanks in which it undergoes a filtration stage. Then it is collected in gas cylinders. Used masses of manure accumulate at the bottom of containers, from where they are periodically removed and stored in other places. After pumping out the waste liquid, new manure is supplied to the tank.

Temperature regime of bacteria functioning

Methane can be released from manure only when a suitable temperature regime is created for it. Manure contains different bacteria that are activated and release biogas at different temperatures and at different speeds:

- Mesophilic bacteria. They start working if the ambient temperature rises above 30 degrees. Biogas is produced very slowly - the products can be collected after half a month.

- Thermophilic bacteria. To activate them, a temperature of 50-65 degrees is required. Biogas can be collected in just three days. Of particular value is sludge - manure waste after strong heating. This is a useful fertilizer and, most importantly, harmless - any helminths, weed seeds, pathogenic microorganisms are destroyed when heated.

- There is also another type of thermophilic bacteria that survive when heated to a temperature of 90 degrees. They are additionally included in manure so that fermentation occurs faster.

As temperatures drop, all types of bacteria become less active. In a small farm, mesophylls are usually used, because in this case additional heating is not required. Further, primary biogas can be used to artificially heat manure and activate thermophilic bacteria.

The disadvantage of storing raw materials is that they should not be subject to temperature fluctuations. Therefore, in winter, it is necessary to take care of a warm room for storing manure.

Preparation of raw materials for pouring into the reactor

As a rule, there is no need to further enrich manure with microorganisms, since they are already contained in it. All that needs to be done is to properly prepare the manure solution, monitor the temperature and change the raw materials in the bioreactor on time.

The moisture content of the raw materials should be at least 90% (the consistency of liquid sour cream). Therefore, before use, dry droppings (goats, sheep, horses, rabbits) are mixed with water. There is no need to dilute pig manure due to its high urine content.

It is also important that the manure is homogeneous and free of solid particles. The amount of biogas produced at the outlet depends on the fineness of the fractions. For this reason, a constantly running mixer is installed inside the equipment, destroying the hard crust on the surface of the raw material and preventing the release of methane.

Highly acidic waste (pig and cow manure) is best suited for the process. When the acidity level decreases, the bacteria slow down their work, so it is important to find out for the first time how long it takes to completely process one portion of the manure solution, and only then refill it.

The resulting product contains about seventy percent methane, one percent impurities (hydrogen sulfide and some volatile elements) and just under thirty percent carbon dioxide.

It can be used as fuel only after purification from impurities. Hydrogen sulfide compounds are removed using special filters. This must be done for the reason that such a substance, forming an acid with water, accelerates the corrosion processes of metals, pipes, tanks and the entire biogas plant, if it is metal.

Carbon dioxide also needs to be removed from the fuel, but this takes a lot of time:

- First of all, biogas is compressed under high pressure.

- Water is sent into the container, in which the impurity will dissolve.

If biogas is produced on a large scale, then purification is carried out with lime, activated carbon and special filters.

Reducing moisture content

At this stage, the purification of raw materials is carried out in different ways.

The first method is similar to the operation of a moonshine still. Biogas is directed upward through cold tubes. The water turns into condensate and flows down the tube, while the methane is sent to a reservoir for further storage.

Another way is to use a water seal. The resulting biogas is mixed with water, where all impurities remain. This method requires less time for cleaning, since water gets rid of both excess liquid and unnecessary elements.

For the manufacture of an installation near farms, a design that can subsequently be easily disassembled and moved to another area is best suited. The main equipment of the entire installation is a bioreactor - a container for pouring manure and fermenting it. Large enterprises use tanks of 50 cubic meters.

Small private farms use an underground reservoir instead of tanks. It is laid out with bricks in a dug hole. For tightness and strength, everything is fixed with cement mass. The volume depends on the amount of manure produced daily.

For above-ground installation, tanks made of plastic, metal or polyvinyl chloride can be used.

Installations can be either automated (in which the entire process occurs without human intervention) or mechanical (you must pump out, add raw materials, take in biogas, monitor pressure and temperature yourself).

On a small farm, it is advisable to use electric pumps, mixers, and grinders, which will prevent the appearance of crusts on the surface of manure and clean the structure of waste.

The most important rule is the absence of oxygen in the reactor. If present, an explosion may occur.

To prevent the reactor lid from being blown off by high pressure, counterweights and protective gaskets between the tanks and lids are needed.

The reservoir should never be completely full. It is advisable to leave a fifth of its volume unfilled.

At the site before installation, the equipment must:

- choose the right location (preferably as far as possible from a residential building)

- calculate the daily volumes of manure produced

- select a location for pipes (shipping, loading, condensing)

- find a place for manure waste

- dig a pit

- purchase a container for the tank and secure it to the bottom of the pit

- seal all joints

- construct a hatch for inspecting the reactor (be sure to place a gasket between the hatch and the reactor)

If the installation takes place in a cold climate, then you should definitely consider ways to heat it.

The final stage of construction is checking the equipment for leaks.

Gas quantity calculation

On average, a ton of manure will provide the owner with hundreds of cubic meters of biogas. In order to calculate the amount of biogas produced, it is necessary to multiply the daily mass of manure from each livestock by the number of animals.

Naturally, different animals and birds produce different amounts of manure:

- poultry (primarily chickens) – 150-170 g per day

- cow - 34-36 kg

- goat – 900 – 1100 g

- horse – 14-16 kg

- sheep – 900 – 1100 g

- pig – 4-6 kg

Pig and cow manure provides more fuel. The amount of biogas released can be increased by adding millet, beet tops, marsh plants, algae or corn to the mixture (the presence of chlorophyll in biomass improves methane release).

Biomass waste after gas production

The sludge formed after heating manure is used throughout agriculture in the form of fertilizers.

The carbon dioxide produced is usually purified, but when it is dissolved in water, a useful liquid is obtained.

Full utilization of biogas plant products

With rational use of manure, there may be no waste at all after the formation of biogas. For example, carbon dioxide is used as a fertilizer for vegetable crops.

The sludge is also used for root feeding.

Therefore, if you have a small installation for the production of biogas, it will be useful to install a biogreenhouse, which, due to fertilizers and the resulting energy, can operate all year round.