Ionic heating boilers for a private home. Why are ion electric heating boilers more effective than their heating element counterparts? Features of installation and operation of ion boilers in various types of heating systems

Energy-saving technologies remain a priority in all areas. They show the greatest efficiency in the field of heating. This approach is associated with a constant rise in fuel costs. Equipment manufacturers offer various options for heating devices. One of them is anode heating boilers.

Design features

In order to understand what we are talking about, let us recall the student and/or military background of many of those who are now reading this article. We are talking about a method of boiling water, for which some used a boiler, while others used a simple handicraft design. These are two blades, fixed at a short distance from each other and connected by a 220V power cord. When this “boiler” was placed in water, heating occurred literally within 2-3 seconds and violent boiling began. This is precisely the principle on which an anode heating boiler works.

Please note that conducting experiments with heating water is dangerous to life and health. On the one hand, a short circuit may occur, on the other hand, a person runs the risk of electrical injury (electric shock).

The convenience of using such devices lies in the fact that it is possible to install electrode heating boilers in parallel into an existing heating system that works, for example, with a gas boiler. The coolant in both cases remains the same. But manufacturing companies produce not quite standard heaters, in which water is simultaneously used as both a coolant and a heating element.

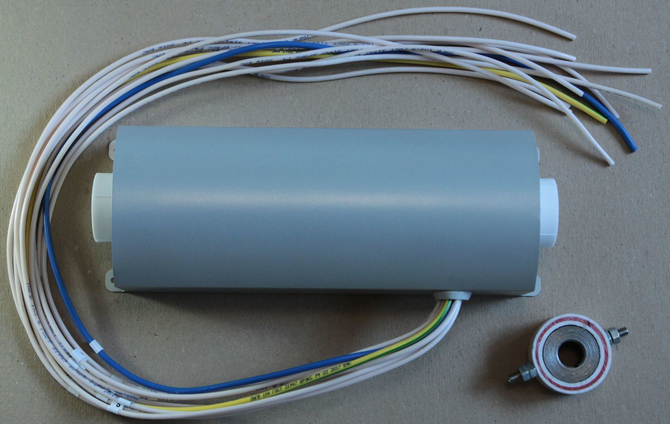

The main elements of the module are:

- steel tube;

- inlet/outlet pipes;

- terminal for connecting wiring;

- heating electrodes;

- high quality insulation.

Cathode heating boilers have a powerful steel body on the outside. The walls are made of sheet metal up to 4 mm thick. Several electrodes up to 20 mm are located inside the household structure. They are made of a refractory alloy that has a long service life.

Modern electrode ion boilers do not have an intermediary material between the anode and cathode. Heating from both terminals occurs directly from the coolant itself, water. Accordingly, there is practically nothing to “burn out” inside the cavity. The scale that appears on the tubes in electric electrode boilers after long-term operation is cleaned off with ordinary sandpaper.

What is the difference between electrode and heating element boilers?

The individual characteristics endowed with electrode heating boilers allow them to be distinguished from heating elements:

- in heating elements, at the initial stage of start-up, the working tubes are heated, and electrode boilers, made by hand or purchased in a specialized store, begin to heat the water immediately after start, which reduces inertia;

- ion heating boilers have positive reviews, as they are 20-0% more economical than devices with heating elements;

- thanks to alternating current with a frequency of 50 Hz, the electrodes move between the terminals and create a chaotic movement that promotes heating; this feature reduces the starting current for the electrode heating boiler, reducing the load on the electrical network

The difference between electrode boilers and heating elements

- A do-it-yourself electrode boiler made or produced at a factory has smaller overall parameters than other household analogues.

Such features ensure significant distribution of this heating system.

What are the advantages of using

Homeowners do not have to completely give up gas if the premises already have wiring from radiators and mains installed. Often such ion heating boilers play a duplicate role in finished systems. Although, if the cost of gas rises faster, then they can be used as the main source of heating.

Their positive properties include:

- high degree of reliability;

- temperature is controlled automatically;

- real efficiency reaches 99%;

- installation of additional equipment may not be carried out;

- startup and operation in systems designed to operate on gas;

- increased efficiency.

An electric electrode boiler operates exclusively on alternating current. Switching to constant voltage is not allowed.

Thanks to the built-in automation, the set optimal temperature is maintained for the specified time. You can increase energy efficiency by programming the system to lower the temperature on weekdays when no one is home, and raise it in the evening and on weekends.

According to reviews, electrode boilers have a good emergency shutdown system. If a possible coolant leak is detected, the device will automatically turn off. Also, short circuits do not occur in these heating devices.

The coolant for such equipment can be purchased directly from the manufacturer, who will provide the appropriate quality composition.

What are the disadvantages of using

In addition to the advantages, each system has its disadvantages. Ion electrode boilers have the following disadvantages:

- increased requirements for electrolytic water quality;

- it is necessary to carry out mandatory grounding of the device in order to reduce possible risks of working with an electrical device;

- it is advisable to maintain the water temperature in the system no higher than 70-75 0 C in order to reduce energy consumption;

- the cathode and anode need periodic descaling to ensure greater efficiency for the ionization process;

- the system requires mandatory coolant circulation, so a water pump must be installed in it.

Voltage drops are not dangerous for the boiler itself, but they are necessary for the accompanying automation. A UPS or, at a minimum, a surge protector will help you avoid damage from an unstable network.

Rules for safe operation

The optimal water temperature for operation is 50-75ºС. This information is indicated in the device passport. In closed and open systems, expansion tanks must be used.

The outlet from the boiler to the expansion tank in an open system should not have any shut-off valves.

Do-it-yourself installation of an electrode boiler into the system must be accompanied by the installation of an automatic air valve, a pressure gauge for measuring the operating pressure and an explosion safety valve at the highest point of the system.

It is possible to install it in the heating circuit as an additional heating source, but in this case it is necessary to bring the quality and type of coolant into proper condition.

Not all radiators can work with ion boilers, and the quality of the coolant is suitable for some. With very big reservations, cast iron radiators can be used.

When installing, one and a half meters of supply pipes to the boiler must be made of non-galvanized metal. After this section, the use of metal-plastic is allowed.

Grounding according to PUE standards is mandatory. The cable should have a cross-section of 4-6 mm. Its minimum electrical resistance must be no higher than 4 Ohms.

If possible, the entire system of pipelines and consumers should be flushed with clean water before installation. It is allowed to use special chemicals to help clean the lines.

After the coolant has been used up, it must be properly disposed of. It is not allowed to pour it into sewers, water bodies or into the ground.

When making calculations, they are guided by the following parameter: 8 liters of coolant must correspond to 1 kW. To operate in the 10 l per 1 kW mode, the device will be turned on almost constantly, which may negatively affect its performance properties.

Let's make a brief overview of the most popular models of electrode heating boilers, which have already been rated by consumers and identified their strengths and weaknesses. When choosing such equipment, the brand name itself means little. Only in operation can you understand how well the boiler copes with the task, how often it breaks down, and what problems there are in operation. The purpose of this rating is to name the best Russian and European brands.

The best Russian electrode heating boilers

The big advantage of domestic equipment is that it is perfectly adapted to real-life operating conditions - with voltage fluctuations, unstable current, etc. At the same time, in terms of price, maintenance costs, unpretentiousness and reliability, it will give a head start to most competitors.

The Galan company was one of the first to begin developing this family of heating devices, using developments in the military space industry and patented engineering solutions. For a quarter of a century, even the first line of devices has not failed and continues to function.

Model power 36 kW, suitable only for three-phase network. The maximum current for three phases is 27.3 A. The control is mechanical; the boiler is installed only on the floor.

This model “Vulcan” 36 has many advantages, let’s highlight the main ones:

- ease of maintenance and operation.

- safety and reliability - if an electric short circuit occurs, the current supply wires overheat, the set temperature is exceeded, or a coolant leak occurs, the boiler turns off.

- the coolant volume is 600 liters, the volume of the heated room is 1700 cubic meters.

- affordable price - the average price is 11,000 rubles.

A safe and productive single-circuit electrode boiler, which is often preferred by owners of country property. Equipment power 15 kW, suitable only for three-phase network. The maximum current for three phases is 22.7 A. The control is mechanical; the boiler is installed only on the floor. As an additional option, it is possible to connect external control.

It is bought due to the following advantages:

- Simplicity and ease of use - even a beginner can understand the device.

- light weight of the structure and compact dimensions - only 5.3 kg.

- large heating area - up to 180 sq.m.

- electronic automatic control - the presence of a control unit that allows you to create an interval for heating the coolant.

- ability to connect to a room temperature indicator.

- The average price of the device will be 7800-8000 rubles.

Manufacturer LLC "Plant RusNIT", Ryazan. Can be used as the main or backup heat source in a house or domestic premises with an area of up to 80 sq.m. Power 8000 W.

Specifications:

- three-stage power adjustment - 30%, 60% or 100%;

- the heat exchanger and heating element are made of stainless steel;

- antifreeze or distilled water can be used as a coolant in the system;

- the presence of a thermal switch that prevents heating of the coolant above 90°C;

- can be connected to a circulation pump;

- Manufacturer's warranty - 2 years.

Among the disadvantages, we note the manual selection of power, difficulties during connection, requiring certain skills.

The cost of the unit is from 15,000 rubles.

The best European electrode heating boilers

It so happens that European brands deserve more trust from us. Objectively, some models are indeed an order of magnitude better than domestic ones, but lack of adaptation to our conditions makes them fail very quickly, and repairing them is not always profitable.

A model from a famous German brand, which is traditionally distinguished by its impeccable performance, high quality, reliability and durability. Power 9.9 kW, recommended for connection to a three-phase network with a maximum current of 15 A for three phases. Wall installation. The package includes a circulation pump and an expansion tank.

Let us highlight the main advantages of this device:

- light weight and compact dimensions.

- Easy installation - brackets included.

- steel body with excellent thermal insulation.

- Efficiency 99%.

- The kit includes a 7-liter expansion tank, a circulation pump, a safety valve, a pressure control sensor, and a blocking sensor that protects the housing from overheating.

Minus - Buderus Logamax E213-10, like all German equipment, is designed for a stable voltage in the electrical network. Therefore, for long-term operation of the device, you need to take care of purchasing a stabilizer.

The cost of the unit will cost on average 38,000 rubles.

One of the best electrode boilers of the Czech brand, the power of which is 24 kW. The single-circuit model for wall mounting is distinguished by functionality, safety in operation and durability. Can be connected to a “warm floor” system or a boiler for heating hot water. The package includes 4 heating elements, a circulation pump and a 7-liter expansion tank.

Let's highlight a few more advantages of the unit:

- electronic control with power indicator, display and thermometer;

- 4 power levels;

- Possibility of temperature control in the range of 30-85°C;

- overheating safety system;

- high efficiency - 99%;

- soft start function;

- presence of a safety valve and air vent.

Of the minuses, it is worth noting that the boiler is too noisy and needs to be connected through a voltage stabilizer.

Cost - from 43,000 rubles.

One of the best domestically produced electrode boilers, which some users call a mini-boiler room - one device contains heating elements, a membrane tank, and a circulation pump.

Let us note the strengths of the device:

- LCD display at the bottom of the case;

- convenient control panel, which is hidden behind a special door;

- the operation is controlled by a microprocessor, but the boiler can also be switched to manual control;

- suitable for heating residential and industrial facilities;

- silent operation;

- emergency condition indication;

- coolant pressure and level sensor.

Like any other device, the Evan Warmos QX-18 also has disadvantages - heavy weight, large dimensions, frequent capacitor failures, mandatory connection through a voltage stabilizer.

The cost of the device is from 49,000 rubles.

Polish-made electrode boiler with a power of 12 kW, capable of heating a room measuring 120 sq.m. The device is stylish and compact in size. Suitable only for a three-phase network with a maximum current of 20 A for three phases. A circulation pump is included in the package. Permissible coolant temperature 20-85°C, maximum pressure 3 Bar.

Let's note the advantages of the model:

- Electronic microprocessor control system for the device.

- Light weight - 18 kg.

- High-quality protection system - against overheating, safety valve, air vent.

- Self-diagnosis system - in case of any malfunction, an error code appears on the display, which can be deciphered according to the instructions.

- Affordable price - from 39,000 rubles.

Cons: no expansion tank included.

The manufacturer's warranty is 1 year.

VIDEO: Is it really possible to save money on an electrode boiler?

Electric ion (electrode) boilers are designed to operate in autonomous heating systems. The fundamental difference between the devices and models with heating elements is a special type of heater, which is a block of electrodes. Innovative types of automation have made it possible to improve traditional heating devices and create modern electrode boilers on their basis. Reviews from experienced users and the opinions of independent experts will help us take a closer look at the technical characteristics, varieties and prices of the most famous models.

Operating principle of electrode boilers

Heating of the coolant in the heating system occurs due to the splitting of water molecules. The differently charged ions resulting from this process actively move, rushing towards the positive and negative electrodes, releasing a large amount of energy. As a result, it turns out that an electric electrode boiler increases the temperature of the liquid without the use of heating elements.

The heating process is accompanied by a decrease in the electrical resistance of the conductor. This can lead to a dangerous situation - electric arc breakdown. To prevent this undesirable phenomenon, a certain amount of table salt should be added to the coolant. The size of the proportions is always indicated in the boiler passport. The increase in power in the electrode units occurs simultaneously with heating of the coolant. The increase in current is directly proportional to the decrease in electrical resistance.

Features of use in everyday life

Ion boilers can be integrated into existing heating systems. But before doing this, it is necessary to take a number of preventive actions to prevent rapid wear of the device. A prerequisite must be flushing the system and filtering the coolant.

As practice shows, it is possible to connect electrode heating boilers in combination with other types of heating devices (solid fuel or gas devices). If necessary, several ion units can be connected in parallel to the system.

Advantages of electrode heating devices

The operation of an autonomous heat source allows you to control not only the microclimate and thermoregulation in the house, but also heat costs. At the same time, electrode boilers have a number of obvious advantages compared to heating elements and induction devices.

Efficiency

All water that enters the electric electrode boiler is heated almost instantly and in full. Due to the absence of uncontrolled inertia of heating the coolant, the design achieves a very high level of efficiency - up to 98%.

Durability

Constant contact of the electrodes with the coolant liquid does not lead to the formation of a layer of scale. And, accordingly, rapid failure of the heater. This is due to the fact that in the design of the device there is a constant change in polarity - alternating movement of ions in different directions at a speed of 50 times per second.

Compactness

The principle of electrode heating of liquid makes it possible to reduce the volume of the heat generator several times compared to heating elements of similar power. Small size and light weight of the equipment are very advantageous features that characterize electrode boilers. Reviews from experienced users confirm the ease of use of household appliances, ease of installation and the possibility of their location in any room.

Automation of control

The presence of a digital adjustment unit on the external panel of the devices allows you to intelligently regulate the intensity of the boiler operation. Operation in a given mode helps save up to 40% of electrical energy in the house.

Fire safety

In case of depressurization of the system or water leakage, there is no fear of electric shock. Without coolant, there will be no current flow, so the boiler simply stops working.

Silence

The absence of sound vibrations ensures quiet operation.

Ecological perfection

The operating principle of an electrode boiler implies the complete absence of combustion products or other types of waste. There is also no need for a reserve of fuel resources.

Negative aspects in the operation of ion heat generators

As most users emphasize in their reviews, for all their attractiveness, electrode electric heating boilers have certain disadvantages in design and operation:

- the need to use only prepared water with specified resistivity parameters creates difficulties in achieving compliance with standards;

- the impossibility of using alternative types of coolants - antifreeze, distilled water or oil;

- for normal operation of the boiler, it is necessary to ensure constant circulation of the coolant in the system, otherwise, when the speed of movement decreases, the water may boil, and if the flow increases, starting the boiler will be impossible;

- Stainless steel electrodes can work for a long time without failures, but gradually they still dissolve in water, so it is very important to monitor their condition and replace them in a timely manner.

In addition, the high cost of electrical energy can also be considered a significant drawback. However, if in your area of residence it is not possible to organize a gas or solid fuel heating circuit, then an electrode heating system can become the only reliable source of heat in the house.

What ensures the efficiency and reliability of ion heating devices?

In any case, electrode boilers for a private home are a profitable purchase. High efficiency in their work consists of a combination of several indicators:

- reduced heating inertia;

- uniform increase in temperature of the entire coolant volume;

- construction of a two-pipe closed type system;

- use of automation to control the temperature of the coolant and ambient air in the room;

- simple design using innovative materials;

- high efficiency of the boiler.

What other savings occur in the operation of electrical appliances?

Regular maintenance and technical work are services that electrode boilers practically do not need. User reviews also note the lower cost of ion units compared to other types of electric heating.

Electrode boilers "Galan" are worthy representatives of domestic heating engineering

Among the large number of ionic electrical units produced in the Russian Federation and the Republic of Belarus, devices assembled according to military equipment standards stand out. Practical implementation is based on conversion developments of industrial enterprises producing for naval vessels.

Structurally, the Galan brand electrode heating boiler for a home is a cylindrical body made of rolled pipe with a diameter of 6 cm and a length of 31 cm. Inside there are concentric tubular electrodes through which current is supplied to the coolant. Well-heated water is intensively distributed through pipes and radiators using forced circulation. Once the optimal fluid flow rate has been reached, the pump can be turned off.

Advantages of ion devices:

Electrode boilers "Galan" are capable of independently adjusting to power consumption and turning off if the specified temperature parameters are exceeded. Automatic protection is also triggered in the event of a short circuit, overheating of the supply wires or a coolant leak.

For the harsh climatic conditions of Western Siberia, the best choice of individual heating is the Galan electrode boiler. The price of the device is significantly affordable - in comparison with other types of electrical analogues - and does not exceed 20 thousand rubles.

Several years ago, a special coolant was developed specifically for Galan boiler models - Potok antifreeze. The distinctive qualities of the innovative liquid are that it is enriched with additives that prevent the formation of scale on the walls of the heat generator. For ordinary water, a mixture has been developed for flushing the system, which successfully dissolves rust, scale and protects internal surfaces from possible corrosion.

The younger brother of the ion boiler

The Galan family of electrical units includes several types of heating devices. These include the electrode boiler "Ochag". It has the smallest dimensions compared to other models. The weight of the device is only five hundred grams. The coolant volume in the system is 70 liters. At the same time, the “baby” is capable of developing a power of up to 5 kW, which allows you to effectively heat a room with a volume of up to two hundred cubic meters.

The Geyser and Vulcan devices with operating power from 9 to 50 kW are known on the market. The basis for their development was also the Galan electrode boiler. The price of the units, depending on the power, is in the range of 3,500-14,000 rubles, which cannot but be attractive to potential buyers.

What is an EOU electrode boiler?

A flow-type installation differs from similar electrode devices in its increased level of reliability and durability. Excellent EOU performance is achieved thanks to the main material - thick-walled pipes. For the production of electrodes, more reliable material is also used, which allows creating a heat flow inside the boiler at an increased speed. The large diameter of the rods also improves the performance of the heating device.

Unlike other types of ion heat generators, the EOU electrode boiler has a wide range of models, which arouses additional interest among buyers. It is noteworthy that the units can operate in closed heating systems without using a circulation pump. The ionization chamber is small in size, so the coolant is rapidly heated and, accordingly, the pressure increases to two atmospheres.

The temperature sensor connected to the relay provides a certain operating mode for which the electrode boilers are configured. Reviews from experienced owners confirm that the active operation time of the EOU boiler is only from two to nine hours a day. Without a doubt, such indicators are among the undoubted advantages of the heating device.

Do-it-yourself production of an electric ion heat generator

Having basic skills in repair and electrical work, as well as having studied the thermal heating circuit, it is quite possible to make an electrode boiler yourself. The price of such an installation will be significantly different when compared with a factory unit. In addition, this work will be an invaluable experience.

First of all, you need to decide how the electrode boiler circuit will be included in the overall system. Several options are usually considered:

- single-phase connection;

- three-phase connection;

- parallel ligament;

- integration of automatic control and adjustment units.

You can also make an electrode boiler with your own hands, and then use it for hot water supply or underfloor heating.

Materials that will be needed for work:

- stainless steel pipe 250 mm long and 80-100 mm in diameter;

- welder;

- electrodes;

- neutral wire and ground terminals;

- insulators for electrodes and terminals;

- metal tee and coupling.

Before you start creating an electrode device, you should understand several important points:

- the boiler body must be grounded;

- Only the neutral wire comes out of the network to the outer pipe;

- the phase must be supplied exclusively to the electrode.

Installation work

The main stages of constructing an ion boiler.

1. A scheme of operation of the heating network is planned. There is a choice:

- single-circuit - intended only for heating;

- double-circuit - provides heating and water heating for household needs.

2. Installation and grounding of the electrode boiler successfully neutralizes static electricity.

3. Selection and installation of heating radiators, the material of which interacts normally with water.

4. Construction of automatic adjustment devices.

Technological process

The steel pipe serves as the base of the boiler. A block of electrodes is placed in its middle using a tee. On the other side of the pipe, a coupling is attached, which serves as a connection to the pipe.

An insulating layer must be placed between the tee and the electrodes. Its role is thermal protection and sealing of the housing. For this purpose, heat-resistant plastic is used, at the ends of which there must be a thread connecting to the electrode and tee.

A screw is welded on the outside of the boiler to which the zero terminal and grounding will be attached. For greater reliability, it is recommended to attach one or two more bolts. The appearance of the resulting structure looks unattractive. To hide it from view, you can decorate it with decorative trim that has electrical protection properties. In addition, the facade covering will limit unwanted access to the device.

Thus, you can easily assemble an electrode boiler with your own hands. All that remains is to insert the resulting device into the heating system, fill it with water and turn on the heating.

Let's summarize

Having understood in detail the structure and operating principle of electrode boilers, several important conclusions can be drawn.

The ability to economically achieve high power levels and quickly heat large volumes of water has a great impact on the overall dimensions of heat generators. Compact devices with minimal weight can be easily installed anywhere in the house.

If there is a need to heat a large room (500 square meters or more), it is quite possible to create a circuit for connecting several electrode boilers. Another positive point should be noted - when installing ion electric heating, permission and control from the boiler inspectorate are not required.

Of all the heating devices existing today, the electrode boiler seems to be the most acceptable solution. Simple and economical equipment can give warmth to our home and heat hot water for domestic needs.

Today, there are many options for arranging individual heating for a private home. And if some homeowners prefer gas or solid fuel boiler models, others believe that nothing better than electric heating systems has yet been invented. In addition, in the context of constantly rising prices for energy resources, any prudent owner begins to think about ways to reduce utility costs and choose a truly effective and cost-effective heat source. Fortunately, modern manufacturers provide everyone with this opportunity.

As an alternative to today's popular heating systems, ion, or, as they are also called, electrode boilers have long attracted the attention of potential buyers. Thanks to the unique method of heating the coolant in the system, they have a number of advantages compared to traditional heating equipment.

Historical excursion

First appearing in the mid-twentieth century, such boilers were used by enterprises of the Soviet defense complex for the needs of the Navy. The compact size of the ion boiler was an ideal model for operation in the limited conditions of the ship. The unit fully coped with its task, worked almost silently, and the role of the coolant in it was performed by sea water.

In the early 90s, the number of orders for the defense industry from the state sharply decreased, and such a successful development for its time as an electric ion heating boiler was not in demand. But engineers A.P. Ilyin used it. and Kunkov D.N., who modified the boiler to an improved “civilian” version and received a patent for their “brainchild” in 1995.

Design features

An ion electrode boiler differs from a conventional boiler in the absence of a heating element, and therefore the heating of the system is carried out entirely due to the characteristics of the special coolant. Instead of a heating element, a block with electrodes is installed in the unit, which serves as the main heating element. Such a replacement made it possible to solve the problems of fragility and low efficiency associated with the operation of most electric boilers.

Despite the seemingly primitive design, the ion heating boiler boasts fairly high efficiency, practicality in use and an almost zero accident rate, which for many private homeowners are decisive factors in favor of choosing such a unit. In addition, if you have the desire and some experience, you can make an ionic electric boiler with your own hands. It is enough to understand the principle of its operation, familiarize yourself with a schematic representation of the design and prepare the necessary materials and tools.

So, externally, such a boiler is a solid steel pipe coated with a layer of polyamide. The following are connected to the product body:

- . coolant inlet/outlet pipes;

- . power supply and ground terminals;

- . an electrode made of a special alloy and insulated with polyamide nuts;

All connector locations are equipped with additional protection against current leakage with rubber gaskets. As you can see, special attention is paid to electrical insulation.

A number of manufacturers equip their ion boilers with automatic control systems. It is the controllers, which include built-in protection against power surges in the network, a starter unit and an electronic thermostat, that allow you to maintain the specified temperature of the coolant, thereby reducing energy consumption. Control can be either direct or remote using GSM channels (in more expensive models).

As for the principle of coolant movement inside the boiler, there are closed and open ion boilers.

Principle of operation

The operating principle of the ion boiler is based on a school physics course. The water circulating in the system, which is the coolant, passes between the cathode and the anode and undergoes ionization and sets in motion “+” and “-” charged ions. This process is accompanied by the production of thermal energy.

In one second, the polarity of ions changes up to 50 times. The constant change of polarity prevents the decomposition of the coolant into individual elements - chemical elements - O and H2. The increasing temperature in the boiler, in turn, increases the pressure, which ensures continuous circulation of water through the heating circuit.

It should be taken into account that the use of distilled water in such a boiler is impossible. A system designed for sea water will not be able to provide an electrical circuit between the coolant and the electrodes, and therefore the boiler must be filled with a liquid specially designed for this purpose. Preventing the formation of salt deposits, it will protect pipes from corrosion.

Main characteristics

The main technical characteristics of the ion heating boiler can be found below:

- . The minimum power of the equipment cannot be lower than 2 kW (it is enough to heat rooms up to 80 cubic meters), the maximum reaches 50 kW (suitable for heating large industrial premises up to 1600 cubic meters);

- . The power of units with one phase varies from 2 to 6 kW, with three - from 9 to 50 kW;

- . Energy consumption reaches its nominal level at 75⁰ temperature inside the boiler. At temperatures exceeding the specified one, energy consumption increases and does not correspond to what is stated in the data sheet.

- . The dimensions of a standard household boiler are usually no more than 320 mm in diameter, 600 mm in length and 12 kg in weight.

Pros and cons of operation

Reviews based on experience in operating ion boilers are contradictory. And if some consumers are satisfied with the overall dimensions, faster heating of the coolant compared to a traditional electric boiler, resistance to voltage surges and economical use, others only talk about the disadvantages of such equipment. These include:

- . mandatory grounding. The risk of electric shock in the event of an insulator breakdown in such a boiler is significantly higher than in its heating element counterpart;

- . dependence on the quality of the coolant, because the power of the device depends entirely on the degree of conductivity of the water used;

- . lack of ability to work in emergency mode, for example, from batteries, and the use of exclusively variable current sources;

- . ban on the use of water from a single-circuit heating system;

- . the impossibility of using such a boiler for installing a heated floor system, etc.

Review of popular models

Today, boilers produced by Galan CJSC, EOU, Coterm, STAFOR EKO LLC, etc. are in good demand on the heating equipment market.

The "Ochag" series of the "Galan" brand, represented by the "Ochag2", "Ochag 3" and "Ochag 5" models, is intended for domestic use and differs in the size and power of the units produced. The “Dachnik” series of ion boilers of the “Coterm” brand is also quite popular. Coterm M1 Summer Resident can be used to heat rooms up to 200 cubic meters. Having 3 power modes (1.2 / 1.7 / 3.5 kW), it has quite economical energy consumption - about 1.5 kW/hour.

It must be said that ion boilers, subject to the operating conditions recommended by the manufacturer, are designed for an impressive service life - up to 10 years. It is recommended to replace electrodes every 2-4 years.

In terms of cost, such units are often much cheaper than other heating boilers, which is an additional advantage in their favor. The price of ion boilers starts from 3000-4000 rubles. for the simplest models. Of course, equipment with advanced functionality will cost much more - from 10,000... 12,000 rubles. and more.

Often, when planning an autonomous heating system, the choice is made on traditional heat sources - gas or solid fuel boilers. What to do in a situation where installation of such equipment is impossible? The recently appeared ionic ones can not only optimally solve the issue of heating a room, but also take up a minimum of space during installation. Their main advantage is the innovative method of heating water in the heating system.

The operation of heating elements of this type is based on the chaotic movement of water ions as it passes between the active elements of the boiler - the anode and cathode. The electric current flowing between them accelerates the movement of the ions, thereby raising the overall temperature of the water. The general scheme of operation is shown in the figure:

Ion boiler operating diagram

But don't be fooled by the simplicity of the design. It is impossible to assemble a reliable and safe ion boiler entirely at home. For the production of the cathode and anode, a special material is used that is not subject to corrosion and has high mechanical strength. The boiler body must be completely sealed, since the slightest discrepancy between the standard connection and the pipe distribution can lead to a breakthrough.

The standard equipment consists of the heating element itself, a thermostat for temperature control and a protective relay.

Advantages

A special feature of using this type of heater is its compactness and the ability to create several closed heating systems in one room. Advantages of using ion heating boilers:

- Overall dimensions allow it to be installed anywhere in the heating system.

- High efficiency (up to 99%). Installing the cathode and anode directly in the heating system reduces energy losses to a minimum.

- The heating area of 1 kW of consumed energy is about 20 m2.

- Short heating time for water in the system. Due to the low start-up inertia, the water in the batteries will warm up to the required level in a short time.

- High degree of protection against voltage surges in the network. Also, the boiler will not fail during “idle” operation - there is no water in the system.

Thanks to the advantages described above, ion heating boilers can be installed both in private homes and apartments.

Wiring diagram

Connecting the ionic heating element does not require special installation skills. To carry out commissioning work, you can follow the simplest diagram shown in the figure:

General connection diagram for an ion boiler

For installation you will need:

Ion boiler. In order to choose a boiler of optimal power, you need to know the parameters of the heated room. Let's consider the option of a 2-room apartment (48 sq. m., ceiling height 2.6 m.) with good thermal insulation. Let's calculate the total volume of the room:

48*2.6=125 m³.

The power consumption for heating 1 m³ with an ion boiler is 0.025 kW, i.e. For a comfortable temperature in the apartment, it will be enough to install a 3 kW boiler in the heating system.

- A ball valve is necessary to shut off the water in the event of an unexpected breakdown or replacement of water in the system.

- The circulation pump ensures the movement of water in the system for uniform distribution among the coolants.

- The filter element prevents contaminants (rust, scale) from entering the boiler tank.

- To drain the water, use a drain valve located at the lowest point of the return pipe.

- An expansion tank is necessary to compensate for the expansion of water during its heating to the desired temperature.

- The boiler automatic switching module will start the system according to the specified parameters.

- Air intake.

It should be noted that for the normal functioning of an ion heating boiler, water of a strictly defined density is required. When installing into a previously operating system, it is necessary to replace all the fluid and add a special inhibitor to the new one. The water must be distilled.

For the first 120 cm of connection between the boiler and the system, use steel (but not galvanized) pipes.

And electrode ones. The latter will be discussed in the article.

Electrode boiler

Characteristic

An electrode boiler (also called an ion or ion exchange boiler) differs from other units operating from the network in that it has an open electrode to which current is supplied.

Refers to direct heating heating devices in which heat is directed directly to the energy carrier. This makes it possible to instantly increase the power of the structure, because there are no obstacles in the heat transfer process.

Heating is carried out using electrodes, which are immersed in a tank of liquid. Current is conducted through the coolant with a frequency of 50 Hertz and creates a barrier to electrolysis. Therefore, the inside of the boiler remains free of scale deposits.

The heating process of the liquid occurs with the help of resistance that appears. This happens very quickly. Thus, the container (tank) may not be large in size, since it is not necessary to wait for the liquid to be heated by the element. Such design properties of this boiler allow you to save the user’s budget by reducing energy consumption in the heating system.

An electrode heating boiler is very sensitive to the composition of water; ordinary tap water cannot be used to operate the unit.

Before installation, special preparation of the liquid is required. It’s good if there are antifreezes available that are recommended by the manufacturer.

It also has another feature, which is the gradual dissolution of the electrodes. This is a natural process, its acceleration and deceleration depends only on the intensity of use of the heating system.

Advantages and disadvantages

To begin with, it is worth saying that it is advisable to install electrode boilers only in those places where there is reliable wiring and a stable network. If there are periodic power outages and strong voltage drops, then it is not worth installing electrode units, as they will not be able to work normally. However, in this case, a solution can be found. For example, buy uninterruptable power source or diesel generator.

It accumulates a small amount of energy, which should be enough for a couple of hours of boiler operation in an emergency. There are UPS models that adjust the voltage using a built-in stabilizer.

Advantages of an electrode heating boiler:

- Safety for human health is at a high level. Ion heating boilers are designed in such a way that current leakage is practically impossible. Fire is excluded, so the structure can be used to maintain a minimum temperature without constant human supervision.

- Small dimensions and the possibility of installation in a heating network operating on gas fuel. It turns out that the electrode boiler starts after the supply of gas fuel is stopped.

- Fast heating of the coolant, quiet operation, easy replacement of heating elements without replacing the entire device.

- If desired, it can be installed in residential premises without installing a chimney and the boiler room itself.

- High efficiency, which reaches 96% during operation, and when heating, energy savings are 40%. Plus the absence of dirt, dust, smoke and soot.

On average, an electrode electric boiler consumes 40% less electricity than another heating device from the network. Users note this nuance as the most important advantage of the unit.

Like any heating system, an electrode electric boiler has its drawbacks.

The disadvantages of these units include the following points:

- Considerable cost of electricity. Electricity is much more expensive than, for example, gas, but at the same time it is perfect for providing heat to a house that is located far from a populated area and is visited from time to time.

- Not universal. An ion boiler for heating a private home is often not compatible with certain types of pipes and batteries. As an example, we can cite the use of cast iron radiators in a heating system, when problems arise due to unevenness on the inside, as well as a large volume of liquid. Typically, one section of a cast iron battery is designed for 2.5 liters of water.

- Problems using . In this case, it is advisable to use.

- The requirement of an ion exchange electric boiler for constant coolant resistance. It can be adjusted by adding additives that prevent the appearance of scale.

Operating principle and device

Electrode boiler device

Electrode boilers for heating a private house operate according to the standard laws of physics. The liquid in the unit is heated not with the help of any element, but with the help of the molecular decomposition of water into differently charged ions. Two electrodes are mounted in a container with coolant, and the supply of electricity is started. Water molecules under the influence of a current with a frequency of 50 Hertz (the number of vibrations per minute) are divided into positively charged and negatively charged ions. At the moment of the separation process, heat is produced. Each ion is drawn with its charge to a specific electrode.

Heating of water is very fast, since the resistance of the coolant is high and the electrolysis process prevents the appearance of scale on the walls of the boiler. We can conclude that an electric electrode boiler is an ever-functioning device.

The design of such a boiler is not complicated. This is a unit of small dimensions in the form of a pipe, which constantly cuts into the pipe junction system by means of a threaded connection using American ones. In addition, the electrodes are connected at one end of the device. The coolant fluid is launched through the side pipe, and the exit is through the unoccupied end.

How to make an electrode boiler with your own hands

The main skill you will need is the ability to operate a cooker. The main parts for the design are a metal tube and an electrode.

Let's get started. To make an electrode boiler with your own hands, you will need the following elements:

- Welding machine.

- Pipe with a diameter of up to 10 cm and a length of no more than 25 cm.

- Electrode (you can take a small metal rod with a diameter of about 11 mm).

- The appropriate size tee.

- Coupling .

- Insulator for electrode and terminals (grounding, neutral).

Let's start the assembly process:

- At the first stage, you need to screw on the coupling with a tee on both sides and tighten the products firmly to prevent leaks.

- At the second stage, you need to immerse the electrode from the tee side into the pipe, firmly installing it inside using a dielectric insulator. You can use a stub with bimetallic radiator The goal is to create space between the pipe and the electrode. All you need to do in the plug is make a hole of the required diameter, insert a rod there and secure it firmly with a nut from the outside.

- The next step will be to weld a pair of bolts on the pipe body (M8 or M10). They are necessary to connect the zero and ground terminals. Exposed connection points must also be protected to limit yourself from electric shock.

- The fourth stage will be the installation of the boiler and its piping. The dimensions of the structure are not large, so it can be hidden under the sink.

- All. You can run coolant for electrode heating boilers and test the heating system.

Review of ion boiler manufacturers

There are several popular manufacturers of electrode energy-saving boilers on the Russian market. Increasingly, those who want to purchase warmth and comfort are buying electrode boilers Galan, EOU, Innovator, etc.

Let's take a closer look at some of the manufacturers.

Electrode boilers Galan. User reviews indicate the demand for this brand in the market of ion heating equipment. Galan is a Moscow company, but its products are supplied far beyond Russia. Her first patents date back to 1990.

The Galan range of electrode boilers is represented by various names and three lines. Also, they all differ in power characteristics.

You can highlight the first series, Galan "Vulcan", designed for heating large houses, apartment buildings and public buildings. The series operates only from a three-phase network and is represented by models with a power of 25, 36, 50 kW.

Electrode boiler Galan Vulcan

Second series Galan "Geyser" is a line of average power characteristics. There are only two items in it, which have powers of 9 and 15 kW. These electrode boilers are well suited for many medium-sized private houses.

The third series is represented by more compact models with power from 2 to 6 kW. Line called "Hearth" has serious characteristics, despite its compact dimensions. Easily heats small houses.

Galan electrode boilers have undergone virtually no changes throughout their existence; they have a reliable and proven design. While the automation for the units is constantly changing and supplemented in accordance with the wishes of users.

Electrode boiler EOU. The abbreviation stands for “Energy-saving heating installation”. This is a Russian company that has long established itself in other countries far and near abroad. Its products have international quality certificates.

Electrode boiler EOU

There are two lines in the EOU model range. The first of them is designed for a single-phase 220 V network and is represented by powers from 2 to 12 kW, the second operates with a three-phase 380 V network, and different brand names have individual powers of up to 120 kW. You can notice the same solution in the external representation of the units.

The EOU company is responsible for the uninterrupted operation of its products for 30 years and even provides a guarantee for the first ten years.

Electrode toroidal boiler Innovator. When mentioning this company, they talk about a toroidal electrode boiler. Reviews online indicate high efficiency(up to 99.9%), as well as about product quality.

The Innovator electrode boiler is a simple design, small size, stability and reliability, which are accompanied by broad requirements for liquid quality and the need for a constant supply of electricity. But there are quite a few disadvantages compared to the advantages of the models.

Electric toroidal boiler Innovator

The advantages of such a boiler are the ability to adjust the power of each model from 1 to 20 kW, and easy installation into any heating system. The toroidal electrode boiler can operate in single-phase, two-phase and three-phase networks.

Dimensions 30*10*10 centimeters.

No steel pipe is required for installation. The Innovator toroidal electrode boiler operates silently and has a service life of 30 years.

The manufacturer guarantees for 60 months.

Cost - 8,200 rubles.