Osb plate moisture resistant dimensions. OSB board - characteristics, dimensions, application. Where OSB sheets are used

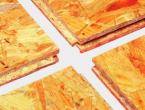

What are OSB sheets and what are they made of? OSB or OSB sheet is an oriented strand board, which is a wood chip material glued with a special polymer. Many mistakenly assume that chipboard and OSB are about the same thing. However, OSB sheets are made only from high-quality chips, which are placed in a special way perpendicular to each other. The sheet itself is formed using synthetic resins, under high temperature and pressure. Due to its robust structure, the material is very durable.

Characteristics of OSB board

The general technical characteristics of chip sheets are as follows:

— Density of plates can vary from 640 to 700 kg/m3;

- the fire hazard of the material is increased - G4, it is usually treated with fire retardant solutions;

- the adhesion and coloring of the sheets is good, they are often covered with various varnishes;

— the manufacturability of the material is practical, it can be sawn, drilled, nailed, ground and cut; fairly simple installation;

- the holding mechanical ability does not have an exact number, but is considered high;

- swelling coefficient - 10-22%.

Where OSB sheets are used

OSB sheets are widely used in the following areas:

— as a material for shelving and stands;

- cladding stairs made of wood;

- sheathing of the walls of houses from the frame;

- in the form of SIP panels;

— as the basis under a tile for a roof;

- in panel formwork structures;

- for filing ceilings;

- as a basis for installing floors.

Building a house from OSB sheets using frame technology.

OSB sheets are widely used in the construction of houses using frame technology. One of them can be found in the article:.

OSB board classes

There are several classifications of OSB sheets. First consider the class, denoted by numbering from one to four. So let's figure out what the numbers mean after the very name of the material.

1. OSB-1 is the material with the lowest strength and lowest water resistance. It is used in rooms and structures without heavy loads (in the form of sheathing and furniture elements).

2. OSB-2 is used for the construction of load-bearing structures for dry rooms, respectively, the level of strength is medium, moisture resistance is low.

3. OSB-3 is a material that has higher strength and is allowed for use in high humidity conditions.

4. OSB-4 is a durable sheet that is designed for maximum moisture levels combined with mechanical stress.

OSB-3 boards are the most widely used because of their strength characteristics. If such sheets are primed or painted, then their moisture resistance characteristics are comparable to OSB-4 boards. OSB-4 boards are not widely used because of their high cost, it is about two times higher than that of OSB-3 boards.

Health hazards of OSB boards

Each chipboard has in its composition another not very useful, or rather, completely harmful component. It is the glue that connects the entire OSB structure into a single whole - formaldehyde. However, in a bound state, it is absolutely safe, but there is one moment that destroys this myth. During the manufacture of the plate, it is compressed, so the structure of the adhesive collapses and during the operation of the sheet, a certain level of toxins is released into the room. The toxicity class is designated as follows:

- E0.5 - formaldehyde emission no more than 0.08 mg / m³ of air;

- E1 - formaldehyde emission from 0.08 to 0.124 mg / m³ of air;

- E2 - formaldehyde emission from 0.124 to 1.25 mg / m³ of air.

For the installation of OSB boards indoors, it is better to use boards with toxicity classes E0.5 and E1. Such plates are also harmless to health like other building materials.

Dimensions and thickness of OSB sheets

The possible dimensions of the OSB board directly depend on the edges of the building material itself. They can be (below are the possible sizes):

A. With smooth edges. In this case, the dimensions of the sheet are:

- 2440x1220 mm;

- 2500x1250 mm;

- 2800x1250 mm;

- 3125x2000 mm.

B. With grooved edge. Such a class includes dimensions in:

- 2440x1220 mm;

- 2440x590 mm;

- 2450x590 mm;

- 2500x1250 mm.

The thickness of each OSB sheet can vary from six to twenty-two millimeters. Here is a range of typical thicknesses: 6, 8, 9, 10, 12, 15, 18, 22mm

On the edges of the OSB sheets, there may be special grooves for the best connection between them.

On the edges of the OSB sheets, there may be special grooves for the best connection between them. Prices for OSB sheets.

Almost all residents of large and not very cities are well aware that in our time it is relatively easy to buy a fake certificate proving clean environmental friendliness and safety of products. Therefore, in order not to get into trouble, it is better to trust only the most famous and popular OSB manufacturers. These include:

- Kronospan-Bolderaj, OSB-3, for example, a plate with a size of 2500 * 1250 mm and a thickness of 9 mm will cost about 650 rubles;

- Glunz and Egger - German plates of the same size and thickness are slightly more expensive - for 850 rubles;

- Kalevala OSB-3 is a Russian plate, which can be purchased for 550 rubles.

OSB sheets, boards and panels in "GdeMaterial" at a price of 452 rubles

OSB boards (OSB) is an oriented strand material, where each layer of chips is perpendicular to the previous one, due to which high strength is achieved. The material came to Russia from Europe, where it has long been used for interior decoration, roofing, and the construction of temporary premises. There are Russian, European and American manufacturers on the market. The price per sheet of European OSB board is higher than that of Russian or American counterparts, due to wood (Americans use cheaper hardwoods) and production quality.

How to choose OSB boards?

In Russia, when choosing, they rely on the European classification, which divides the plates into 4 different types (in fact, there are more of them, but these 4 are used in house construction):

- OSB-1 are boards for use in dry rooms (humidity no more than 65%) without load. They are used for sheathing, partitions, and also in the manufacture of furniture.

- OSB-2 - can carry the load in dry rooms.

- OSB-3 - can carry the load in wet areas. This is the most common and sought-after universal material.

- OSB-4 - can withstand severe loads in high humidity conditions. Used as roofing material.

Another parameter to consider when buying OSB boards for interior decoration is the formaldehyde emission class. There are three of them: 30-60 mg, 10-30 mg and up to 10 mg. Plates of the first type are prohibited for production in Europe and are almost never found in Russia, plates of the second type can be used for outdoor work (flooring, external walls), plates of the third are suitable for interior decoration. Many people are afraid of the presence of formaldehyde, but it is worth remembering that ordinary wood also contains it (up to 12 mg per 100 grams of wood).

In terms of size, OSB-plates are produced in several versions - American (1220x2440) and European (1250x2500), sometimes other sizes come across. When choosing, you should prefer larger plates: the fewer joints, the better. According to the thickness of the slab, they are selected for the task:

- for roofing, take plates up to 15 mm thick;

- materials of 9-12 mm are used for sheathing;

- for ceilings and floors use plates of 15-18 mm;

- for filing the ceiling or walls, you can take thin slabs of 6-9 mm.

But it is better to choose the thickness of OSB-plates based on the designer's calculations, since here much depends on the planned load, the size of the spans and ceilings, the height of the ceiling and other parameters. Another point: with a large required thickness of the plates (from 20 mm), it is better to make the flooring in two layers. So you can block the joints and evenly distribute the load.

Types of processing OSB-boards

When choosing, you should pay attention not only to the dimensions, but also to how the OSB sheets are processed. The surface of the plates can be smooth, rough or corrugated. Rough and corrugated materials go to roofs and floor coverings: an uneven surface improves adhesion to other materials. Smooth slabs are well suited for cladding.

Along the edge of the plate, they can be smooth or with a tenon-groove grip. The latter are good for cladding, roofing and laying on the floor, as they allow you to get a strong, windproof connection.

OSB (or OSB, YUSB) are orientated chipboards, which are pressed slab material from chips with glue.

Sheet sizes do not have strict regulation and are produced by different factories. Especially, it swings various handicraft industries. Sheets can be ordered to order the required size.

In practice, in the world in most large industries, 3 basic sizes of plates are produced, which are considered standards:

Standard dimensions of OSB sheet:

1. Length (L): 2440 (mm), width (B): 1220 (mm), thickness (H): from 6 (mm), to 25 (mm);

2. Length (L): 2500 (mm), width (B): 1250 (mm), thickness (H): from 6 (mm), to 25 (mm);

3. Length (L): 2440 (mm), width (B): 590 (mm), thickness (H): from 6 (mm), to 25 (mm).

When choosing which sheet to buy, I recommend choosing large sheets, as you will have fewer joints, which is extremely important and convenient for installation.

OSB Sheet Size Chart

Each manufacturer has its own sizes, which in fact do not differ much from each other. For greater clarity, we have made a table with which you can easily find out all the necessary information.

Which OSB sheets are better to buy:

Which OSB sheets are better to buy:

There are many manufacturers of sheets. Among the most popular and high-quality, the following should be highlighted: Austrian Kronospan, Russian DOK Kalevala, German GLUNZ, Romanian EGGER.

In terms of quality, I did not notice much difference between the inexpensive Russian brand Kalevala and the foreign manufacturers listed below. Also, if you are looking for the most inexpensive and affordable OSB, then the Russian manufacturer Ultralam will suit you. This plant produces high-quality and inexpensive products.

OSB size standards for thickness.

There are thin, medium and thick sheets. The table of dimensions for such plates is presented below:

OSB sheets are usually used in various applications depending on the thickness.

The OSB board has been actively used in construction work for about 35-40 years. In Russia, such a view arose relatively recently, because some professionals of the "old school" treat it with prejudice, preferring to use the classic chipboard. And craftsmen who keep up with technological progress actively use OSB for wall cladding, flooring, the production of removable formwork and almost all other processes.

- Varieties of OSB

- Basic dimensions

- Buyer Tips & Pricing

The Americans dubbed the board with chips arranged in perpendicular layers, the Oriented Strand Board.

Accordingly, the abbreviation in British is written as OSB, and in Russian - OSB. But the literal translation of the name will sound "oriented strand board", that is, OSB. The term "OSB plywood" is also used. Therefore, Russian consumers should know that we are talking about the same thing.

There are 4 basic types. Classification is carried out according to two criteria: strength and moisture resistance.

They can be called universal. Applications:

- external and internal wall cladding;

- roof arrangement;

- "rough floor";

- reusable formwork;

- containers for transportation;

- creation of external marketing boards;

- production of trade racks;

- sheathing structures for children's and sports grounds.

The advantage of the plate is its relatively low cost. You can buy an OSB sheet much cheaper than chipboard or plywood of the same characteristics.

OSB dimensions

OSB boards are produced in pairs of basic dimensions.

2500x1250x9mm - one of the more popular types. Such shields weigh 18 kg, have a density of 650-670 kg / m³, which is comparable to coniferous wood. Sheets of other sizes are produced, options 2440x1220, 2500x1250 or 2800x1250 with a thickness of 9, 12, 15 and 18 mm are more represented on the market.

Wholesale price starts from 360 rubles apiece. The cost of the plate depends on the manufacturer. So, OSB from Kronospan is economical. The product 2500x1250x9mm costs from sellers from 520 rubles. It will be significantly more expensive to purchase an Egger stove. OSB of the same dimensions is offered for 700 rubles and more.

Given that sheet 2500x1250x9mm, as well as having a different thickness, is becoming more and more popular, it is necessary to reveal some of its secrets.

The term "moisture resistant" is not applied to the wood-chip core of the board itself, but to the adhesive. This means that the resin does not lose its binding properties when exposed to moisture. Insignificant short-term wetting is allowed, but direct contact with water for OSB-3 must be excluded.

2. North American and European companies have different standards. For Europe, swelling is allowed by 15% after a day's stay in water, and for the USA and Canada - 25%. Therefore, most of the American and Canadian sheets meet the European aspects of OSB-1 and OSB-2. Only North American products with Exterior Bond adhere to the European EN 300 OSB-3 marking.

The modern creation of plates has reached the highest level of environmental performance. Almost all companies no longer use harmful formaldehydes as a binder, and the percentage of wood in the sheet reaches 95%. Therefore, for the inner lining, you can purchase exactly this type of OSB. For external work, a plate with formaldehyde glue, which has the lowest cost, is suitable.

4. In Russia, there is a certain inconsistency in GOSTs and specifications for OSB, which is interpreted differently by manufacturers.

When buying, the client must ask the sellers for certificates that indicate clear properties (hydrophobic characteristics and formaldehyde emission class).

Prices for OSB-3 2500x1250 9mm (unpolished, standard EN300):

Characteristics

OSB or strand board is gaining immense popularity all over the world.

In some countries, it is used as the main building frame for prefabricated buildings. The construction of such facilities can save a lot of time and money. So what is the individuality of OSB plates?

At first glance, it can be confused with chipboard, but both have different properties. In addition, the development of production they also have differences. OSB is created by the hot press method, but at the same time, layers of chips and chips are laid strictly in the direction of technology. The design acquired after pressing has an increased strength and hardness. Apart from this, a directional chip sheet has other advantages:

- it is light;

- has the highest degree of moisture resistance;

- is a good sound insulator;

- burns badly;

- is completely clean m, harmless to human health;

- simply processed with an ordinary hacksaw.

It is thanks to all these features that this has become widespread.

It is used to create partitions, erect temporary structures, insulate and create a layer of sound insulation.

In the main construction work, OSB boards are used, the dimensions of which correspond to 2440x1200 or 2500x1250 mm. They can be used as wall cladding, subfloor, bedding or additional protective layer. The thickness of the sheet in this case can vary from 8 to 40 mm. Specially to order, extraordinary products can be produced, the dimensions of which differ markedly from industry standards.

Another advantage of OSB can be called ease of processing. It is not necessary to have special equipment to give the workpiece the desired shape and size.

Varieties of OSB

In total, there are about 4 main types of OSB chipboards:

- The first class is thin sheets that are used as wall cladding.

They have the smallest thickness and rather low insulation and stability properties.

- The second class - workpieces with a width of 11 mm. They have compacted walls, but do not differ much from the previous type. Can be used as a heater or sound insulator. Able to withstand short-term exposure to a humid environment without consequences.

- The middle class - three, is the most popular m. Corresponds to the economic equation price = quality. The thickness of the shields from 15 mm allows the use of class 3 OSB for the creation of partitions, floor coverings and as a protective wall. It has an overestimated resistance to the influence of a humid environment.

- Reinforced shields of class 4 with a width of 20 mm or more are used in the frame construction of buildings and for the creation of reinforced partitions.

The highest moisture resistance and rather high mechanical properties are used to protect vulnerable parts of the structure. Sheets of the 4th grade are a good option for creating a fine floor covering. The highest quality of production requires additional costs, because the cost of the extreme view is quite high and from time to time can differ almost twice from the 3rd class.

The most popular are 3-4 classes. They are able to replace several layers of protective parts, while they are much easier and faster to mount.

Large sheet sizes allow you to cover a gigantic working area using just one unit.

This means that only two blanks and little glue are needed for one room. The use of OSB is cost-effective. The only inconvenience when working with it is the delivery and transportation of large sheets.

It is worth seeing that there are different sheet sizes on sale from global manufacturers from different countries.

For example, the Belgian usual sheet size is 2700x1200 mm, and in Austria it is 2800x1250. That is, you can find different blanks, and this is extremely helpful when you need to cover a certain area with a solid monolithic canvas.

What are OSB boards

Owing to its own structure, the OSB board was indeed the first wood board specifically designed for use in the construction industry.

Speaking most figuratively, such boards are "modified" wood, which has an increased strength and elasticity.

This became possible due to the fact that, even after appropriate processing, it fully retains the properties that the wood mass possesses.

In addition, OSB boards are completely devoid of such misunderstandings as knots, multidirectional fibers and almost all others.

Characteristics and advantages of OSB boards

If we talk about the physical composition, then it consists of nine 10s of a real tree.

In addition, particle board is actually as good as wood at holding nails and screws.

Moreover, it is ecologically harmless, even despite the fact that in the process of its production various chemical binding agents are used.

Excellent mechanical characteristics in OSB are unsurpassed mixed with the highest features in the field of operation. Due to the fact that, according to the texture, it is a large chip, very compressed, its edges and corners are unsurpassedly protected from chipping, along with this, there is the “same” hardness that is needed for comfortable sawing.

By the way, you can cut these plates with the same tools that are used for ordinary wood.

But if you need to drill them, it is recommended to use those drills that are intended for hard rocks.

There are quite a few of them:

- They are extremely high-strength, and confirmation of this is the recent earthquakes in the Land of the Rising Sun. There houses, sheathed with chipboard, withstood the cataclysm, unlike concrete and brick buildings. OSB also holds nails and screws perfectly, almost two and a half times better than chipboard.

- copies all the positive properties of a real tree with almost 100% accuracy.

- In addition, it has a homogeneous structure on the inside, and the surfaces on both sides are of the same top quality.

- There are no natural defects - cracks, knots, fistulas.

- No shortcomings that characterize plywood or wood were noticed in OSB-boards.

They do not deform, internal voids do not appear in them, knots do not fall out. Due to the unique production process, the possibility of getting various kinds of fungi or insects is excluded.

- There is practically no waste left.

- Unique resistance to natural weather irritants, resistance to moisture, allowing it to be used as a kind of waterproof enclosure. Even after a day in water, swelling often does not exceed 20 percent, and at the same time it does not collapse and does not lose its initial characteristics.

- Excellent aesthetic characteristics, which are achieved by approaching the appearance of a real tree.

- OSB board is quite simply processed: it is easy to drill or cut, glue or paint.

- Good soundproofing characteristics, quick installation.

- Durability - if the construction is well planned, then the service life is actually not limited.

- Strength.

- Special processing, at times increasing all the characteristics.

Dimensions of OSB boards

Many owners of suburban areas, apartments and private houses are interested in cheap and high-quality suitable for renovating a room, cladding a building, or building a frame country house in a very short time.

At present, a relatively fresh type of coating has become quite popular - OSB slab, the dimensions of which allow covering a rather huge area with an even layer without any special costs and immediately carry out external finishing on it (for more details about OSB finishing, see here and here).

Advantages of OSB boards

OSB is a product that replaces the previously popular chipboard and in many ways resembles its own predecessor.

But the use of the most advanced production technology, which involves the use of a certain type and size of wood chips and a special method of laying it (three mutually perpendicular layers), allows you to get quite fundamental advantages:

- Great strength and elasticity. The outer layers of chips, directed along the main axis of the plate, and the inner layer, perpendicular to them, form a single construct with improved characteristics;

- Moisture resistance. It is provided with the help of advanced modifications of resins as a filler and a binding element;

- Ease of processing.

The dimensions of the OSB plates and their shape are strictly similar, therefore it is extremely easy to close and level the surface of all sizes with these plates. In addition, they are perfectly cut by any hand or electric tool;

- Low cost. The cost of the more popular OSB board is around 150 rubles per square meter.

What sizes of OSB boards exist?

Depending on the operational parameters, which are determined by the raw materials used and the production method, OSB boards are divided into four classes.

They are indicated by a combination of the letters OSB and the corresponding number. More popular are OSB-3 standard boards, which, due to the highest moisture resistance, have the widest scope.

Unlike chipboard panels, there is no single agreed standard for OSB sheet size. Therefore, manufacturers produce various types of plates both in terms of the ratio of width and length, and in thickness.

Historically, the first oriented strand boards were made in the countries of North America and only a little later appeared on our side of the ocean. This led to the division of manufactured products into South American and European versions, each of which has its own traditional dimensions and surface treatment method.

The most common types of slabs are:

In addition to the most popular, there are also extraordinary options for plates. For example, the Austrian manufacturer Kronospan produces OSB sheets 2800 x 1250 mm, and the Belgian Norbord NV - 1200 x 2700 mm.

A few words about the 3rd size - thickness.

On sale there are plates with a width of 6 to 40 mm. The following sizes are more necessary:

- 6 mm, 9 mm - for the subfloor, packaging and other structures that are not subjected to huge loads;

- 12 mm - a device for a solid base for roofing, internal partitions;

- 15 mm, 18 mm, 22 mm, 25 mm - flooring, outer cladding of buildings. The thickness of the OSB on the floor is selected depending on the distance between the lags on which the plates are laid - 15-18 mm at a step of up to half a meter, 18 mm - 22 mm - up to 60 cm, and 25 mm - at huge distances.

It is necessary to mention separately that the OSB of the leading manufacturers is subject to fairly solid standards for the probable deviation of the size of each unit of production from these values.

For example, for OSB-3 boards, the South American standards CSA0437 and CSA0325 set the largest tolerance for thickness of 0.3 mm, and for linear dimensions - no more than 3 mm.

Such manufacturing accuracy guarantees the absence of gaps and irregularities when installing coatings of a large area.

What is OSB board, dimensions and price

Today, for sure, there is no person who has never heard anything about OSB, which in British sounds like oriented strand board (OSB) and translates as directed strand board. This sheet, produced in the form of sheets, is applicable for frame construction, roofing, apartment renovation, etc.

Such panels are called differently: both OSB, and OSB and OSB.

This is all the name of the same plates.

OSB (oriented strand board) - consists of layers (usually 3-4) of thin chips or wood shavings. Various resins are used to hold the chips together, synthetic wax and boric acid are added as an antiseptic.

Since the plates are called targeted, the chips in them have a certain orientation: transverse in the inner and longitudinal in the outer.

The first NDEs arose more than 30 years ago.

This was facilitated by the general construction of frame prefabricated houses, in which millions of people in Europe, the USA, and Canada currently live.

They are three-layer pressed OSB boards for the production of which elongated chips from coniferous wood are used. The length of the chips is equal to 60-90 mm. The substance that binds the wood chips together is glue, the main component of which is formaldehyde resins and wax.

Technical properties of OSB and dimensions

OSB boards have the following technical characteristics:

On the market, various manufacturers offer a wide range of OSB sizes, which makes it possible for developers and owners of houses and apartments that are undergoing renovations to choose more suitable solutions.

The most popular slab sizes that can be found in retail are:

- 2000*3125mm;

- 1250*2800mm;

- 1250*2500mm;

- 1220*2440 mm.

The thickness can vary between 6-22 mm.

Variety and price

Today, it is customary to distinguish 4 types of OSB, which differ in technical features and are used in various industries:

- OSB 1 is characterized by low density and is applicable for the production of furniture.

This type of plate is susceptible to moisture.

- OSB 2 has the highest strength, but is also susceptible to moisture. We apply this type of plate for interior decoration.

- OSB 3 is resistant to moisture (not long exposure to moisture is implied) and extremely high strength. Specifically, this type is more needed and suitable for exterior decoration of buildings. In this case, the plates need to be additionally impregnated and painted.

- OSB 4 is suitable for use in humid environments and can withstand intense mechanical stress. this type is expensive, therefore it is not used as often as OSB 3. The technical properties of OSB 4 allow it to be used repeatedly for formwork without additional processing.

- There are also slabs already, varnished on one side, laminated (well suited for formwork), and tongue-and-groove, in which the ends are processed under the tongue and groove, for laying over a large area.

The most popular plates with class 3.

Approximate prices for various sizes of plates are:

- OSB-3 2500x1250x6 mm - $7.9

- OSB-3 2500x1250x8 mm - $8.4

- OSB-3 2500x1250x10 mm - $9

- OSB-3 2500x1250x12 mm - $11

- OSB-3 2500x1250x15 mm - $13.7

- OSB-3 2500x1250x22 mm - $20

Also, the scope of implementation of OSB depends on the thickness of the plate. Thin slabs are suitable for sheathing objects that do not load the OSB sheet (framework for soft coating, sheathing of wooden floors, walls, etc.).

Slabs of greater thickness can be used for objects with a rather high overload on the slab (flooring on the floor, structures on which heavy objects will stand, etc.).

OSB application

Due to the beautiful technical features, OSB boards are applicable in almost all areas of construction:

- Arrangement of walls of frame houses;

- Creation of interior partitions;

- Installation of flooring;

- Leveling the floor surface for the next installation of the finish coating;

- Creation of a base for some roofing (bituminous tiles, etc.);

- Creation of SIP panels;

- Ceiling lining;

- Sheathing of stair structures;

- Creation of formwork structures;

- Creation of racks and stands;

- Construction site fencing, etc.

In all areas of implementation, OSB is fastened with self-tapping screws to both wood and metal bases.

The popularity of this is growing once a year, since with its help you can quickly and at the same time perfectly build reliable frame houses with a long service life.

The dangers of OSB boards

The issue of the harmfulness of OSB boards to human health is controversial.

Manufacturers guarantee the safety of the plates, but experts are skeptical in this matter and believe that their sanitary and hygienic standards are not suitable for use in residential premises.

The reason for this polarity of opinions is the presence of adhesives in formaldehyde in the composition of the boards. In the chemically bound state, OSB is completely safe. But under the influence of temperature during the pressing of the plates, gaseous formaldehyde is released from them, since the molecular chains of the adhesive break.

In the production of modern OSB-3 boards, fewer binders are used than for chipboard

But, for example, modern chipboard is made using the latest technology, it corresponds to class E1 - the highest in terms of environmental safety.

And for the production of OSB-3 boards, even fewer binders are required, which indicates even greater environmental friendliness and safety. At the same time, the creation of OSB-3 is a modern process. OSB-3 boards are not woodworking waste, but modified wood. The development of their production in terms of cost and process is similar to the creation of plywood or glued beams.

Different types of resins are used in different layers of the sheet:

- for external - melamine-formaldehyde or urea-formaldehyde;

- for internal - phenol-formaldehyde or urea-formaldehyde resin.

It must be realized that formaldehyde in a small concentration is not dangerous, but if the number of molecules in the air is large, then it will act like a poison.

It is customary to distinguish four classes of OSB according to the content of formaldehyde resins:

- E0 - 3-5 (up to 6.5) mg per 100 g. substances

- E1 - 10 mg/100 gr.

- E2 - 10-20 mg / 100 gr.

- E3 - up to 30 mg per 100 g.

The certificate for each batch contains information about the method of analysis, the maximum allowable values and the final results. The emission class of toxic substances is determined according to the European standard DIN EN120.

In residential premises, in accordance with sanitary and hygienic standards, only plates of class E0 and E1 can be used.

Suppliers of such oriented strand panels are the Austrian company Egger, the Canadian Norbord and the German Glunz.

Products labeled E2-E3 (Kronospan, Kronopol) can only be used for external work, including under-roofing of non-residential attics, load-bearing structures in makeshift buildings, etc.

The maximum allowable amount of formaldehyde in the atmosphere is 0.003 mg/m³, and in domestic water - 0.05 mg/l.

To determine the harmfulness of building materials, another indicator is used as a toxicity index. OSB boards have a toxicity index of 70-120%, which indicates that they are non-toxic according to the sanitary classification.

According to a different system for determining toxicity in ppm units, the classes look different.

The South American SIP Building Association states that OSB emits no more than 0.1 ppm, that is, parts per million. This is the smallest possible level - even lower than is allowed in housing construction. Formaldehyde emission classes: E1 (up to 0.1 ppm), E2 (up to 1.0 ppm), E3 (up to 2.3 ppm). From the E1 class, you can not only build houses, but also make children's furniture.

For example, ordinary plywood belongs to the class E2.

To protect your home from formaldehyde emissions, you need to follow some recommendations:

- Acquire OSB of a class not higher than E1;

- Before doing work inside the premises with the use of OSB, the plates must first be kept for 3 months (at least 2 days) under an open canopy (formaldehyde concentration will decrease several times during this period), while 5-10 cm bars must be laid between the sheets;

- For interior finishing of the plate, you must first treat it with a special detox primer;

- Rooms with OSB sheathing should be ventilated daily;

- Avoid overheating of the room (above +30);

- Do not allow the humidity in the room to rise above 70%.

By following the tips listed above, the concentration of formaldehyde fumes emitted in the air will not exceed the permissible limits, and, therefore, will not be harmful to human health.

The main advantages of OSB boards

OSB boards are products similar to chipboard, which was popular not so long ago, and have almost all similar features.

But in the production of OSB boards, special technologies are used that involve the use of a certain size and type of wood chips. In addition, the method of stacking chips, which is carried out in three mutually perpendicular layers, allows you to get additional advantages.

Advantages:

- It is thanks to this laying of the plate that they receive additional elasticity and strength. A single structure with the best features appears as a result of the fact that the outer layers of chips, directed along the main axis of the plate, are combined with the inner ones located perpendicular to them.

- Moisture resistance is another quality of OSB boards.

This quality is ensured with the help of the most modern and advanced modifications of resins used as fillers and a binding element.

- OSB boards are comfortable in processing, their sizes and shapes are constantly similar, which is why any surfaces that have different sizes are simply closed and leveled by them.

- When cutting plates, both manual and electric cutting tools are used.

- And another important advantage is the low cost of the system. On average, one OSB plate costs about 150 rubles per square meter.

Dimensions of OSB boards

OSB boards are divided into four main types, it depends on the operational parameters determined by the method of their production and raw materials.

Each species is designated by OSB signs and the corresponding number for this species. The most needed among others are OSB-3 boards. They have a fairly high moisture resistance and are widely distributed and popular among consumers.

Another difference between OSB boards and chipboard sheets is that OSB boards do not have uniform common dimensions. They are produced in different sizes, widths, lengths and thicknesses.

There is also a division of manufactured plates into South American and European options.

Each of the species differs in traditional processing methods and sizes. This distribution has developed due to the fact that for the first time particle boards were made in the countries of North America, only later they appeared in our country.

In most of their own plates are divided into the following types:

- The most popular is the type of OSB boards, South American production, size 2440x1220 mm. These include such brands that are especially popular in Russia as Arbec, Norbord, Grant, etc.

- Their European analogues are plates produced by Kronospan, Bolderaja, Glunz and almost all others.

Their size is 2440x590 mm.

- Another type of South American-made slabs - Norbord has tongue-and-groove edges, they are most often used when constructing the base of floors, their size is 2440x590 mm.

In addition, there are extraordinary types of OSB boards, they are not more popular. Among them are plates of the Austrian manufacturer Kronospan, which produces plates with a size of 2800x1250 mm, another manufacturer is the Belgian company Norbord NV, which produces sheets of 1200x2700 mm.

I wanted to say a few words about one more parameter of OSB boards - thickness.

Often, the consumer is offered plates having a thickness of 6-40 mm.

Among them, the most needed plates of the following sizes:

- Plates with a width of 6.9 mm are mainly used for subflooring, other structures that will not be subjected to excessive loads.

- OSB slabs 15, 18, 22 and 25 mm are used for laying the floor, as well as the outer cladding of buildings. In this case, the thickness of the plates intended for floors is determined based on the distance between the lags. With a step of 0.5 meters, plates of 15-18 mm are used, with a step of up to 60 cm, the thickness of the plates is 18-22 mm, and with a large distance between the lags, the thickness of the plates must be 25 mm.

Plates from leading manufacturers are determined by serious standards for acceptable differences.

For example, the South American standards CSA0325 and CSA0437 define small thickness tolerances of 0.3 mm, tolerances for linear standards - no more than 3 mm. When mounting surfaces of a large area, this makes it possible to eliminate bulges and gaps.

Methods of delivery of OSB boards

As a rule, plates are offered to buyers either individually, if the lot is small, or in packs. At the same time, when buying plates from one pack, it will affect the cost reduction. That is why, when purchasing plates, it will be purposeful to choose the desired thickness and size.

And for this you need to know how the manufacturer packs the plates for shipment to the markets. In general, the number of plates in a pack and its weight depend on the technological features, the linear dimensions of the plates and their thickness.

These characteristics indicate that the plates have more popular dimensions, and also have everything that allows them not only to be simply moved manually, but also to work with them at a height when installing roofing surfaces and upper floors.

The characteristics of OSB boards discussed above explain the most and most growing popularity, its extensive use in the construction of structures and suburban houses.

OSB boards: technical properties, types, dimensions, painting

OSB boards are becoming more and more popular every day.

What is OSB? These are oriented strand boards, which are made using wood shavings and sawdust.

The boards are extremely strong, flexible and have good technological properties. They are used in frame construction works in order to sheathe walls, make a roof or partitions.

This plate looks like a pressed panel, which is created from chips, shavings and various sawdust. Closely examining this canvas, you will see that it includes far more than one layer. The layers that are on the outside are placed along, and the layers that are on the inside are made in the other direction.

All layers are unsurpassed glued together with different resins, wax, impregnation, so the product itself is extremely durable.

We will consider what OSB boards are, how they are used in construction, we will see all their advantages, we will list the most popular types of boards.

Types of OSB boards and their scope

Today, specialists make varieties of OSB in the amount of four types. Their difference is that they have different properties and are used in different industries.

- Plate OSB 1- This is a chipboard board, which has a low density.

Such a tile does not like moisture, therefore, with the help of it, furniture is mainly made.

- Plate OSB 2- denser and stronger than the previous one, but also afraid of water and water. The fact that these boards are extremely dense in their structure makes it possible to use them in the internal sheathing of objects that are load-bearing, while the humidity must be low.

- Plate OSB 3- is the most necessary.

It is extremely durable and resistant to moisture. But it should be borne in mind that under the humidity here only getting wet for an extremely short time is assumed. In order to trim an object with it from the outside, it will be necessary to additionally protect this sheet with additional mi, that is, paint or impregnate.

- Plate OSB 4– especially strong, super resistant to moisture. It can be in a humid environment for a long time, and additional protection is not required. But such plates are quite expensive, therefore they are not used as often as OSB 3.

Also sheets of slabs are classified according to their own thickness.

Thin plates are used for sheathing objects that do not load the plate. For example, walls, the basis for a soft coating, wood flooring.

A thick plate is used for objects with extremely high overload per sheet. Of these, the floor is laid, structures are made where, according to the plan, heavy ones will stand.

Characteristics of OSB boards

OSB boards have a lot of positive features, in connection with which they are so often used for construction work.

Characteristics of OSB boards:

- Very strong. The thicker the plate, the more overload it endures. It can even be 100 kg per sq.m.

- Flexible and lightweight. This feature allows the use of plates for sheathing uneven surfaces with the highest rounding.

- Homogeneous.

Such sheets are intact, even during overload. Not prone to delamination, unlike conventional plywood.

- Good quality, just like real wood. And there are no minuses of uneven shape, defectiveness during application.

- Easy to handle. Extremely simple is sawing, attaching, connecting those in.

- They have the highest thermal insulation and sound insulation, comparable to other means.

- Resistant to chemicals and damage.

- Antiseptic. In these sheets there are additions that do not allow fungal and mold bacteria to multiply.

- Invariable in form even with long-term use and after it.

The only disadvantage of OSB is that glue with formaldehyde often comes into their composition, and this substance is harmful to health.

But not all manufacturers use it.

Important! Be careful when choosing plates, paying attention to the adhesive base, it must be safe!

Table of physical and mechanical features of OSB boards

| Indicators | Mill- dart | Aggloply OSB 2 | Aggloply OSB 3 | OSB 2 | OSB 3 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Thickness, mm | 10-18 | 10-18 | 6-10 | 10-18 | 18-25 | 6-10 | |||

| Thickness tolerance, mm: - unpolished board - polished plate | EN 324-1 | 0,3 0,3 | 0,3 0,3 | ±0.8 ±0.3 | ±0.8 ±0.3 |

||||

| Length tolerance, mm | EN 324-1 | 3 | 3 | 3 | 3 | ||||

| Width tolerance, mm | EN 324-1 | 3 | 3 | 3 | 3 | ||||

| Squareness, mm | EN 324-2 | 1,5 | 1,5 | 1,5 | 1,5 | ||||

| Straightness, mm/1m | EN 324-1 | 2 | 2 | 2 | 2 | ||||

| Modulus of elasticity, N/mm²: - longitudinal axis - transverse axis | EN 310 | >6000 >2500 | >6000 >2500 | 3500 1400 | 3500 1400 |

||||

| Bending strength, N/mm²: - longitudinal axis - transverse axis | EN 310 | >35 >17 | >35 >17 | 22 11 | 20 10 | 18 9 | 22 11 |

||

| Cross tension, N/mm² | EN 310 | >0,75 | >0,75 | 0,34 | 0,32 | 0,3 | 0,34 | ||

| Formaldehydes, mg/100g | EN 120 | <6,5 | <6,5 | <8 | <8 | ||||

| Swelling in 24 hours when completely immersed in water,% | EN 317 | 12 | 6 | 20 | 15 | ||||

Dimensions of OSB boards

These sheets traditionally have a thickness of approximately 8-25 mm.

Thus, they are divided into three subgroups:

- thin;

- medium;

- thick.

The thin plate has a thickness of 8, 9 and 10 mm. The medium plate is 12 and 15 mm, and the thick one is 18, 22 and 25 mm. The thicker the sheet, the more the plate weighs. A plate with a width of 8 mm will weigh 16.6 kilograms, 9 mm - 18.4 kilograms, 10 mm - 20.6 kilograms, and so on.

Sheets with dimensions of 2440 by 1220 mm are most popular. They are often used in building work. According to European standards, a sheet of 2500 by 1250 mm is considered popular.

The size of 2440 by 590 mm is quite rare and is used mainly for flooring.

Table of sizes of OSB boards

Types and application

The production of OSB panels is classified into 4 types, which have distinctive properties and, accordingly, are used in different areas, depending on the tasks.

OSB-1 - the density of this panel is quite small and has low resistance to moisture.

That is why this is most often used for the production of furniture.

OSB-2 - sheets of the second type are an order of magnitude higher in density, unlike the first, but also do not "like" water. They are used for sheathing various structures in rooms where the water level is within the normal range.

OSB-3 - on the market, the system in this subspecies is the most popular, so resistant to water, to its short-term actions.

It can be used for external work, resorting to additional protection in the form of painting or impregnation with special liquids.

OSB-4 - this type of sheets has all the advantageous features, including the highest wear resistance in a humid environment without additional protection. But its cost is an order of magnitude higher than that of other similar ones, so it is rarely used.

Characteristics

Among the relevant features of OSB panels, light weight can be distinguished, which makes it easy to work at height. Light weight does not affect the strength, which depends on the thickness of the panel (layered structure of the sheet) and is able to withstand quite huge loads.

lends itself well to processing various construction activities - sawing, drilling, fastening, gluing.

Due to the flexibility of the panels, they are often used where the radius of curvature is large and the surfaces are curved.

Aesthetic appearance similar to natural wood makes the product suitable for interior finishing work. Unlike holistic natural OSB, it has form stability regardless of humidity and with weights - the sheets do not delaminate and do not deform.

OSB panels are often used in surface cladding, as they have the highest sound and thermal insulation characteristics.

A special impregnation with antiseptics does not allow decay and reproduction of fungal spores on it.

VIDEO TO HELP: