Varieties of bolted joints. Calculation of bolts in the joints working on m, n, q. Calculation of bolts in joints working on axial force

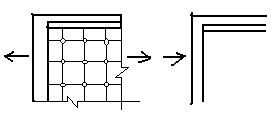

The bolt is placed on straight lines - disks. The distance between the bolts in the direction of force is called the step, perpendicular to the path. The location can be ordinary and chess.

The minimum distance between the bolts is taken from the possible position of their installation and the conditions of safe puncture. The maximum distance is taken subject to the density of the elements.

Using our technology, test teams can perform repeated and accurate fretting tests in a wide range of materials. Our best fretting test offerings include: Servo-hydraulic or electromechanical full and bench-top reactive frames for various power requirements. Digital controllers with high channel density, high bandwidth and superior configuration. Intuitive, versatile, easy to use software with powerful testing features.

d- hole diameter t- thickness of the thinnest outer element

17.Calculation bolted connections in elements working on bending, longitudinal and transverse forces. Features of bolted joints in structures made of aluminum alloys.

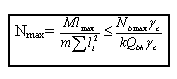

Calculation of bolts in joints working on axial force.

The required number of bolts is determined

What led me to these considerations was my concern and desire to better raise the awareness of users and activists in this area of \u200b\u200bconstruction, which in Brazil is still surrounded by many questions and doubts. Structures using metal structures, widely used in Europe and the USA for more than two centuries, are increasingly used and known by Brazilian engineers, architects and users in recent years.

Today we can be proud that we have made progress in this area, which in some cases places us in parallel with the achievements of the so-called First World. Fortunately for the pride of national engineering, we already have several companies whose production and quality facilities satisfy many companies of the first world.

n \u003d, where N bmin \u003d minN bs

For connection on high strength bolts

R bun - tensile strength of high strength bolt

μ \u003d 0.57 - shot blasting, shot blasting.

μ \u003d 0.5 - shot blasting, shot blasting with conservation by met. aluminum

μ \u003d 0.42 - flame treatment

μ \u003d 0.35 - steel brushes

μ \u003d 0.25 - without treatment

Calculation of bolts in joints working on axial force

However, they are not yet the majority, and because of the emerging awareness of the advantages of the characteristics of metal structures and the progressive support of Brazilian architects, many medium and small companies have emerged that still face a shortage of specialized personnel, whether in the areas of projects, production or assembly.

Calculation of bolts in joints working on bending

These companies, as before, in an unbridled search for the best production prices, often sin against the qualities, generating needs for repair and replacement, which denies the image of the system and creates serious losses for manufacturers. Let's look at the three most expressive areas of this art of construction and the most desirable characteristics of professionals. The objectivity and adequacy of structural design, effective and economic practice and their relationship with various complementary structural systems.

γ b \u003d 0.8 –n<5

γ b \u003d 0.9 - 5n<10

γ h - connection reliability coefficient

γ h \u003d 1,02 ... 1,7 is taken depending on the method of surface treatment, the effective load (static, dynamic), the difference between the diameters of the hole and bolt and the coefficient μ.

k is the amount of friction surface

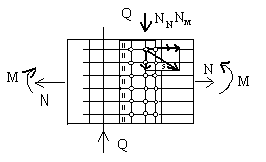

When calculating a rivet or bolt connection in difficult stress the effect of bending moment, transverse and longitudinal forces proceed from the assumption that the longitudinal and transverse forces are equally distributed between all rivets and (bolts) half-joints, and the maximum force from the action of the moment occurs in the rivets (bolts) farthest from the neutral axis. The calculation formula for determining the maximum force in the extreme rivet (bolt) has the form:

Calculation of bolts in joints working on m, n, q

Knowledge of the Resistance of Materials and how they appear in structures with structural steel. Knowledge of sustainability and the necessary conceptualization of structural behavior characteristic of steel structures. The correct concept of differentiating this behavior against the characteristics of other structural processes, such as concrete, wood or aluminum, and especially mixed metal concrete structures.

Knowledge and sensitivity in the use of national and foreign technical standards related to calculation calculations, materials and the implementation of production and installation drawings, including connecting materials such as screws and welds. Particular attention is paid to the size of the connection.

where is the force attributable to the most loaded (extreme) horizontal row of half rivets (bolts):

The sum of the squares of the distances between the horizontal rows of rivets (bolts) equidistant from the neutral axis;

The number of vertical rows in a half-joint;

The total number of rivets (bolts) in the half-joint.

In the absence of longitudinal forces in the formula take, and in the section of a clean bend, in which and, the maximum force on the extreme rivet (bolt). Knowing the voltage of the connections is checked by the formulas, assuming.

Knowledge of principles and standards for preparation and protection against glandular defense. Knowledge of the characteristics of steels resistant to oxidative effects of the environment. Knowledge and acquaintance with the tables of characteristics of various profiles, rolled up or welded, national and foreign. Consciousness and sensitivity of proportionality of characteristics due to the size of the cuts and resistances due to the properties of the steel used. The ability to associate this sensitivity with the intensity and typology of queries that represent structural details.

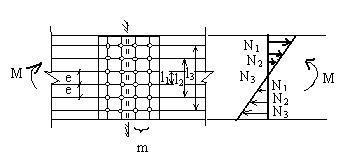

Calculation of bolts in joints working on bending.

When bent, the force in the bolts increases unevenly

The effective moment M is

M \u003d m ΣN i l i \u003d m (N 1 l 1 + N 2 l 2 + ... + N i l i)

l 1 \u003d l max, N 1 \u003d N max

N 3 \u003d ... \u003d N max M \u003d m (N max + N max + ... + N max) \u003d m (l 1 2 + l 2 2 + ... + l i 2) \u003d mΣl i 2

Knowledge of the basic operations used in the manufacture, protection, transportation and assembly, for adaptation to concepts, calibration systems and interconnects, to operational means of production and assembly. Knowledge of the principles that guide the system of drawings and parts for manufacturing. Knowledge of conventions of symbols, markings and lists, combined with knowledge of assembly difficulties, problems with lifting and interconnections, when a poorly thought out connection can lead to loss of time and refinement.

Knowledge of quality characteristics, appropriateness of use and specifications of additional materials of construction or parts with interfaces. Knowledge of standards and systems for passive fire protection. Knowledge of the existence and characteristics of innovation and technological evolution, such as.

Calculation of bolts in joints working on m, n, q

18. Scope, classification of beams. The layout of the beam platforms: the main schemes, their advantages and disadvantages. Beam flooring. Determination of loads and selection of the section of rolling beams.

Special steels with increased resistance to stress and increased corrosion resistance. Higher quality in cold profiles. Differentiation of specific strength values \u200b\u200bof suitable steels for cold formed sections, welding or laminates. Brazilian and foreign standards are more adequate and relevant, trying to keep abreast of changes compared to previous ones.

- More complex and adequate equipment.

- Using computer controlled machines.

- Brazed and welded electrodes.

- Features and care for observation.

Precision bolts

The diameter of the holes for these bolts is taken equal to their diameter (without plus tolerances for the bolt and minus tolerances for the hole is not allowed). The surface of the non-thread part of the bolt and the surface of the hole should be smooth. Bolts in such holes " are sitting»Tightly and well perceive shear forces; however, insufficient forces tightening the package worsen its operation compared to joints with high-strength bolts or rivets.

In the field of design, it is necessary to integrate most of the knowledge about the structural process with steel. It is not enough that only one project is well-calculated, and the profiles correspond to the requests detected by stability calculations. In addition to this importance, the structure must be designed to be economical without compromising resistance and quality, practicable in its production and easily installed in the work, with criteria corresponding to the relationship with other materials and processes associated with the work.

High precision bolts provide a tight, slightly deformable connection - they are called cleanbolts. The complexity of manufacturing and mounting bolts of high accuracy has led to the fact that the connection on such bolts is rarely used.

High strength bolts

They are made of carbon steel 35 or of alloy steels 40X, 40XFA and 38XC and are thermally processed in finished form. High-strength bolts, as well as bolts of normal accuracy, are installed in holes 3 mm in diameter larger than their diameter, but their nuts are tightened with a calibration key, which allows you to create and control a large tension force of the bolts. Such a bolt tension force tightly pulls together the elements to be connected and ensures a monolithic connection. When shear forces act on such a connection, frictional forces arise between the connected elements, which prevent the shear of these elements relative to each other.

For manufacturing professionals, the following basic knowledge is required. Organization of structural plants. More efficient layouts Minimizing distances and movements. Selection of possible overdraft operations and those that are recommended to be performed under hedging conditions. Necessary care for openwork.

The adequacy of this equipment is relative to their capabilities, given the weighted products that will be manufactured. Knowledge of the processes associated with production.

- Adequate choice for your purchases and installations.

- Tool - adjustments and limits of use.

- The importance of making the right choice.

Thus, a high-strength bolt, works on axial tension, provides the transmission of shear forces by friction between the connected elements, which is why such a connection is often called frictional. To increase the friction force of the surfaces of the elements at the junction, it cleans of dirt, oil, rust, and scale.

Training in regular inspection procedures and size control. Inventory Management - Convenience and justification - Locations and devices for storage, handling and inland transport. A system for cleaning and preparing surfaces for antiferugenic protection. Care for inaccessible places or susceptible to the most common aggression.

Characteristics of vehicles for work and its movements in order to protect the structure from its consequences. The suitability of the dimensions of transported structural assemblies, taking into account the number, size of work and conditions of access roads. Awareness of the obligation to use protective material and the transfer of this awareness to subordinates in all sectors, emphasizing necessity and usefulness.

Anchor bolts

They are used for fastening the bases (shoes) of columns and racks to the foundations.

Rivet joints

Used since the beginning of the century before last; they work reliably under static and dynamic loads. However, the overexpenditure of metal in the joints and their greater complexity in comparison with welding limited the scope.

The head or management of the plant will be responsible for transferring to subordinates, each in their own specialty, the principles of respect for quality, compliance with drawings, order and professional respect, for the harmonious implementation of all types of activities. Professionals involved in this area are highly recommended.

Correct interpretation of assembly design patterns. Familiarization with design agreements and systems. . Interpretation and application of mounting mark systems. The importance of placing marks both on the drawings and on the part to be assembled. Build Standards - Sensitivity and understanding in the application.

1 - locking head; 2 - embedded head

1) - with a semicircular head; 2) - with countersunk head; 3) - with half-secret

Rivets in steel structures differ in the shape of the mortgage and trailing heads. The locking head is formed by deforming the protruding portion of the rivet shaft. Riveting can be done hot and cold way.Knowledge of equipment and tooling systems - Compliance with maximum loads and recommendations of relevant manufacturers. Care and maintenance - Ordering and protecting equipment for use during periods of use. Knowledge of connection processes - interlocking, fastening and pre-fastening.

Sensitivity to determine the center of gravity of the parts to be erected, in order to avoid imbalances, loss of time and accidents. Control of props, levels and areas.

- Constant and readable maintenance of the main reference quotas.

- Carefully check the axes of the bases and supports.

In hot mode the closing head is formed in a rod heated to a temperature of about 800-1000 ° C with a pneumatic hammer.

With cold riveting a locking head is formed in an unheated rod using powerful riveting brackets. The force pulling together the package is 2-3 times less with cold riveting than with hot, since the package is compressed only by the force of the riveting bracket; in the process of hot riveting, the rivet shortens and tightens the packet during cooling (tensile stresses in the rivets reach 10-15 kN / cm.

Quality control of the finish as a whole. Torque control on bolted connections. Check for deformations due to assembly operations and damage to protective paints. Correct use of touch panels, if possible, using a variety of tonal inks.

Knowledge of additional systems, such as foundation blocks and associated anchors, coatings, slabs and interfaces with other work components. - Cleaning interface areas. Knowledge of the importance of the grilles under the base plates in the foundation blocks. The concept and importance of security systems in general. Use of adequate and safe scaffolding, stairs and equipment.

In aluminum constructionsalloysbolts of normal and increased accuracy are also used. They are made of aluminum alloys; their shape and dimensions are the same as steel ones.

High strength bolts for aluminum alloy structures are made of steel. When setting high-strength steel bolts, direct contact of steel and aluminum alloys is unacceptable, since intense electrochemical corrosion occurs at the points of contact. In these cases, the washers of the high-strength bolts must be cadmium-plated or galvanized, and the part of the bolt shaft located in the connected package must be wrapped with insulating tape (or cadmium-plated, or the entire bolt is galvanized).

The considerations in this presentation represent my desire to collaborate with younger professionals and with users who are more and more interested in the system so that they can better visit and trust metal structures with all their good qualities.

Andrade is a consultant in the field of metal structures. The famous and warlike partner of the Engineering Institute. Steel deck surfaces are subject to severe environmental conditions. Therefore, they need a sufficient level of corrosion protection to maintain their structural integrity in the long run. Some approaches are usually used for this.