Torque and torque of the bolt. Tightening with a torque wrench - moments of effort. Torque wrench rules

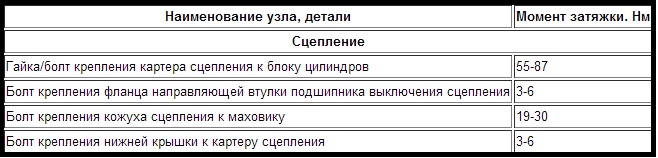

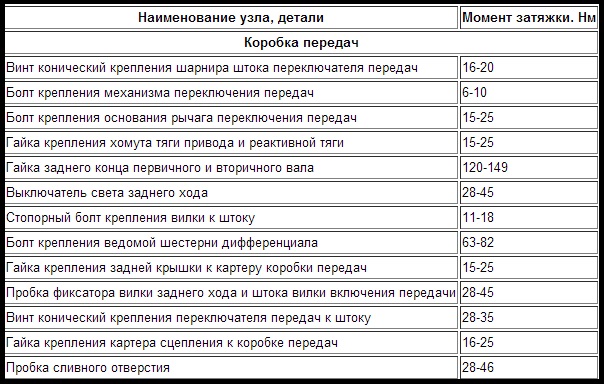

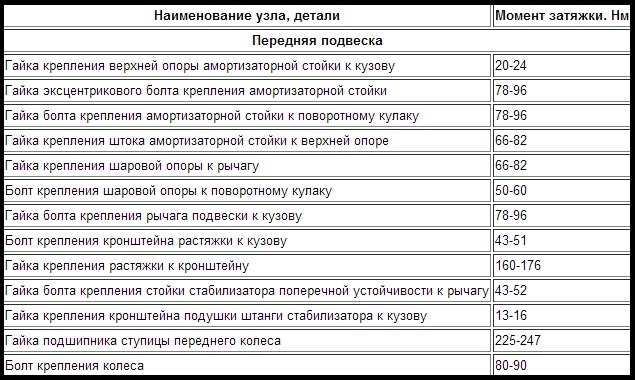

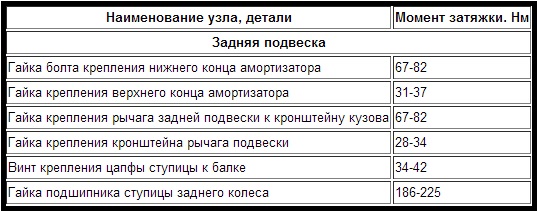

I think that many are aware that the majority of those responsible threaded connections By car, Lada Kalina must meet a specific tightening torque. That is, each such bolt or nut must be tightened with a certain force. This is necessary in order to:

- Do not twist the thread, as it often happens in the practice of domestic car owners. And then many are used to pulling with all their might, without thinking about the consequences. Incidentally, I also sometimes pulled with some force fastening some components and parts that often had to change the bolts and nuts due to the rolled thread.

- Secondly, so that the connection is twisted sufficiently rigidly and spontaneous unscrewing does not occur.

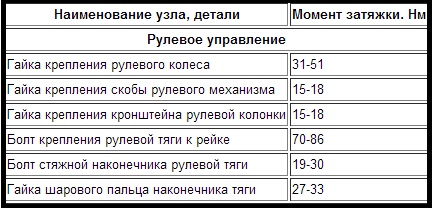

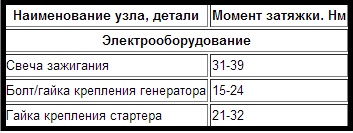

Until recently, there was no need for tightening torques for me, but after that these data became relevant for me. I hope that they will be useful to many other owners of Kalina. I recently found a table on the Internet, and in many manuals it is, but in order not to send my regular readers to another resource, I decided to post it here. I think that this information will not be redundant in any way.

An opening moment occurs when an already installed screw rotates or loosens further. The preload force is the result of tightening the screw. Torque is applied while the screw rotates, until it is tightened. The torque that begins after the torque is called the torque.

This is the force acting on the joint after assembly. Static friction occurs when the body rests on another body. The movement of the body is prevented by static friction. Moving friction occurs when a body moves through another body. The motion of a body on another body is inhibited by sliding friction.

Tightening Procedure

There are many different connection methods. Our clamps also have screws on the body to securely and securely attach them to a hose or nozzle. First, the tightening torque is applied when, as the name implies, the screw is tightened. At the same time, the torque increases gradually and evenly until the specified tightening torque is reached.

Preload and Clamping Force

The screw, combined with the body and belt, creates a pre-tension force. Here, the process can also be obtained from the name: the screw exerts stress on the parts. The preload force must be calculated so that in the case of our clamping, there is sufficient clamping force. Therefore, the preload force should not be too low. In addition, it should not be too high, as the parts may be damaged. This ensures, for example, a long service life of the connection in the engine compartment of the vehicle.

As you can see for yourself, the list is very large and someone would have thought that even for wheel bolts there is a strictly defined moment of force and, according to the rules, you need to use a torque wrench. But now, even for the sake of interest, I will go over the basic elements of my Kalina and check how all the compounds correspond to the data presented in the tables.

Since the correct preload force is difficult to verify, a tightening torque is set for each joint. If the screw already installed is turned further, torque will occur. The torque increases briefly above the tightening torque until the screw begins to rotate. This effect is explained by the transition from static friction to sliding friction. More precisely, static friction is overcome at this moment.

With our clamps, tear-off torque is determined at the design stage to ensure sufficient clamping force - in addition to all existing requirements. For example, we do this in relaxation tests. Based on this, we recommend the tightening torque and the tightening speed, which must be observed for our customers.

As for the cylinder head bolts, it is tightened in 4 stages. Below is the procedure in more detail:

- Tighten the bolts to a torque of 20-25 N * m

- Once again, we twist each to 70-85 N * m

- Pull all the bolts 90 degrees

- Last move - finally spin another 90 degrees

I will not describe the procedure and drawing scheme for all 10 bolts here. I'll do everything a little later, when I will describe the procedure for removing and installing the cylinder head on my Kalina. I hope that during the summer I will prepare this material and then I will sign everything in detail and with detailed photographs of the repair.

How to work with a torque wrench

Compliance with these sizes ensures a long and reliable connection life - even in extreme conditions. Screwing on the wheel during its replacement seems like a trivial task. In fact, the matter is not so simple. Unnecessary tightening of bolts can end tragically, so it’s good to know some golden rules.

Wheel abolition in a car is usually not a problem. But the time has come when the wheel needs to be screwed. How to do it right so that subsequent driving is safe? Screws must be screwed in manually. Why? The screw must be screwed with the correct thread. An alternating system is also important. For example, if the wheel is screwed onto four screws, then screw in one and the next one on the other side of the center hole of the rim. The other two screws lock in the same way.

Torque wrench - a wrench with a built-in dynamometer.